Method for manufacturing steel-based golf club heads containing reactive metals

A golf club head and active metal technology, which is applied in the manufacture of tools, metal processing equipment, casting molding equipment, etc., can solve the problems of decreased fluidity of molten metal, difficulty in reducing casting costs, difficulty in melting, etc., and achieve an increase in conversion ratio , reduce casting cost, and avoid the effect of wasting casting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

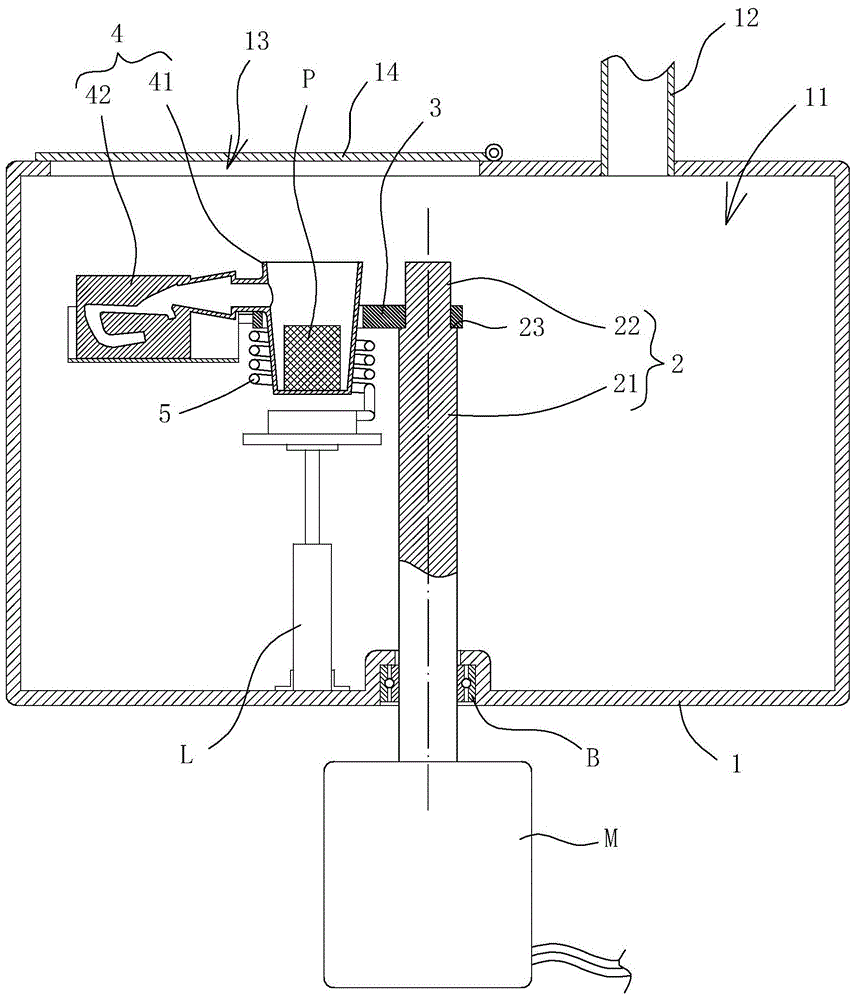

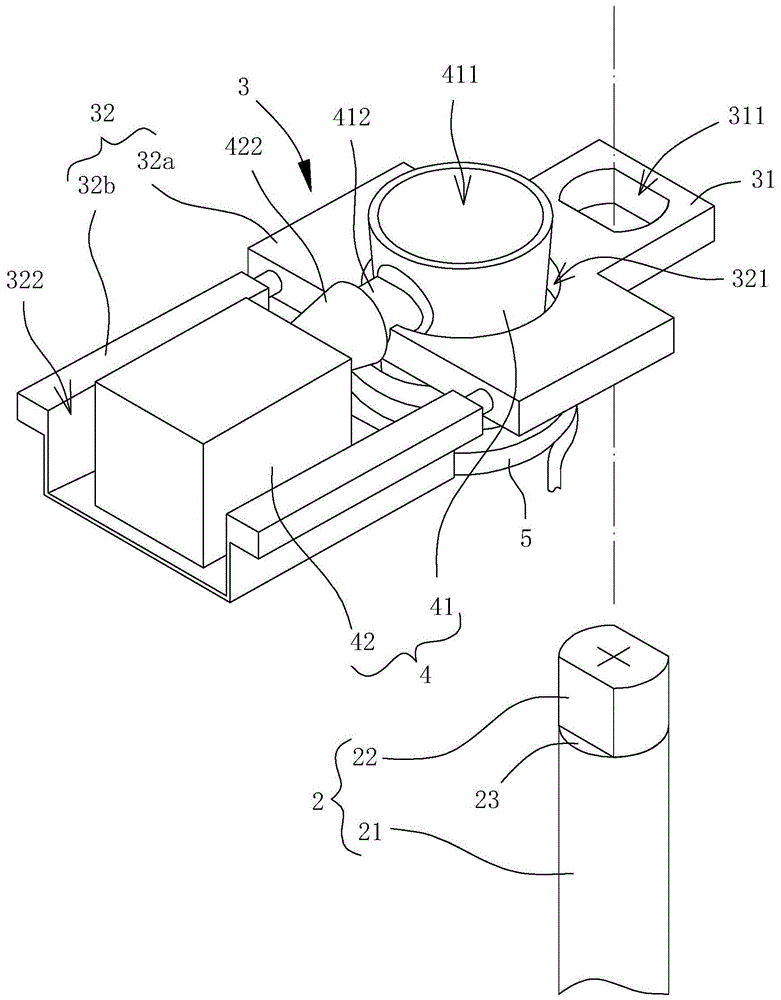

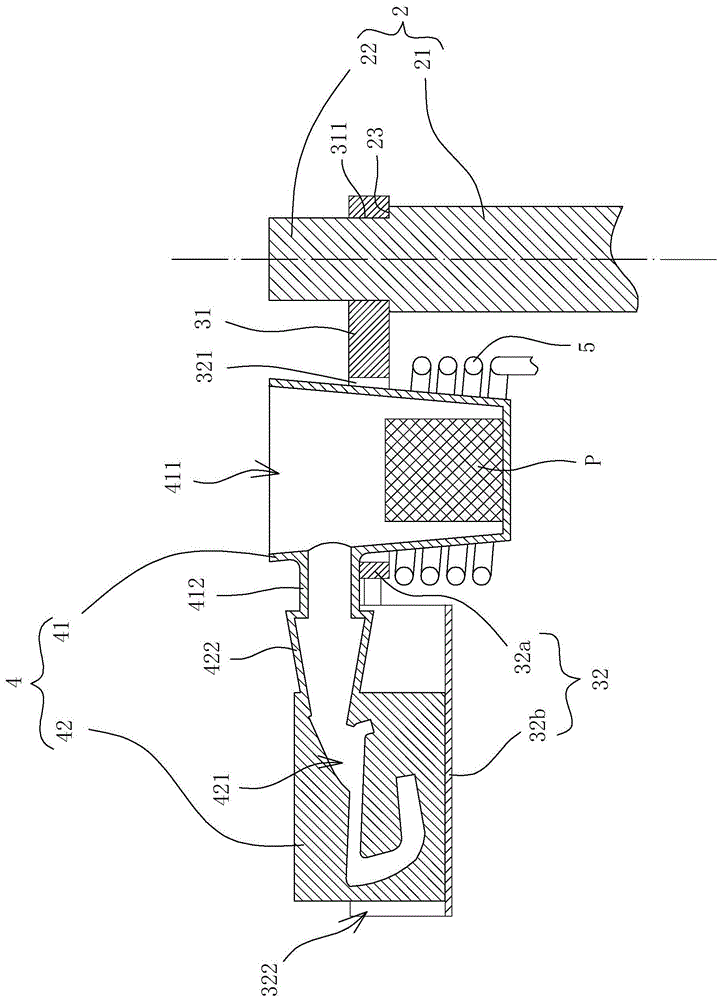

[0048] see figure 1 , which is a vacuum centrifugal casting device used in conjunction with the manufacturing method of the active metal-containing steel golf club head of the present invention. Wherein, the vacuum centrifugal casting device comprises a vacuum furnace 1, a rotating shaft 2, a rotating platform 3, a shell mold 4 and a heater 5; the rotating shaft 2, rotating platform 3, shell mold 4 and heater 5 are all located on In the vacuum furnace 1 , the rotating platform 3 is connected to the rotating shaft 2 to rotate synchronously with the rotating shaft 2 , the shell mold 4 is positioned on the rotating platform 3 , and the heater 5 is used to heat the shell mold 4 .

[0049]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com