Method for processing and recycling waste water containing phenolic compounds

A technology of phenolic compounds and treatment methods, which is applied in the field of treatment of industrial wastewater containing phenolic compounds, and can solve problems such as difficulty in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

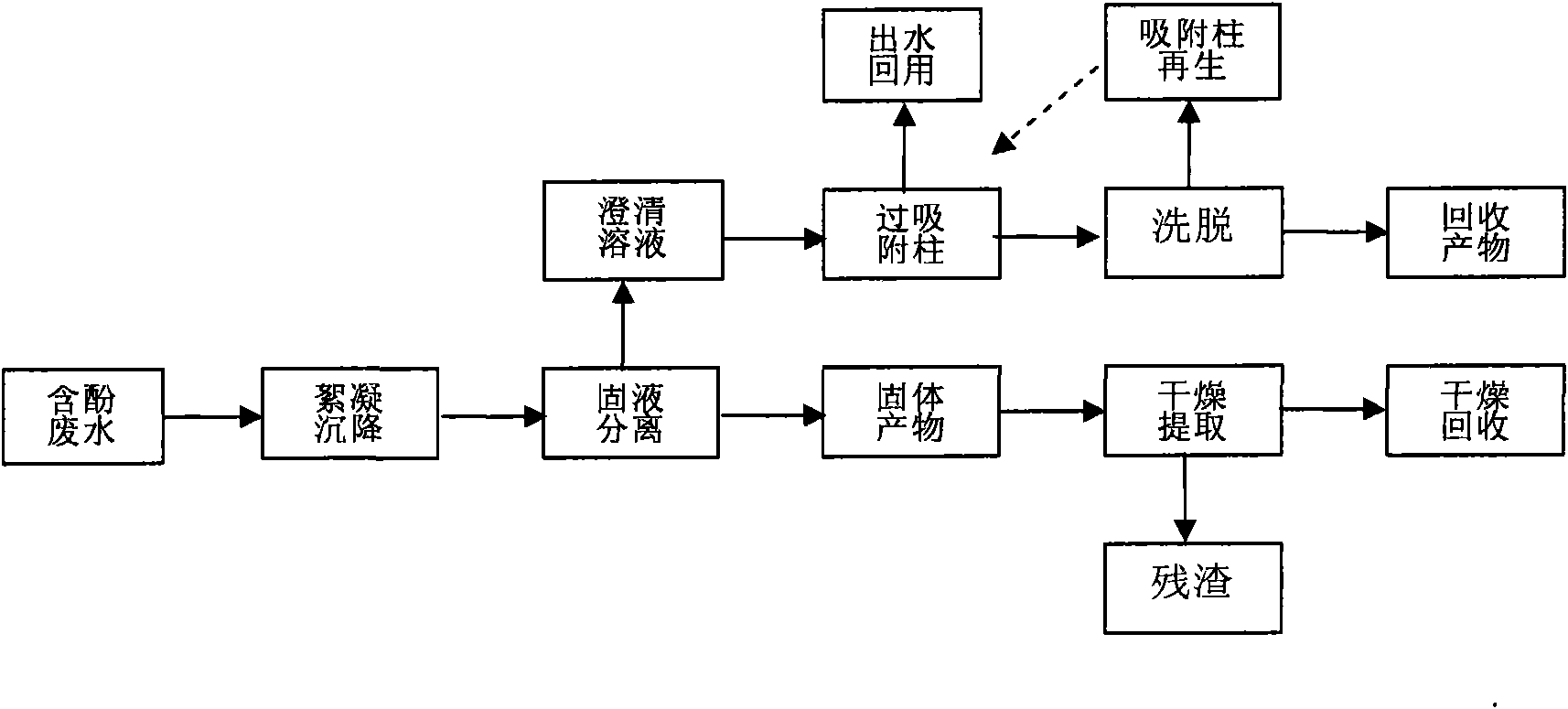

Method used

Image

Examples

Embodiment 1

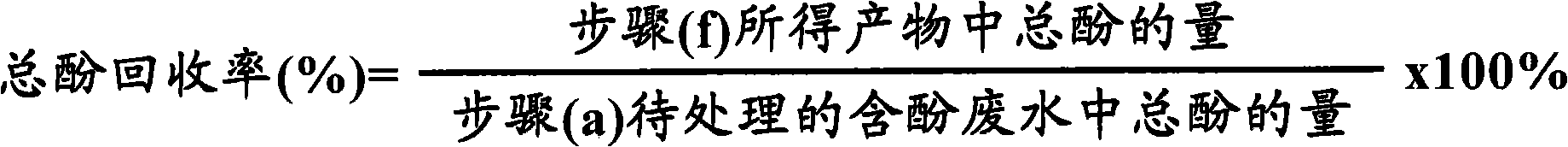

[0125] Embodiment 1: The present invention reclaims the method for phenolic compound and / or contains phenol from phenol-containing wastewater Application example of waste water treatment method

[0126] 1. Process:

