Patents

Literature

98 results about "Micro explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

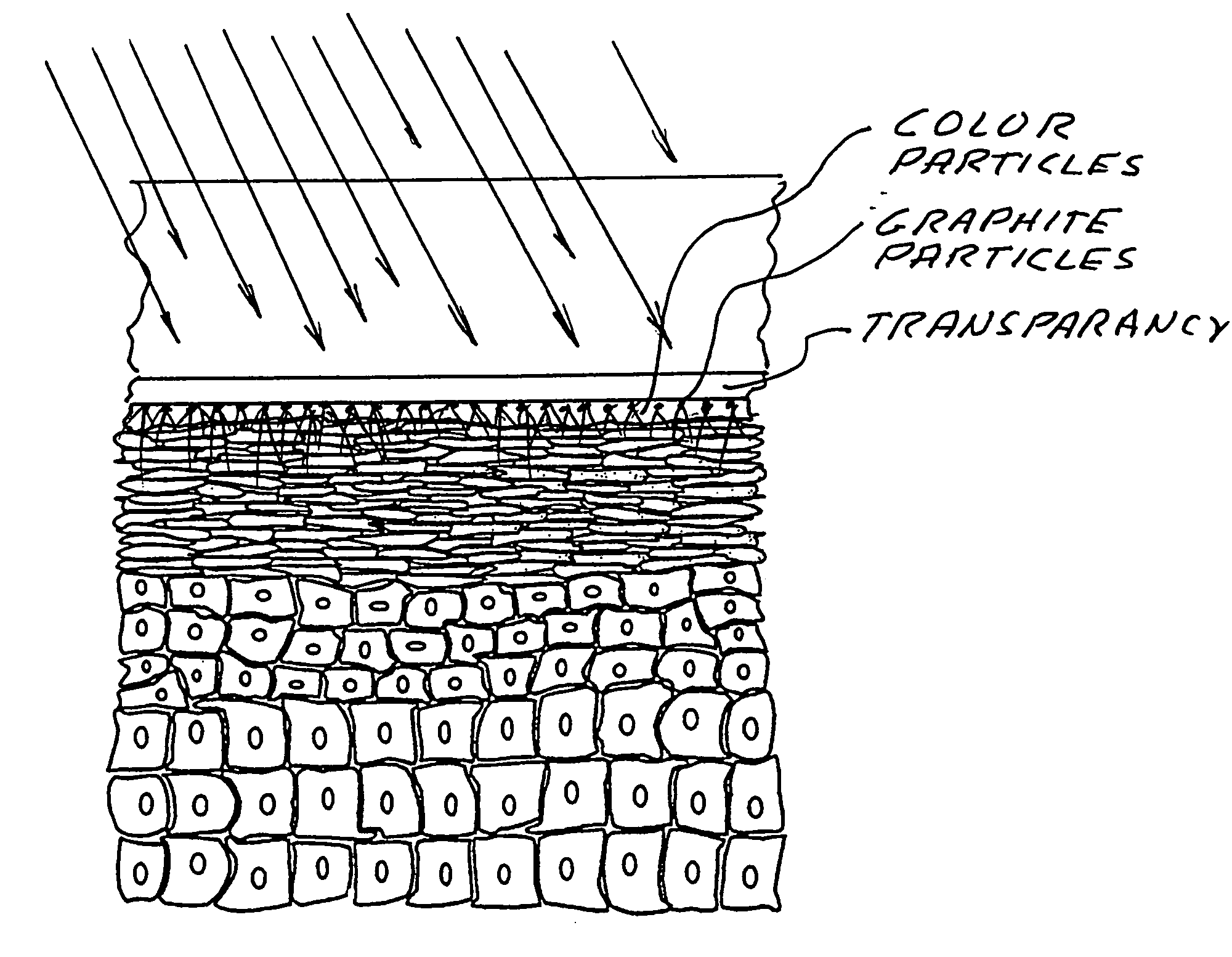

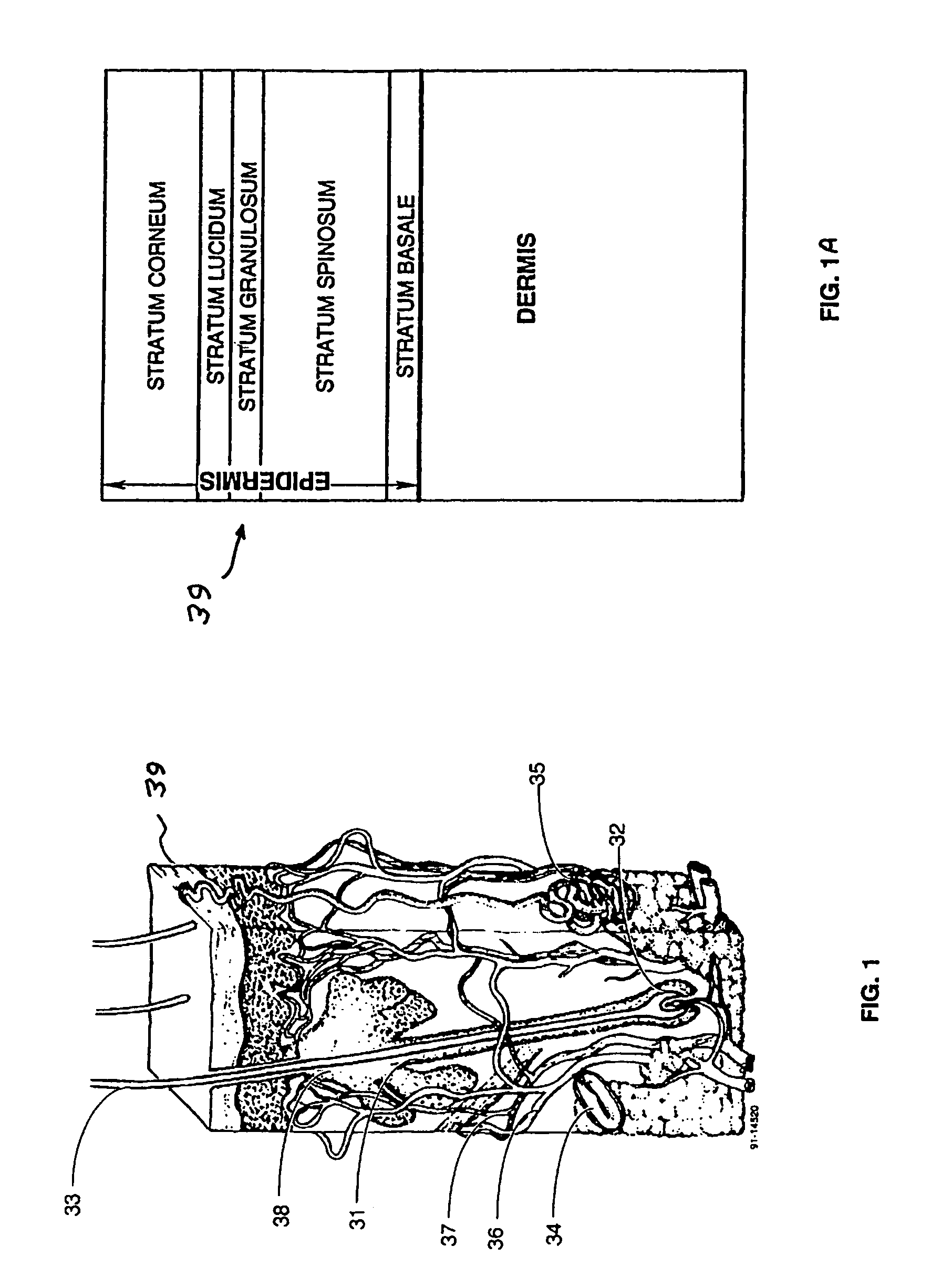

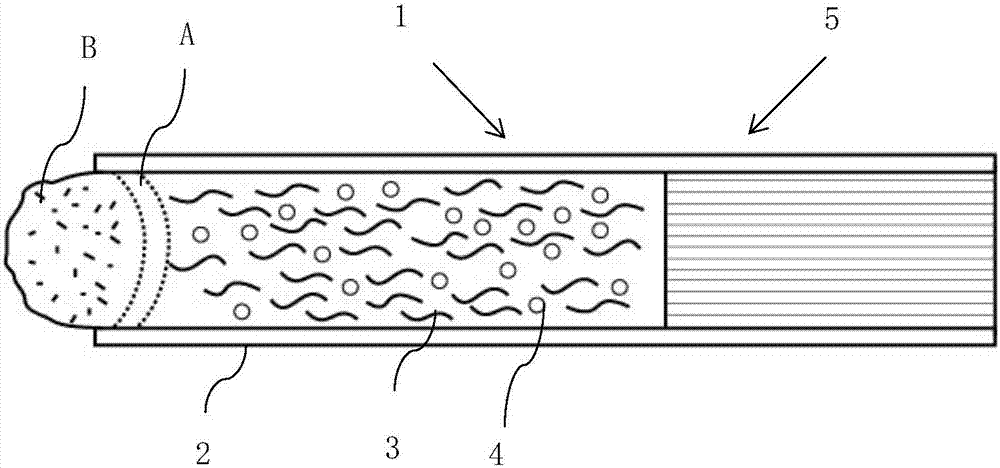

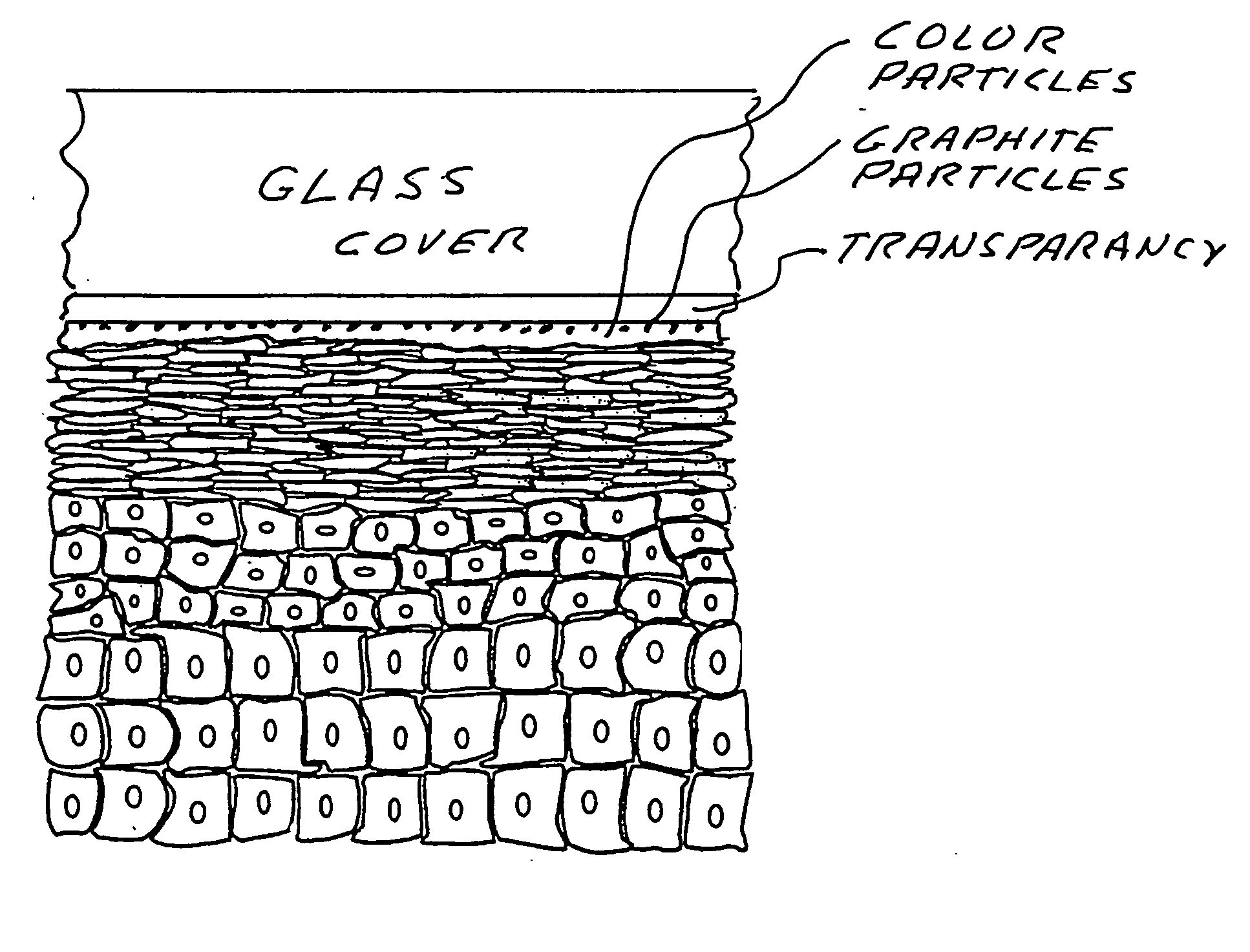

