Lifting and installation method of high curved-surface net racks

An installation method and network frame technology, which are applied in the processing of building materials, construction, building construction, etc., can solve the problems of construction cost, construction quality, construction safety, lack of construction progress, and imperfection, so that the construction quality can be easily guaranteed , small amount of measures, rich construction machinery and equipment resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

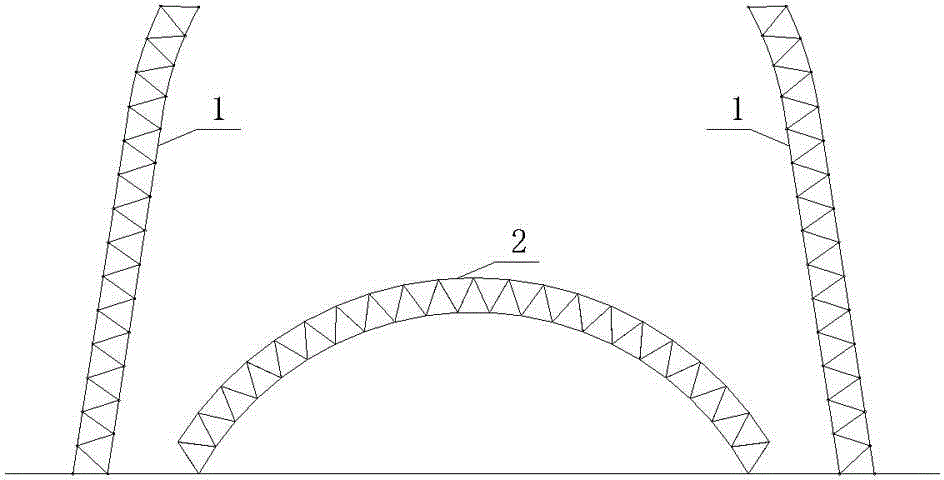

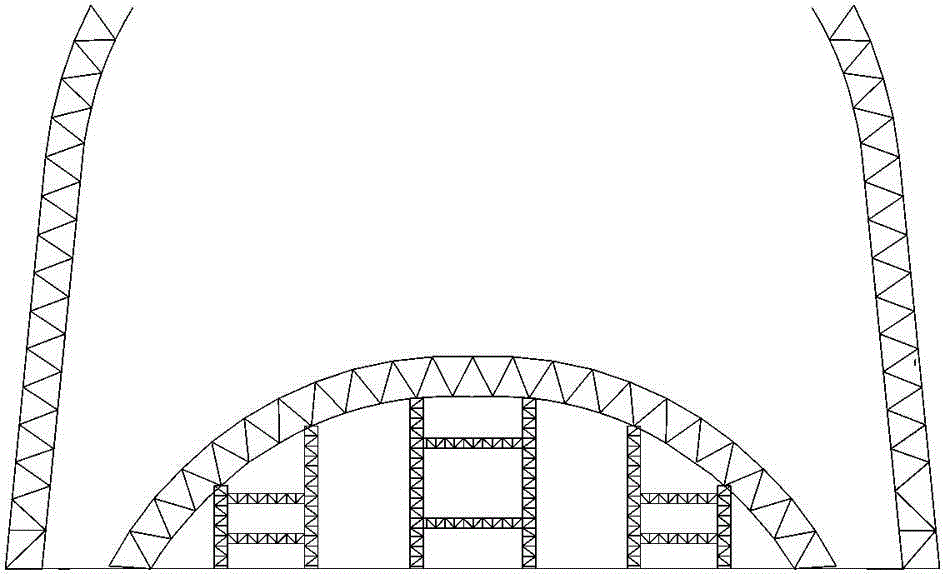

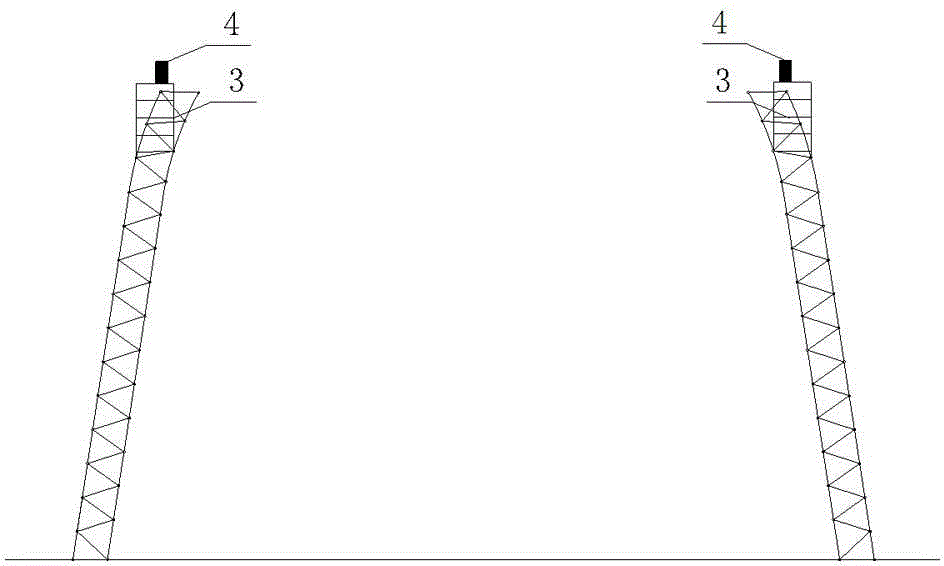

[0042] Example 1: If figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a method of lifting and installing a high-curved grid is carried out in the following steps:

[0043] (1) Upgrading preparation stage:

[0044] 1) The grid frame of the facade support part of the ultra-high curved grid frame is first installed in place, and temporarily fixed by means of lattice support frame and wind rope. The distance between the support frame is 15-30m, and the wind rope is used to pull Set at 2 / 3 of the height of the supporting part of the facade, the angle between the wind rope and the ground is controlled within the range of 30-45 degrees; the height of the supporting part of the facade is within the range of 60m or less;

[0045] The height of the ultra-high curved grid structure is 80m;

[0046] 2) Assemble the 60m or more arched grid of the ultra-high curved grid on the assembly tire frame directly below its projection to reduce the assembled height of the cu...

Embodiment 2

[0060] Embodiment 2: A method for lifting and installing a high-curved network frame, which is carried out according to the following steps:

[0061] (1) Upgrading preparation stage:

