Machining alignment and location method of cable tower segment

A machining and steel cable tower technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low accuracy, scribing error, low efficiency, etc., and achieve alignment, positioning, and positioning accuracy. High, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

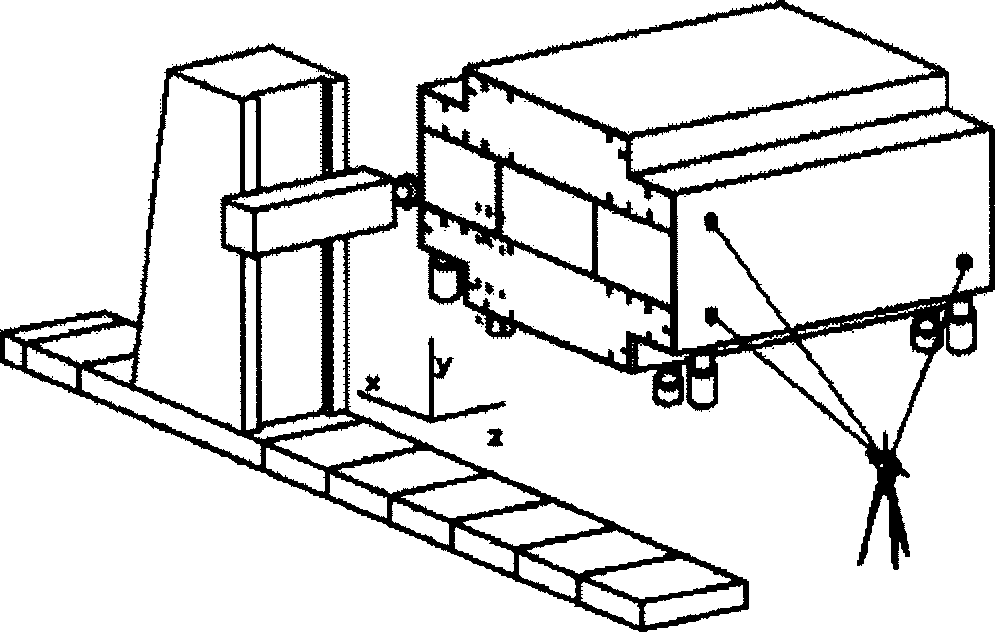

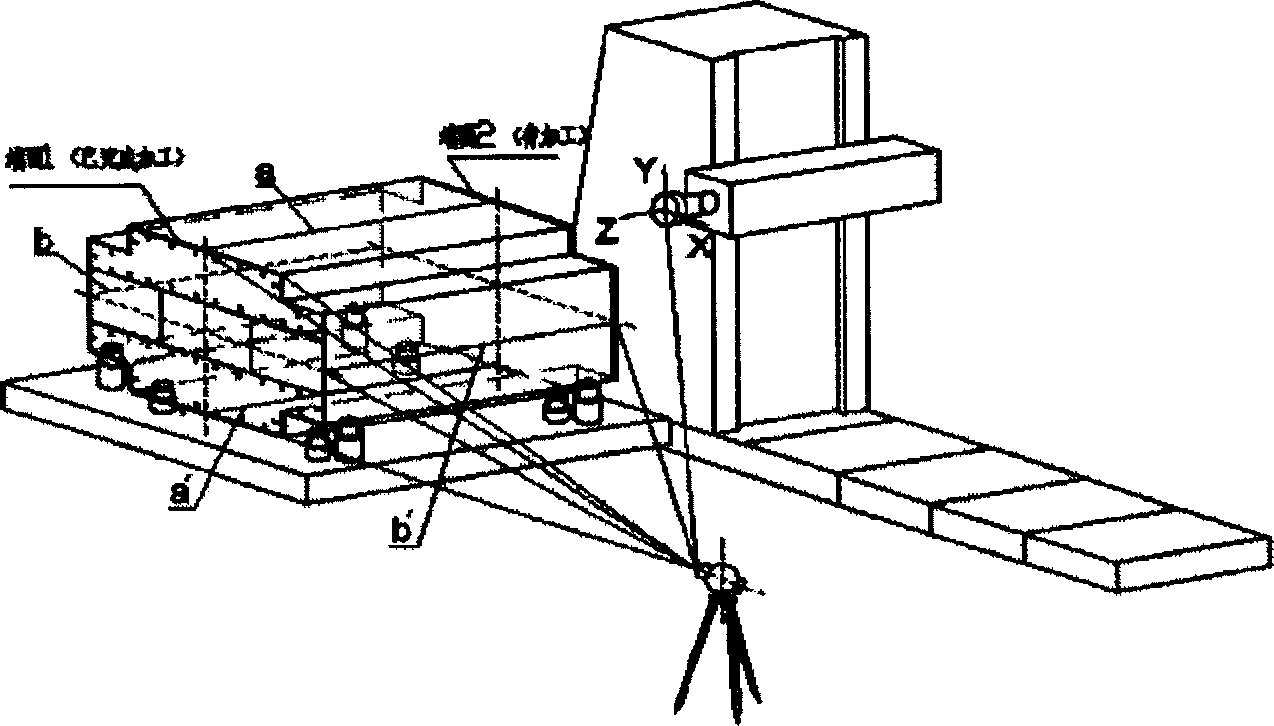

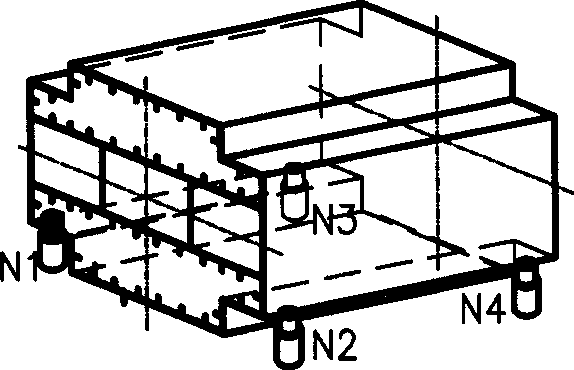

[0013] Embodiment 1: with reference to attached figure 1 and 2 . Straightening and positioning methods of steel cable tower section end face machining, (1) end face rough machining and straightening: use CNC hydraulic positioning system to control force support for the segment, that is to say, to support the steel cable tower segment support point force There are certain requirements and controls. At the same time, based on the machining line of the end face of the segment, adjust the spatial posture of the segment to make it positioned at the correct machining position; (2) The first end face finishing alignment: 1. Set the uniform temperature Finally, the section to be processed is transported to the machine tool processing position, and the steel cable tower section is controlled and supported; 2. Use a three-dimensional tracking measuring instrument to measure the three laser station marks on the machine tool and the section wall plate, and use the measurement data The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com