Patents

Literature

148results about How to "Processing applicable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

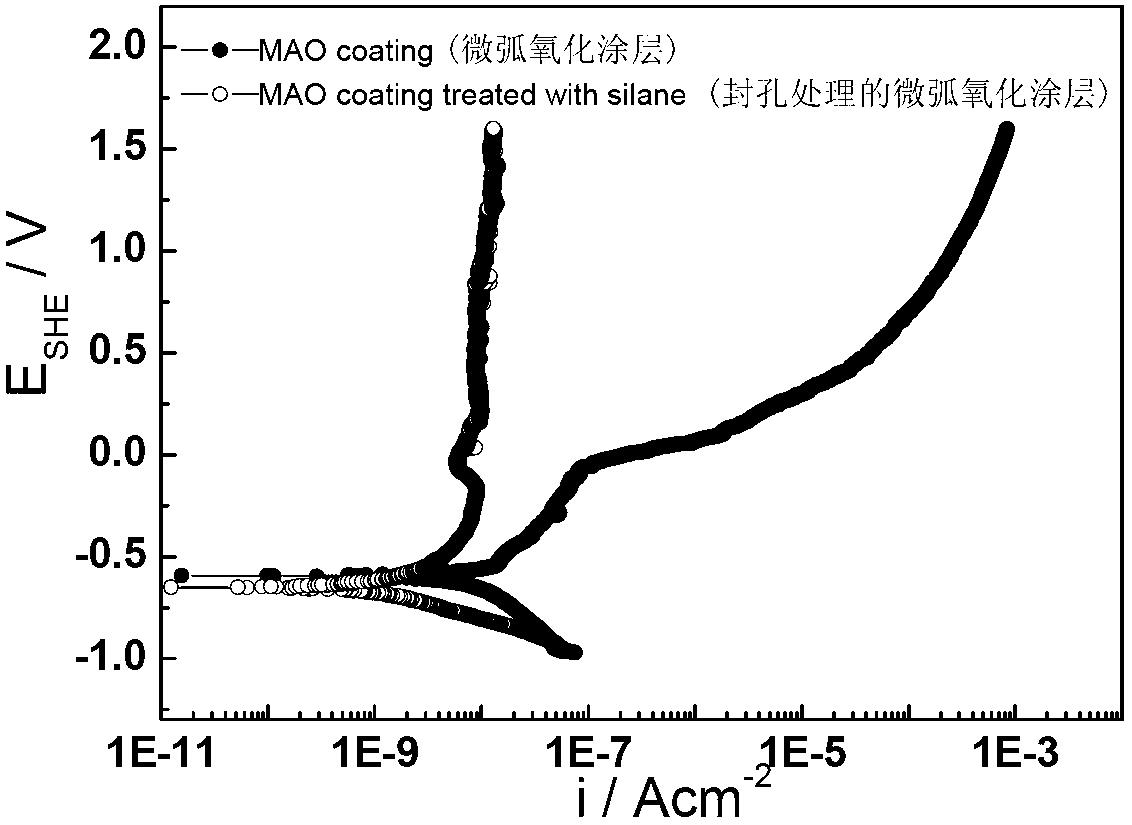

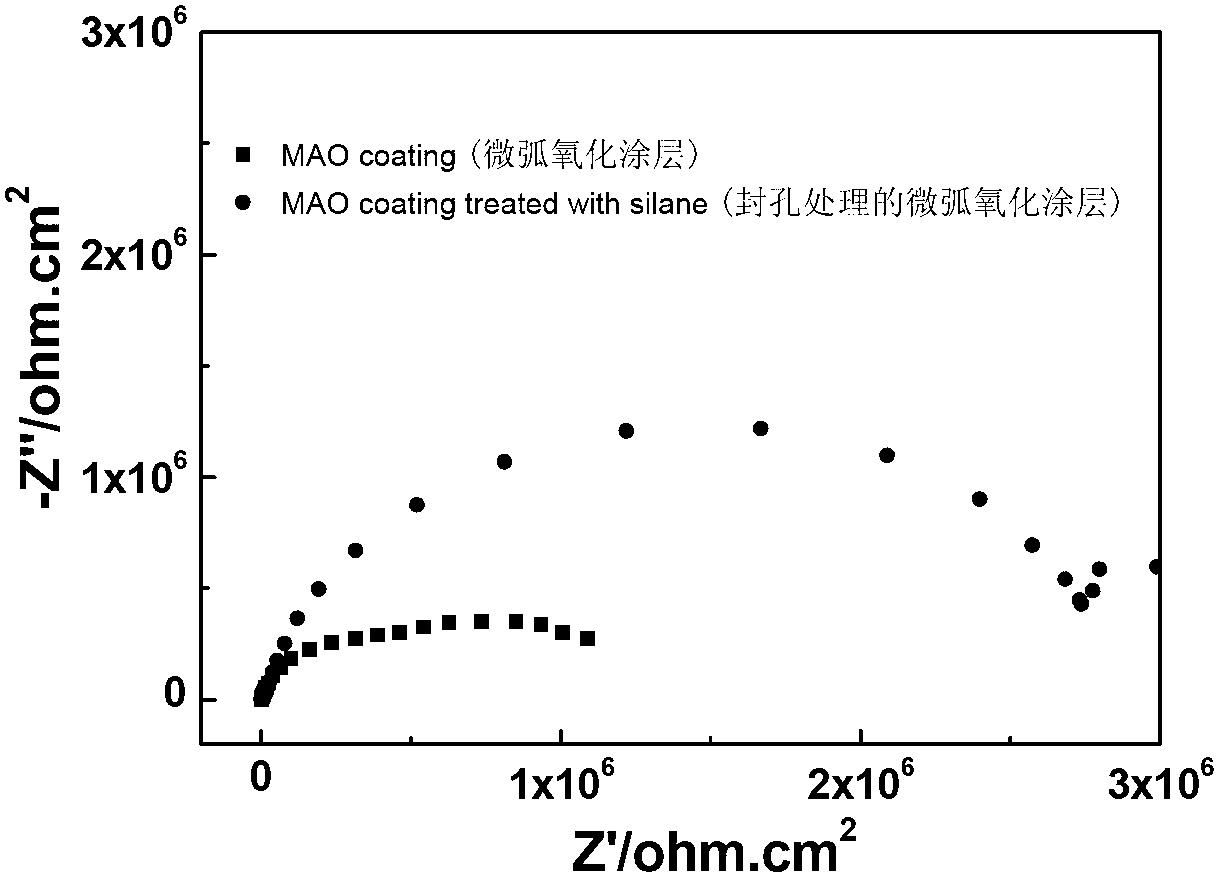

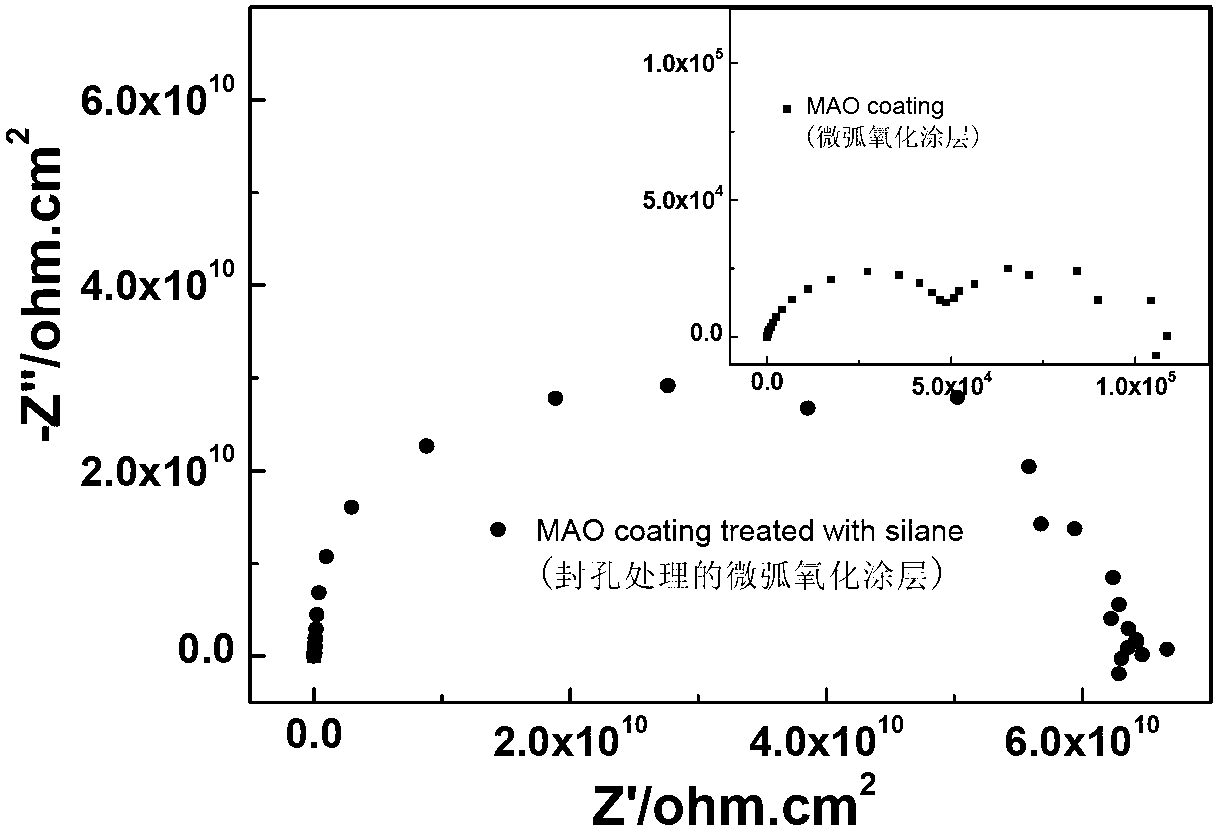

Microarc-oxidized coating silylation fluid and hole sealing method thereby

InactiveCN102703892AImprove corrosion resistanceRich varietyAnodisationMetallic material coating processesMicro arc oxidationChemistry

The invention provides microarc-oxidized coating silylation fluid and a hole sealing method thereby. The hole sealing method by the microarc-oxidized coating silylation fluid includes: firstly, mixing deionized water, alcohol and silane coupling agent according to a volume ratio of 3-6:1:1, and adjusting pH value to obtain the microarc-oxidized coating silylation fluid; secondly, hydrolyzing the microarc-oxidized coating silylation fluid for more than 12 hours to obtain silane coupling agent hydrolyzed solution; thirdly, soaking microarc-oxidized coating in the silane coupling agent hydrolyzed solution for 19s to 20min, taking out the coating for air drying to obtain coating with absorbed hydrolyzed solution; and fourthly, heating and solidifying the coating with absorbed hydrolyzed solution at 50-300 DEG C for 15-300 minutes. The microarc-oxidized coating is silylated by the soaking-solidifying method, the process is simple, cost is low, and the hole sealing method by the microarc-oxidized coating silylation fluid is applicable to hole sealing of microarc-oxidized coatings of magnesium alloy, aluminum alloy and titanium alloy.

Owner:HARBIN ENG UNIV

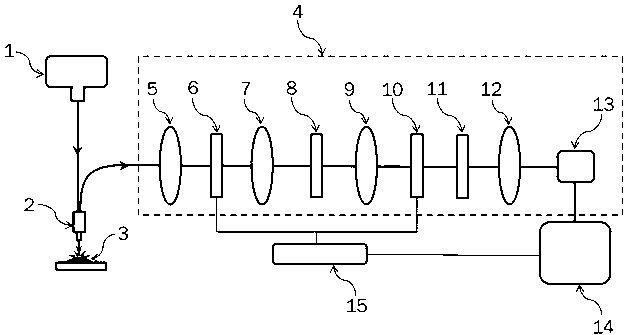

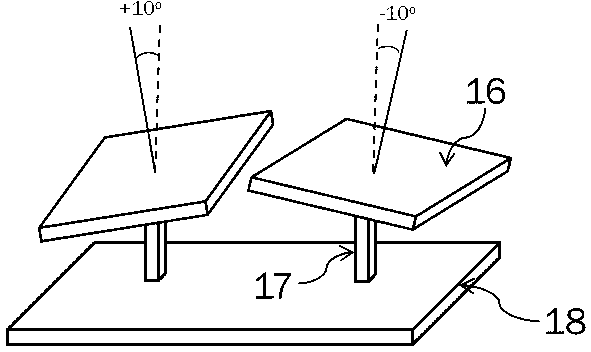

Portable raman spectrometer based on spectral analysis of micro electro mechanical system

InactiveCN103196889AMaintain detection resolutionHigh sensitivityRadiation pyrometryRaman scatteringRayleigh scatteringLine width

The invention provides a portable raman spectrometer based on spectral analysis of a micro electro mechanical system. On the basis of the micro electro mechanical system, the portable raman spectrometer comprises a laser light source, a raman probe head and a spectrum detection system of a spectrograph, wherein the laser light source comprises a semiconductor laser which is used for generating lasers, the power of the generated lasers is not less than 200 milliwatts, and the line width of the generated lasers is not greater than 0.2 nanometers; the raman probe head comprises a laser outputting optical path and a raman scattered light collecting optical path which does not comprise a light filter for filtering rayleigh scattered light; and the spectrograph comprises the spectrum detection system which sequentially consists of a focusing lens I, a digital micromirror device (DMD) module I, a collimating lens, a chromatic dispersion optical grid, a focusing lens II, a digital micromirror device (DMD) module II, a de-chromatic dispersion optical grid, a focusing lens III, a single-point detector and a signal processor. The portable raman spectrometer has the advantages of being capable of keeping the resolution ratio of spectrum detection and improving the sensitivity of spectrum detection, being suitable for detection on weak signals such as raman signals, and the like.

Owner:许春 +2

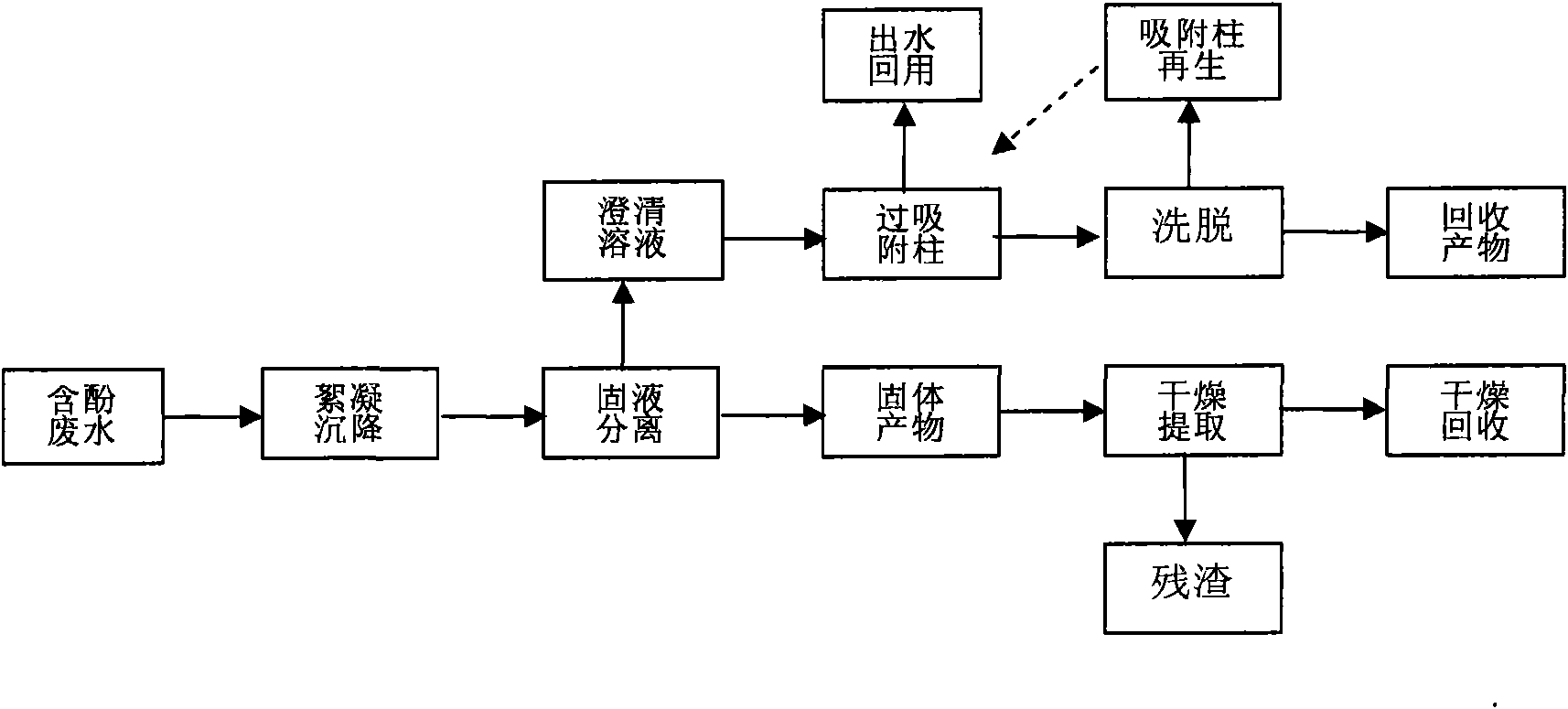

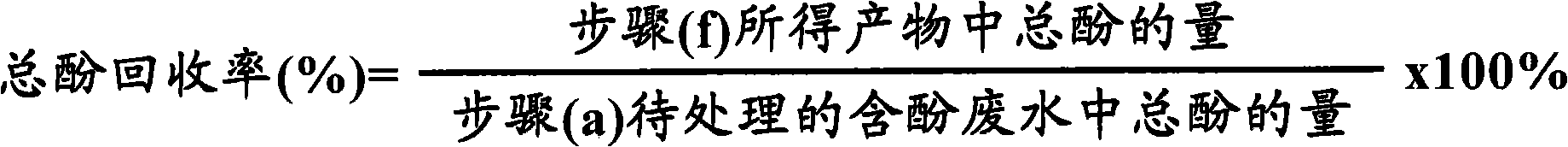

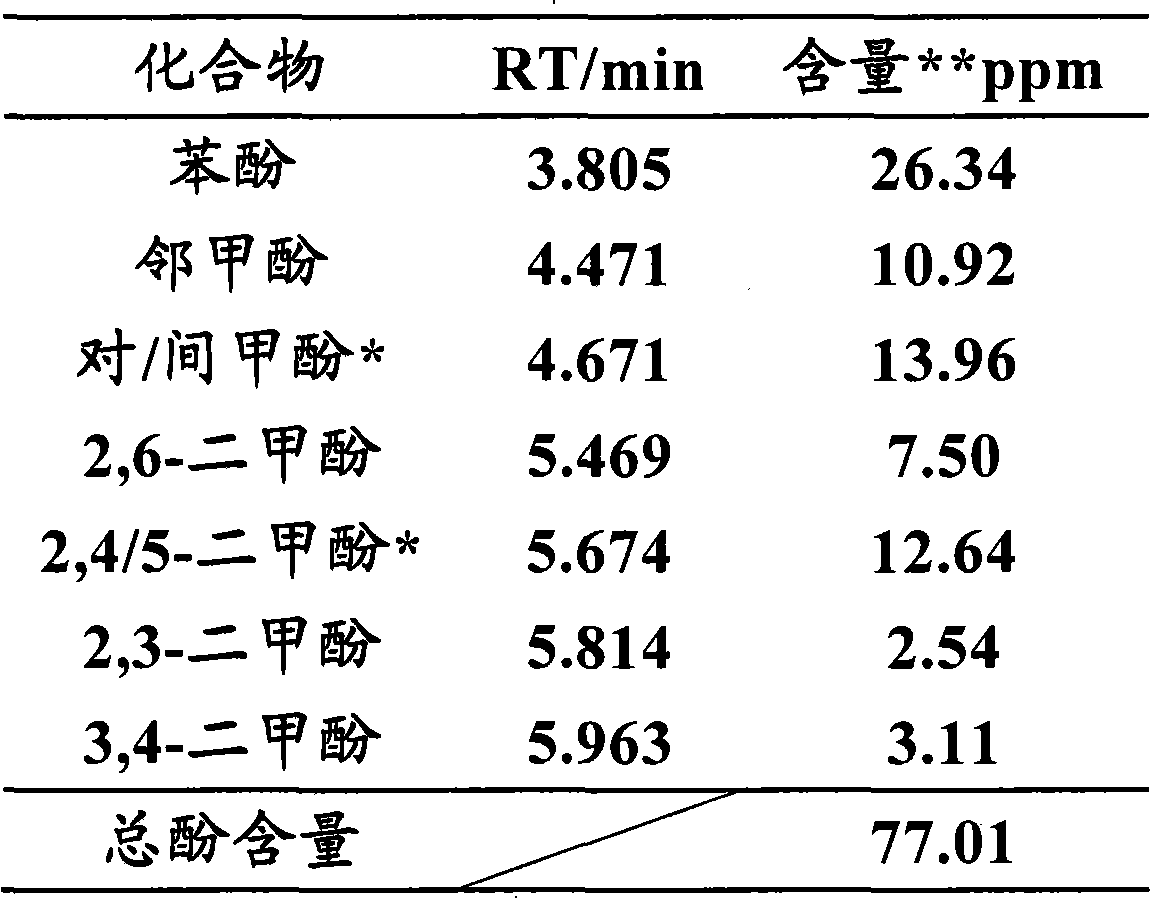

Method for processing and recycling waste water containing phenolic compounds

InactiveCN102417248AEasy to purifyRealize automatic continuous productionOrganic chemistryOrganic compound preparationFlocculationAlcohol

The invention relates to a method for processing and recycling waste water containing phenolic compounds, in particular to a method for recycling phenolic compounds from the phenolic waste water, comprising the following steps: (a) adding a flocculating agent in the phenolic waste water to be processed for flocculation; (b) carrying out solid-liquid separation on the material of the step (a); (c) determining the pH value of the liquid material obtained by the step (b), and adjusting the pH value to acidity; (d) letting the material obtained by the step (c) pass through a resin column, and measuring the total phenol content in water; (e) eluting the resin column which absorbs the phenolic compounds with a small molecular alcohol and / or ketone solvent; and (f) recovering the solvent from the eluate, and drying to obtain a product which is rich in phenolic compounds. Correspondingly, the invention further provides a method for processing the waste water containing phenolic compounds and the obtained phenolic product. According to the invention, the method disclosed herein is suitable for processing the waste water with low phenol content, and is environmental friendly; by using the raw materials which has the advantages of low pollution, or low price, or easy processing, and or recycling property, the method has the advantages of low cost and low energy consumption.

