Geotechnical engineering landslide model test box

A technology of landslide model test and geotechnical engineering, which is applied in the direction of soil material test and material inspection product, can solve the problems of increased test cost, time-consuming and labor-intensive test, and long test period, so as to save manpower and financial resources, conveniently obtain materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

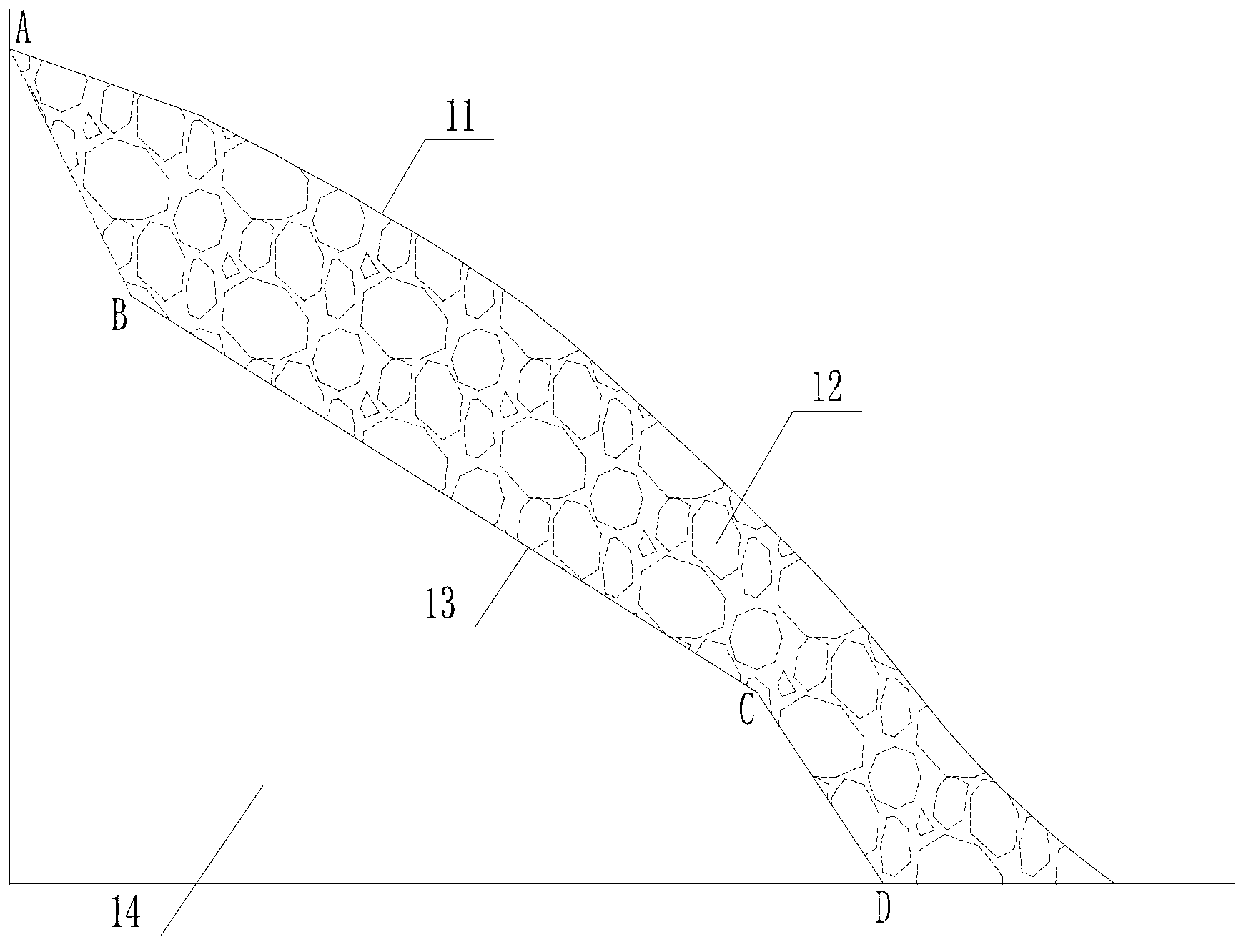

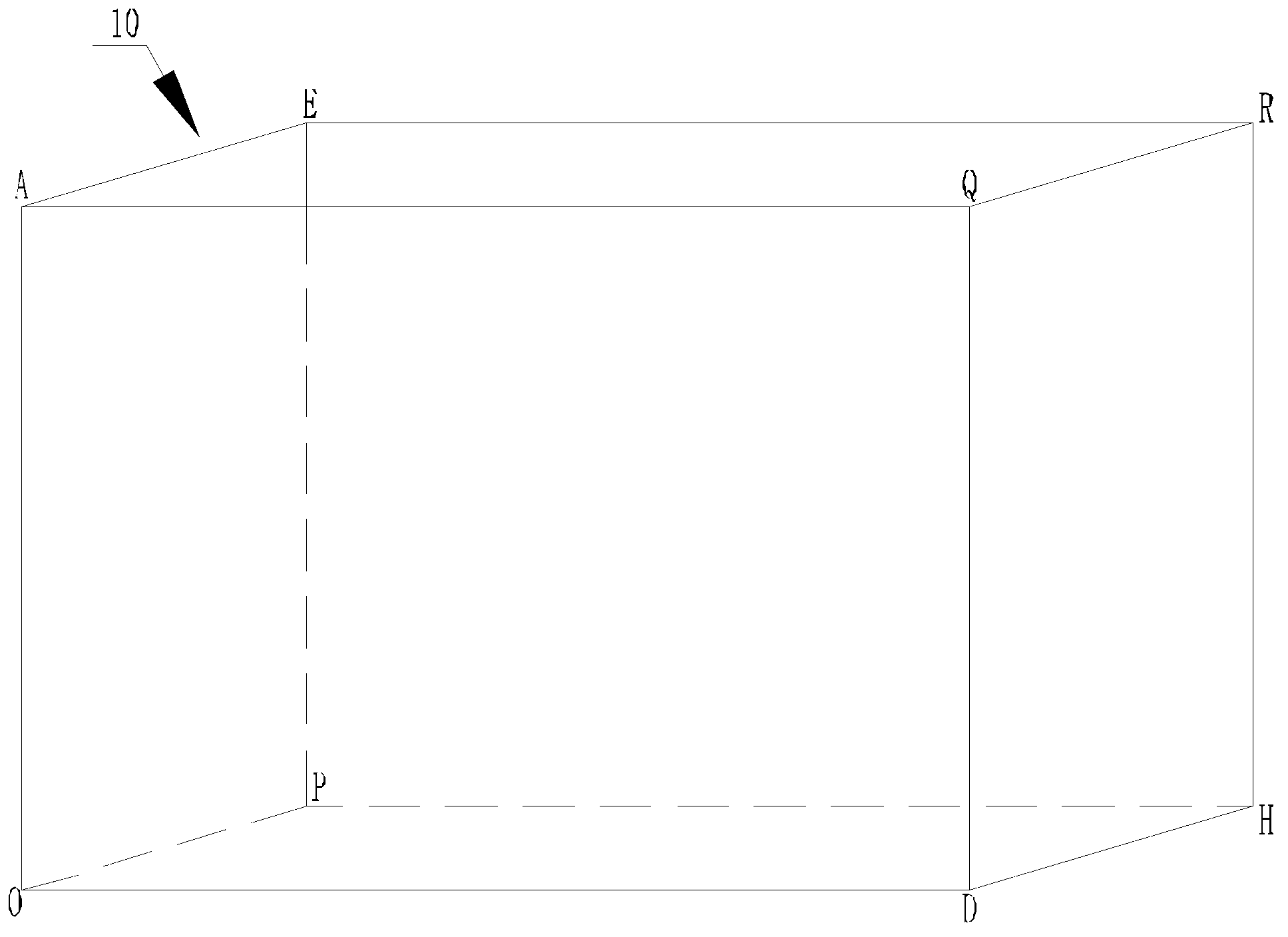

[0037] This example geotechnical engineering landslide model test box, box body 10 structures are as Figure 4 As shown, it is basically a cuboid. The two opposite sides of the cuboid with the largest area, the front AODQ and the back EPFR are provided with inclined planes 13, such as Figure 4 As shown in ABCDHGFE, the slope 13 divides the internal space of the cuboid 10 into upper and lower parts. The slope 13 is perpendicular to the front AODQ and the back EPFR of the cuboid 10. The shape of the slope 13 is similar to that of the simulated sliding surface in the geotechnical engineering landslide model test.

[0038] Depend on Figure 4It can be seen that the slope 13 is composed of plane ABFE, plane BCGF and plane CDHG connected, and these three planes have the same width, namely Figure 4 The length of the line segment AE in is determined by the size of the box structure. Change the inclination angle of plane ABFE, plane BCGF and plane CDHG (such as Figure 4 α in ) a...

