Liquid metal cooling reactor based on increase of fuel utilization rate and management method

A liquid metal cooling and utilization rate technology, applied in the field of nuclear reactors, can solve the problems of large neutron leakage in liquid metal cooling fast reactors, reduce fuel utilization, and affect core fuel economy, etc., to improve average unloading and reduce loading The effect of increasing the quantity and enhancing the realizability of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

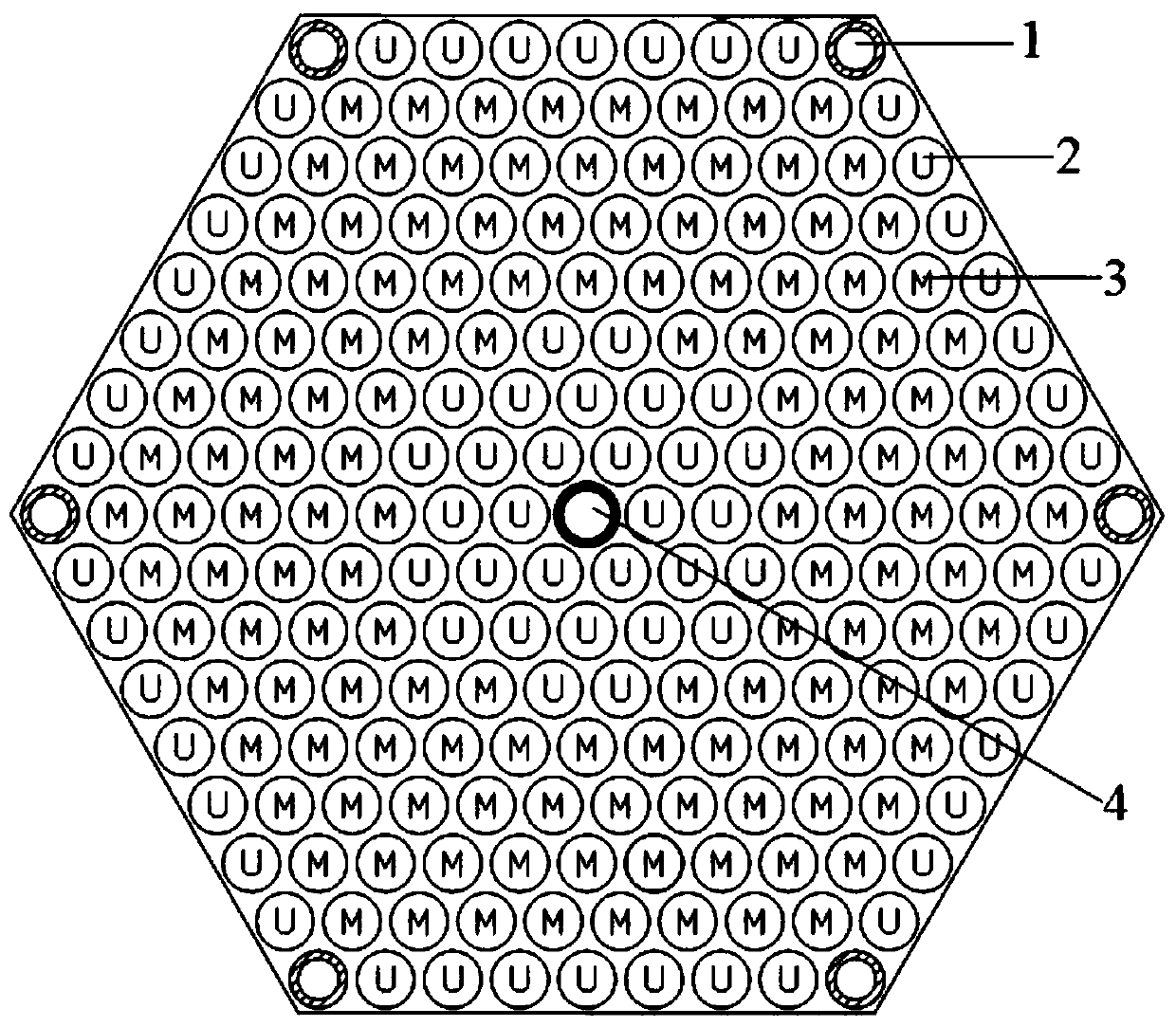

