Al-Mg-Si aluminium alloy material for pressed module heat radiator and machining process thereof

A technology of aluminum alloy material and processing technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problem of incomplete application and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

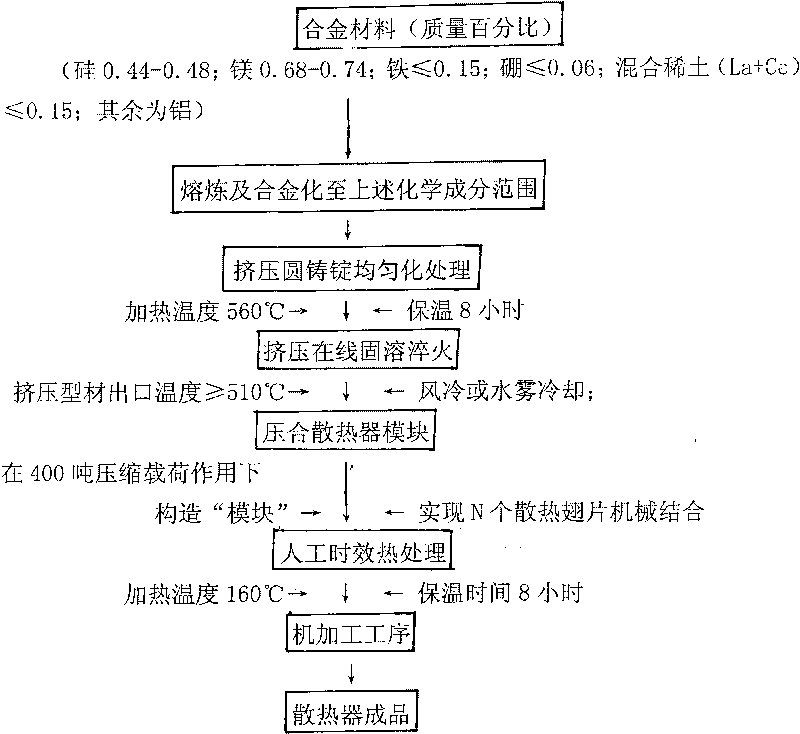

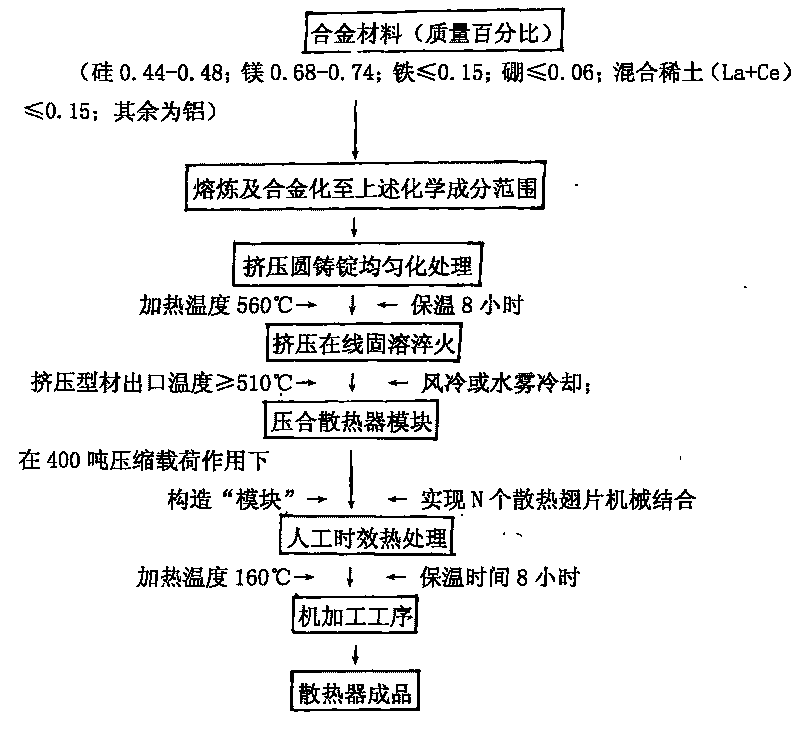

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are cited hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to figure 1 .

[0015] Such as figure 1 Shown:

[0016] The chemical composition of the alloy material in terms of mass percentage is: silicon 0.44-0.48; magnesium 0.68-0.74;

[0017] Iron ≤ 0.15; Boron ≤ 0.06; Mixed rare earth (La+Ce) ≤ 0.15; the rest is aluminum. That is, on the basis of conventional aluminum-magnesium-silicon systems and gold, a new type of heat dissipation alloy material suitable for press-fit module heat sinks is developed. That is to maintain an appropriate ratio of magnesium and silicon as the main alloying elements, so that the mass ratio of magnesium to silicon is slightly less than 1.73 (for example, the ratio of magnesium to silicon is 1.65). Dissolving in the aluminum matrix increases its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com