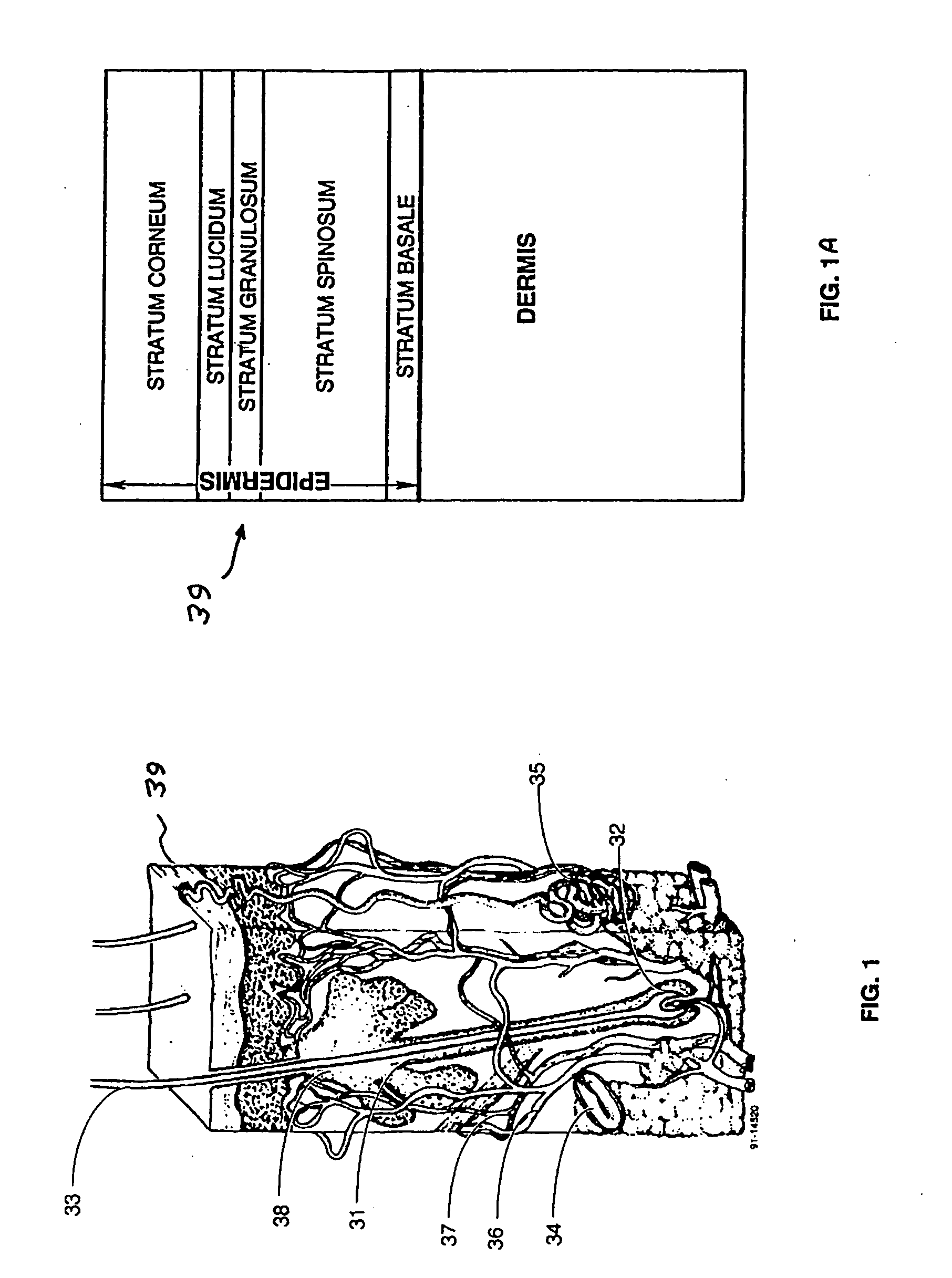

Light-triggered tattoo process

A light-triggered tattoo process. A strong absorber of light energy and tattoo material are sandwiched under pressure between a skin region and a transparent window. Short pulses of light, at frequencies strongly absorbed by the strong absorber, illuminates the strong absorber through the window creating micro-explosions in the strong absorber that drive particles of the tattoo material into the skin region producing a tattoo.

