Method for utilizing micro-explosion of electrode striking arc to process engineering ceramics and device thereof

A technology of engineering ceramics and electrodes, which is applied in the field of special processing, can solve problems such as cracking of ceramic materials, and achieve the effects of low power supply, guaranteed processing efficiency and quality, low equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

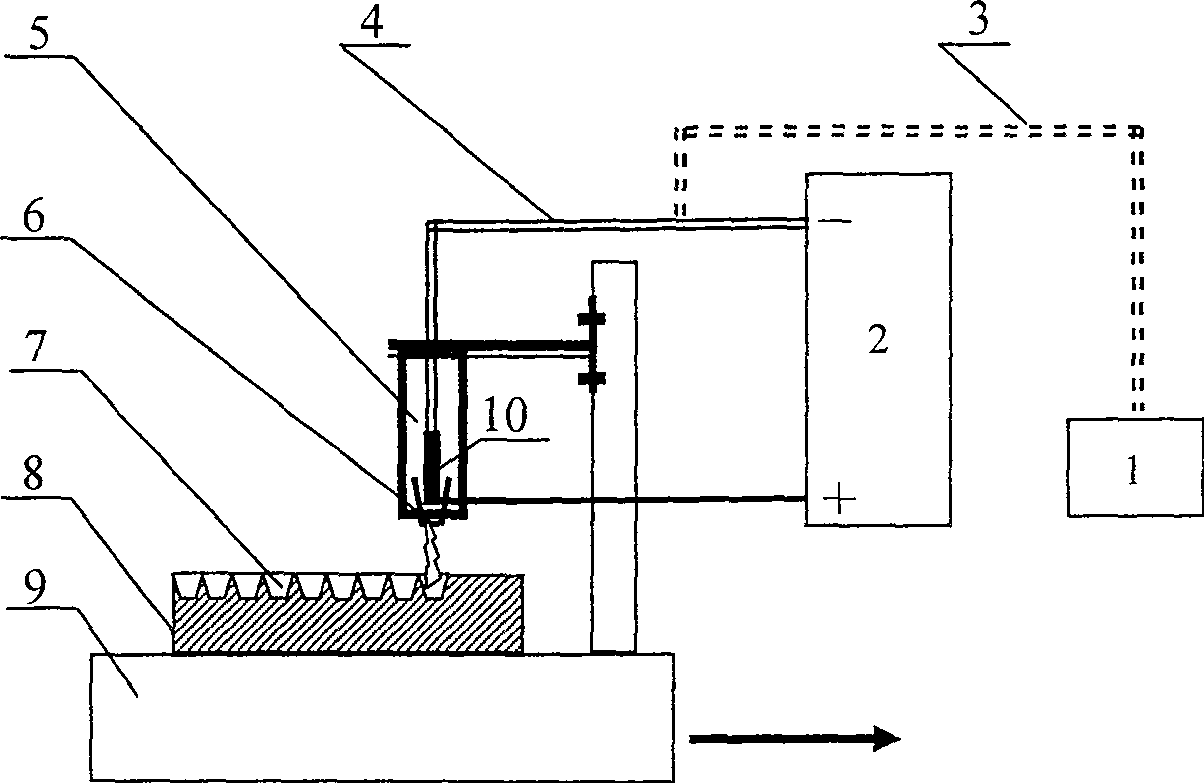

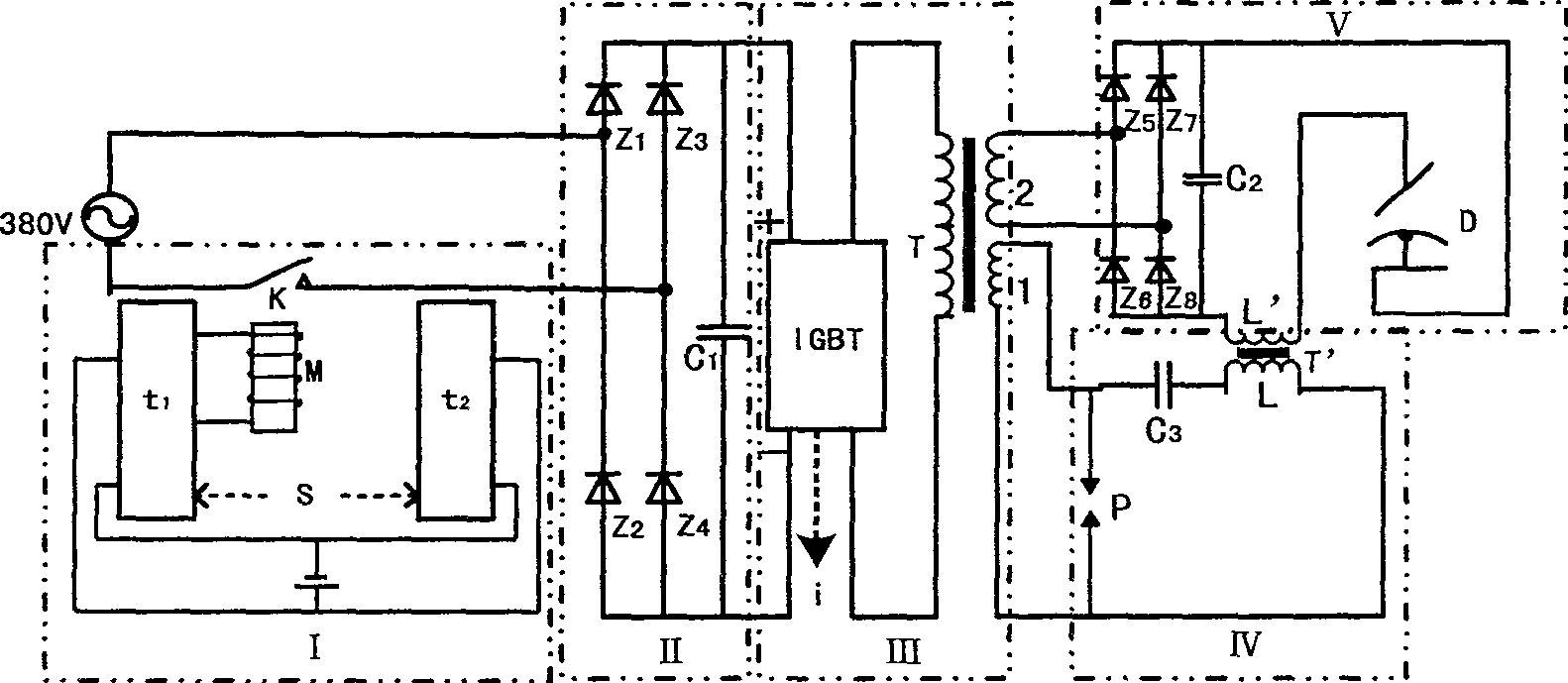

[0017] The method and device for processing engineering ceramics developed by the present invention using electrode arc ignition micro-detonation are further described as follows in conjunction with the accompanying drawings and examples:

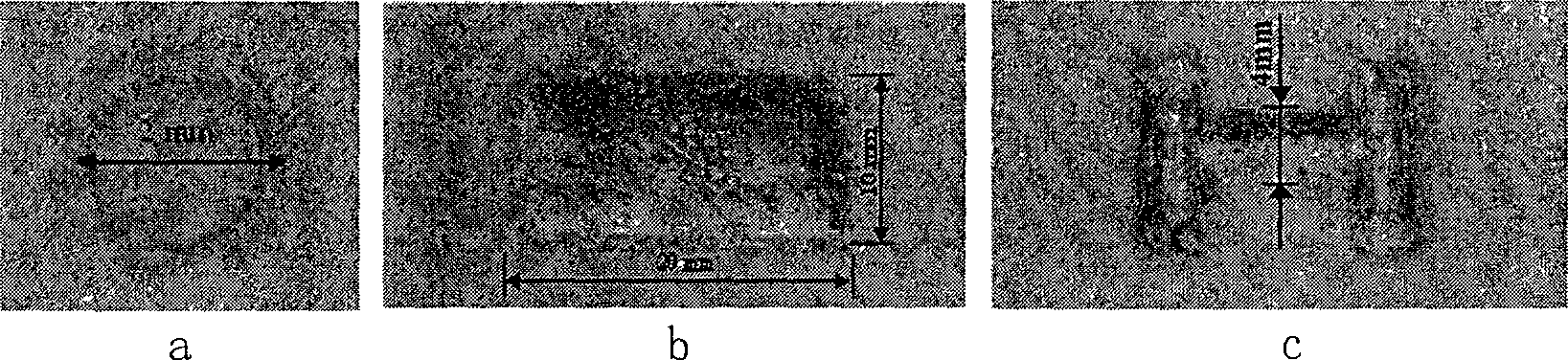

[0018] The method of the present invention is to use the micro-explosion bombardment waves produced at the moment of electrode arc ignition to aim at the surface of the ceramic workpiece, and to erode out a circular pit with a diameter of about 1-2 mm and a depth of 0.01-1 mm on the surface of the ceramic workpiece. The pulse of the explosive bombardment wave controls the launch and the feed movement of the worktable at a corresponding speed to realize the removal of the surface. The specific implementation steps of the above method are:

[0019] A pulse-controlled working current is loaded between the two electrodes. At the moment when the arc is ignited by a high-frequency electric spark, the compressed air input simultaneously with the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com