Adhesive composition for semiconductor, adhesive film and semiconductor device

A technology for adhering films and semiconductors, applied in the direction of semiconductor devices, films/sheets without carriers, film/sheet adhesives, etc. The effect of improving manufacturing efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

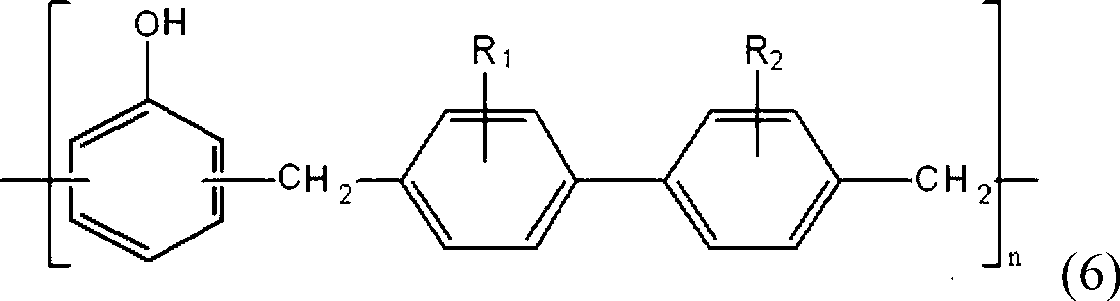

[0099] Examples 1-2: Preparation of Adhesive Compositions for Semiconductors

[0100] Add the solvent (cyclohexanone) to the thermoplastic resin, epoxy resin, phenolic curing agent, amine curing resin, curing accelerator, filler and silane coupling agent as listed in Table 1 so that the solid content in the solution is 20wt %, and then fully kneaded with a ball mill to prepare an adhesive composition for semiconductors.

experiment example

[0118] Experimental Example: Evaluation of Physical Properties of Adhesive Films Prepared Using the Adhesive Compositions of Examples and Comparative Examples

[0119] The physical properties of the respective adhesive films prepared using the adhesive compositions of Examples 1 and 2 and Comparative Examples 1, 2 and 3 were evaluated by the following methods, and the results are shown in Table 2.

[0120] Table 2

[0121]

[0122] (1) Chip shear strength: A 530 μm thick wafer was cut into chips having a size of 5 mm×5 mm. These chips were laminated with each adhesive film at 60°C and cut to leave only bonded parts. An upper chip having a size of 5 mm×5 mm was placed on a wafer having a size of 10 mm×10 mm, and then a force of 10 kgf was applied on a hot plate at 120° C. for 5 seconds. The chip shear strength was then measured with DAGE4000, and the results are shown in Table 2.

[0123] (2) Curing initiation temperature: The heat generated by the adhesive composition p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com