Owner:TANG KENNETH Y +2

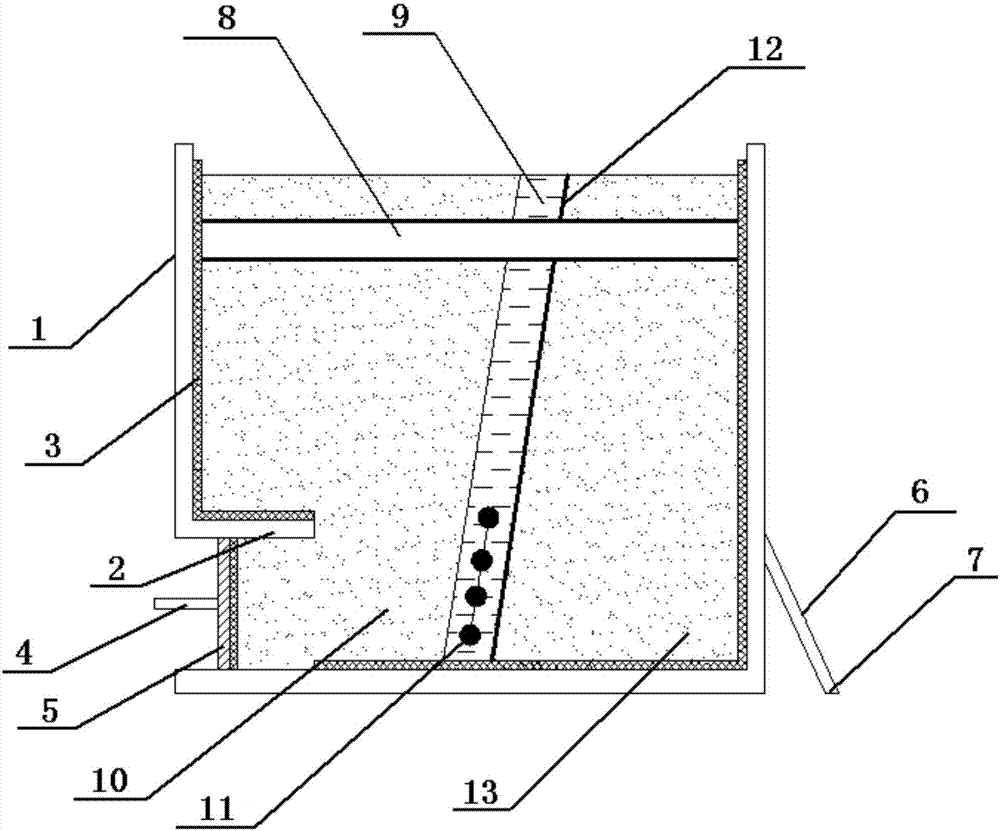