Owner:ENN SCI & TECH DEV

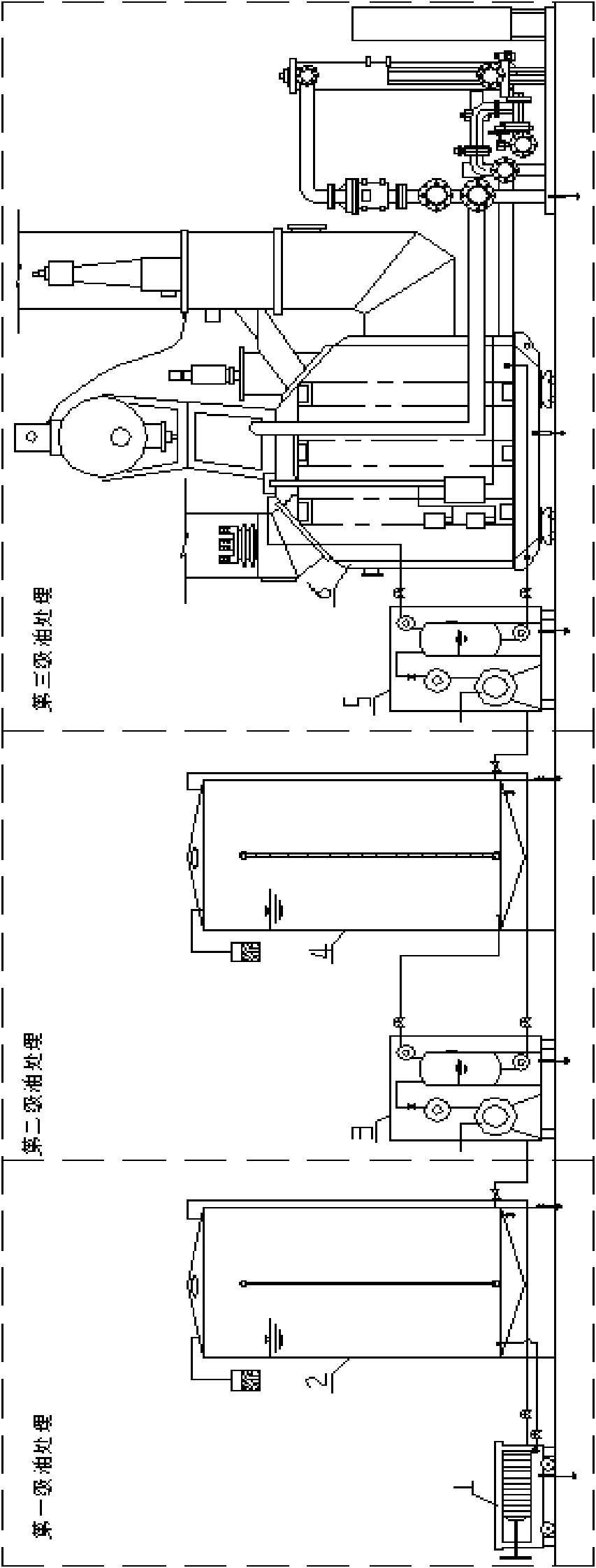

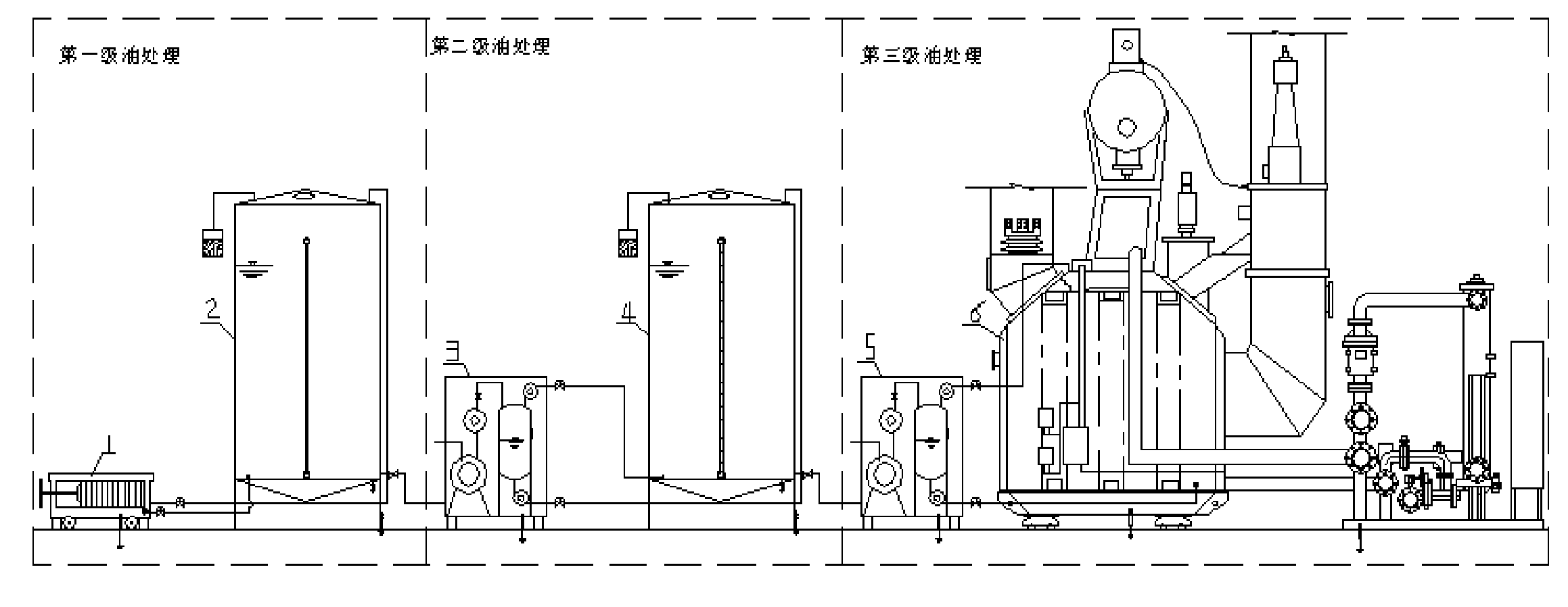

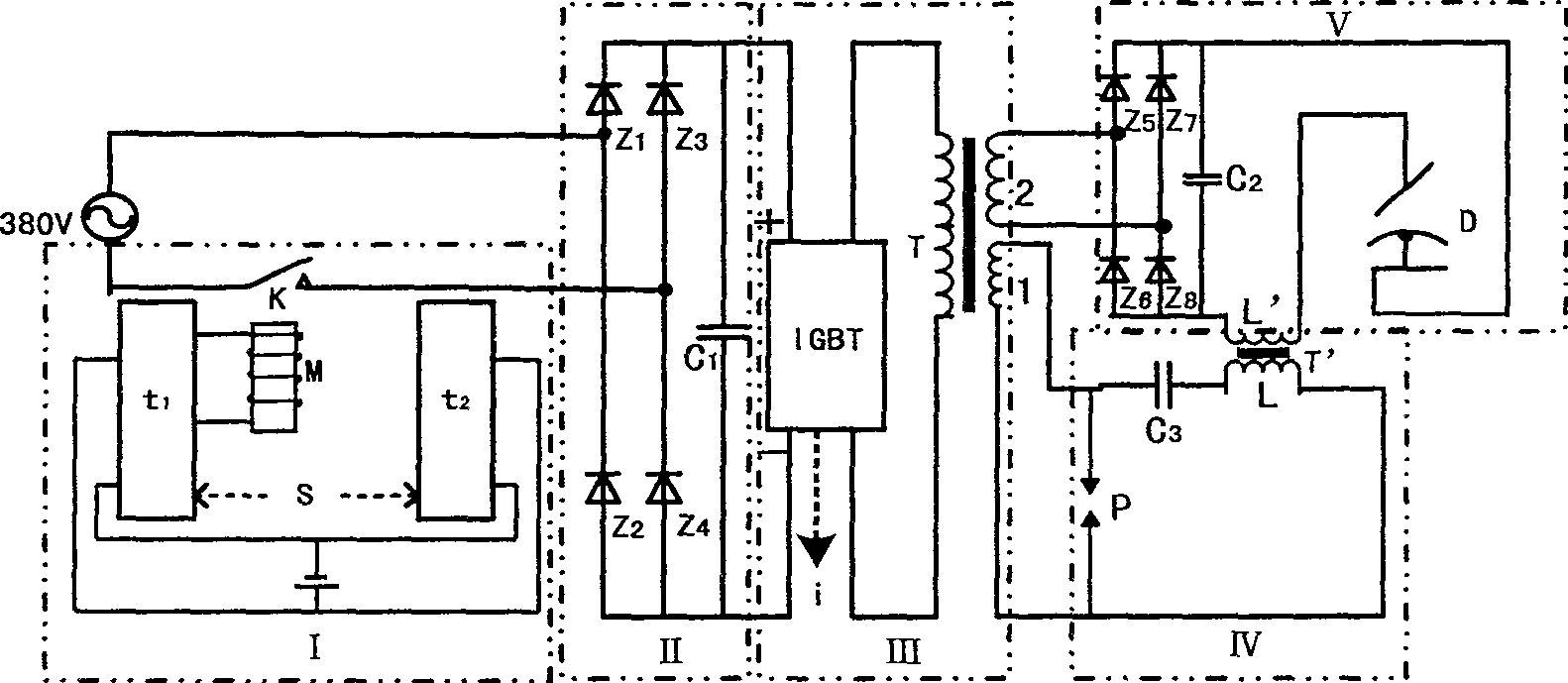

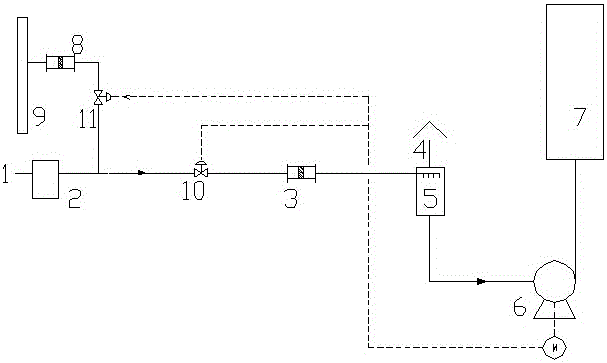

Method for treating insulating oil for transformer

InactiveCN102136348AProcessing applicableOvercome the defects of incomplete removalTransformers/inductances coolingTransformerElectric power system

The invention relates to a method for treating insulating oil for a transformer. The method comprises the following three treatment steps: first-stage oil treatment: using a pressure oil filter to carry out pressure filtering on granules and impurities in the insulating oil; second-stage oil treatment: using a first vacuum oil filter to carry out vacuum degassing and dewatering on the insulating oil undergoing the first-stage treatment; and third-stage oil treatment: using a second vacuum oil filter to inject the insulating oil undergoing the first-stage and second-stage treatment into a transformer to undergo cyclic hot oil degassing and dewatering treatment to dry the transformer. The method has the following beneficial effects: the insulating oil is independently treated by stages; after the technical indexes of the oil reach the specified values, the oil is injected into the machines on the next stages to be treated until the indexes of the oil undergoing the third-stage treatment are qualified; respective advantages of pressure filtering and vacuum filtering are fully and reasonably used; and the method is especially suitable for treating the insulating oil during field installation of high-capacity power transformers and reactors with voltage being 750KV and above.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

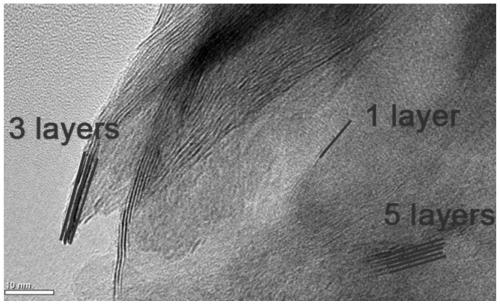

Carbon-based material adsorbent for removing heavy metals in waste water, its preparation method and application

InactiveCN102941065AHigh removal rateEasy to makeOther chemical processesWater/sewage treatment by sorptionSorbentSodium citrate

The invention discloses a carbon-based material adsorbent for removing heavy metal in waste water, comprising 98.2-99.8% of carbon-based material and 0.2-1.8wt% of sodium citrate modified component, wherein the specific surface area of the carbon-based material is 800-1200 m<2> / g, the total pore volume of the carbon-based material is 0.5-0.7 cm<3> / G(cm<3> / g), and the average aperture of the carbon-based material is 2-4 nm. According to the invention, the preparation process is simple, there is no secondary pollution, and heavy metals in waste water can be efficiently removed.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

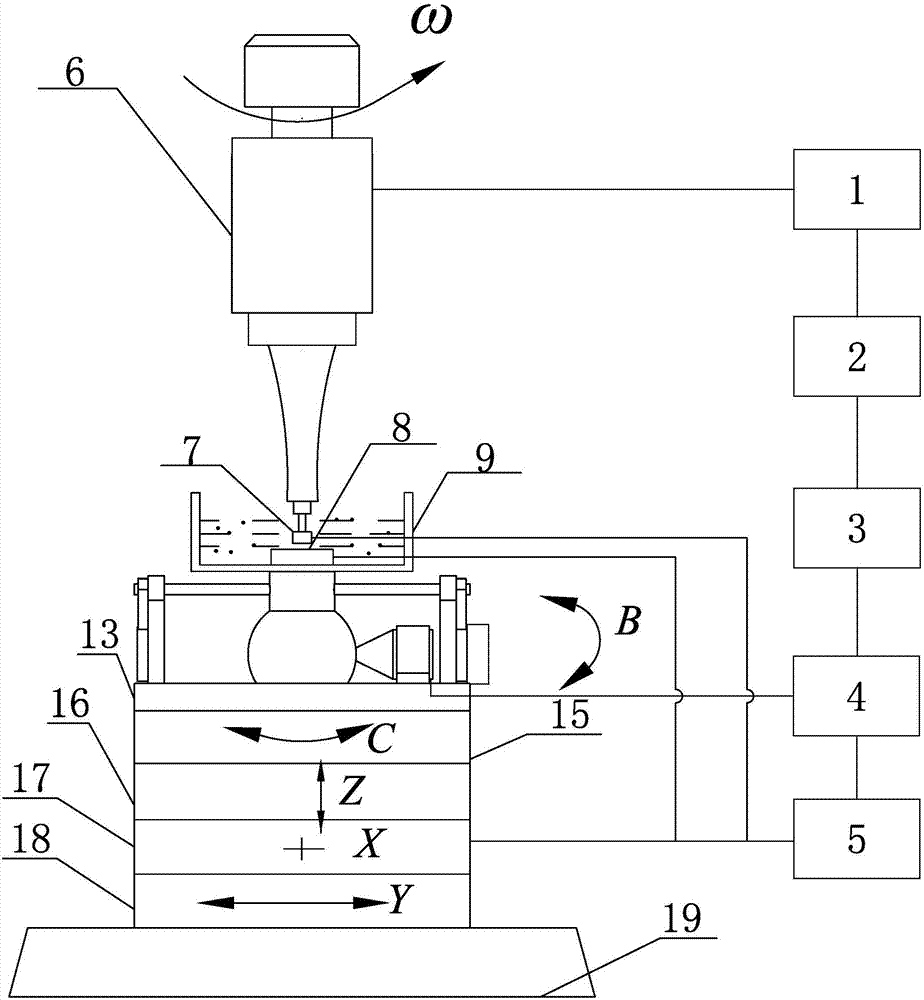

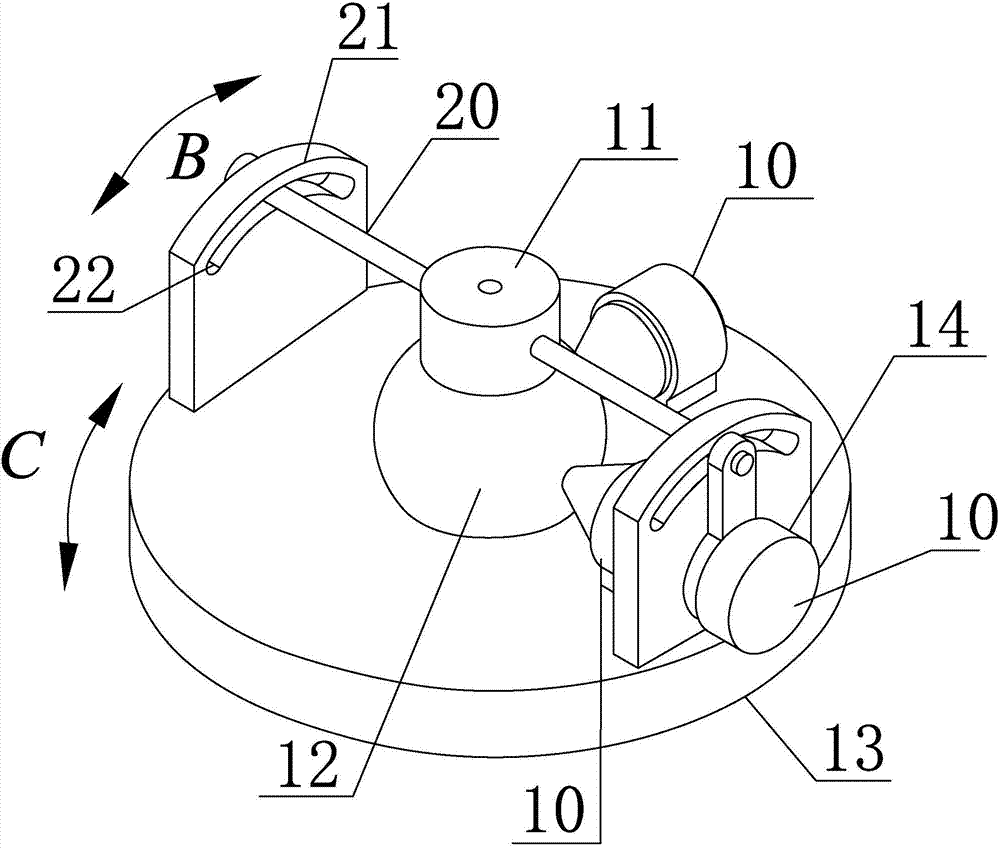

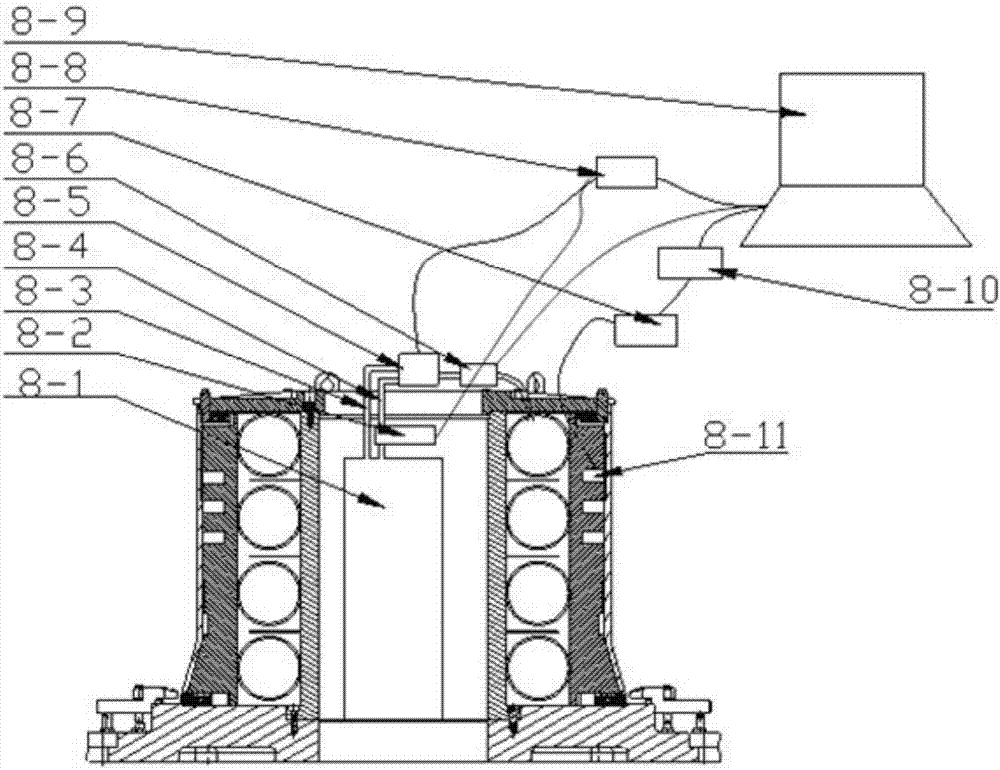

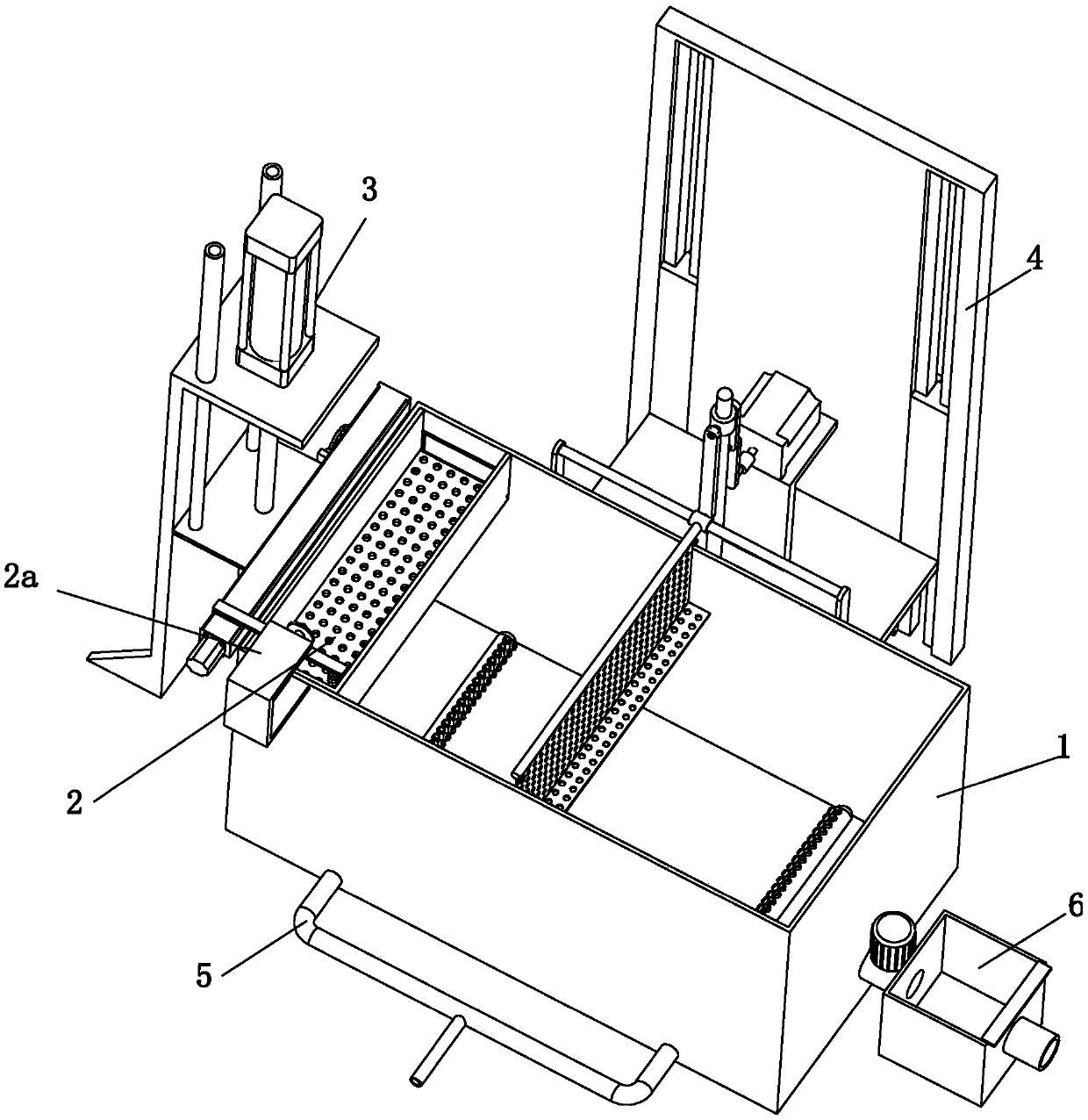

Multidimensional rotation ultrasound generating machining mechanism and machining method thereof

