Magnesium alloy melting pool type crucible electrical resistance furnace

A crucible resistance furnace, magnesium alloy technology, applied in the direction of crucible furnace, furnace, furnace type, etc., can solve the problems of lower production efficiency, difficult gas protection, large consumption, etc., and achieve good working conditions, good kinetics and thermodynamics conditions , the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

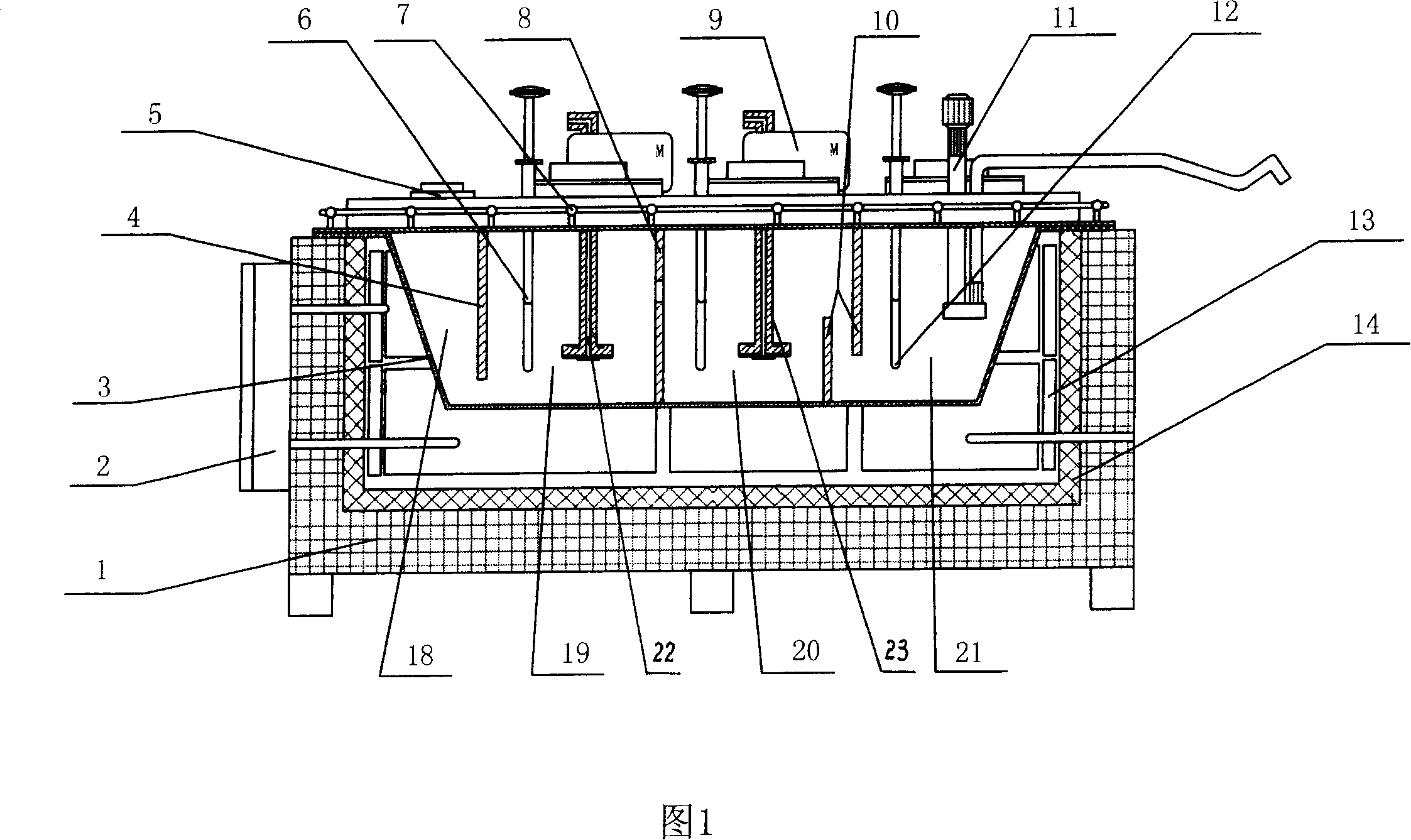

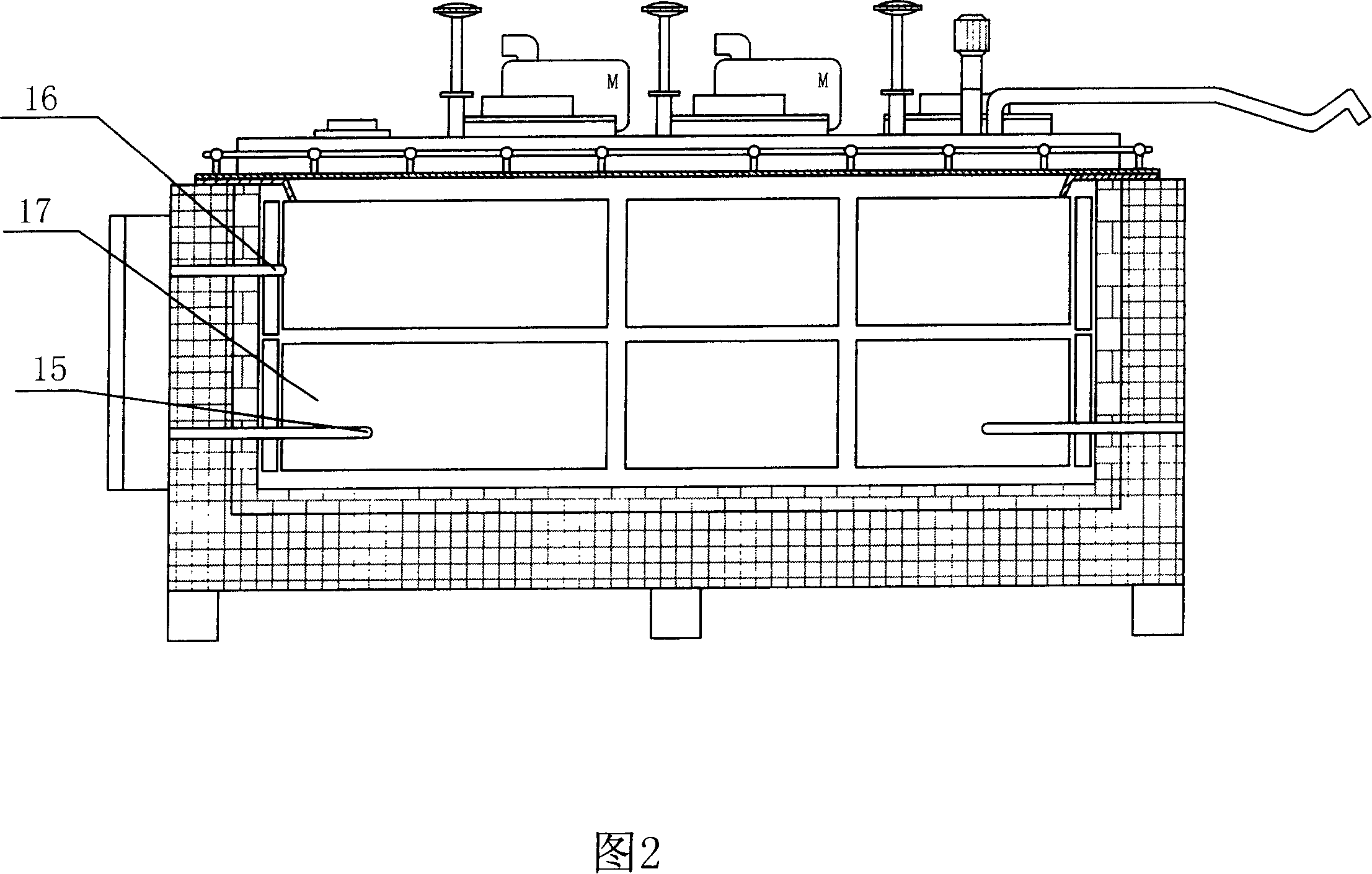