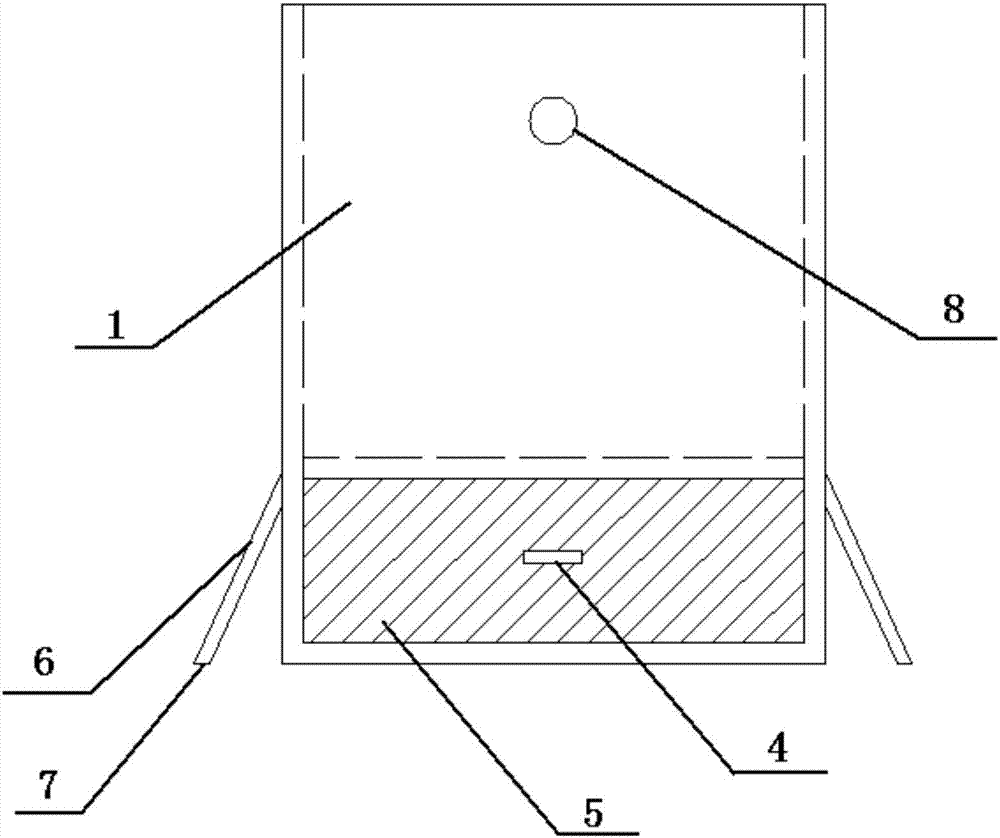

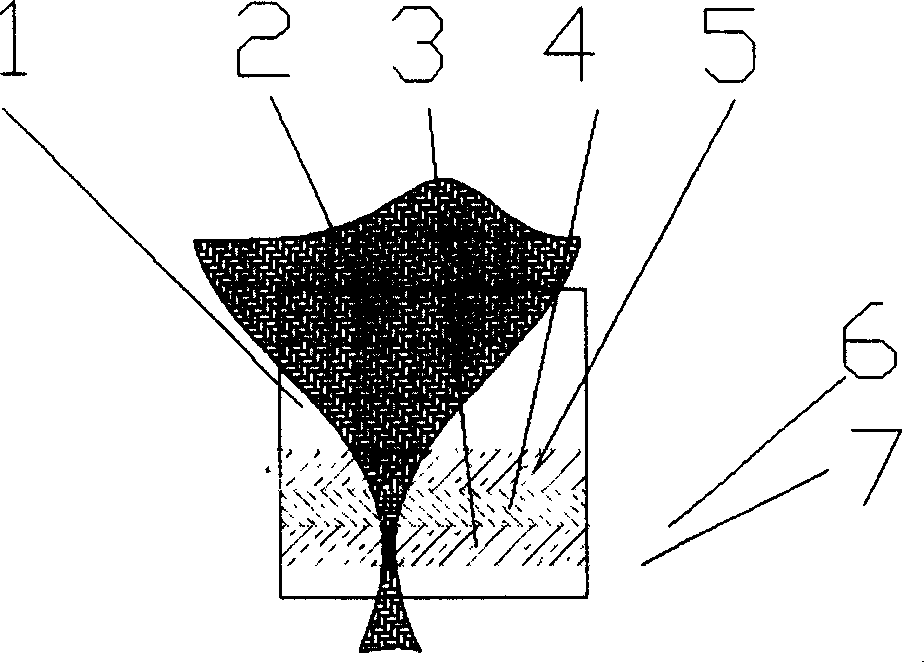