ActiveCN107378655ASimple manufacturing processSatisfy processabilityGrinding carriagesGrinding feed controlVibration amplitudeNumerical control

Disclosed is a multidimensional rotation ultrasound generating machining mechanism and a machining method thereof. By using coupling action of axial rotation ultrasound and double radial ultrasound, component space molded surface generating machining is conducted in a stimulating mode. The multidimensional ultrasound vibration and axial rotation motion can remarkably enhance effects such as ultrasound impacting, polishing and cavitation. The removing efficiency of crisp and hard materials, cycling updating of abrasive material working fluid and timely excluding of machining products are accelerated. Parameters such as ultrasound vibration parameters, gaps between tools and workpieces and temperature are detected on-line, computer operation processing and control are used, real-time adjusting and multi-axis linkage feeding amount control are conducted on the key parameters such as multidimensional ultrasound vibration amplitude and the machining gaps, the reasonable amplitude and the machining gaps of an ultrasound system in generating feeding machining are maintained, the machining efficiency of the crisp and hard materials can be remarkably improved, and the machining precision is improved. The multidimensional rotation ultrasound generating machining mechanism is novel and unique, the multidimensional rotation ultrasound vibration and multi-axis linkage feeding motion can be effectively achieved, the machining method is in conquering the unyielding with the yielding mode and used for generating motion flexible machining forming, the technical advantages of multidimensional ultrasound machining and multi-axis linkage numerical control are achieved, and the machining difficult problem of special-shaped curved surface components of all kinds of crisp and hard materials can be effectively solved.

Owner:YANGZHOU UNIV

Treatment method of copper-bearing waste water

InactiveCN102010084AEasy to handleImprove efficiencyMultistage water/sewage treatmentTreatment effectSilver plate

The invention belongs to the field of sewage treatment, and relates to a treatment technique of industrial waste water. The invention particularly relates to a treatment method of copper-bearing waste water. In the treatment method, a water-soluble sulfide serves as a precipitant to realize the recovery of copper; the using amount of the sulfide is controlled by a photo-chromic reaction; a hypochlorite or persulfate type oxidant is adopted to perform oxidation desulphurization, thereby fulfilling the aims of recovering excessive sulfur and achieving up-to-standard emission of the copper and the sulfur in the waste water. The basic process of the treatment method comprises sulfide precipitation and the oxidation desulphurization, and the treatment method has a good treatment effect and a high efficiency, is easy to operate and control; and the treated waste water is colorless and transparent, and the copper and sulfur content is far lower than a national emission standard. The copper sulfide and elemental sulfur recovered by the treatment method are high in purity and can be directly used as industrial products. The treatment method of the copper-bearing waste water is suitable for treating the copper-bearing waste water such as copper powder washing and copper powder silver plating waste water, printed circuit board etching waste water, electroplating waste water, copper wet-process metallurgical waste water and the like, and is particularly suitable for treating the copper powder washing and copper powder silver plating waste water.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

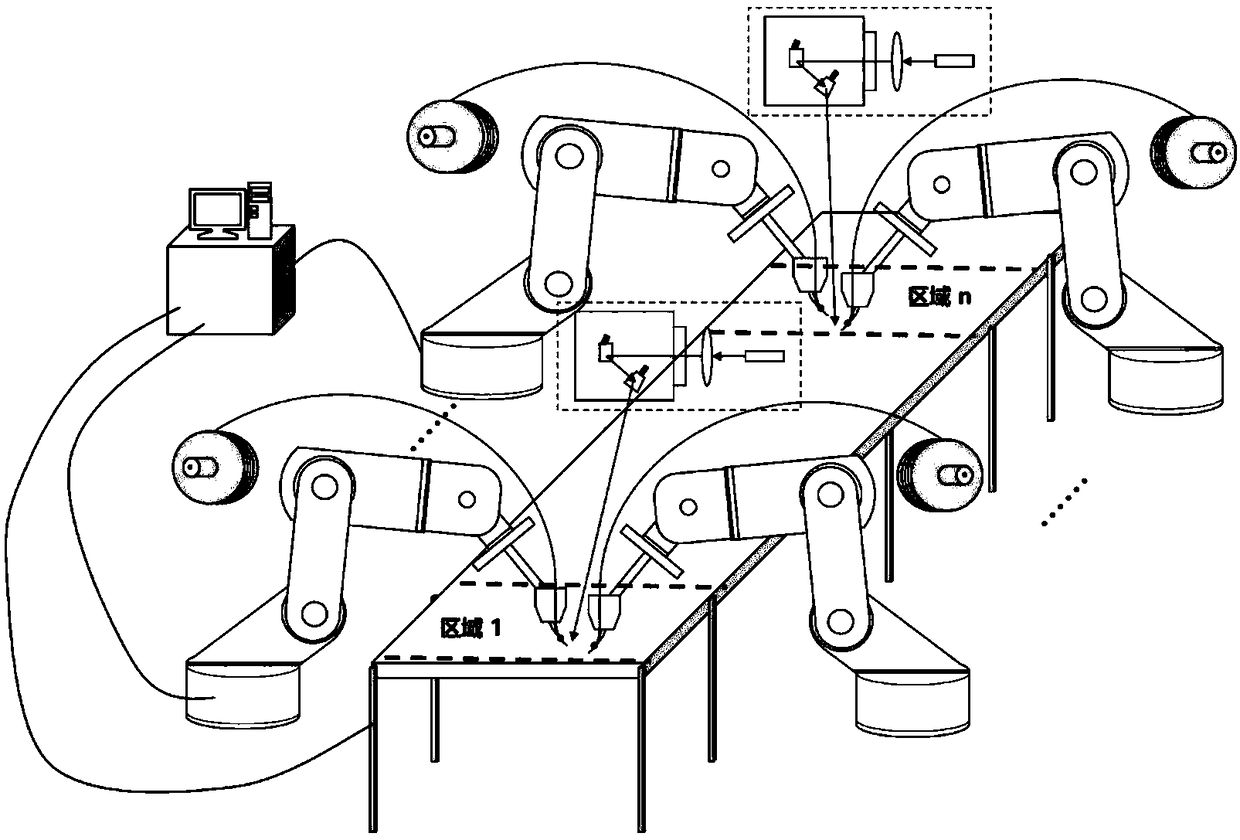

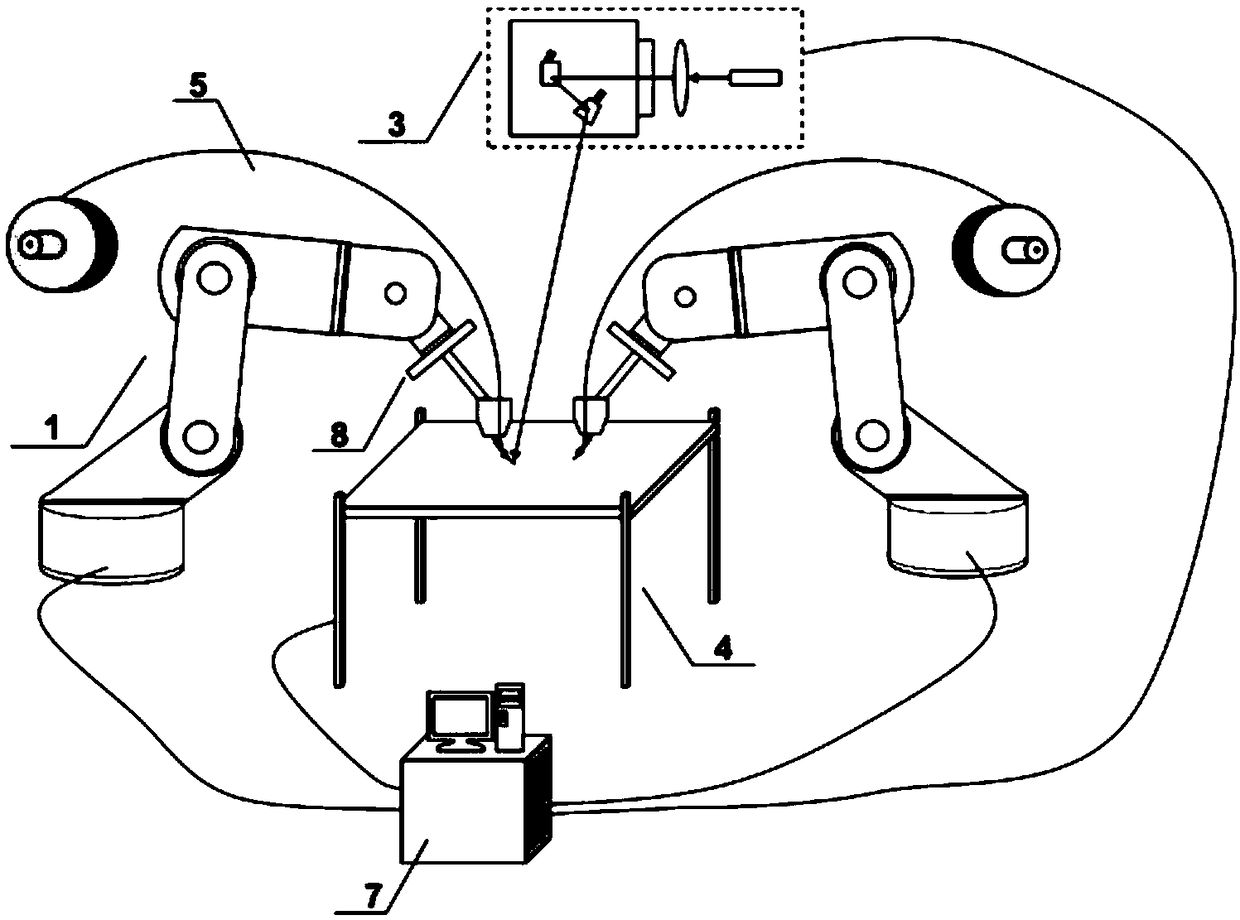

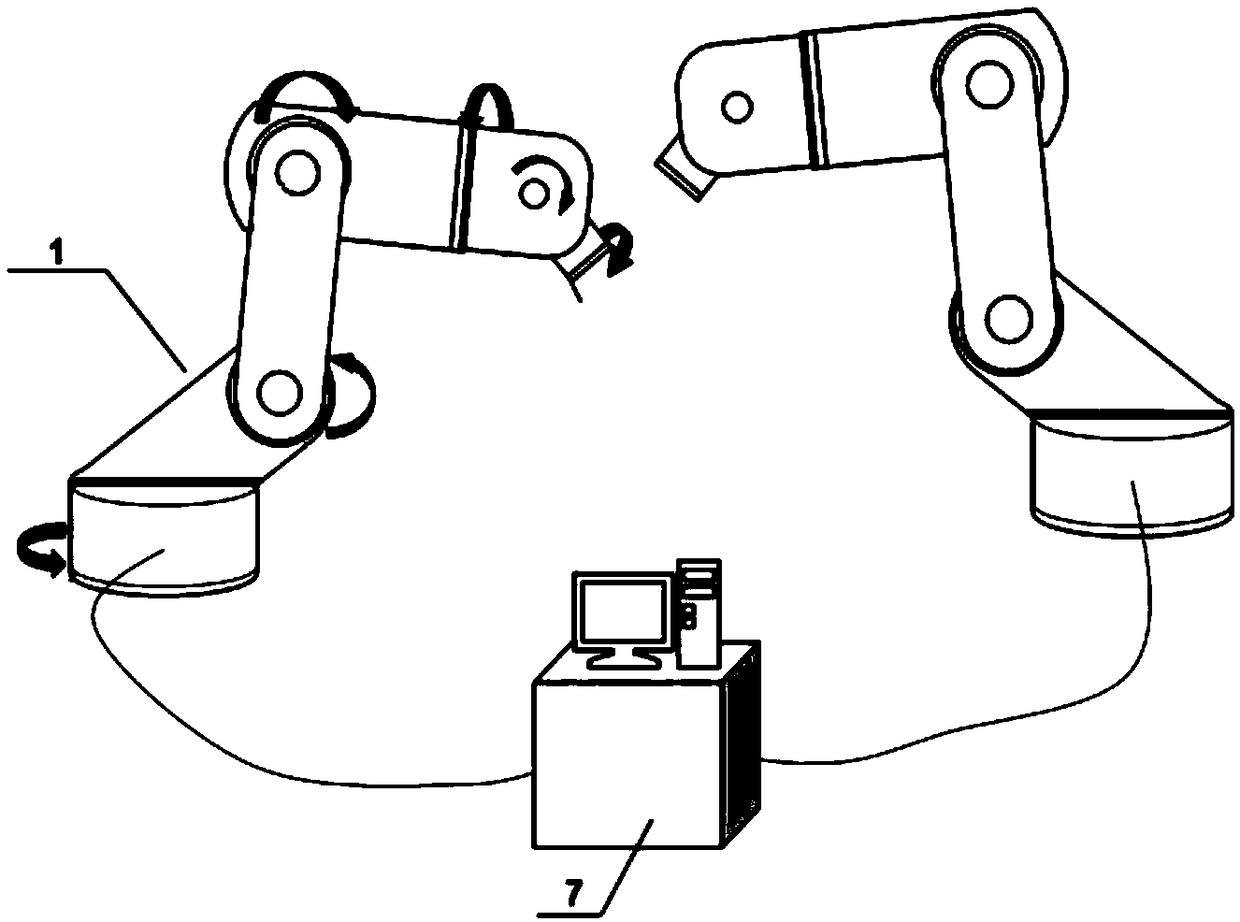

Polymer multi-material multi-laser flexible additional material manufacturing system and method

ActiveCN109130171AProcessing applicableRealize formingAdditive manufacturing apparatus3D object support structuresMulti materialComputer module

The invention belongs to the field of wire laser additional material manufacturing, and discloses a polymer multi-material multi-laser flexible additional material manufacturing system and method. Thesystem comprises a plurality of modules, the modules correspond to different regions in a single slice layer, each module comprises a laser emitting unit, a plurality of robots and wire feeding unitsand extruding units which are matched with the robots, the laser emitting units and the extruding units are arranged separately so that extruding and melting are performed separately to avoid clogging of spray heads of the extruding units; the extruding units are arranged at the tail ends of the robots, the robots carry the extruding units to preset positions to achieve the transportation of wires, each robot conveys a wire correspondingly, the robots perform wire feeding according to preset trajectories and sequence, and the fed wire is melted under the action of the laser emitting unit to achieve forming of a plurality of materials of each slice layer. The polymer multi-material multi-laser flexible additional material manufacturing system and method solve the problem that the spray heads are easy to clog, improve the flexibility of the manufacturing system and achieve forming of large-sized products.

Owner:HUAZHONG UNIV OF SCI & TECH

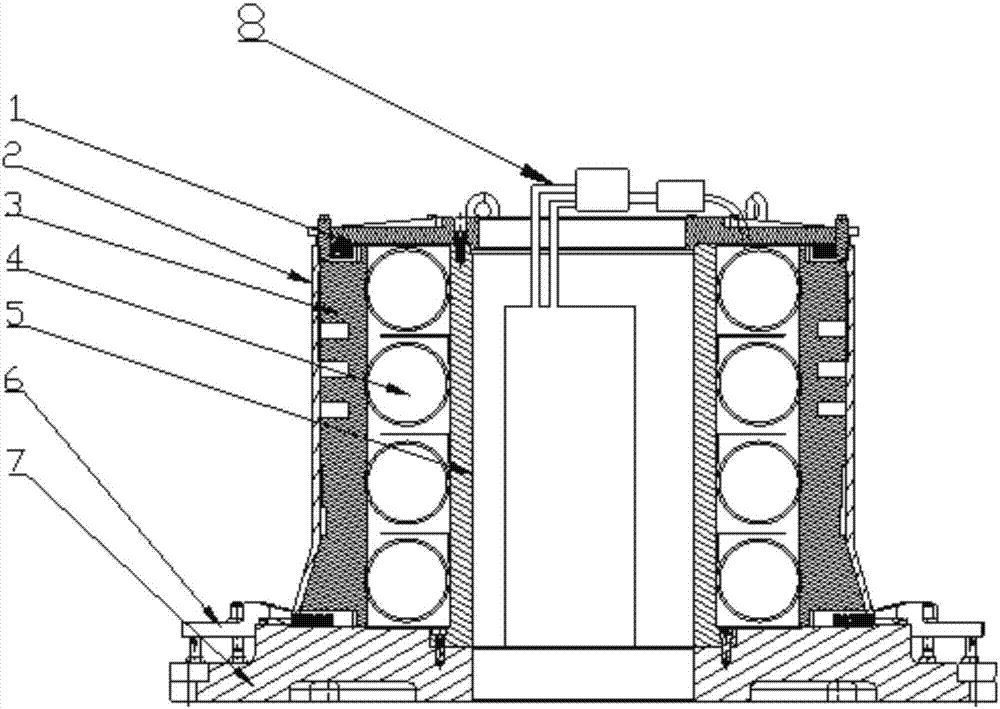

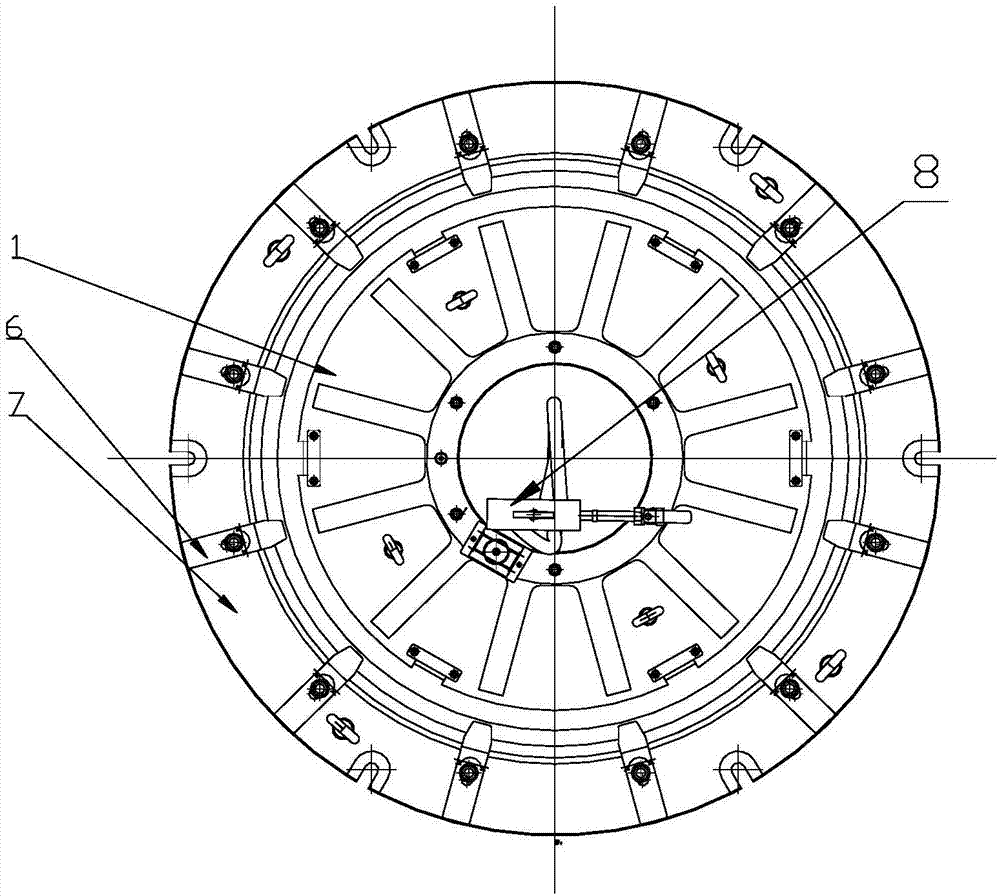

Vibration reducing device used for machining of annular thin-wall part

ActiveCN107486749AIncrease stiffnessImprove dynamic stabilityMeasurement/indication equipmentsMaintainance and safety accessoriesMachining vibrationsEngineering

The invention provides a vibration reducing device used for machining of an annular thin-wall part. The vibration reducing device comprises a base, a pressing plate, an axial limiting assembly, a damping wave absorbing piece, a gas damper and an intelligent pressure adjusting system; the axial limiting assembly is composed of a supporting column and an upper cover plate, and the supporting column is installed on the base; the gas damper is composed of an airbag and at least two bulging type blocks, the airbag is an annular airbag, the supporting column is sleeved with the air bag, and all bulging type blocks are placed on the base in a surrounding mode and connected with the airbag; the number of the damping wave absorbing piece is the same as the number of the bulging type blocks, and the damping absorbing piece are pasted on the outer sides of the corresponding bulging type blocks; the upper cover plate is placed at the upper end of the machined annular thin-wall part and connected with the supporting column; and the intelligent pressure adjusting system is used for adjusting the gas pressure in the airbag. Combination of the gas damper, the damping wave absorbing piece and the axial limiting assembly greatly reduces machining vibration, deformation of the machined annular thin-wall part in the X, Y, Z directions is restricted, and stiffness and dynamic stability of the part are improved.