[0062] 1) The grid frame of the facade support part of the ultra-high curved grid frame is first installed in place, and temporarily fixed by means of lattice support frame and wind rope. The distance between the support frame is 15-30m, and the wind rope is used to pull Set at 2 / 3 of the height of the supporting part of the facade, the angle between the wind rope and the ground is controlled within the range of 30-45 degrees; the height of the supporting part of the facade is within the range of 70m or less;

[0063] The height of the ultra-high curved grid structure is 100m;

[0064] 2) Assemble the 70m or more arched grid of the ultra-high curved grid on the assembly tire frame directly below its projection to reduce the assembly height of the curved grid; the height of the arched grid is 60...

Embodiment 3

[0078] Embodiment 3: A method for lifting and installing a high-curved grid structure, which is carried out according to the following steps:

[0079] (1) Upgrading preparation stage:

[0080] 1) The grid frame of the facade supporting part of the ultra-high curved grid frame is installed in place first, and the measures of lattice support frame and wind rope are adopted for temporary fixation. The distance between the support frames is 30m, and the wind rope is pulled at At 2 / 3 of the height of the supporting part of the facade, the angle between the wind rope and the ground is controlled within the range of 45 degrees; the height of the supporting part of the facade is within the range of 80m or less;

[0081] The height of the ultra-high curved grid structure is 116m;

[0082] 2) Assemble the 80m or more part of the arched grid of the ultra-high curved grid on the assembled tire frame directly below its projection to reduce the assembled height of the curved grid; the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com