Multidimensional rotation ultrasound generating machining mechanism and machining method thereof

A technology of rotating ultrasonic and processing mechanisms, which is applied in the direction of stone processing tools, stone processing equipment, metal processing equipment, etc., which can solve the problems of affecting processing accuracy and efficiency, fast wear of tool heads, and difficulty in manufacturing ultrasonic processing tools, so as to improve processing efficiency, enhanced ultrasonic impact, and accelerated ultrasonic removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings:

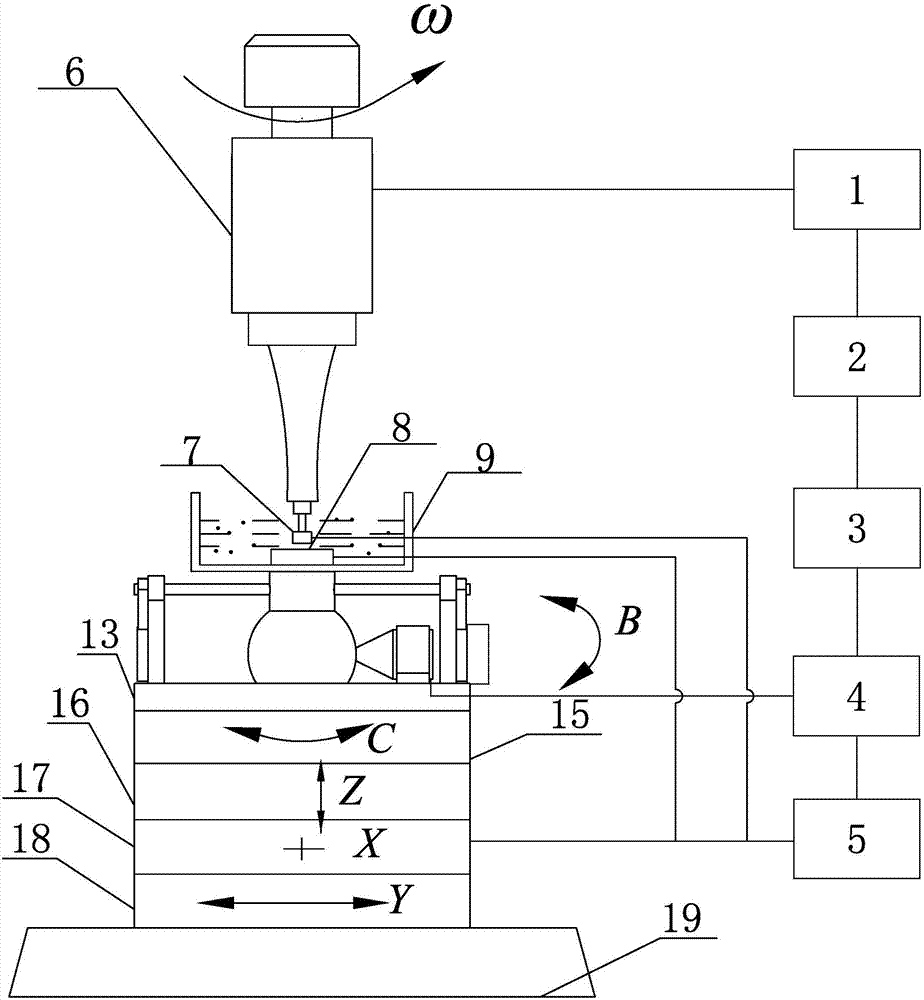

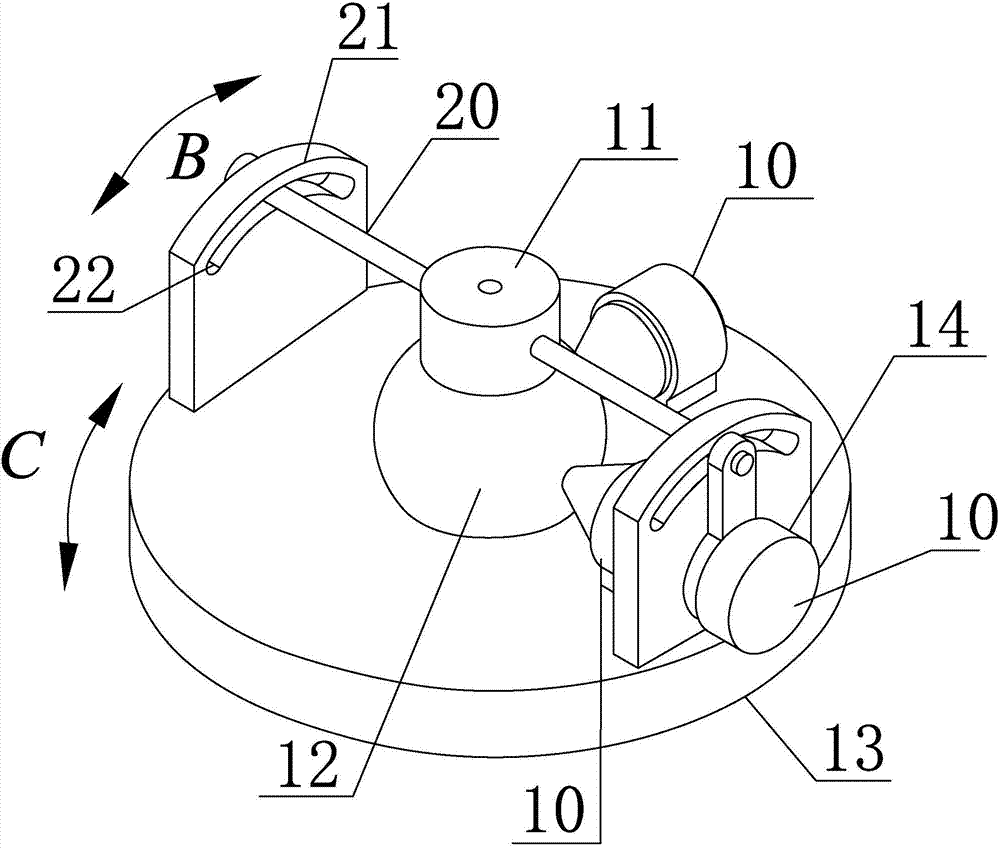

[0026] like Figure 1-2 As shown, the multi-dimensional rotary ultrasonic generating processing mechanism, the Y-direction feeding mechanism 18 is provided on the base 19, the X-direction feeding mechanism 17 is provided above the Y-direction feeding mechanism, and the Z-direction feeding mechanism 16 is provided on the X-direction feeding mechanism. Above the feeding mechanism, the rotary feeding mechanism C15 is arranged above the Z-direction feeding mechanism 16, and above the rotary feeding mechanism C15 is a circular bottom plate 13, a spherical structure 12, two radial ultrasonic vibration devices 10 and The rotary feed mechanism B 14 is arranged on the circular base plate 13, the rotary feed mechanism B 14 is located on one side of one of the radial ultrasonic vibration devices, the worktable base 11 is located above the spherical joint 12, and the top of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com