Quick-sticking type modified chloride butyl acrylic emulsion as well as preparation method and application thereof

An acrylic emulsion and fast-bonding technology, which is applied in the direction of adhesive types, adhesives, graft polymer adhesives, etc., can solve the problem that the fast-bonding performance and bonding work efficiency of emulsion adhesives cannot be satisfied, and the adaptation of pre-baking schemes In order to achieve the effect of improving the efficiency of sizing, fast sticking and small monomer residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

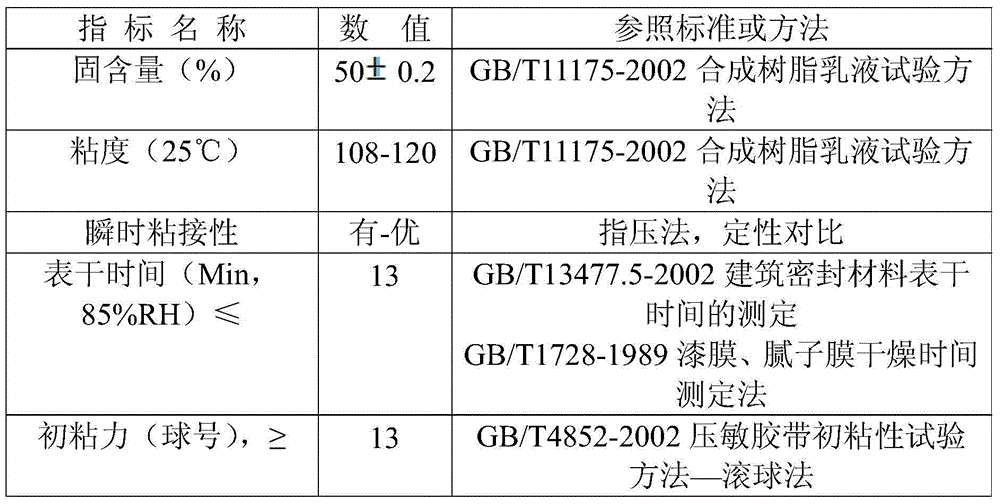

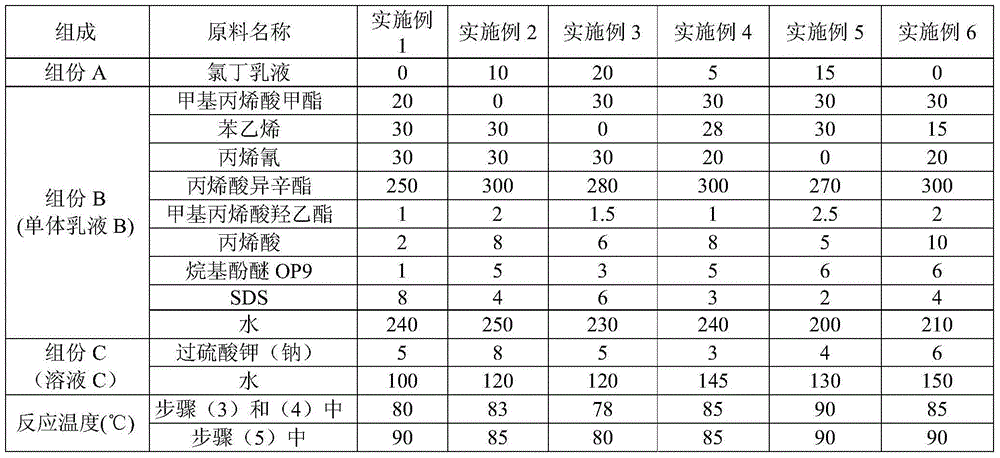

[0033] The preparation method of fast sticky type chloroprene modified acrylic acid emulsion is according to the following steps:

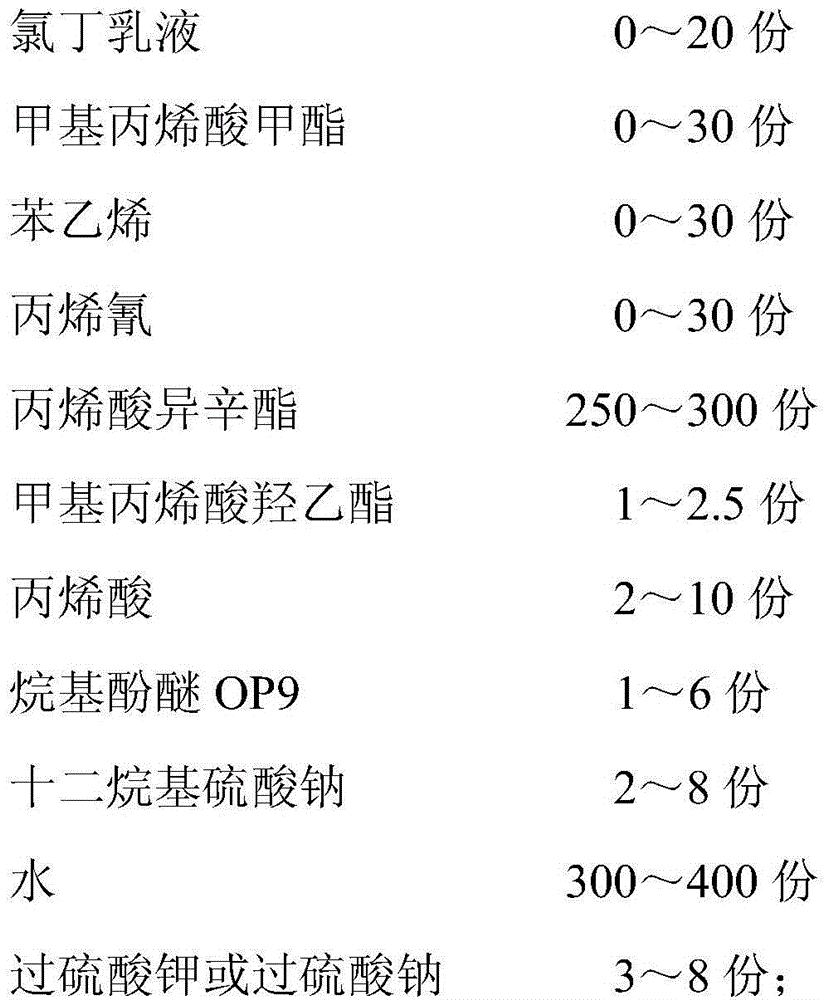

[0034] (1) Mix methyl methacrylate, styrene, acrylonitrile, isooctyl acrylate, hydroxyethyl methacrylate, acrylic acid, alkylphenol ether OP9, sodium lauryl sulfate and water, and pass through a homogenizer Emulsifying to obtain monomer emulsion B;

[0035] (2) dissolving potassium persulfate or sodium persulfate in water to obtain solution C;

[0036] (3) take by weighing 30% of the monomer emulsion quality of step (1) gained and 30% of the solution quality of step (2) gained, and chloroprene emulsion, under stirring state, add successively the In a normal-pressure reactor, react at a constant temperature of 78-90°C for 30 minutes until the emulsion shows blue light;

[0037] (4) Add dropwise the remaining part of the monomer emulsion obtained in step (1), and simultaneously supplement the remaining part of the solution obtained in step (2) syn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com