Embodiment 2

[0042] This example geotechnical engineering landslide model test box, the frame that box body 10 is made of section steel and the baffle plate that is installed on the described frame are made of, see Figure 6 , Figure 7 and Figure 8 .

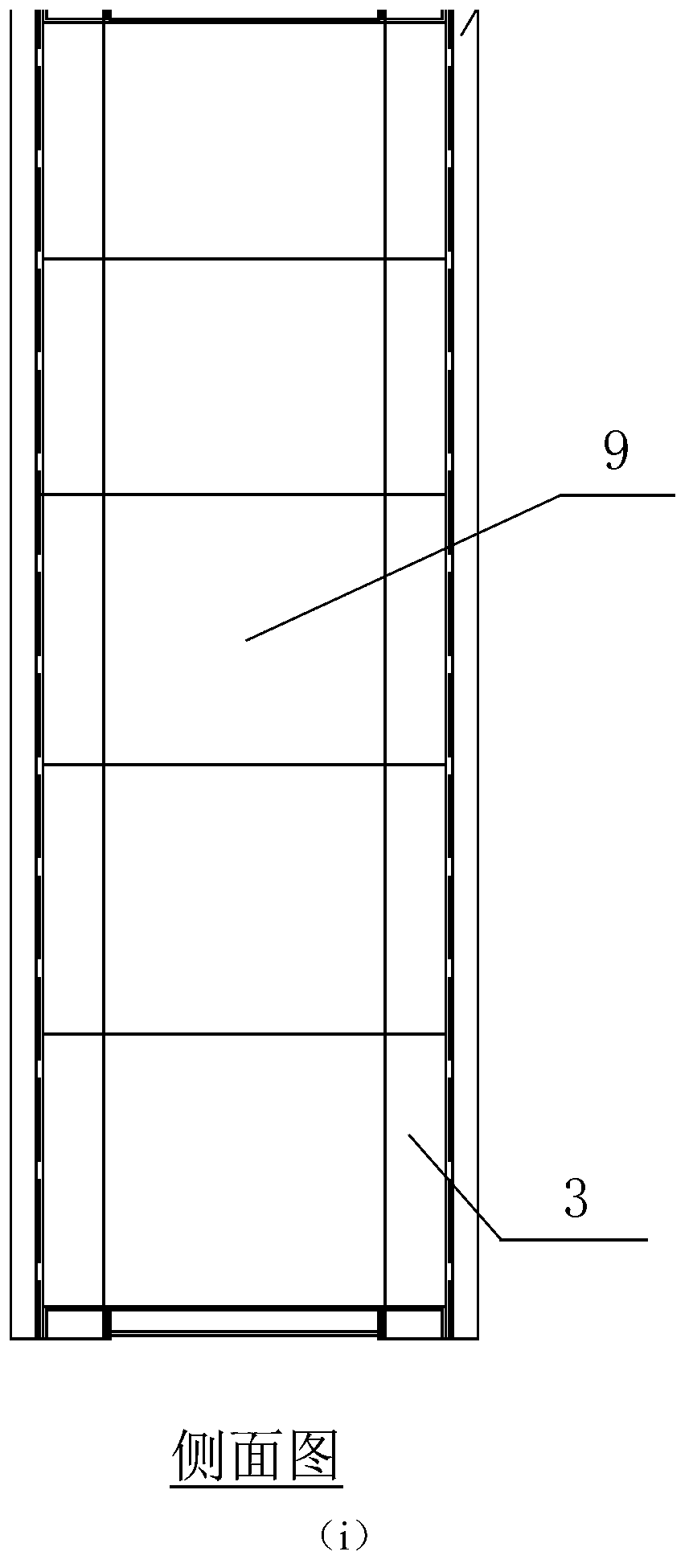

[0043] The vertical angle steel 3 arranged on the four sides of the cuboid and the vertical channel steel 2 on each side are welded to form the frame of the box body 10, and transparent tempered glass 1 is installed on the front and rear (in the direction of the long side of the box body 10), and the left and right sides are on the When the channel steel is welded, a slot 30 is reserved at the joint with the angle steel, and pluggable side baffles 9 are installed in the slot 30 in blocks according to the height of the box body 10, and there is no baffle between the channel steels on the top surface plate, and the bottom surface of the box body 10 is placed on a flat and hard cement floor. Depend on Figure 6 and Figure 7 It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com