Stress whitening resistant and scratch resistant polypropylene composition, and preparation method thereof

A polypropylene composition and polypropylene resin technology, applied in the field of polypropylene composition and its preparation, can solve problems such as difficult balance, and achieve the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

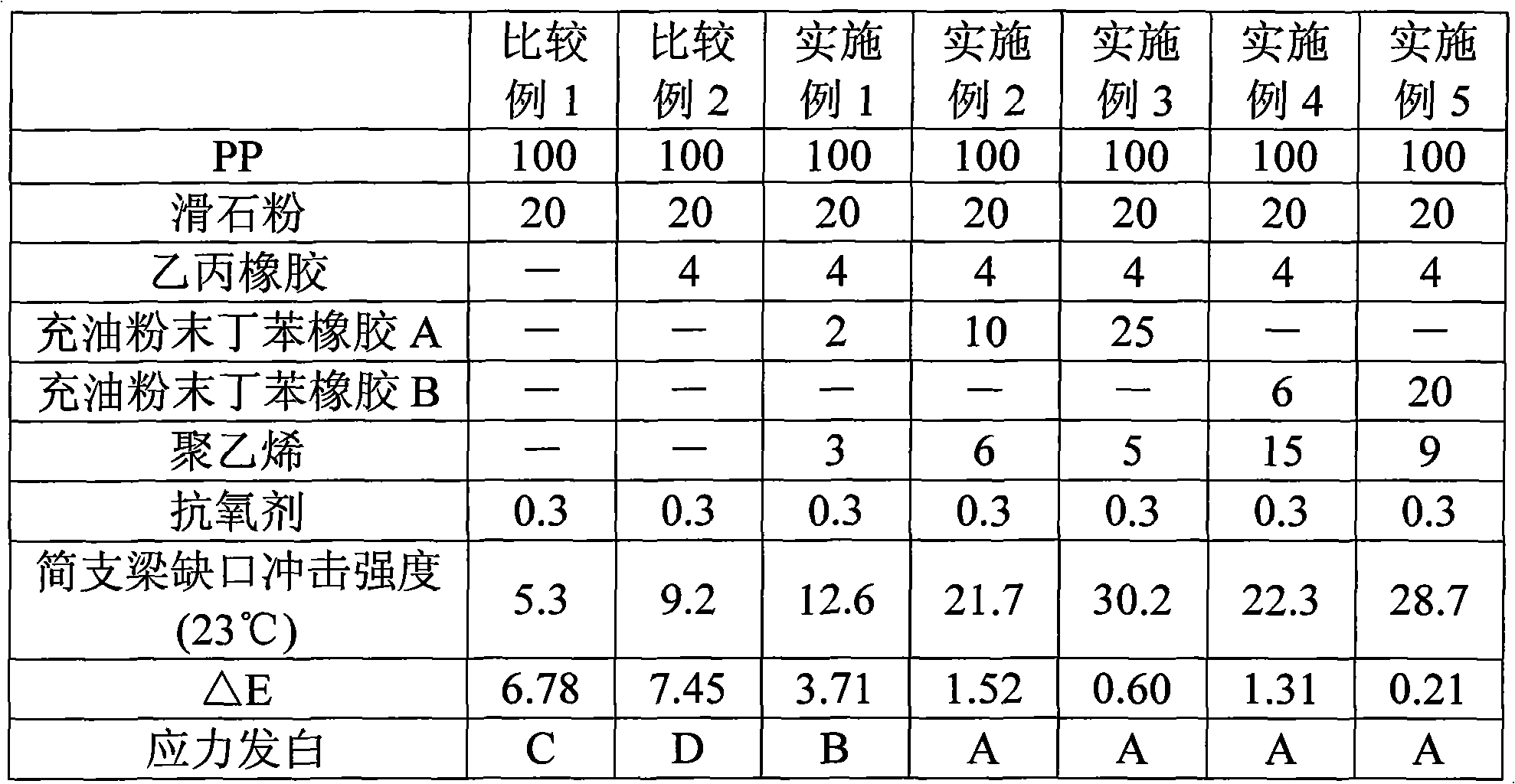

Embodiment 1~3

[0021] Polypropylene (Sinopec Beijing Yanshan Petrochemical Company, brand: K9726, melt index: 26g / 10min), talc (Dalian Fuji Mining Co., Ltd., 2500 mesh), ethylene propylene rubber (Dow Chemical Company, brand: NORDEL IP ), oil-extended fully vulcanized powder styrene butadiene rubber A (the weight ratio of fully vulcanized powder styrene butadiene rubber to linear polymethicone lubricant (Beijing Second Chemical Industry Plant) is 100:35, of which the fully vulcanized powder styrene butadiene rubber Beijing Research Institute of Chemical Industry, brand: VP101, average particle size 0.1μm), polyethylene (Sinopec Beijing Yanshan Petrochemical Company, brand: 3300J, melt index: 2.5g / 10min), antioxidant (Swiss Ciba Chemical Company, brand: B225) After mixing uniformly (see Table 1 for specific formula), use twin screw to extrude and granulate at 190~230℃. The samples were injected by the injection machine, and the mechanical properties, scratch resistance and other properties wer...

Embodiment 4~5

[0023] Except that the oil-extended fully vulcanized powder styrene butadiene rubber A is changed to oil-extended fully vulcanized powder styrene butadiene rubber B (the weight ratio of fully vulcanized powder styrene butadiene rubber to linear polymethylsiloxane lubricant is 100:90). The remaining components and preparation conditions are the same as in Example 1, and the specific formula and test results are shown in Table 1.

[0024] The examples of the present invention use a scratch resistance tester to evaluate the degree of scratch resistance. A mechanically driven scraper is used to scrape a line segment pattern on the prepared plastic surface. Then use a colorimeter to measure the color deviation of the unscratched surface. In the same sample area, use a spectrophotometer to measure the light scattering value of the sample before and after scratching. The difference in light scattering before and after scratching ΔE is used to measure the scratch resistance of polypropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com