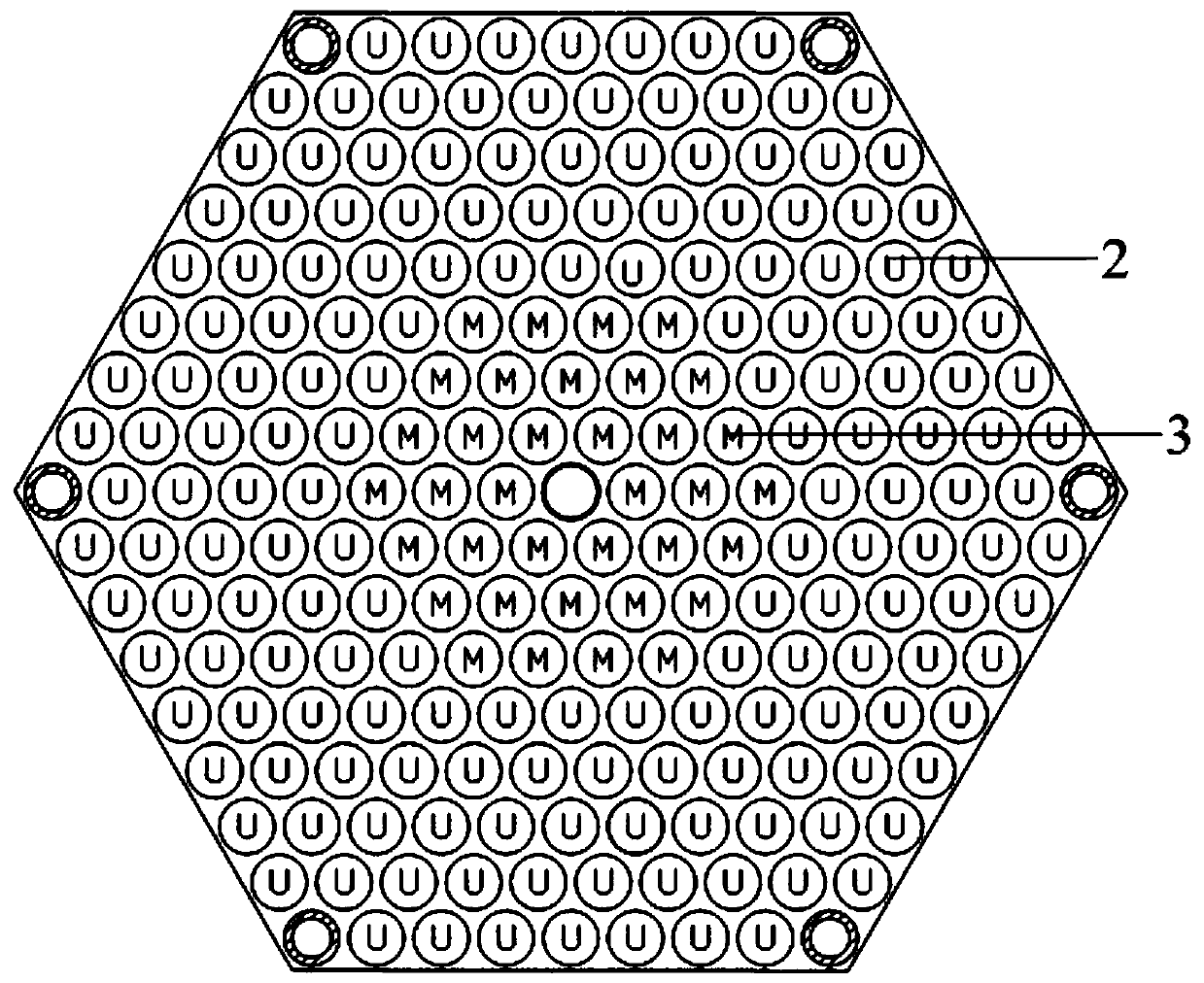

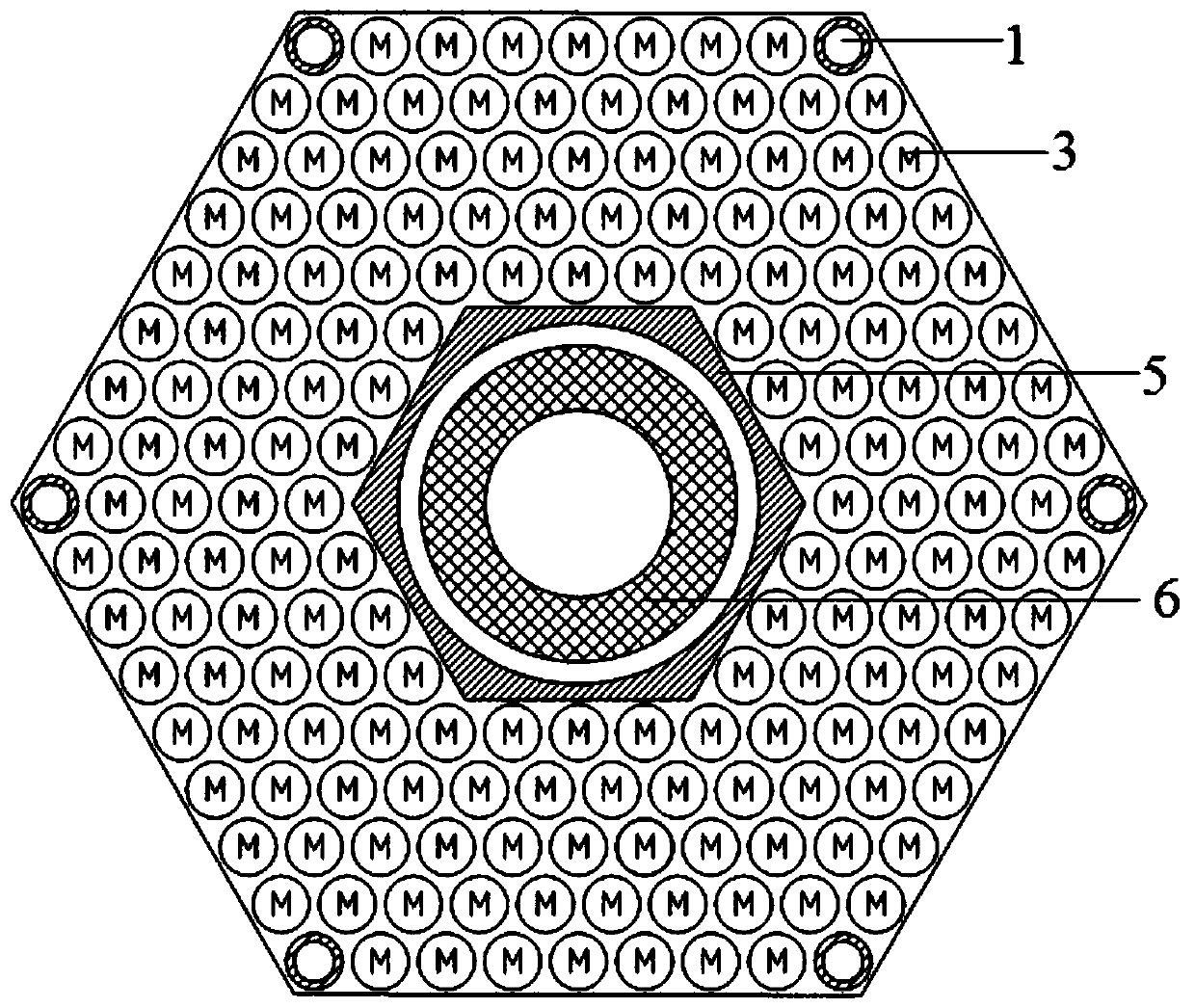

[0027] Such as Figure 1 to Figure 4 As shown, based on the liquid metal cooling reactor with improved fuel utilization rate, a circle of low-power fuel assemblies 7 is arranged on the outermost periphery of the reactor core, and control rod assemblies 9 and high-power fuel assemblies 8 are arranged crosswise in the inner area of the core. Both the low-power fuel assembly 7 and the high-power fuel assembly 8 are hexagonal fuel assemblies composed of a positioning tube 1, an instrument tube 4, a natural uranium dioxide fuel rod element 2 and a uranium-plutonium oxide fuel rod element 3; The natural uranium dioxide fuel rod element 2 is arranged in two circles in the power fuel assembly 7, the uranium plutonium oxide fuel rod element 3 is arranged between the two circles of natural uranium dioxide fuel rod elements 2, and the high power fuel assembly 8 is natural The uranium dioxide fuel rod element 2 is arranged in a circle, and the uranium plutonium oxide fuel rod element 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com