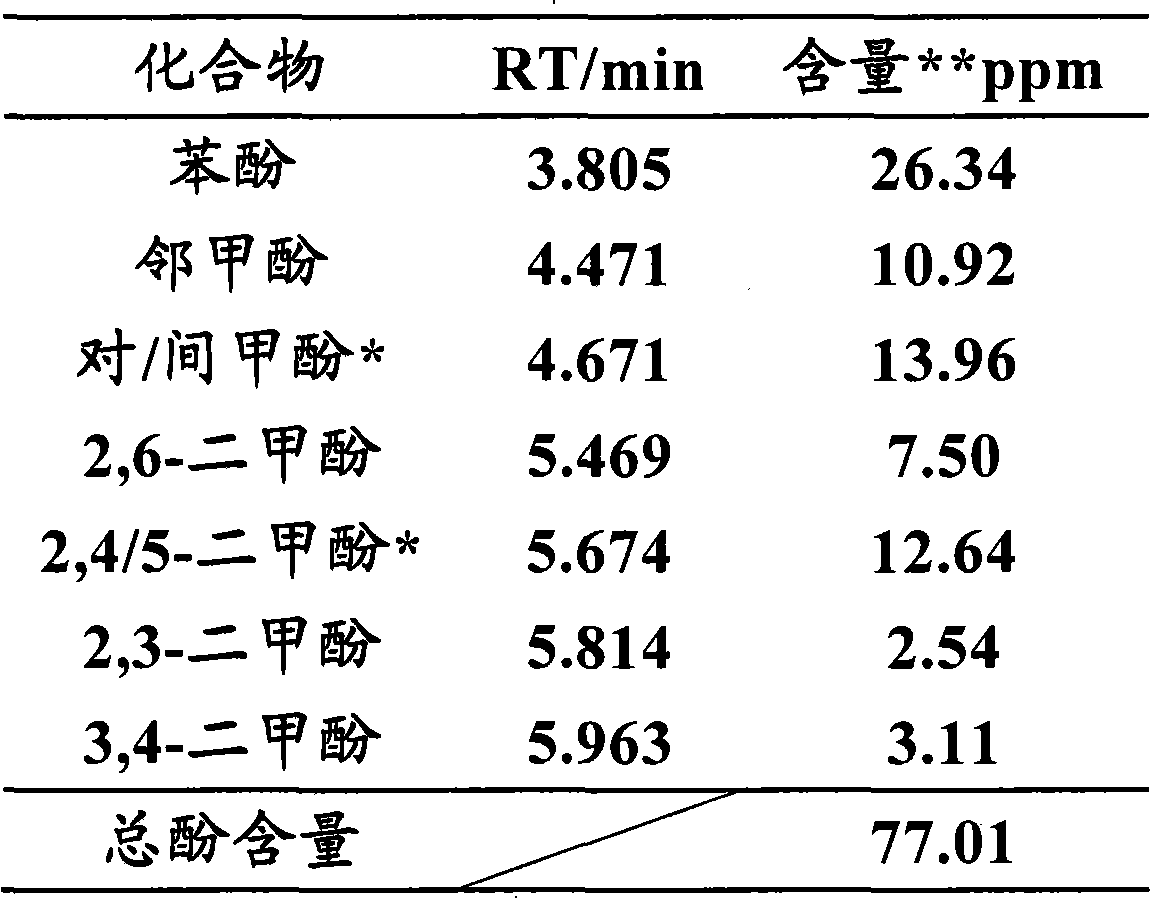

[0127] (1) In the material tank, add phenolic wastewater to be treated [source: coal gasification wastewater, collected on December 3, 2009; volume: 10L; total phenol content: 88ppm]; add flocculant [polyaluminium, 5% aqueous solution (add 5g flocculant to 100ml water), dosage: 8ml], stir evenly, carry out flocculation, sedimentation for 24 hours;

[0128] (2) by pouring first, and then filtering, the material of step (1) is subjected to solid-liquid separation through flocculation and sedimentation to obtain a solid material part and a liquid material part; the above-mentioned solid material part is dried, extracted with ethanol, and the residue It can be used as building materials or other purposes, and the solvent is recovered from the extract to obtain 15...

Embodiment 2

[0139] Embodiment 2: the present invention reclaims the method for phenolic compound and / or contains phenol from phenol-containing wastewater Application example of waste water treatment method

[0140] 1. Process:

[0141] (1) In the material tank, add phenol-containing wastewater to be treated [source: coal gasification wastewater, collected on December 4, 2009; volume: 10L; total phenol content: 75ppm]; then add flocculant [polyaluminum , 5% aqueous solution (add 5g flocculant to 100ml water), dosage: 7.5mL], stir evenly, carry out flocculation, settling for 24 hours, stir slightly occasionally during;

[0142] (2) By first pouring and then filtering, the material of step (1) through flocculation and sedimentation is subjected to solid-liquid separation to obtain a solid material part and a liquid material part; the above-mentioned solid material part is dried, extracted with ethanol, and discarded Residue, the solvent was recovered from the extract to obtain 1.0 g of ...

Embodiment 3

[0151] Embodiment 3: the present invention reclaims the method for phenolic compound from phenol-containing wastewater and / or contains phenol Application example of waste water treatment method

[0152] 1. Process:

[0153] (1) In the material tank, add the phenolic wastewater to be treated [source: coal gasification wastewater, coal gasification wastewater approved on September 28, 2009; volume: 10L; total phenol content: 90ppm]; add flocculant [Polyaluminium, 5% aqueous solution (add 5g flocculant to 100ml water), dosage: 62mL], stir evenly, carry out flocculation and sedimentation for 24 hours, occasionally stirring slightly during the period;

[0154] (2) By first pouring and then filtering, the material of step (1) through flocculation and sedimentation is subjected to solid-liquid separation to obtain a solid material part and a liquid material part; the above-mentioned solid material part is dried, extracted with ethanol, and discarded Residue, the solvent was reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com