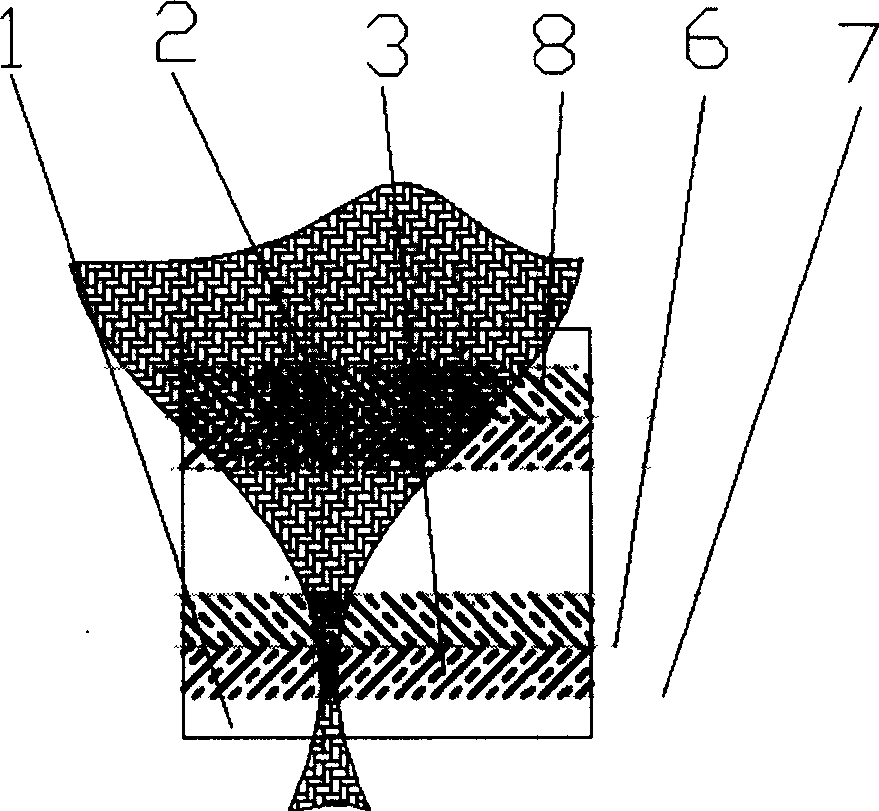

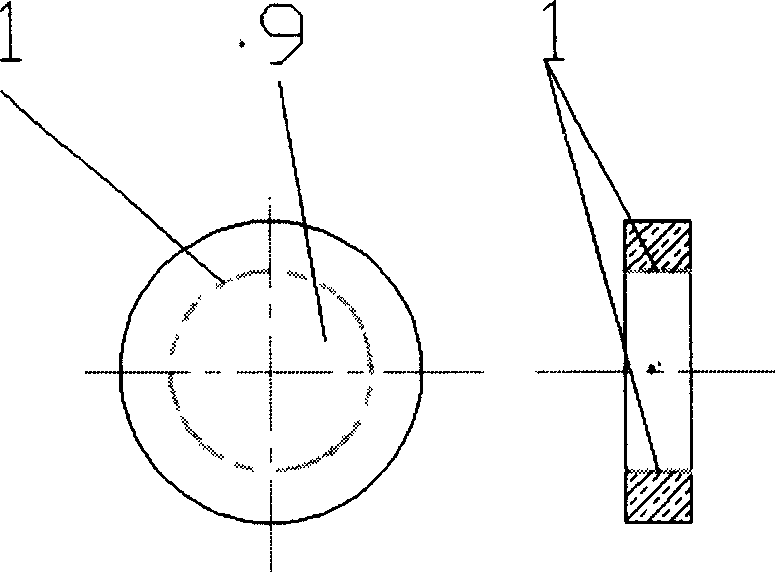