Owner:AECC AERO SCI & TECH CO LTD +3

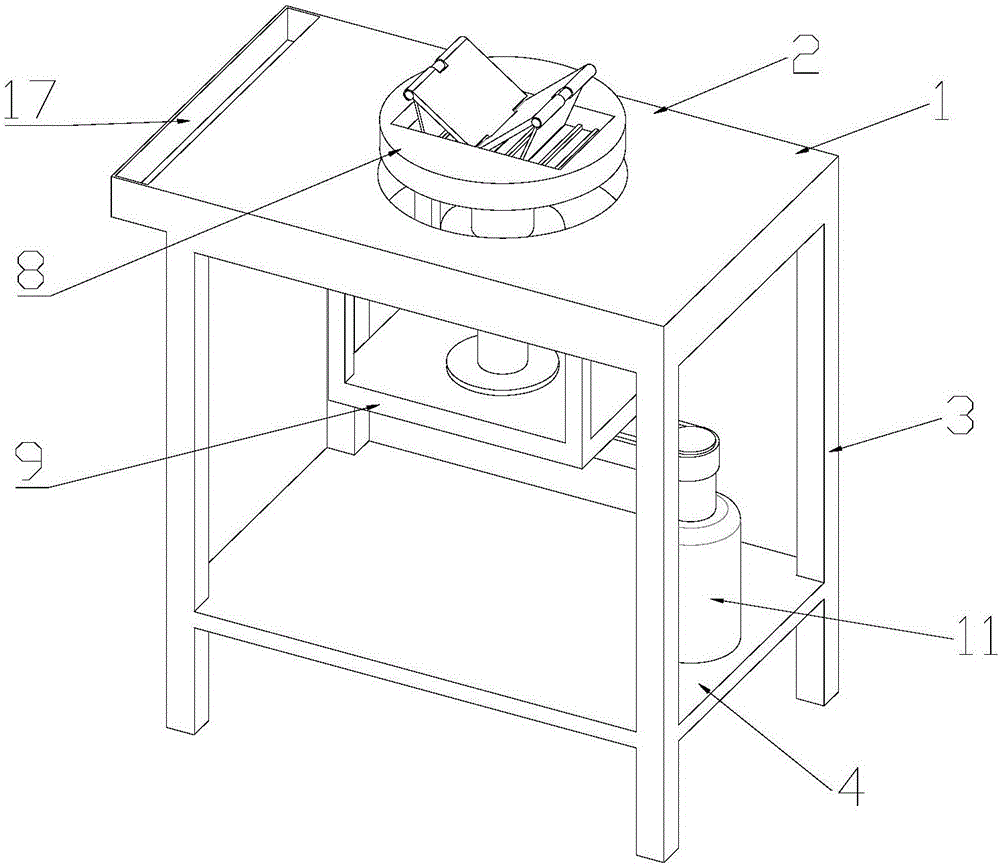

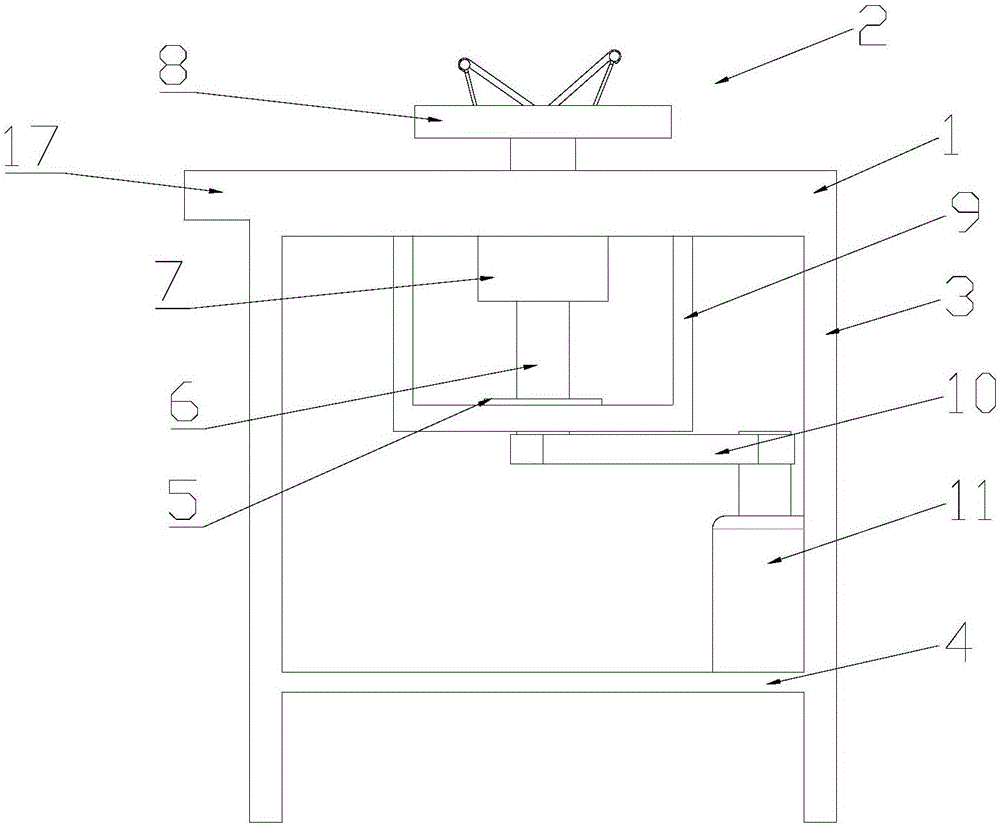

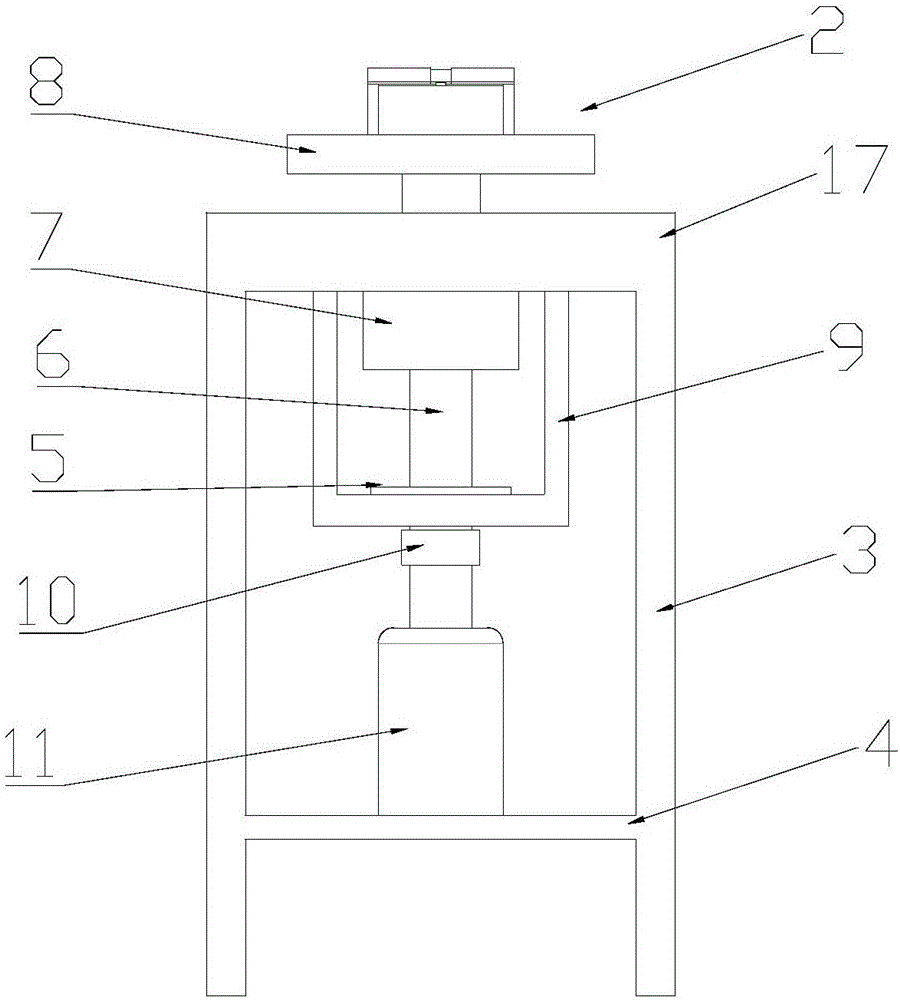

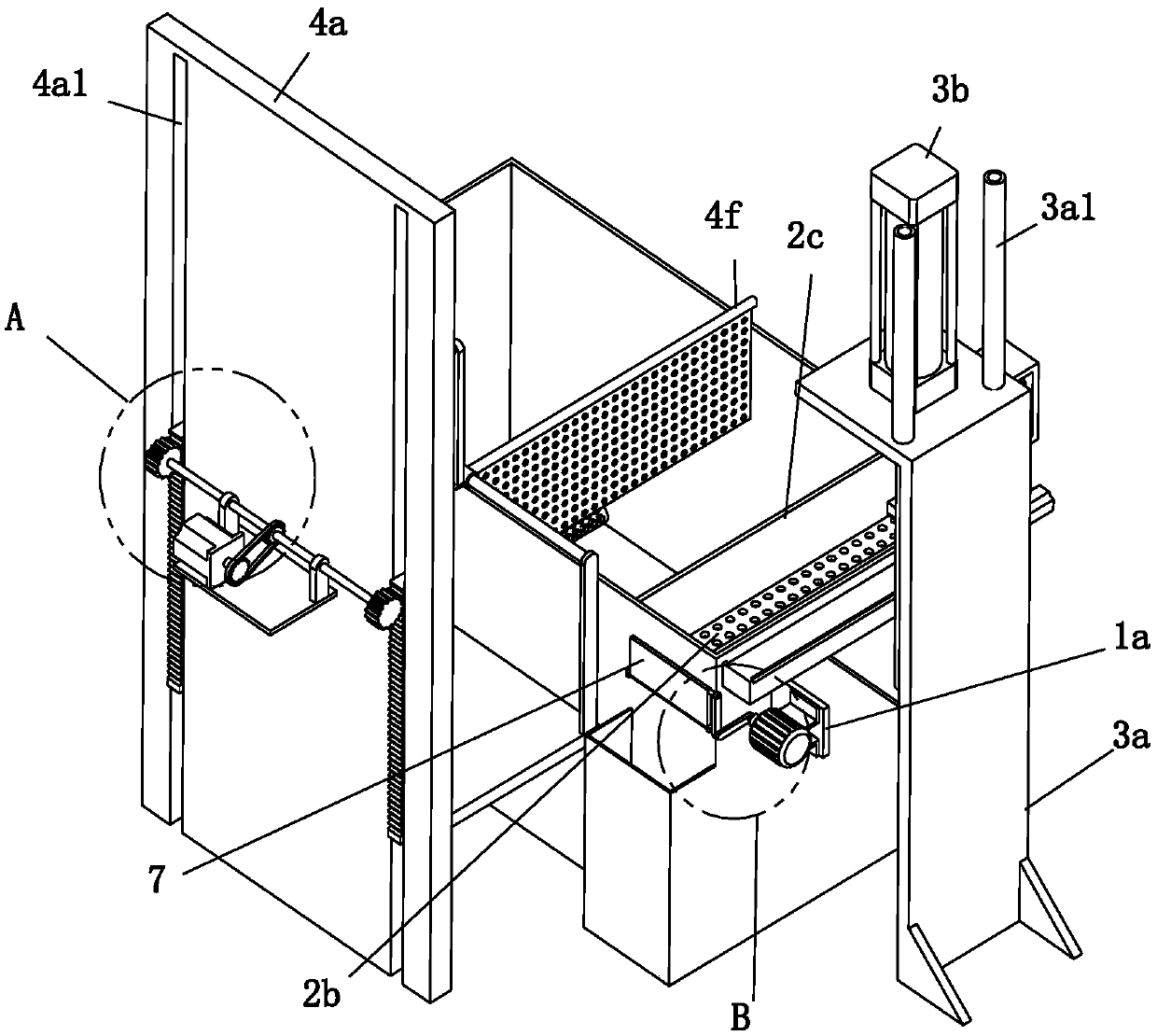

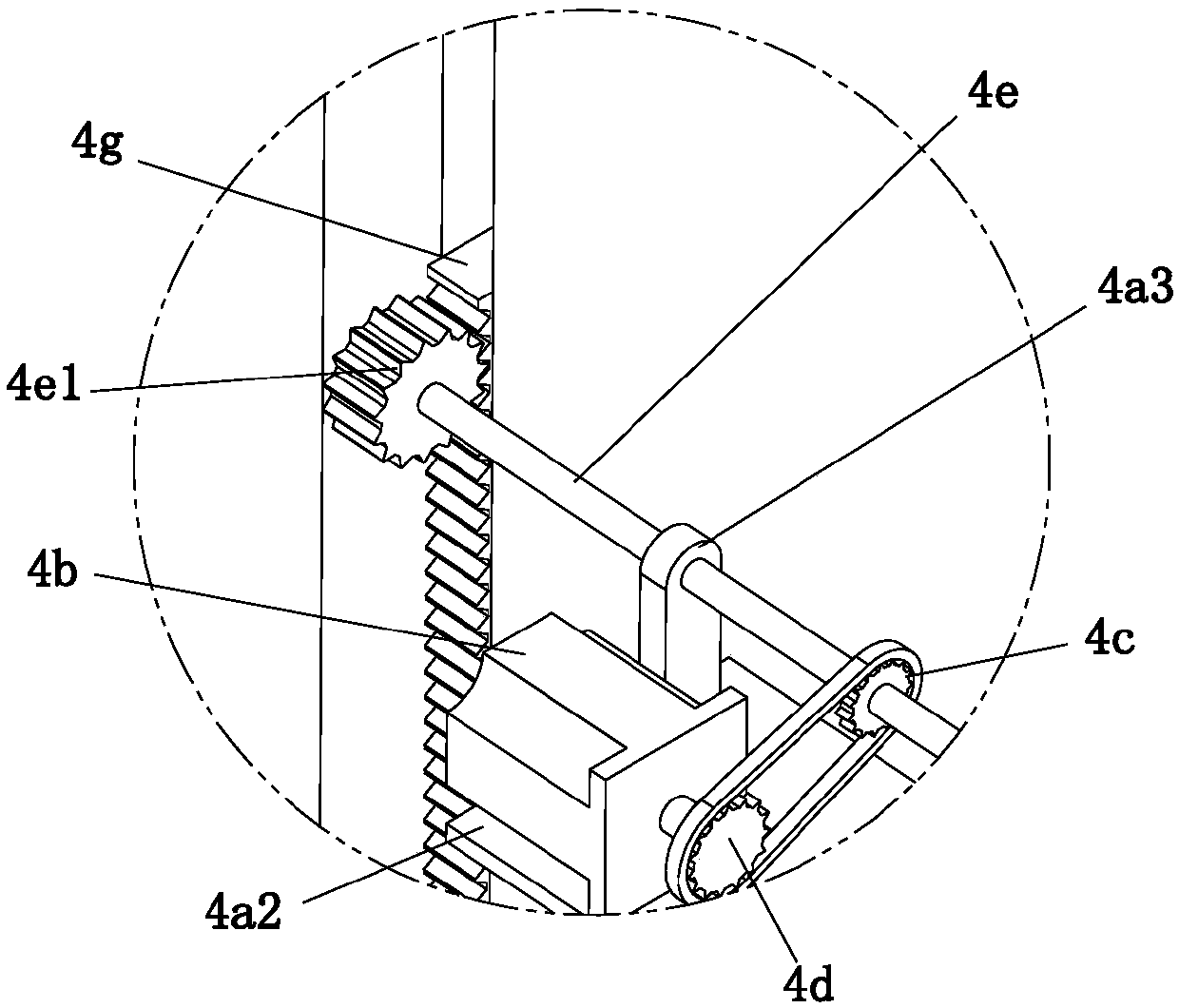

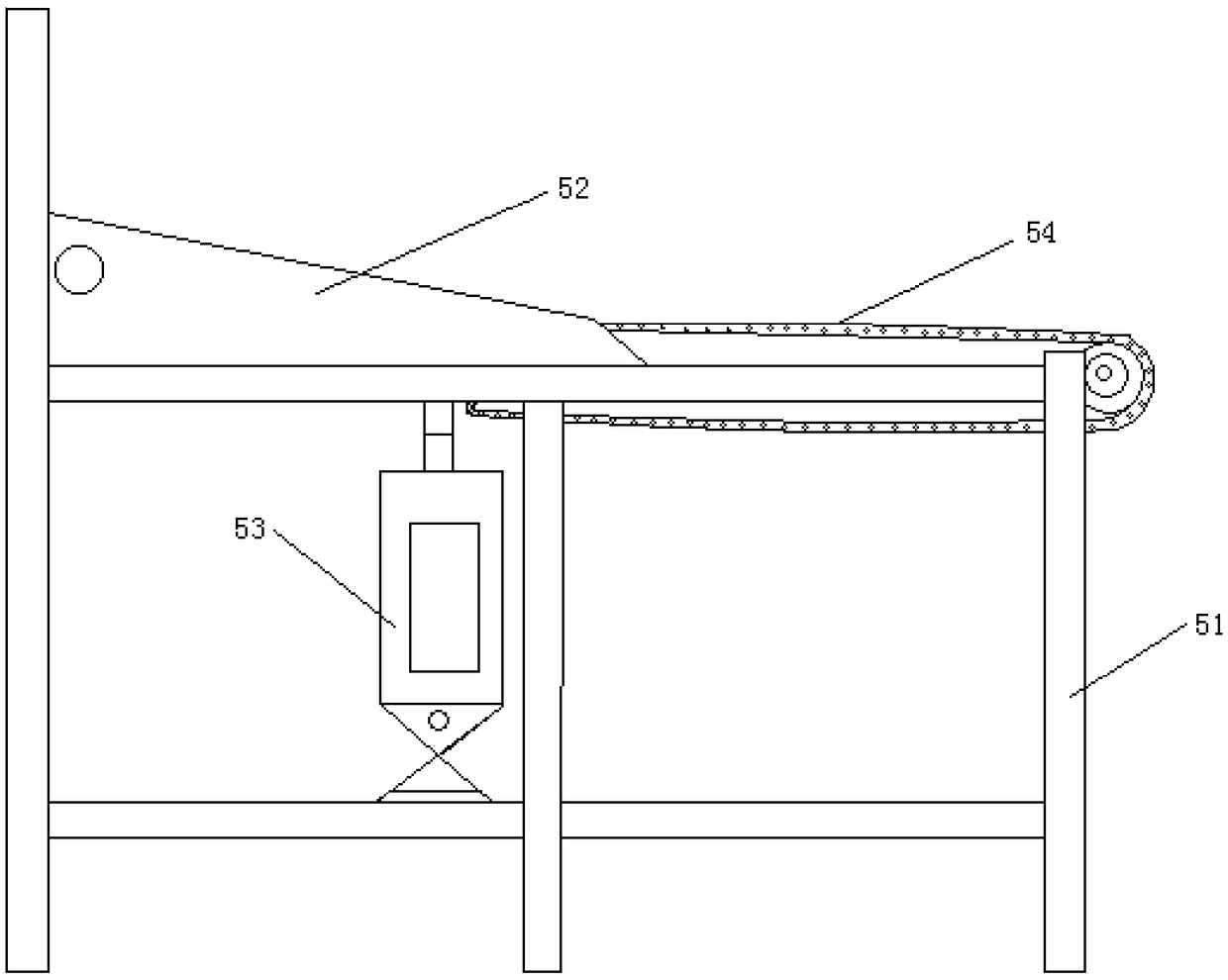

Multifunctional lifting rotary worktable

InactiveCN106584384AEasy to adjust heightEasy to adjust the angleWork benchesRotation functionMachining

The invention provides a multifunctional lifting rotary worktable. The multifunctional lifting rotary worktable comprises an operating table and a rotary lifting table, wherein the four corners of the operating table are each fixedly connected with a supporting leg; the rotary lifting table is arranged in the middle of the operating table in a penetrating mode; and a shelf is fixedly connected under the rotary lifting table through the four supporting legs. The multifunctional lifting rotary worktable provides the lifting and rotation functions, the machining height and angle of workpieces can be conveniently adjusted, the requirement for machining inclination angles of some special workpieces can be also met, and the multifunctional lifting rotary worktable is suitable for machining most workpieces.

