Electromagnetic shielding impregnation coating sandwich wall cloth and manufacturing method thereof

A technology of electromagnetic shielding and sandwich walls, applied in the direction of surface coating liquid devices, coatings, coverings/linings, etc., can solve problems such as poor environmental performance, poor 3D effect, and poor firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

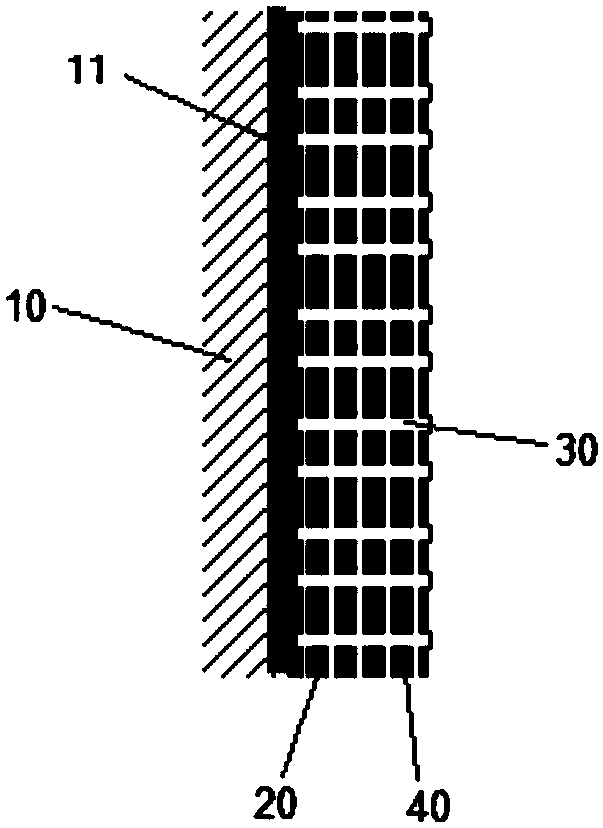

[0154] refer to Figure 1A , the structure of the electromagnetic shielding impregnation coating sandwich wall covering of the present invention is as follows: the impregnation coating composite sandwich coating complex comprising the base color coating 11, the base color coating surface, and the impregnation coating composite sandwich coating complex It includes a transparent or translucent first coating 20 , a transparent or translucent second coating 40 , and a fiber network sandwich core 30 sandwiched between the first coating 20 and the second coating 40 . Wherein, conductive fillers are added in the base color coating 11, so as to provide the coating with an electromagnetic shielding function.