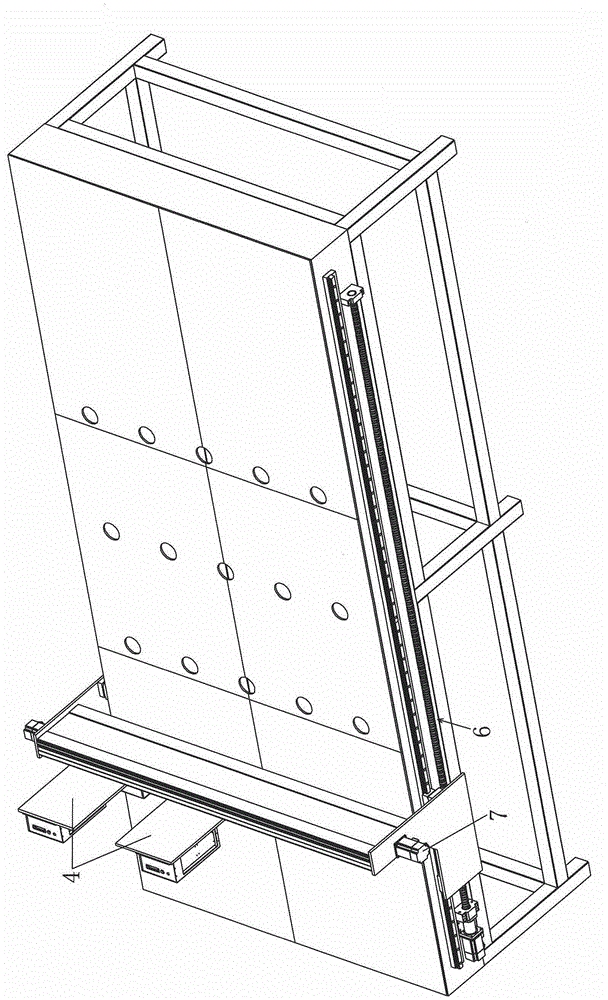

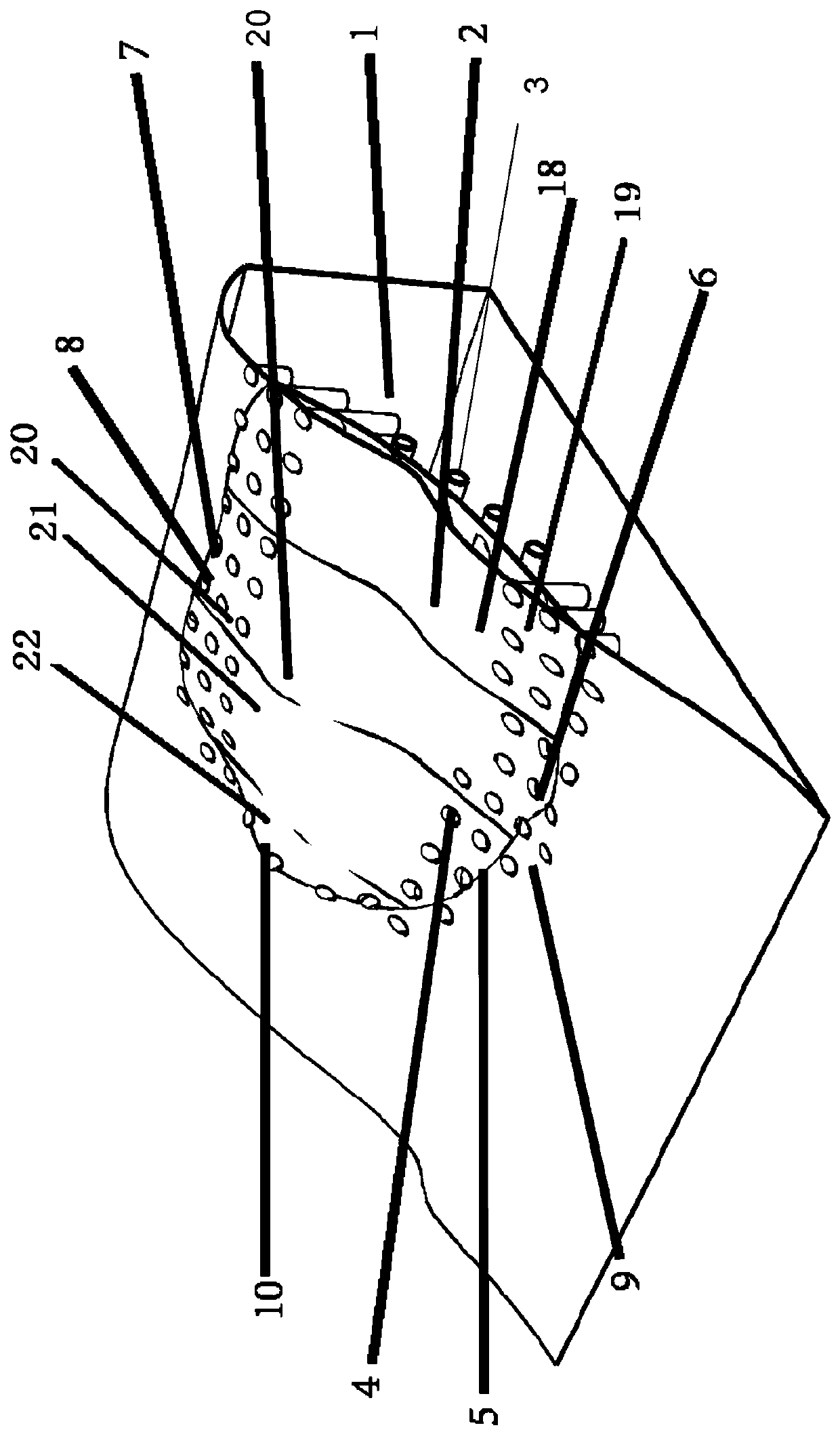