Owner:天津俊新源科技有限公司

Garlic straw-nanocopper composite blue alga treatment agent and preparation method thereof

InactiveCN105858777AGood flocculationGood flocculation effectBiocideOther chemical processesWater qualityAllium sativum

The invention discloses a garlic straw-nanocopper composite blue alga treatment agent. The blue alga treatment agent is prepared from, by weight, 40-60 parts of diatomite, 5-10 parts of plant ash, 5-10 parts of garlic straws, 3-5 parts of nanocopper, 0.2-0.4 parts of acrylamide, 3-5 parts of sodium gluconate, 0.3-0.5 parts of polyethyleneimine, 0.03-0.05 parts of ammonium persulfate, 1-2 parts of alum, 0.5-1 part of hydroxyethylurea, and 10-15 parts of a composite assistant. The blue alga treatment agent has the advantages of good adsorption activity and flocculation performance, very good flocculation effect on blue algae, fast blue alga removal rate, low cost, no secondary pollution, high cyanotoxin adsorption and removal efficiency, good removal effect on various organic and inorganic pollution substances in water, bacterium killing and alga inhibiting efficacy, effective improvement of the quality of water, lasting effectiveness, and suitableness for treatment of complex water environment.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

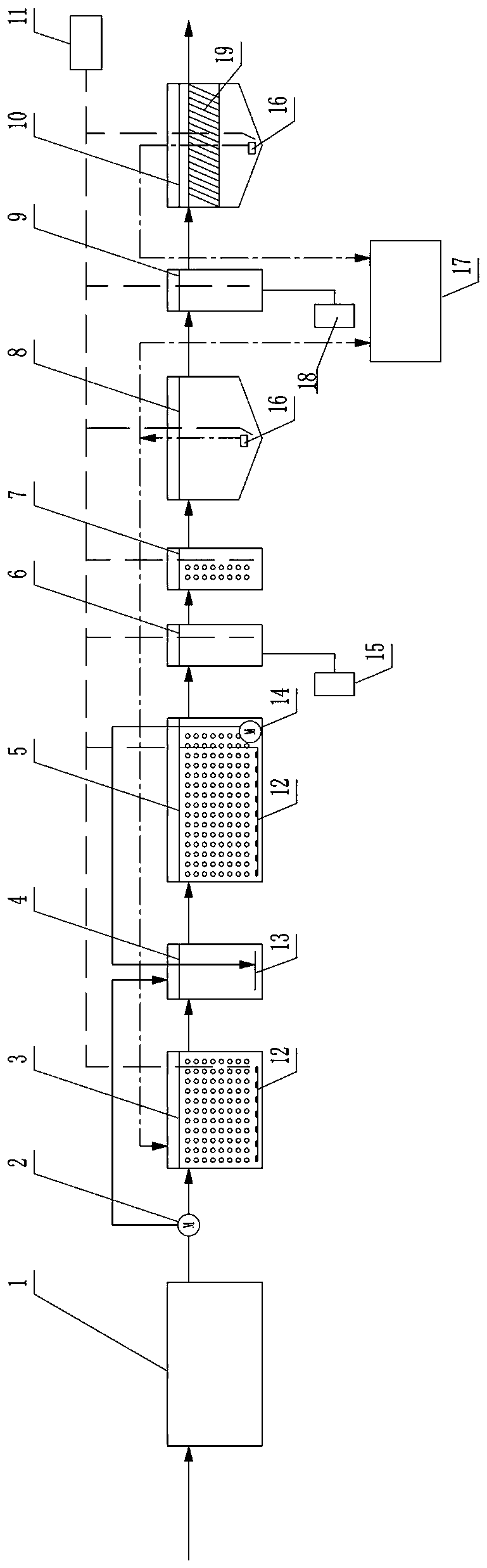

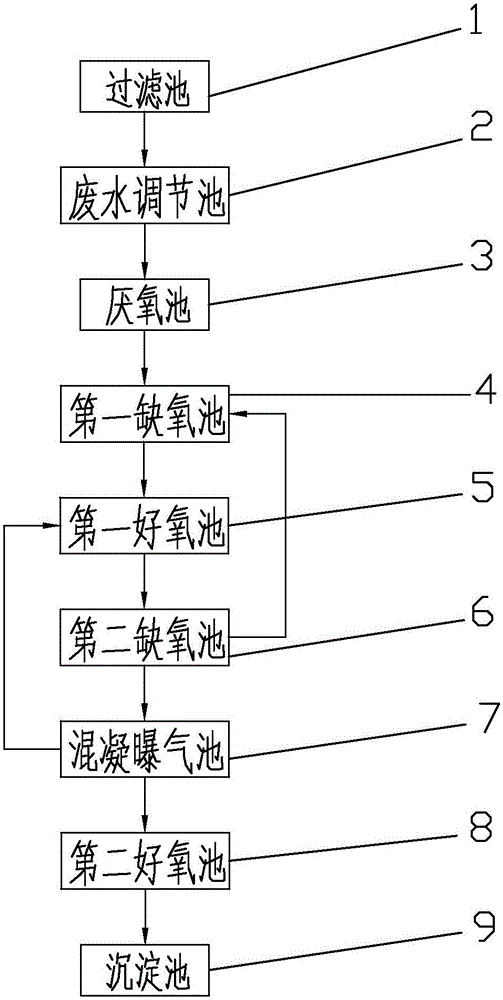

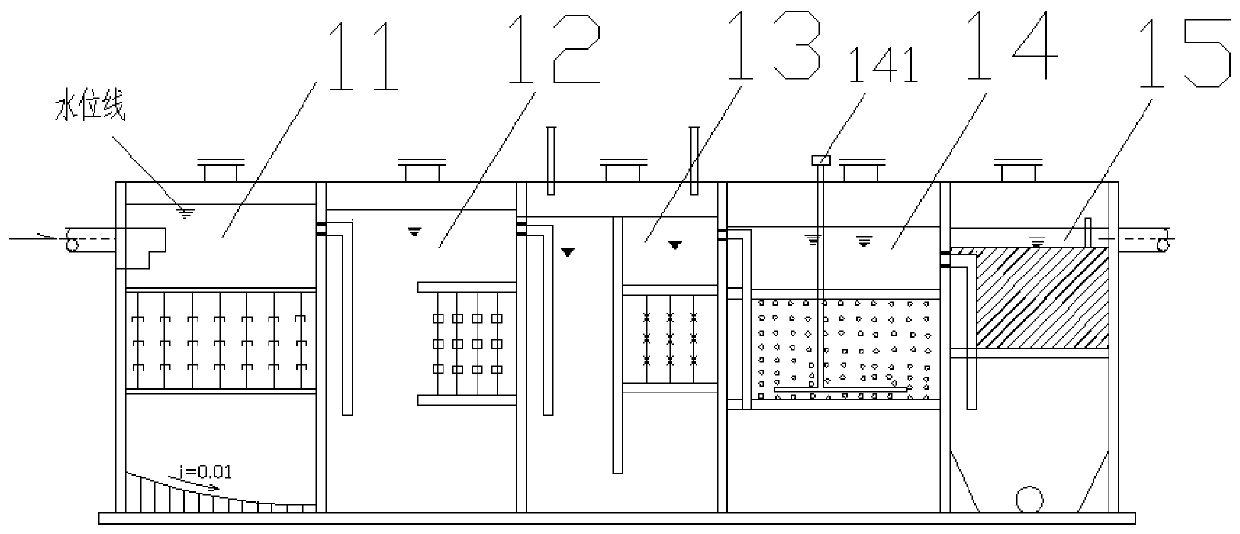

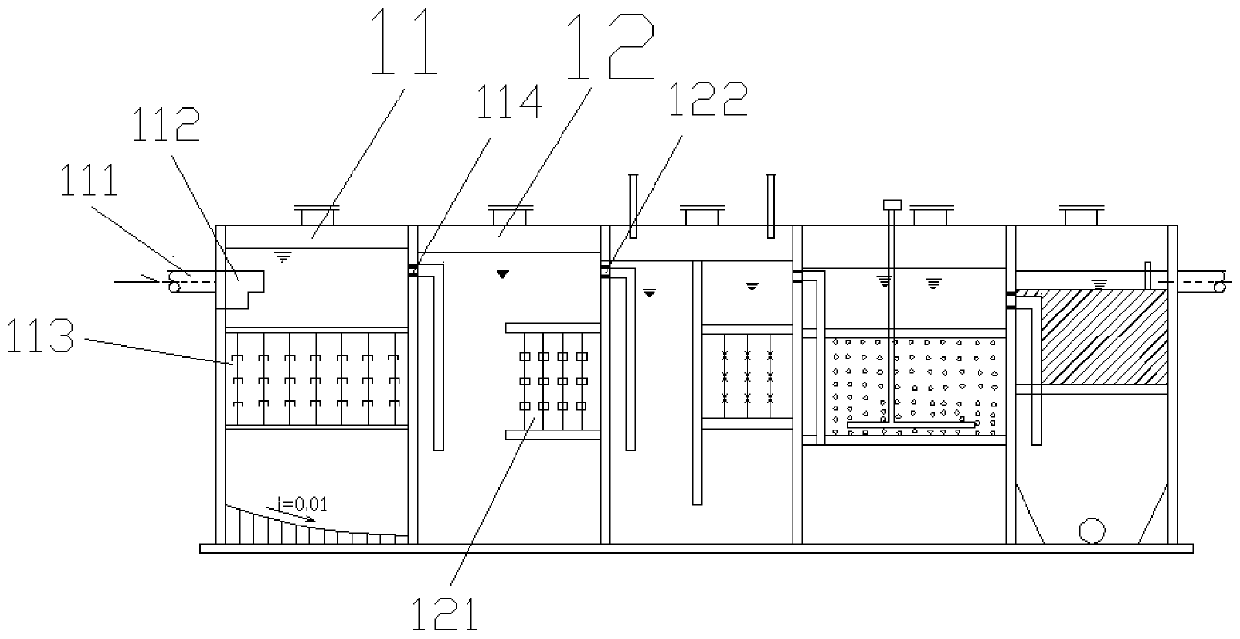

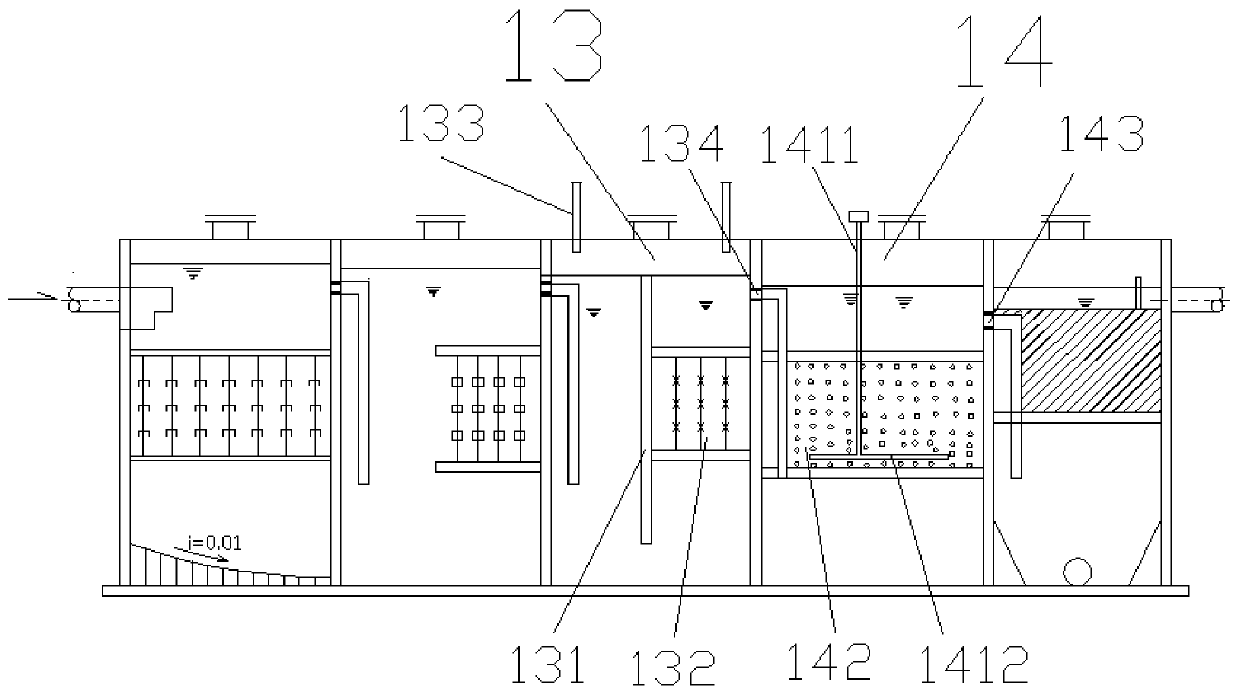

Integrated small and medium multi-point water inflowing deep nitrogen and phosphorus removal sewage processing system and processing method

InactiveCN109626746ALow investment costSmall footprintTreatment using aerobic processesWater treatment compoundsChemistryHigh concentration

The invention discloses an integrated small and medium multi-point water inflowing deep nitrogen and phosphorus removal sewage processing system and a processing method. The system and method are mainly used for processing high-concentration town sanitary sewage and high-concentration industrial waste water, especially COD, sanitary sewage with high ammonia nitrogen content or industrial waste water. The processing system comprises a grating adjusting pond, an aeration tank, a first anoxic pond, a first aerobic pond, a second anoxic pond, a second aerobic pond, a precipitating pond, a flocculation reaction pond and a flocculation precipitating pond which are successively communicated. The multi-point water inflowing mode is adopted, water resources are reasonably utilized, and the system has the advantages of being low in cost, efficient, capable of resisting loading and impacting, stable in quality of discharged water, convenient to operate and manage, and beneficial for integrated construction and saving of occupied area.

Owner:中原环保郑州设备工程科技有限公司

Stock-cutter

InactiveCN101396746ASimple structureLow costShearing machinesShearing machine accessoriesHydraulic cylinderThin slab

The invention relates to a stock cutter which has simple structure and low cost. The stock cutter is suitable for cutting and processing a medium and thin slab and has higher market popularizing rate. The stock cutter comprises a stander and is characterized in that a hydraulic cylinder is arranged on the stander, a piston rod of the hydraulic cylinder is connected with a slipper block that is embedded on a guide way which is arranged on the stander, an upper blade is arranged at the lower end of the slipper block, a lower blade is arranged on the stander corresponding to the cutting direction of the upper blade and the slipper block is provided with a spring compressing mechanism at the lateral part of the upper blade.

Owner:肖荣

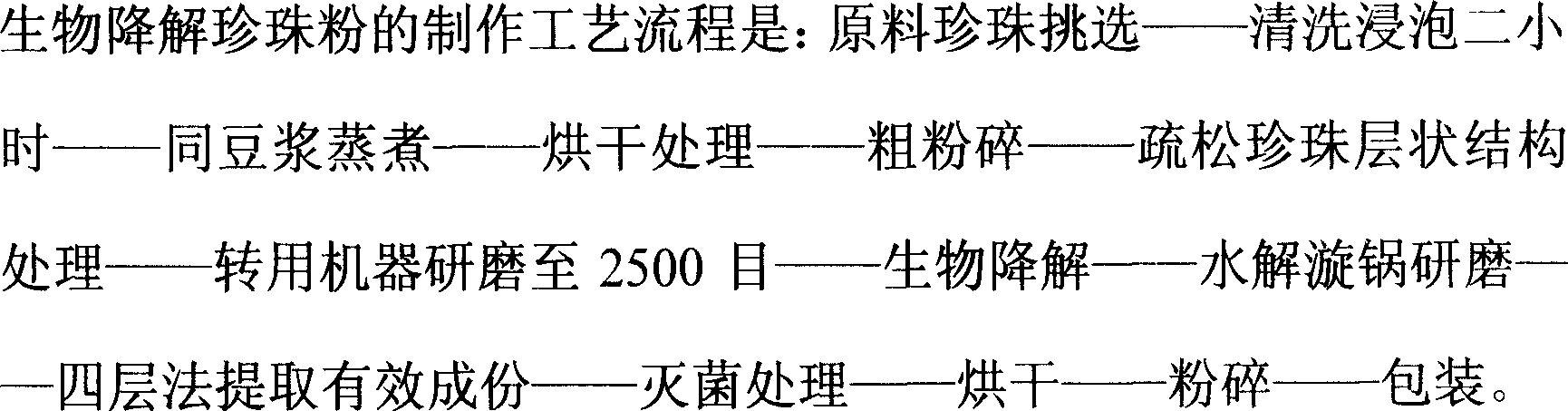

Biological degradable pearl powder, and preparation technique

InactiveCN1872089AFully absorbedWide range of natural ingredientsPowder deliveryMolluscs material medical ingredientsSolubilityAmino acid

A biodegradable pearl powder is prepared from pearl through screening, washing, immersing, boiling in soybean milk, baking, crushing, loosening the laminar structure, mechanical grinding by 2500 meshes, biodegradating, hydrolytic cyclone grinding, 4-layer extracting, sterilizing, baking, pulverizing and packing. It has high water solubility (99.92%) and high contents of Ca and amino acids.