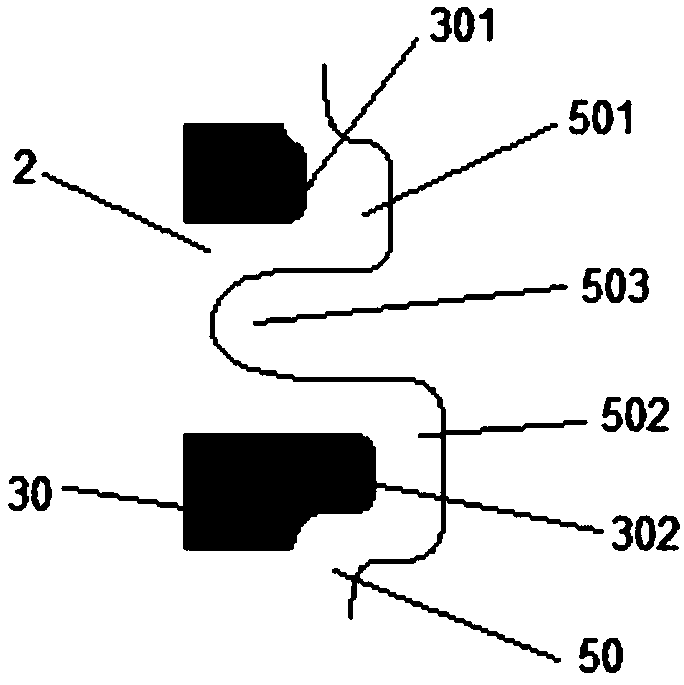

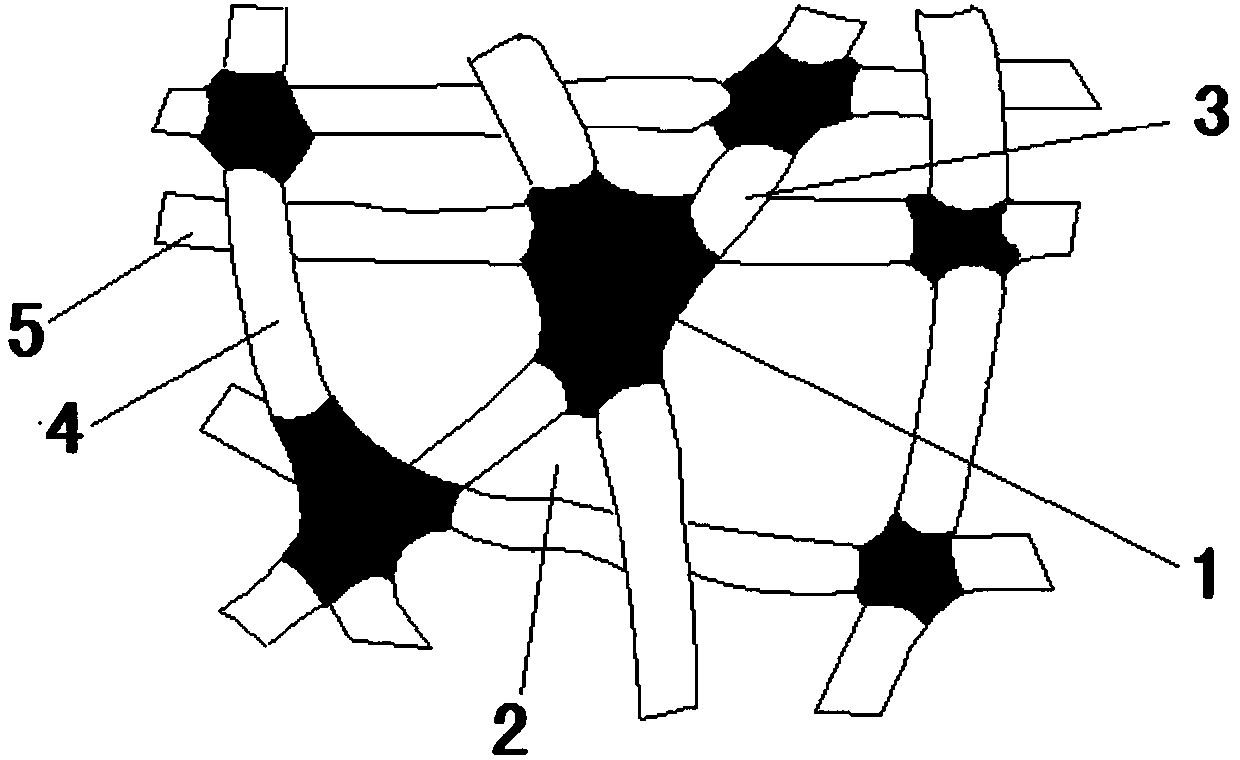

[0155] In this embodiment, the fiber texture network sandwich core 30 contains a three-dimensional interpenetrating network structure formed by fibers, and the fibers include horizontal fibers, vertical fibers and fibers in an oblique direction, Figure 2A-Figure 2C The top view ...

Embodiment 2

[0176] In the present embodiment, the method for making electromagnetic shielding impregnation coating sandwich wall covering is as follows: coat the base color coating 11 on the surface of the wall body 10,

[0177] After the base color coating 11 is dried, a transparent organic adhesive, such as an epoxy resin adhesive, is applied on a part of the surface of the base color coating 11, and the fiber texture network sandwich core 30 is pasted to the bottom by the organic adhesive. Color coating 11 surface;

[0178] Coating an organic coating to form a second coating, applying pressure to make the organic coating infiltrate the fibers of the three-dimensional interpenetrating network structure and immerse into the meshes of the three-dimensional interpenetrating network structure; forming a sandwich coating;

[0179] When the sandwich coating is cured, the organic coating on the surface of the mesh sags inwardly, while the organic coating on the surface of the fiber is blocked ...

Embodiment 3

[0185] In the present embodiment, the method for making electromagnetic shielding impregnated and coated sandwich wall covering is as follows:

[0186] The surface of the wall body 10 is coated with a primer coating 11,

[0187] After the base coat 11 is dried, the base coat 11 surface is coated with a transparent or translucent first organic coating, such as latex paint, to form a transparent or translucent first coating 20;

[0188] Applying the fiber texture network sandwich core 30 to the surface of the first coating 20, applying pressure to the fiber texture network sandwich core 30 to make the first organic coating soak into the fiber and penetrate into the pores of the three-dimensional interpenetrating network structure;

[0189] Apply transparent or translucent second organic paint, also can be latex paint, as a transparent or translucent second coating, apply pressure to make the second organic paint infiltrate the fibers of the three-dimensional interpenetrating net...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com