Laser annealing equipment and laser annealing method

A laser annealing and equipment technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of non-transformation of the amorphous silicon layer, damage to the base, and influence on the transformation ratio of the polysilicon layer, and achieve the goal of increasing the transformation ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0045]The laser annealing equipment provided by various embodiments of the present invention can be used to carry out laser annealing to various materials, optionally, the laser annealing equipment provided by various embodiments of the present invention can be the excimer laser annealing that can emit excimer laser ( English: Excimer Laser Annealing; Abbreviation: ELA) equipment.

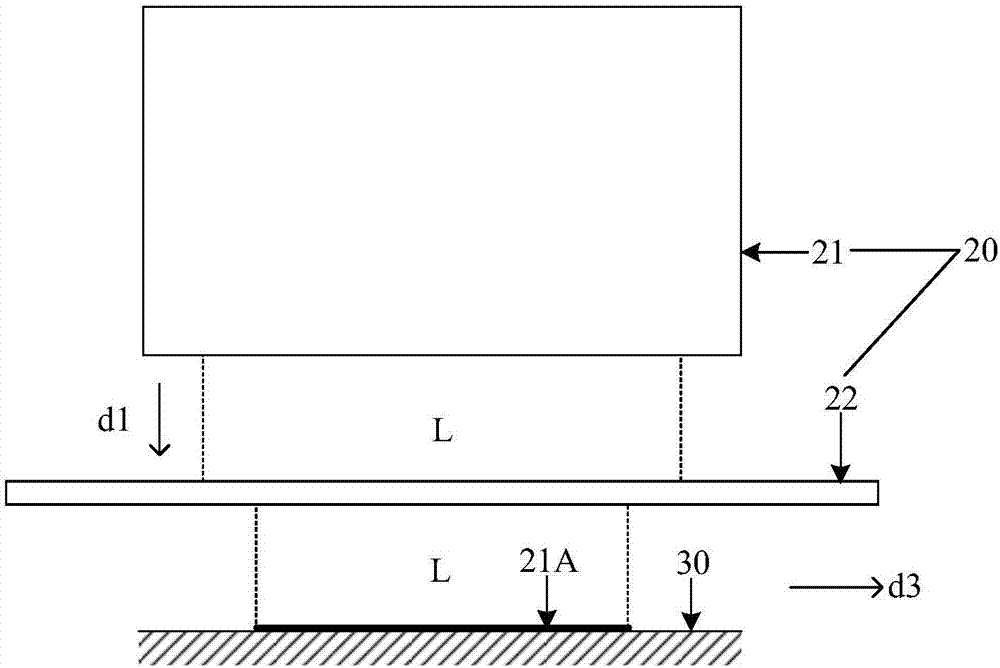

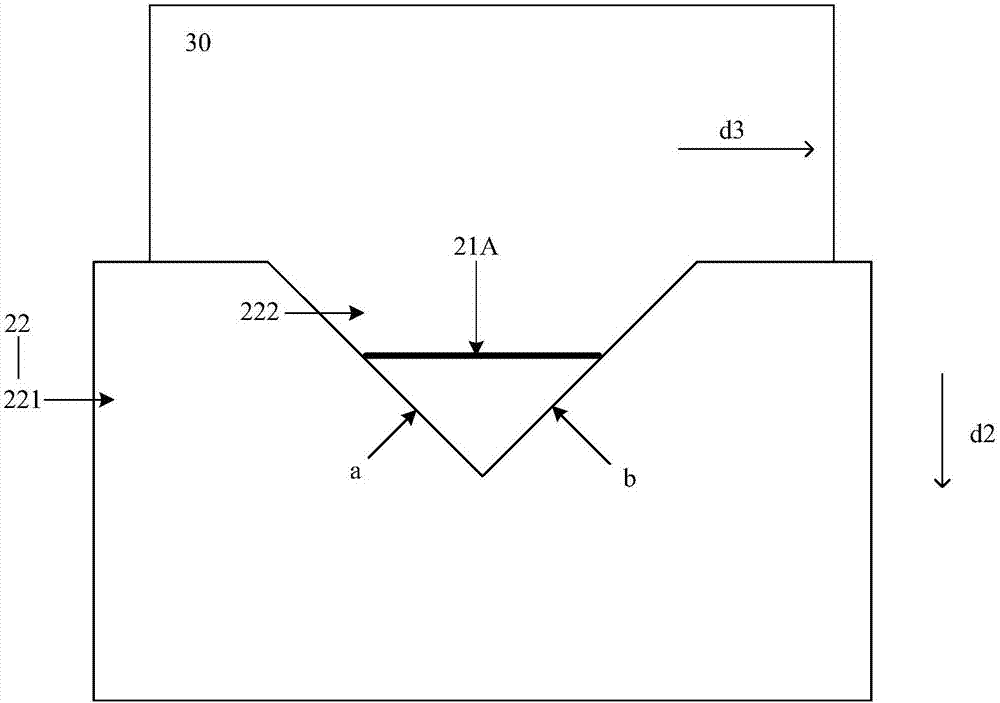

[0046] diagram 2-1 It is a structural schematic diagram of a laser annealing device shown in an embodiment of the present invention. The laser annealing equipment 20 may include:

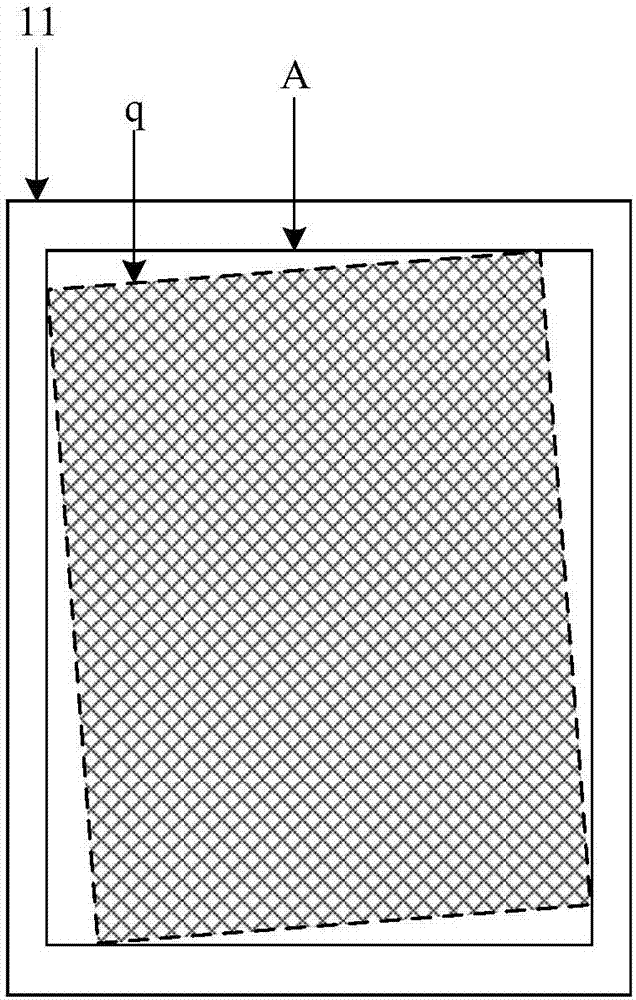

[0047] The linear laser 21 and the light cutter 22 arranged in the light emitting direction d1 of the linear laser 21 . The length direction of the linear spot 21A of the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com