Owner:傅华朵

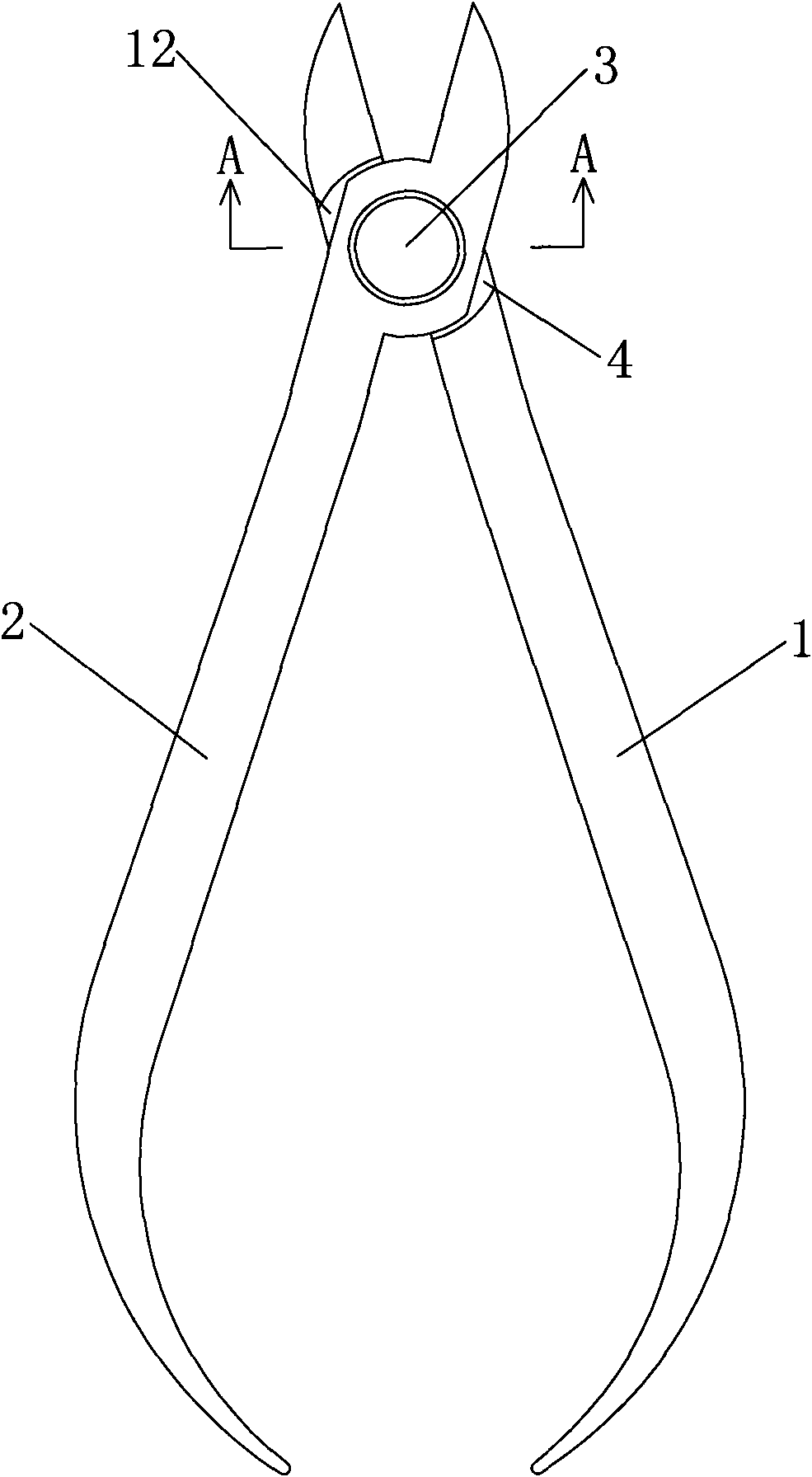

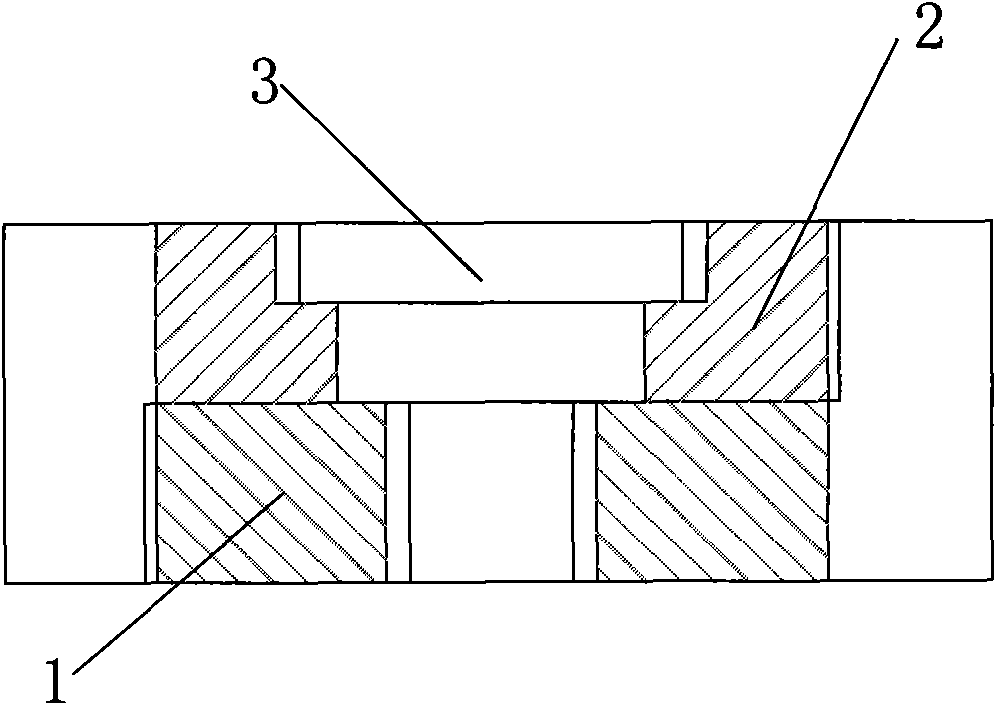

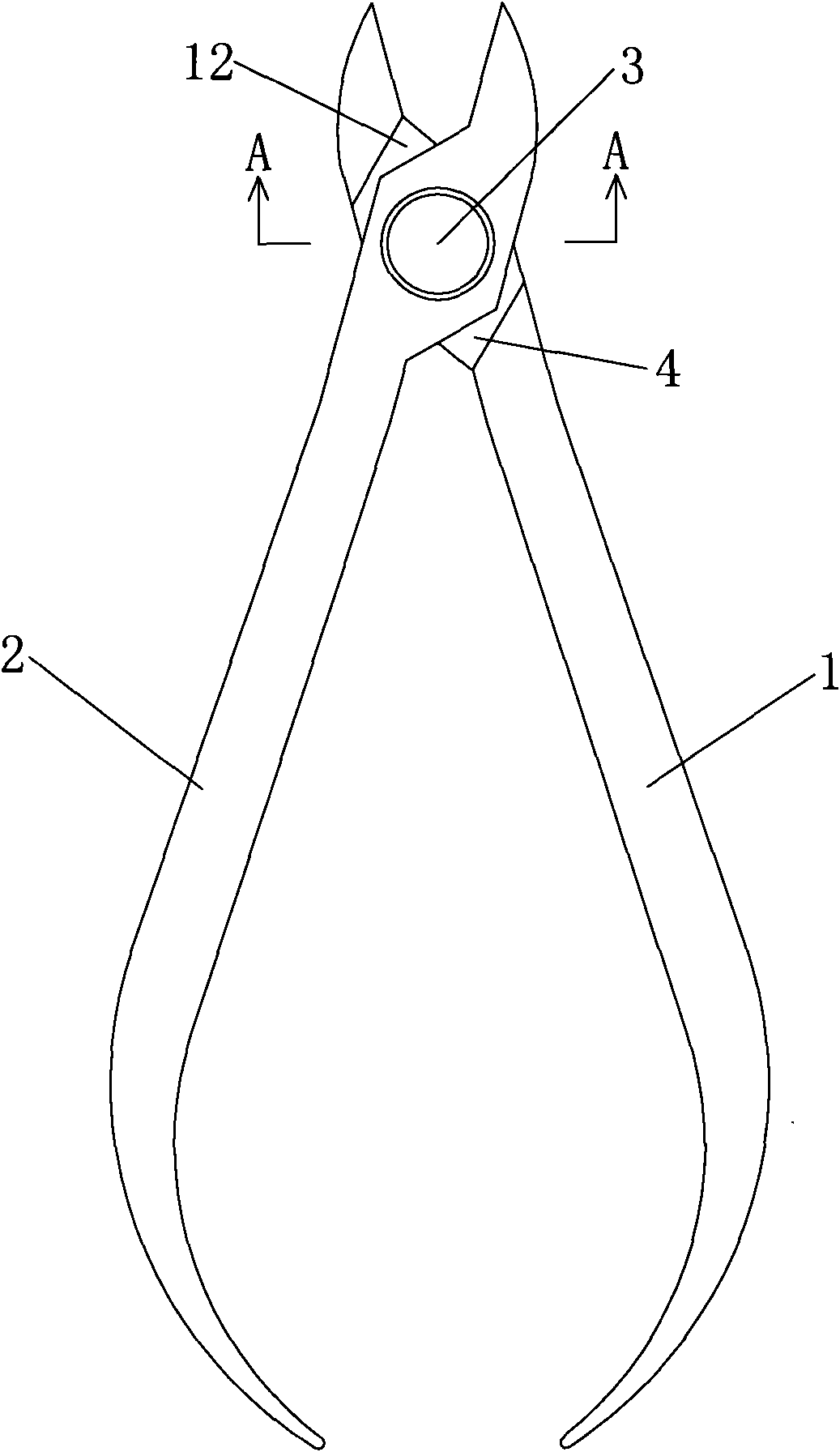

Strontium-running fold strontium pliers and processing method

InactiveCN101890681AReduce exposureAchieve the effect of strontium strontium strontium pliersPliersStrontiumEngineering

The invention discloses strontium-running fold strontium pliers and a processing method. The pliers comprise a left plier body and a right plier body, wherein pin joint grooves are respectively arranged on opposite inner sides of the right and left plier bodies; the right plier body and the left plier body are jogged through the pin joint grooves; a second pin joint groove in the position corresponding to the position of the pin joint groove on the inner side of the left plier body is arranged on the outer side of the left plier body and is provided with a cover plate; the upper and lower ends of the cover plate along the length direction of the plier bodies are fixedly welded with the joint surface of the right plier body; axle holes are correspondingly arranged on the cover plate, the left plier body and the right plier body; and pivots for folding and unfolding the plier bodies are assembled in the axle holes. The pliers can be designed with round fold strontium structure, thus reducing the fold strontium surface exposed when the plier bodies are unfolded to the greatest extent, ensuring the structure to be more compact and beautiful, solving the defect that the traditional strontium-running square fold strontium pliers processing method can not be used for processing the compact strontium-running round fold strontium pliers in the past, filling in the gap in production of the strontium-running round fold strontium pliers and beginning a new era.

Owner:王光良

Modified zeolite-nanocarbon cyanobacteria treatment agent and preparing method thereof

InactiveCN105776403AGood adsorption activity and flocculation performanceGood flocculationSpecific water treatment objectivesWater/sewage treatment by flocculation/precipitationMaleic anhydrideAmmonium sulfate

The invention discloses a modified zeolite-nanocarbon cyanobacteria treatment agent. The modified zeolite-nanocarbon cyanobacteria treatment agent is prepared from, by weight, 30-40 parts of zeolite, 10-20 parts of kieselguhr, 3-5 parts of nanocarbon, 0.1-0.2 part of maleic anhydride, 1-2 parts of ethyl orthosilicate, 3-5 parts of kapok fibers, 0.2-0.4 part of acrylamide, 0.3-0.5 part of hydroxyethyl cellulose, 0.03-0.05 part of ammonium persulfate and 10-15 parts of a composite assistant. The cyanobacteria treatment agent has good adsorption activity and flocculating performance, has very good flocculation on cyanobacteria, is high in cyanobacteria removing speed, low in cost and free of secondary pollution, also has a good adsorption and removing effect on cyanobacteria toxins and various organic and inorganic pollutants in water, especially has the decomposition and conversion effects on organic pollutants and toxins, and is capable of effectively improving the water quality and suitable for treatment in complex water environments.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Agent and method for reducing COD (chemical oxygen demand) of phenolic wastewater

InactiveCN102951753ALow priceReduce dosageWater contaminantsMultistage water/sewage treatmentTreated waterFenton's reagent

The invention relates to an agent and a method for reducing COD (chemical oxygen demand) of phenolic wastewater. The method comprises the following steps: (1) Fenton's reagent is added to wastewater; (2) potassium permanganate is added to the wastewater; and the addition of the Fenton's agent and the potassium permanganate is adjusted to reduce the COD value of the wastewater until the treated water with the target content of COD value is finally obtained. The Fenton's agent adopted in the invention is lower in price, and the dosage of the Fenton's agent is increased, so that the dosage of the potassium permanganate is reduced, and the removal rate of COD in the wastewater is improved by more than 85%.

Owner:TIANJIN BINHUAN CHEM ENG TECH RES INST

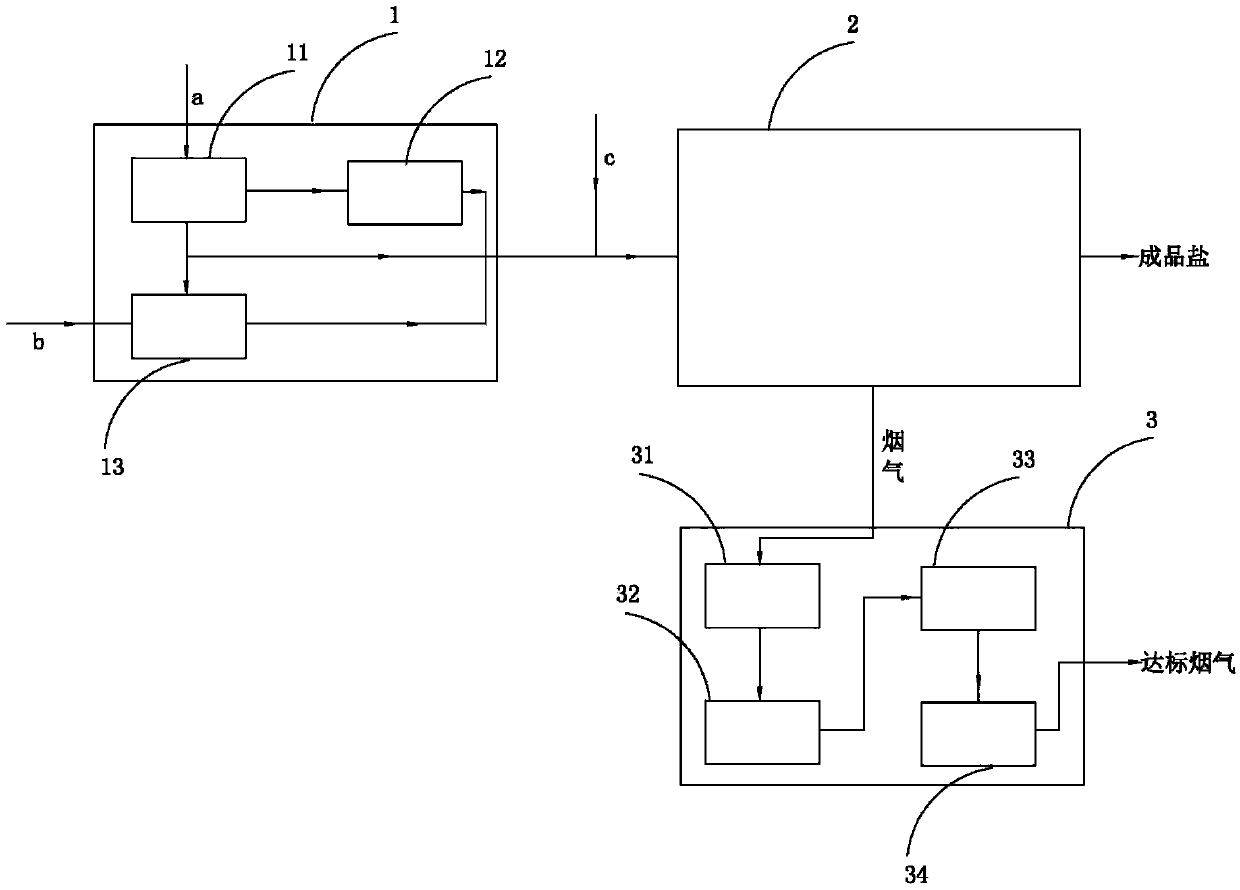

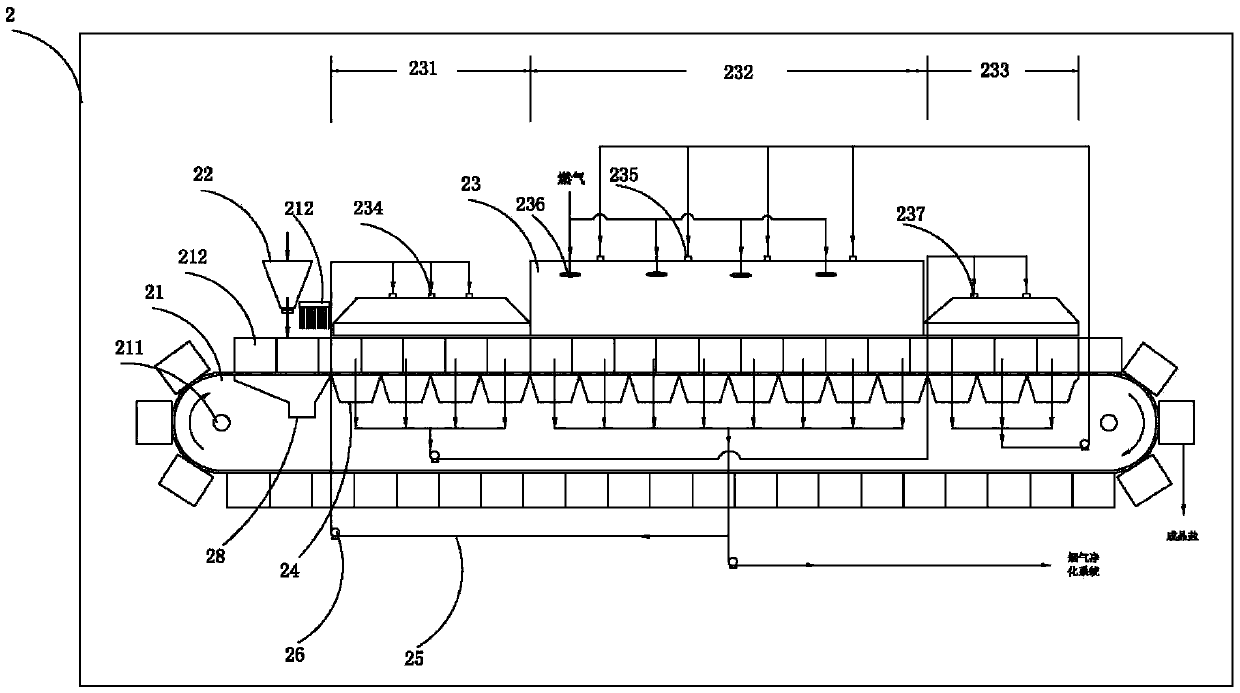

Method and system for treating chemical abraum salt containing organic matter through self-propagating pyrolysis method

PendingCN109519928AStable and controllable pyrolysis temperatureUniform temperature distributionIncinerator apparatusPelletizingPre treatment

The invention relates to the field of solid waste treatment, in particular to a method and system for treating chemical abraum salt containing organic matter through a self-propagating pyrolysis method. The method comprises the following steps that pretreatment is carried out in a pelletizing or washing or treating-free mode according to particle size distribution of chemical abraum salt; 2, materials are distributed; 3, pyrolysis treatment is carried out, and particularly organic matter in a material layer is pyrolyzed into a gas compound through a self-propagating pyrolysis method; 4, the pyrolyzed material layer is cooled to obtain finished salt; and 5, flue gas treatment is carried out, and particularly flue gas containing the gas compound is introduced into a flue gas purifying treatment system for purifying treatment. The finished salt obtained from the abraum salt treated through the method has no melting and agglomeration phenomenon, the TOC content is as low as 10.00ppm, and the requirements of ionic membrane caustic soda can be met. The invention further provides a treating system adopting the method, a self-propagating pyrolysis device in the system can sufficiently utilize heat, can stably control pyrolysis temperature and is suitable for treatment various kinds of abraum salt.

Owner:CHONGQING ANGRUIYUE SCI & TECH

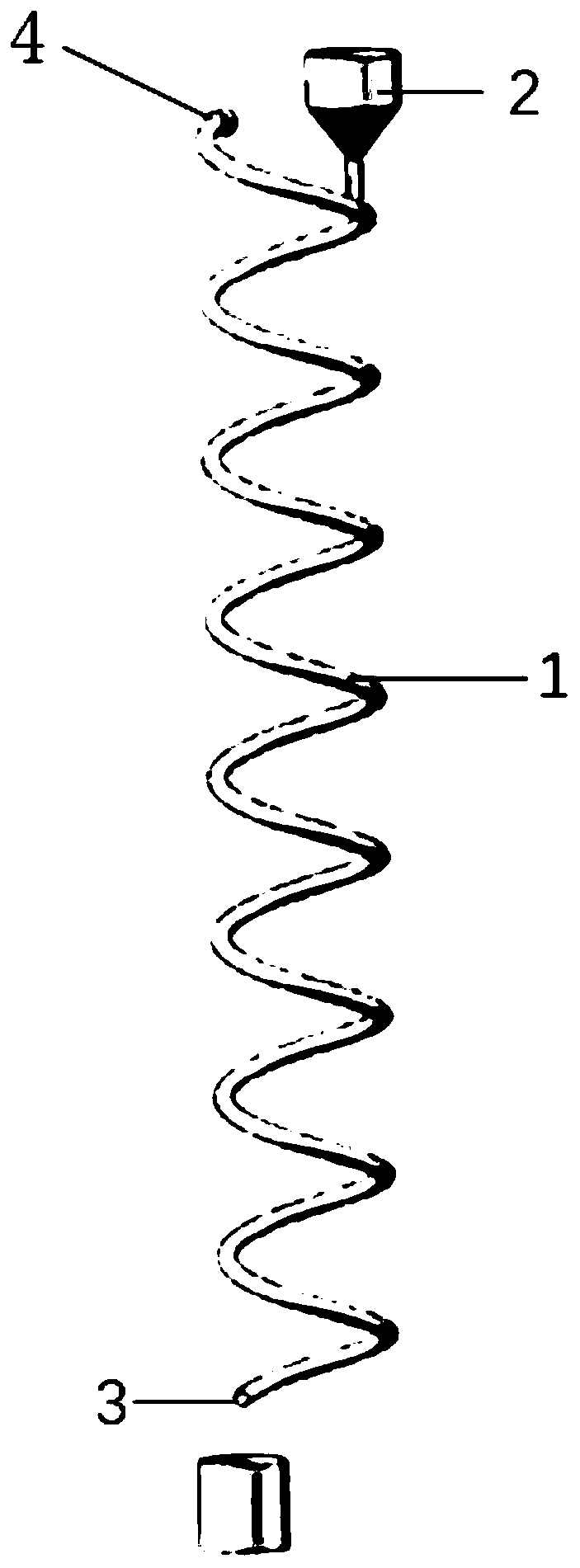

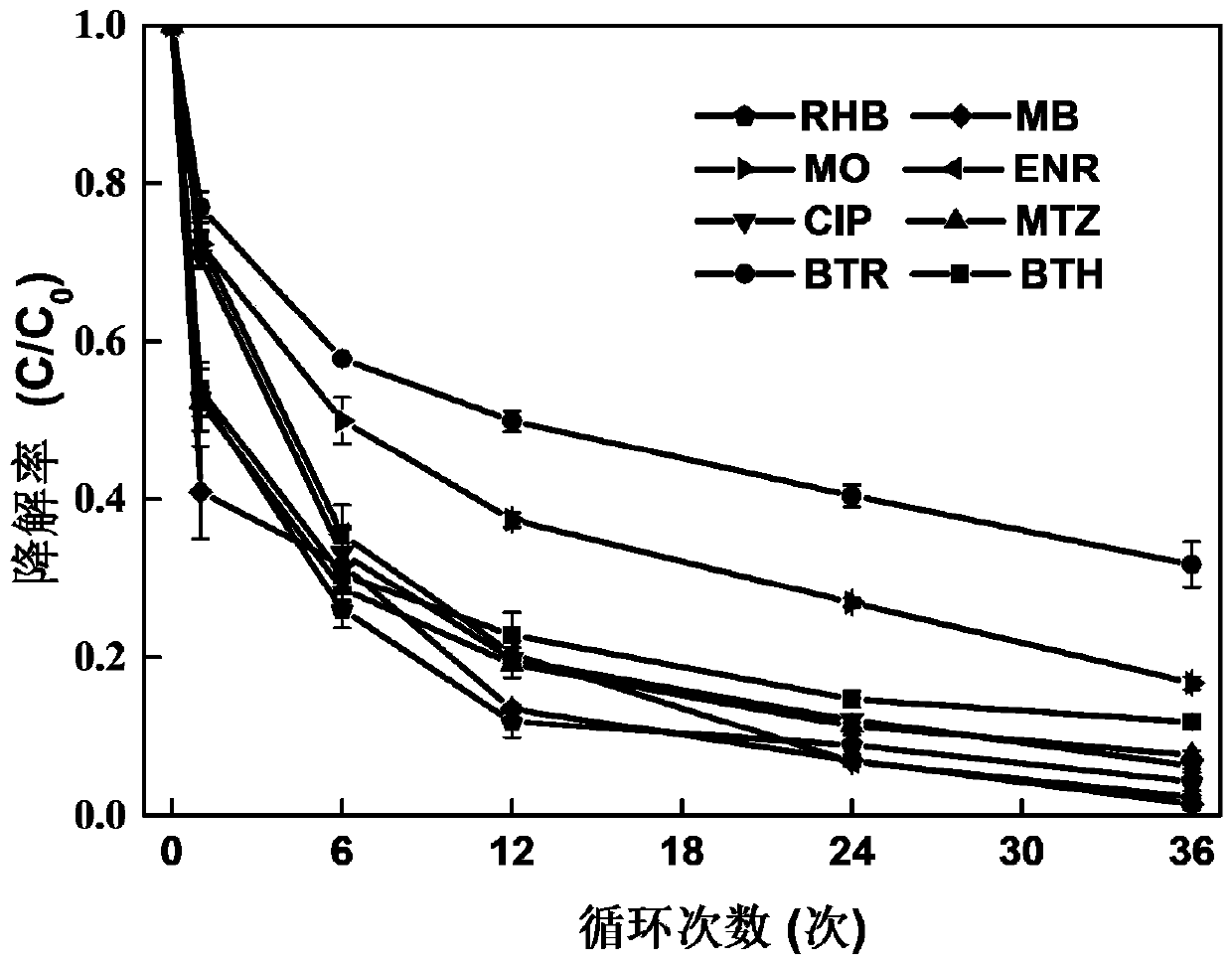

Novel water vortex-piezoelectric self-driven sewage treatment microreactor and treatment method thereof

ActiveCN111196623ASimple structureEasy to operateWater contaminantsDispersed particle separationMicroreactorExternal energy

The invention discloses a novel water vortex-piezoelectric self-driven sewage treatment microreactor and a treatment method thereof. The reactor comprises a spiral coil and a water inlet liquid storage funnel, the spiral coil is a spiral hollow pipe and comprises a water inlet and a water outlet, and the water inlet liquid storage funnel is arranged at the water inlet or near the water inlet. Thesewage treatment method comprises the following steps of: S1, preparing a pollutant solution, weighing a piezoelectric catalytic material, and uniformly mixing the piezoelectric catalytic material with the pollutant solution, S2, pouring the mixed solution into the spiral coil from the water inlet liquid storage funnel, S3, receiving all the mixed liqui at the water outlet, and repeating the stepS2 for multiple times. The reactor is simple in structure, convenient to operate, low in cost and low in maintenance cost and subsequent management cost. External energy supply is not needed, the two-dimensional piezoelectric catalytic reaction is driven only by mechanical force generated by flowing of liquid in the spiral coil to degrade pollutants, and weak water flow machinery which can be seeneverywhere in the nature is fully applied to the field of environmental governance, so that waste of the water flow machinery is avoided.

