Macromolecular adhesive containing dopamine phosphate ester structure as well as preparation method and application of macromolecular adhesive

A molecular weight, amino-containing technology, applied in the direction of bonding methods, adhesive types, grafted polymer adhesives, etc., can solve problems such as environmental sanitation and environmental protection that are difficult to meet, and achieve process parameters that are easy to control and easy to purchase , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

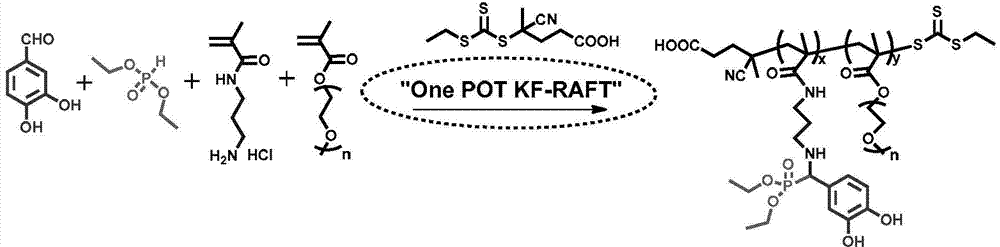

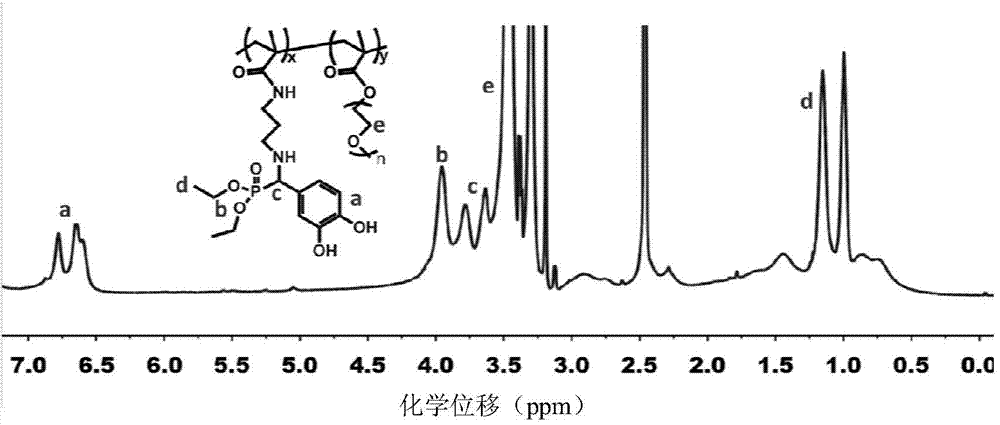

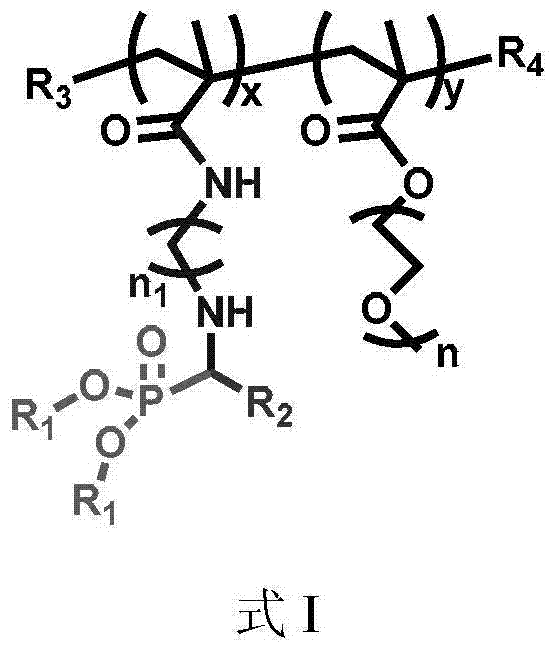

[0050] Example 1, preparation of a polymer adhesive containing a dopamine-based phosphate-like structure:

[0051] The monomers N-(3-aminopropyl)methacrylamide hydrochloride, 3,4-dihydroxybenzaldehyde, diethyl phosphite and polyethylene glycol monomethyl ether methacrylate were synthesized in one pot (Copolymerization monomer) is added in the mixed solvent of ethanol and acetonitrile (wherein, the volume ratio of ethanol and acetonitrile is 1:1) according to molar ratio of feeding 1:1.2:1.4:0.5, and then add triethylamine thereinto, The molar ratio of triethylamine and monomer N-(3-aminopropyl) methacrylamide hydrochloride is 1.2:1, and the purpose of adding triethylamine is to neutralize the hydrochloride carried by the monomer, trigger agent azobisisoheptanonitrile (mass accounts for 0.4% of monomer N-(3-aminopropyl) methacrylamide hydrochloride mass) and chain transfer agent 4-cyano-4-(ethylthioform Acylthio)valeric acid (the mass accounts for 0.8% of the monomer N-(3-aminop...

Embodiment 2

[0052] Example 2. Using a polymer adhesive containing a dopamine-like phosphate structure to carry out an adhesion experiment between material substrates:

[0053] 1) Dissolve 1.0 g of the polymer binder powder obtained in Example 1 in water, and constant volume to obtain 1 mL of a polymer binder aqueous solution with a concentration of 1 g / mL;

[0054] 2) Take 10 μL of the aqueous polymer binder solution in step 1) and drop them on the surface of the two material substrates in a 1cm×1cm area, and let it stand for a while to evaporate;

[0055] 3) Compress the two material substrates dripped with the aqueous polymer adhesive solution in step 2), clamp them, place them in a 60°C oven and heat them for 20 hours, take them out and cool them to room temperature, and then bond the two material substrates together;

[0056] Tensile tests are performed on two material substrates bonded together:

[0057] The multi-functional digital testing machine controlled by a microcomputer tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com