Self-compacting concrete for high-speed railway turnout area slab ballastless track filling layer

A slab ballastless track and self-compacting concrete technology, which is applied in the field of concrete, can solve the problems that self-compacting concrete cannot meet the design requirements, and achieve the effects of meeting the requirements of mechanical properties and durability indicators, good filling effect, and good cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

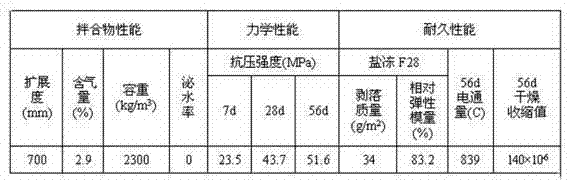

Embodiment 1

[0013] The self-compacting concrete used for the filling layer of the slab ballastless track in the high-speed railway branch area is made of the following raw materials in the following weight ratio: 335 parts of P O4 2.5 grade cement, 195 parts of I grade fly ash, 75 parts of SBTJM-ⅢC type expansion agent, 805 parts of medium sand, 360 parts of 5-10mm continuous graded gravel, 355 parts of 5-16mm continuous graded gravel, 185 parts of water, 7.5 parts of polycarboxylate superplasticizer, WHDF Type concrete reinforced compact anti-cracking agent 6.5 parts.

Embodiment 2

[0015] The self-compacting concrete used for the filling layer of the slab ballastless track in the high-speed railway branch area is made of the following raw materials in the following weight ratio: 333 parts of P O42.5 grade cement, 200 parts of I grade fly ash, 70 parts of SBTJM-ⅢC type expansion agent, 808 parts of medium sand, 355 parts of 5-10mm continuous graded gravel, 360 parts of 5-16mm continuous graded gravel, 180 parts of water, 8.0 parts of polycarboxylate superplasticizer, WHDF Type concrete reinforced compact anti-cracking agent 6.2 parts.

Embodiment 3

[0017] The self-compacting concrete used for the filling layer of the slab ballastless track in the high-speed railway branch area is made of the following raw materials in the following weight ratio: 330 parts of P·O4 2.5 grade cement; 198 parts of I grade fly ash; 72 parts of SBTJM-ⅢC type expansion agent; 806 parts of medium sand; 357 parts of 5-10mm continuous graded gravel; 357 parts of 5-16mm continuous graded gravel; 183 parts of water; 7.8 parts of polycarboxylate superplasticizer; WHDF Type concrete reinforced compact anti-cracking agent 6.0 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com