Owner:JINAN UNIVERSITY

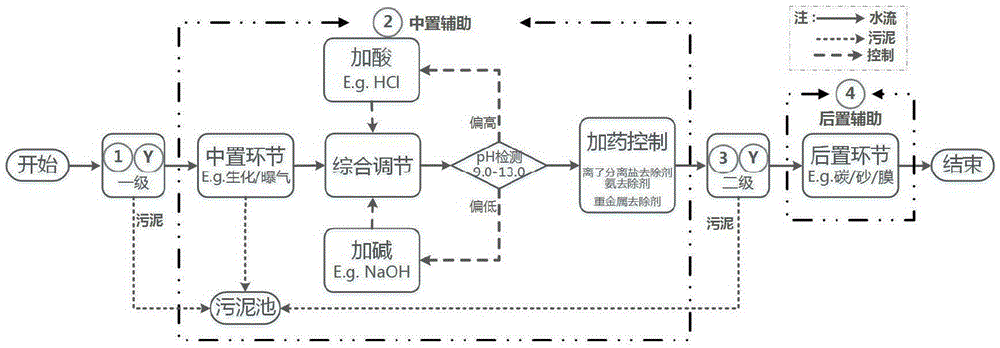

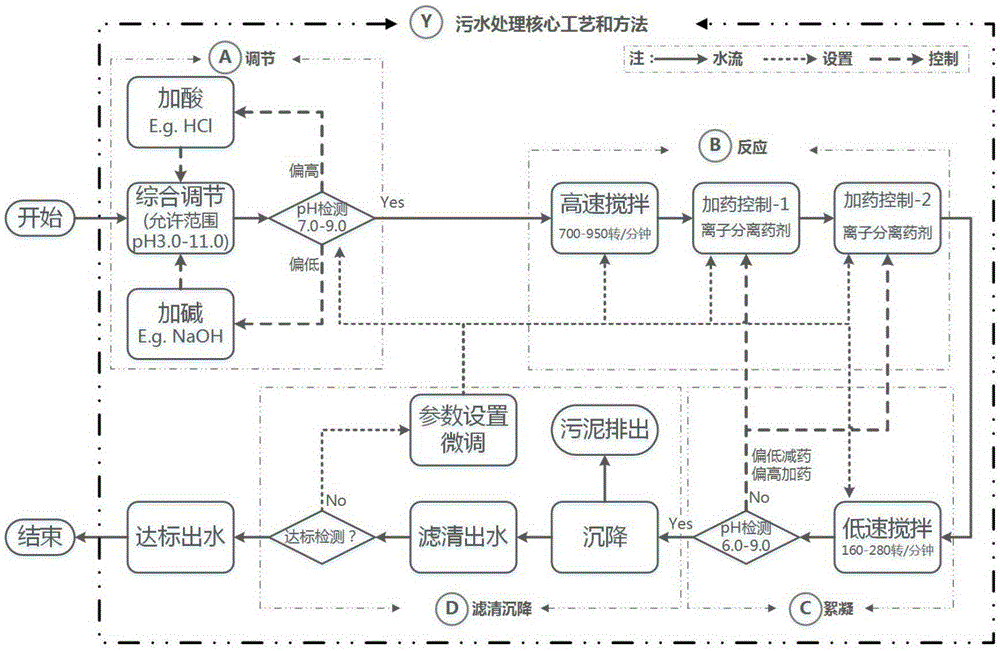

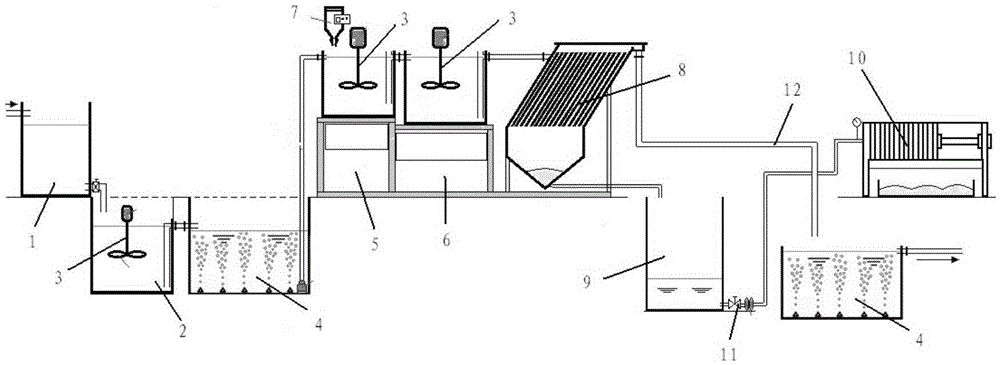

Coal chemical industry wastewater treatment fundamental technology

ActiveCN105293822AEasy to transformGuaranteed stabilityWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSludgeEmission standard

The invention discloses a coal chemical industry wastewater treatment fundamental technology. The coal chemical industry wastewater treatment fundamental technology comprises the steps of a first-grade wastewater treatment core process, middle assisting, a second-grade wastewater treatment core process and post assisting, controlling is conducted on the pH value based on all processing point water bodies in an overall process, and all parameters are set according to requirements of water inflow and outflow indexes. According to the coal chemical industry wastewater treatment fundamental technology, the advantages of ion separation medicament in practical application for an applicant can be fully guaranteed, and the representative advantages that quantity of reagent (10-300 g per ton of water) is less, dilution is not needed for direct solid state dosage, buffering is not needed for wastewater real-time treatment (the reaction speed ranges from 3 min to 15 min), water content removal rate reaches up to over 80 percent, all national wastewater treatment emission standards can be accorded to and met, and treated water is colorless, odorless and free of secondary harmful chemicals, and sludge produced through flocculation is low in moisture content (smaller than 35 percent), free of odor and adhesion and the like.

Owner:周朝晖

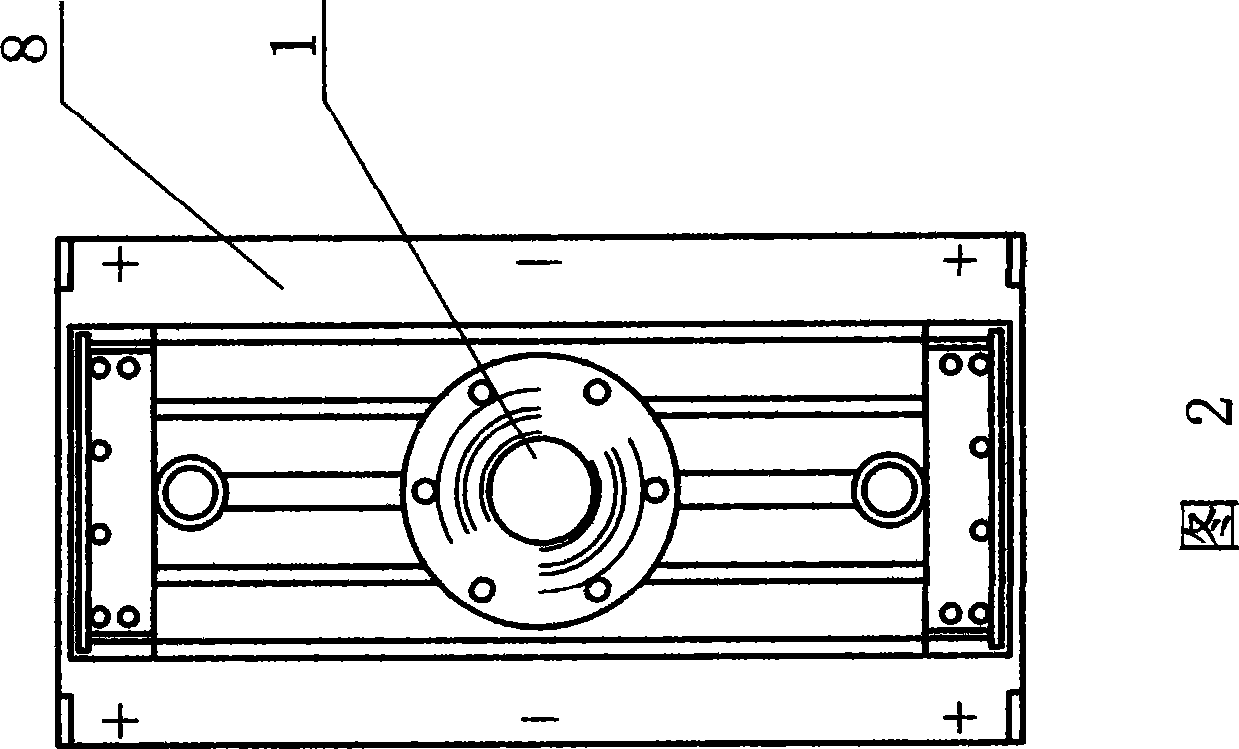

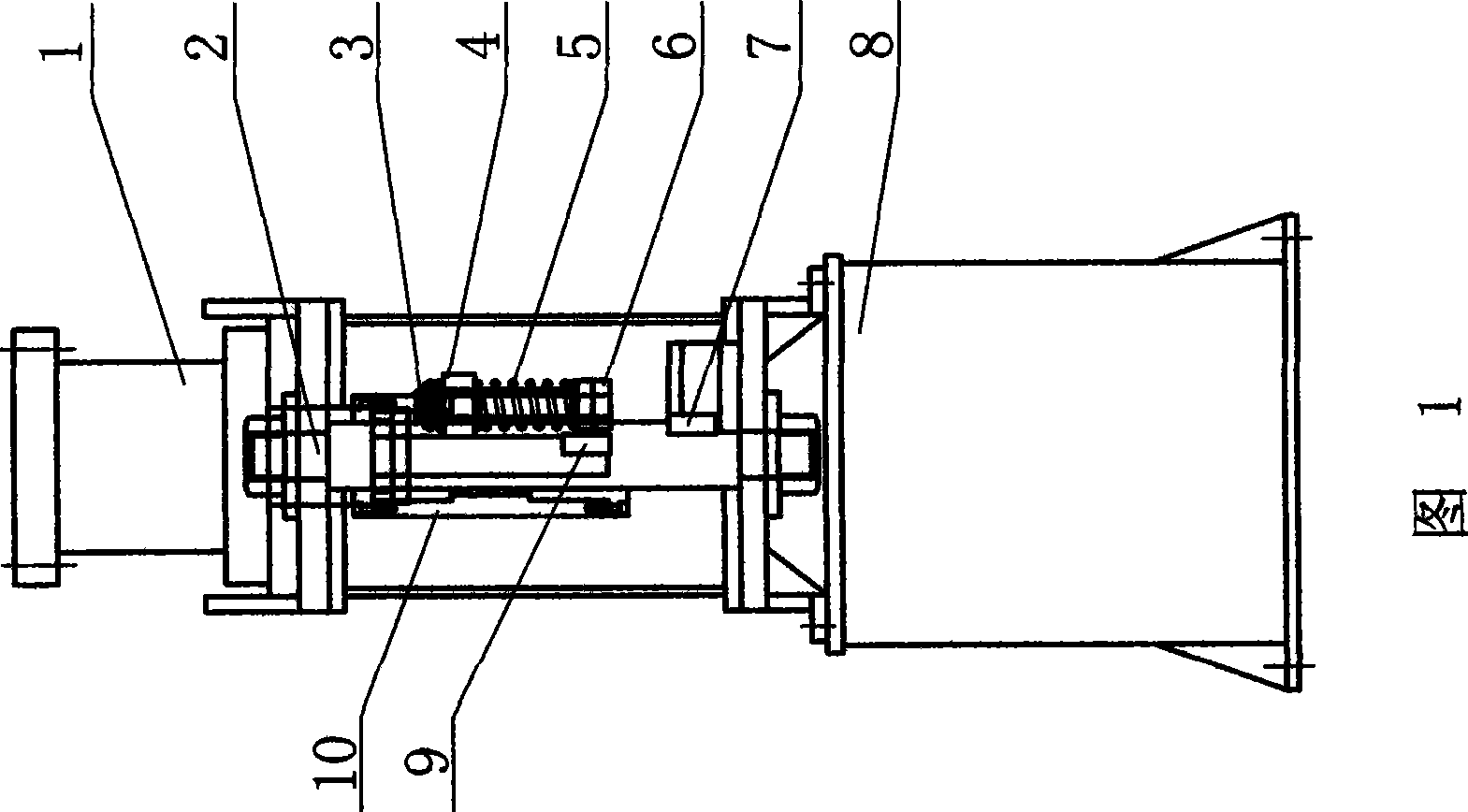

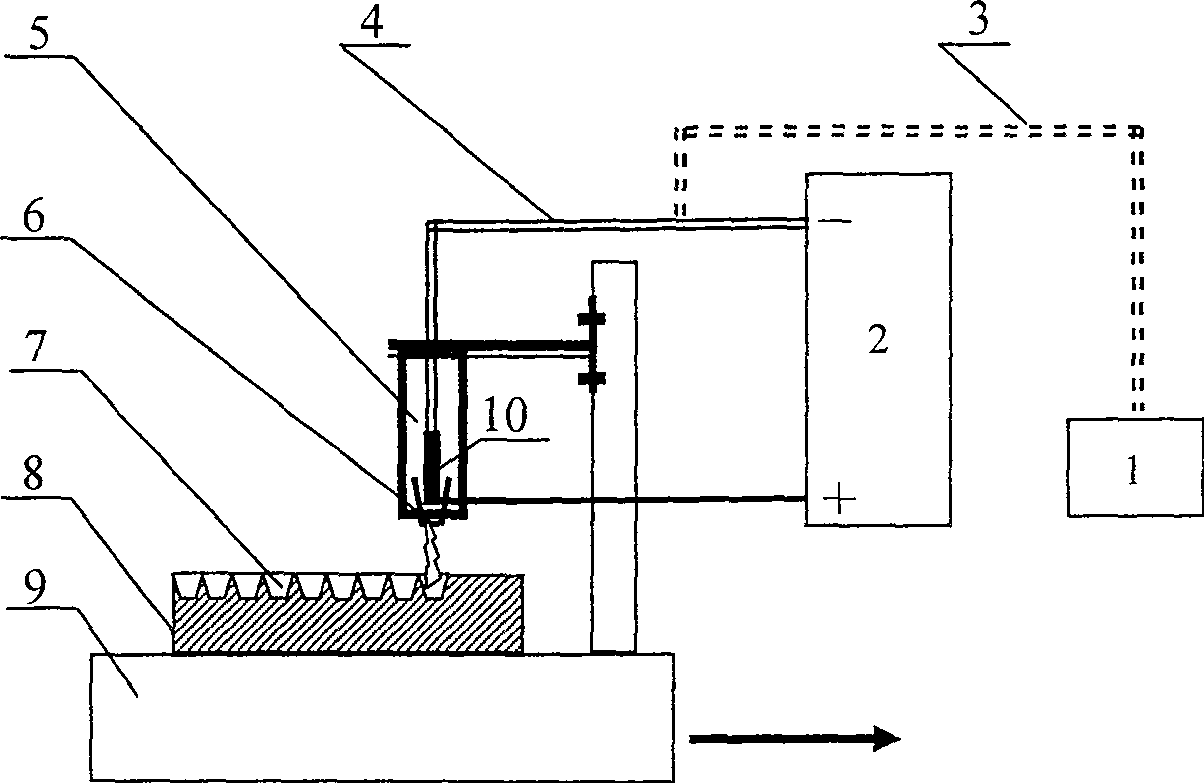

Method for utilizing micro-explosion of electrode striking arc to process engineering ceramics and device thereof

The invention relates to a method for utilizing the micro-explosion of an electrode striking arc to process engineering ceramics and a device thereof, and belongs to the technical filed of non-traditional machining. The method is that a micro-explosion bombardment wave generated by the electrode striking arc is used for being targeted at the surface of a ceramic workpiece; the surface of the ceramic workpiece is eroded to form a circular concave pit with 1-2 mm diameter and 0.01-1 mm depth, so as to realize the removal and the processing of the surface of the workpieces. The device comprises an air-compressor, a special impulse power supply, a numerical control three dimensions working table and a bombardment wave launcher, wherein, the compressed air output by the air-compressor is led into the inner cavity of the bombardment wave launcher through the cathode power supply duct of the special impulse power supply; the cathode of the special impulse power supply is connected with a core pole of the bombardment wave launcher; the anode of the special impulse power supply is connected with the nozzle of the bombardment wave launcher; and the nozzle of the bombardment wave launcher opens towards the table-board of the numerical control three dimensions working table. The invention has remarkable advantages of simple structure, low price, easy control on parameters, and capability of realizing the processing of a heteromorphic curved surface.

Owner:田欣利 +1

Method for preparing coarse-grain iron manganese silicon based shape memory alloy

The invention discloses a method for preparing coarse-grain iron manganese silicon based shape memory alloy, and belongs to the field of shape memory alloy. The average size of austenite grains of theiron manganese silicon based shape memory alloy prepared through the method is larger than or equal to 1 mm. The method includes the specific steps that (1) the iron manganese silicon based shape memory alloy is treated at the temperature of 1260-1300 DEG C for 5 min to 1 h; (2) the following treatment process is repeated at least once: the iron manganese silicon based shape memory alloy is cooled to 1100-1200 DEG C with the speed of 0.1-10 DEG C / min and treated for 5-30 min, and then the iron manganese silicon based shape memory alloy is heated to 1260-1300 DEG C with the speed of 0.1-10 DEGC / min and treated for 5 min to 1 h; and (3) finally, the iron manganese silicon based shape memory alloy is cooled to 1150-1200 DEG C with the speed of 0.1-5 DEG C / min, and then subjected to water cooling to the room temperature.

Owner:SICHUAN UNIV

Treatment method applied to chemical industrial wastewater

InactiveCN106007207ASolve processing problemsReduce the content of harmful substancesWater treatment parameter controlTreatment using aerobic processesHazardous substanceTherapeutic effect

The invention discloses a treatment method applied to chemical industrial wastewater. The treatment method comprises the following treatment steps of (a) chemical industrial wastewater pretreatment, (b) biochemical treatment of chemical industrial wastewater and (c) physical treatment of chemical industrial wastewater. According to the treatment method, the chemical industrial wastewater is sequentially subjected to the chemical industrial wastewater pretreatment, the biochemical treatment of chemical industrial wastewater and the physical treatment of chemical industrial wastewater, and the chemical industrial wastewater reaching the discharge standard is obtained. The treatment method is especially suitable for treatment of organic chemical industrial wastewater having strong biological toxicity and poor biochemical properties and can deeply treat chemical industrial wastewater, the harmful matter content in the treated wastewater is reduced to the most degree, the lower treatment degree is avoided, and accordingly the problem that treated wastewater still cause large environmental pollution is solved. In addition, in the wastewater treatment process, all links can be performed in order, the treatment method is simple in structure, scientific, convenient, strong in pertinence, high in automation degree, low in actural application cost, advanced in technology and good in treatment effect, and the chemical industrial wastewater treatment problem is well solved.