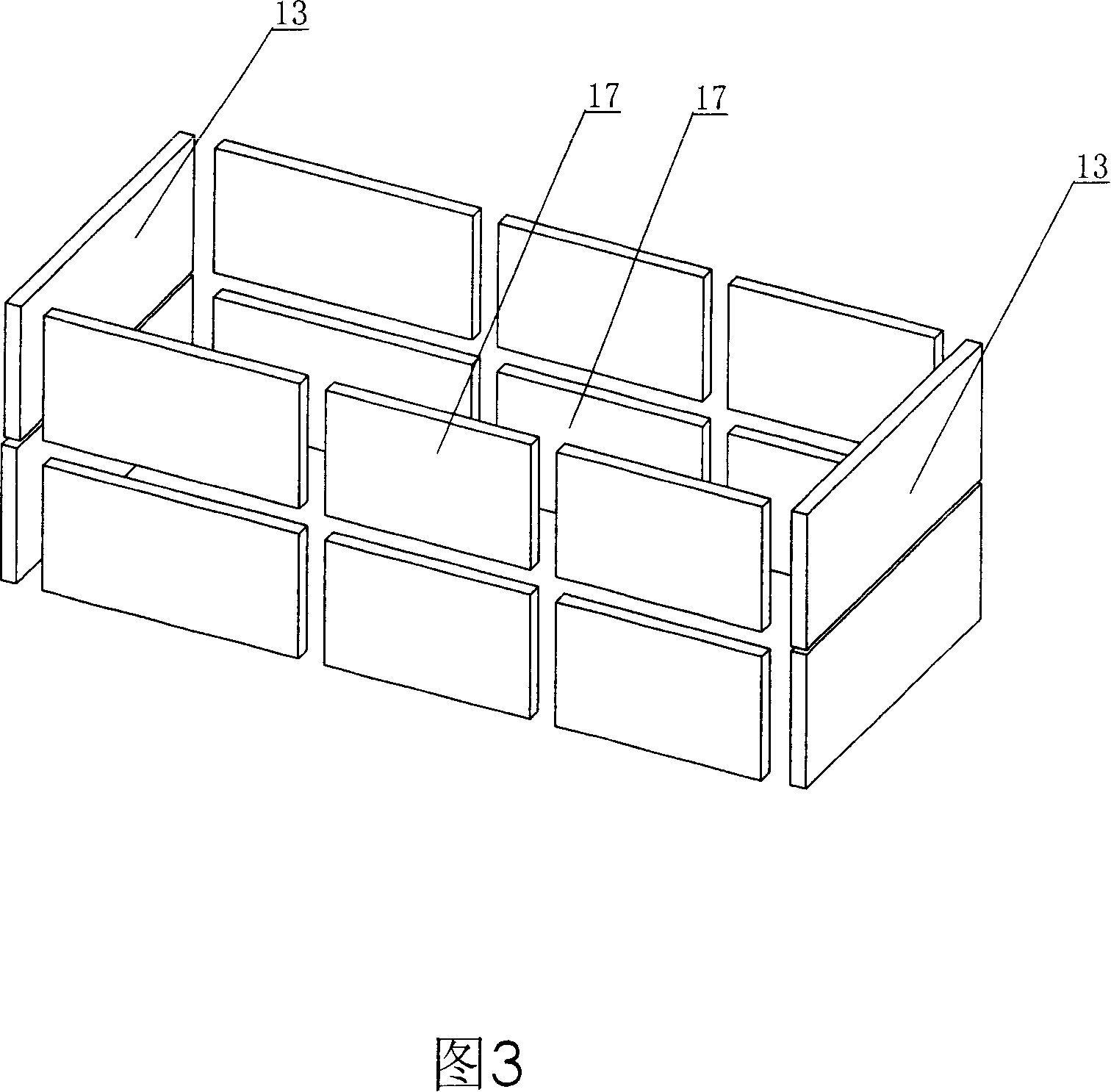

[0029] Embodiments of the present invention are shown in accompanying drawings 1, 2, 3, and 4. The apparatus of the present invention is composed of a furnace body 1, a pool-shaped crucible 3, a temperature control system, a gas protection system, a refining system, and a feeding and discharging system. The furnace body 1 includes a furnace shell, a heat-resistant insulation material, a heating template, a furnace cover, a liquid level instrument and an electric control device, etc., wherein the furnace cover is equipped with a feed inlet, a thermocouple socket, an observation hole, a slag removal sealing compound Cover, refining device placement hole, discharge port, etc., the liquid level instrument can monitor the liquid level, temperature, refining parameters and pouring rate stabilization process. Heat-resistant and heat-insulating materials are filled between the furnace shell and the heating template, and the pool-shaped crucible 3 is installed in the center of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com