Owner:衢州市协成化工有限公司

Blue alga treatment agent adopting licorice root residues as raw material, and preparation method thereof

InactiveCN105858831AGood flocculationHigh activityBiocideOther chemical processesWater qualityLicorice roots

The invention discloses a blue alga treatment agent adopting licorice root residues as a raw material. The blue alga treatment agent is prepared from, by weight, 5-10 parts of the licorice root residues, 3-5 parts of pine needle powder, 0.2-0.4 parts of sodium dodecyl sulfonate, 30-40 parts of diatomite, 20-30 parts of meerschaum, 3-5 parts of glutinous rice flour, 0.2-0.4 parts of acrylamide, 0.03-0.05 parts of ammonium persulfate, 0.5-1 part of an EVA emulsion and 10-15 parts of a composite assistant. The blue alga treatment agent has the advantages of good adsorption activity and flocculation performance, very good flocculation effect on blue algae, fast blue alga removal rate, low cost, no secondary pollution, high cyanotoxin adsorption and removal efficiency, good removal effect on various organic and inorganic pollution substances in water, bacterium killing and alga inhibiting efficacy, effective improvement of the quality of water, and suitableness for treatment of complex water environment.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

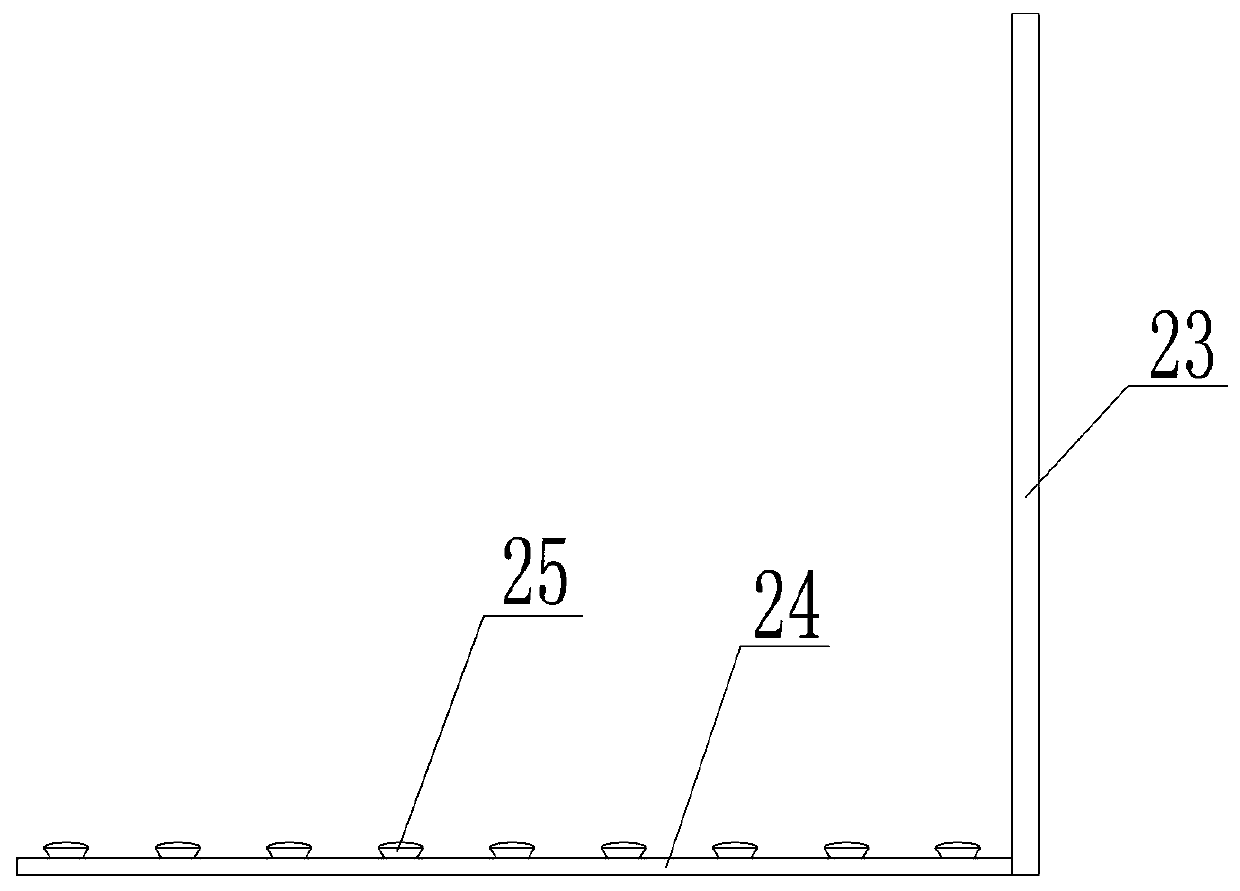

Papermaking sewage treatment method

PendingCN109553210AImprove processing efficiencyProcessing applicableSpecific water treatment objectivesTreatment involving filtrationSewage treatmentSewage discharge

The invention discloses a papermaking sewage treatment method, and belongs to sewage treatment devices. Equipment adopted by the method comprises a sewage treatment tank, a preliminary filtering device, a debris removing device, a fishing filtering device, an air jetting device and a sewage discharging device, wherein the preliminary filtering device is installed at the top of the sewage treatmenttank, the debris removing device and the fishing filtering device are vertically arranged beside the sewage treatment tank, the debris removing device is located beside the preliminary filtering device, the outer wall of the sewage treatment tank is provided with a sealing assembly matched with the debris removing device, the air jetting device is installed at the bottom end in the sewage treatment tank, and the sewage discharging device is installed at one end, far away from the debris removing device, of the sewage treatment tank. The papermaking sewage treatment method is simple in structure, improves the treatment efficiency of sewage, saves production cost and is suitable for treatment of papermaking sewage.

Owner:刘利娟

Medicine factory waste gas purification treatment device

InactiveCN107648941AProcessing applicableEffective dust removal and deodorizationGas treatmentDispersed particle filtrationPharmaceutical industryHazardous substance

The invention discloses a medicine factory waste gas purification treatment device which comprises a purification pipeline, wherein a particle pollutant filtering box is arranged in the middle of thepurification pipeline, the purification pipeline is divided into a photolysis pipeline body and an absorption pipeline body by the particle pollutant filtering box, ceramic corrugated packing is arranged in the absorption pipeline body, and a plurality of vertically-arranged high-powered ultraviolet lamp tubes and a plurality of horizontally-arranged nano photocatalytic nets are arranged in the photolysis pipeline body. The medicine factory waste gas purification treatment device disclosed by the invention has the advantages of novel design, simple structure, superfine multilevel treatment onwaste gas, ability in effectively dedusting, deodorizing and killing bacteria, good absorption and decomposition effects on hazardous substances in the waste gas and great suitability for waste gas treatment in pharmaceutical industry.

Owner:李景春

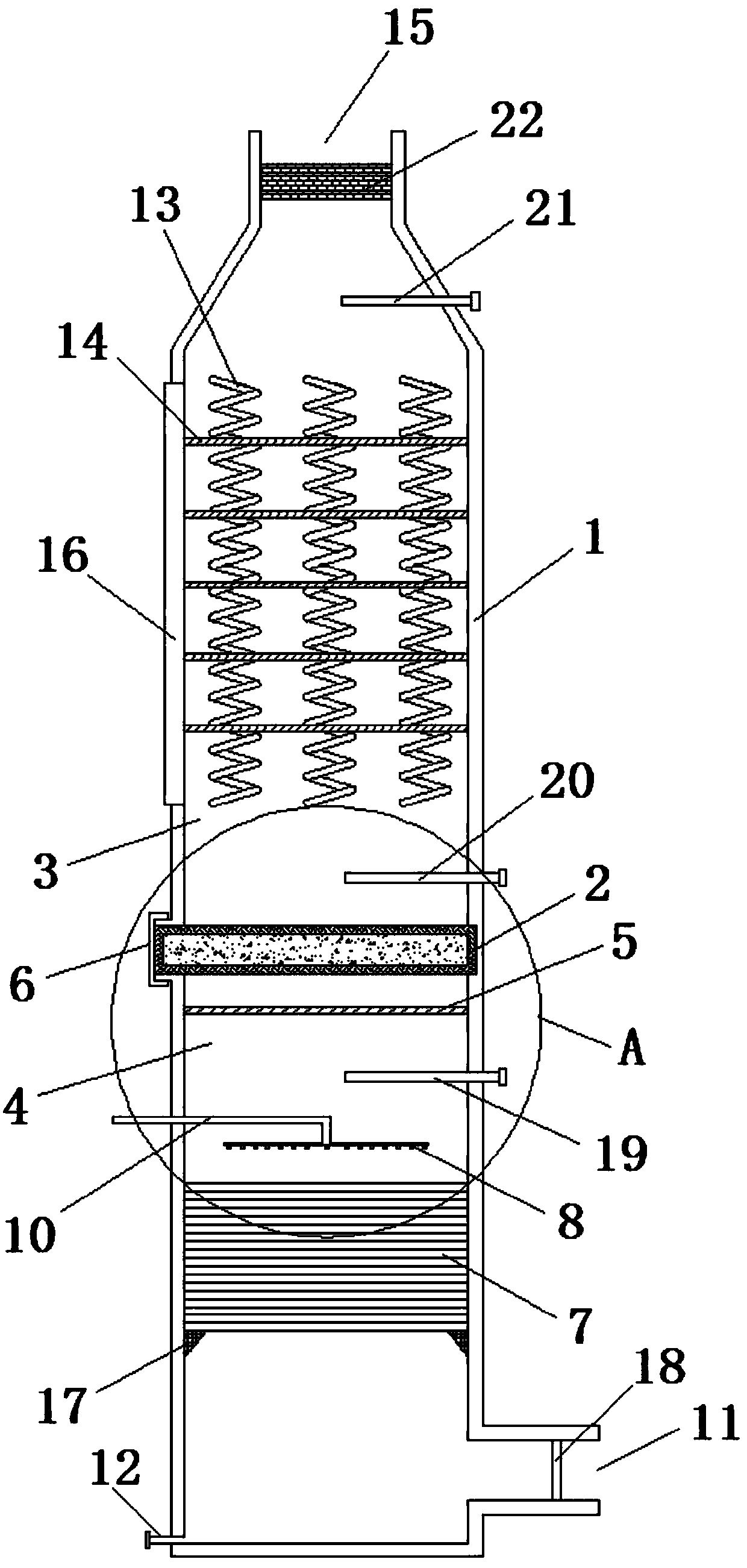

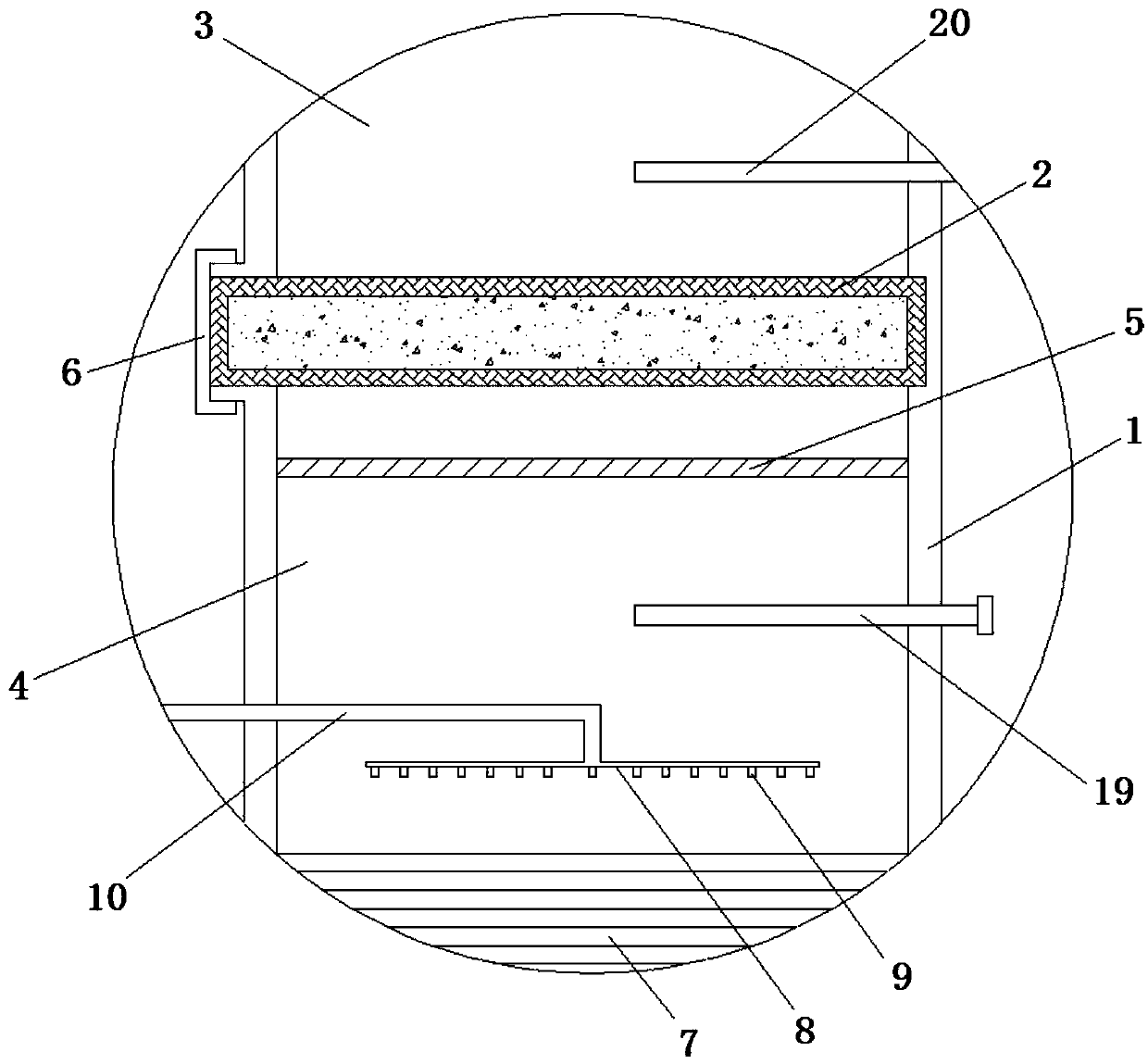

Rural distributed micro-power ecological sewage treatment device and sewage treatment system comprising same

PendingCN110078319APurify waterReduce energy consumptionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentPollutantAnaerobic reaction

The invention provides a rural distributed micro-power ecological sewage treatment device and a sewage treatment system comprising the same and relates to the technical field of sewage treatment. Therural distributed micro-power ecological sewage treatment device comprises a pre-sedimentation unit, an anaerobic reaction unit, a facultative reaction unit, an aerobic reaction unit and a sedimentation unit which are sequentially communicated; the aerobic reaction unit comprises an aerobic floating bed biological reaction tank, and an aeration device is arranged in the aerobic floating bed biological reaction tank. The rural distributed micro-power ecological sewage treatment device is formed by sequentially communicating the five unit modules and can well remove pollutants in domestic sewage. Meanwhile, through tests, the energy consumption of the rural distributed micro-power ecological sewage treatment device is 0.1*0.125 kW / m<3> every day, which is only about 25% that of a traditionalsewage tretament method adopting an A-O process, so that the rural distributed micro-power ecological sewage treatment device has the advantage of low energy consumption.

Owner:HUNAN AIRBLUER ENVIRONMENTAL PROTECTION TECH

Cordierite-polylactic acid fiber composite blue-green alga treating agent and preparing method thereof

InactiveCN105776402AGood flocculationHigh activityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium BentoniteSodium potassium tartrate tetrahydrate

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

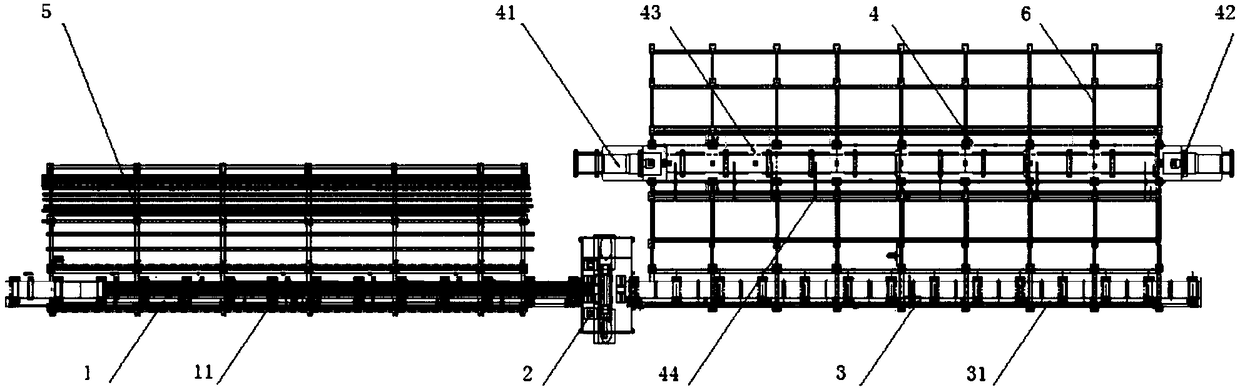

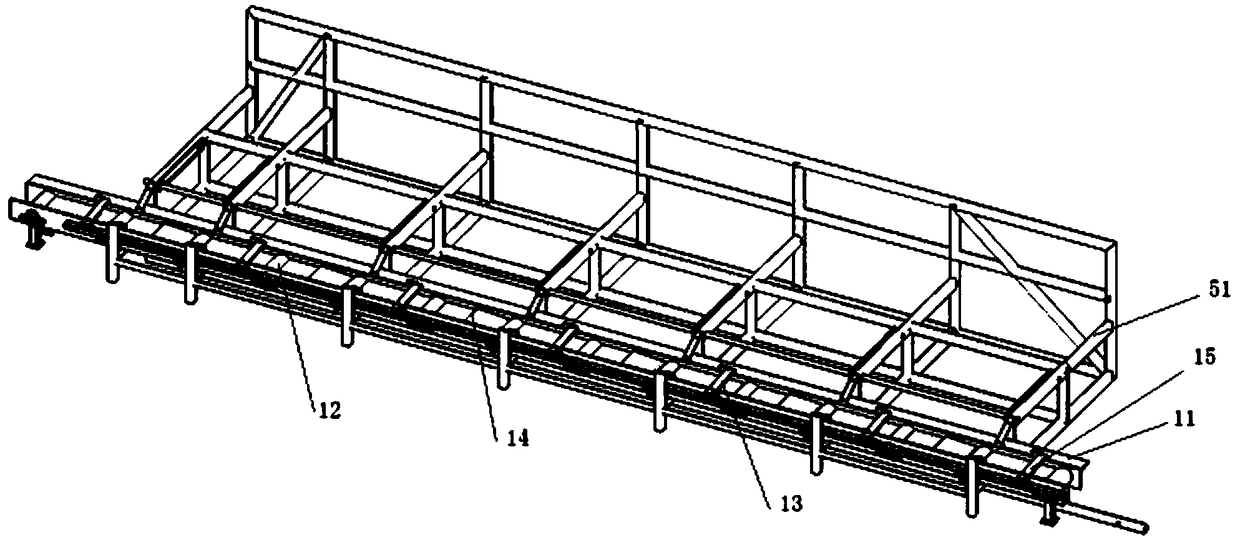

Reinforcing steel bar mantle fiber production line and processing process

PendingCN108788330AImprove processing efficiencyNo need for double luckThread cutting feeding devicesThread cutting machinesProduction lineFiber

The embodiment of the invention discloses a reinforcing steel bar mantel fiber production line and a processing process. The production line comprises a charge roller way assembly, a saw cutter, a discharge roller way assembly and a mantle fiber assembly which are sequentially arranged along the process, wherein the charge roller way assembly and the discharge roller way assembly are arranged at the two sides of the saw cutter in the horizontal direction; the mantle fiber assembly is parallel to the discharge roller way assembly; the mantle fiber assembly comprises a first mantle fiber machine, a second mantle fiber machine and a slide rail; the slide rail is parallel to the discharge roller way assembly; the first mantle fiber machine and the second mantle fiber machine are separately arranged at left and right ends of the slide rail; and the first mantle fiber machine and the second mantle fiber machine move along the slide rail. According to the reinforcing steel bar mantle fiber production line disclosed by the invention, the charge rail assembly, the saw cutter and the discharge roller way assembly are arranged in a length direction of the reinforcing steel bar, so that the two end heads of the reinforcing steel bar are flush in a transport process, and one saw cutter can complete processing, and therefore, the cost is reduced. Besides, the two mantle fiber machines are arranged at the two ends of the slide rail, and can move left and right along the slide rail, so that processing for the mantle fiber at one end of the reinforcing steel bar can be completed, and mantlefiber processing for the two ends of the reinforcing steel bar also can be completed.

Owner:THE 4TH ENG OF CHINA RAILWAY 12TH BUREAU GROUP +1

High concentration organic waste gas treatment method and high concentration organic waste gas treatment apparatus

ActiveCN106362552AWill not interfere with normal operationAvoid wastingDispersed particle separationIncinerator apparatusExhaust gas emissionsEmission standard

The invention discloses a high concentration organic waste gas treatment method, which comprises that (1) high concentration organic waste gas enters a diesel oil absorption device, such that the organic matter concentration in the waste gas is stabilized at 5000-35000 mg / m<3> after treatment; (2) by examining and calculating the waste gas emission amount and the organic matter concentration in the step (1), the existing heating furnace having an appropriate wind distribution amount is selected, such that the organic matter concentration is less than 200 mg / m<3> and the oxygen consumption amount of the oxidation pollutant is less than 0.05% after the waste gas and the heating furnace wind distribution air are mixed; (3) under the premise of the step (2), the absorbed waste gas in the step (1) is introduced into a gas mixer according to a certain ratio, and is mixed with the heating furnace wind distribution air; and (4) the mixed gas is conveyed into the heating furnace to burn, and the purified gas achieves the emission standard. According to the present invention, the diesel oil is used to absorb the organic matter in the waste gas and stabilize the organic matter concentration, and the existing suitable heating furnace is selected according to the concentration, such that the normal running of the heating furnace and the wind distribution fan cannot be interfered, and the explosion risk and the insecurity hidden danger do not exist.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com