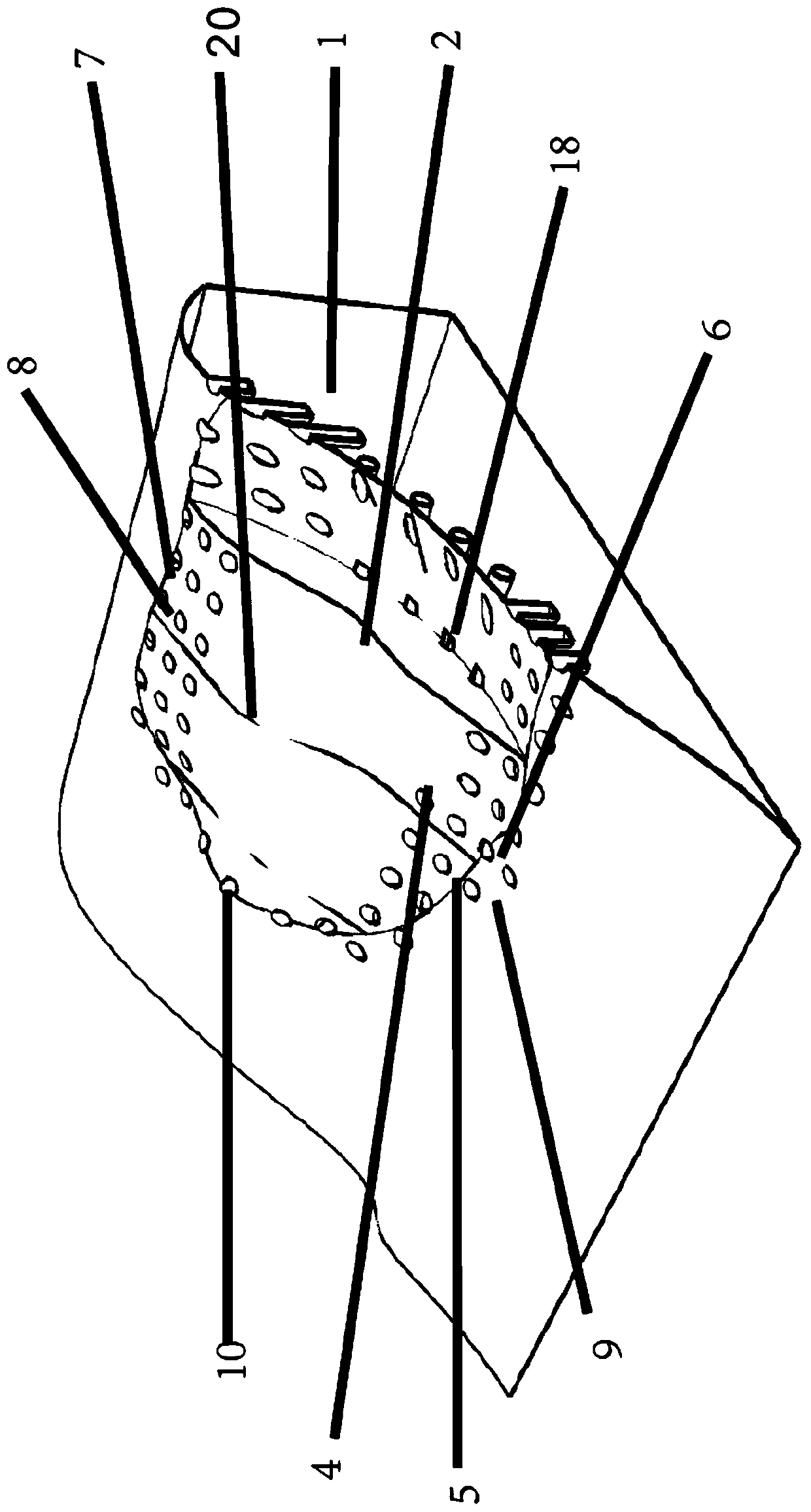

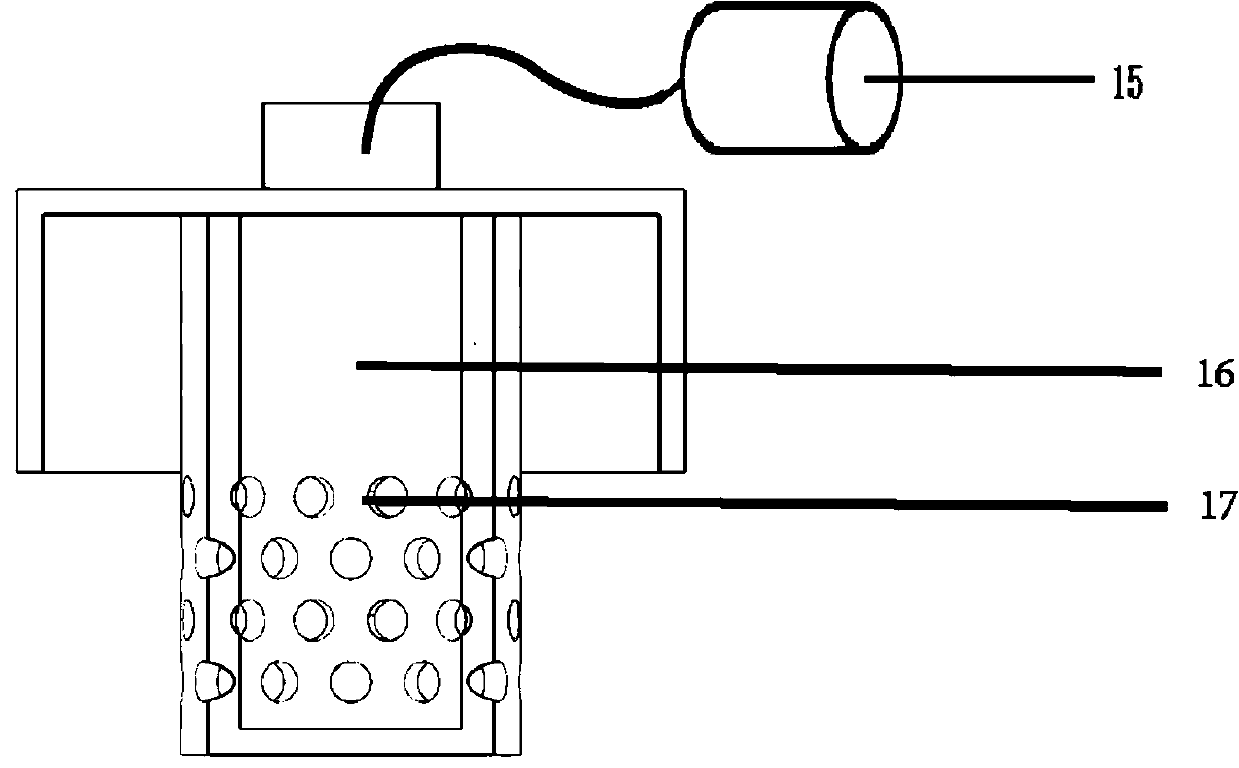

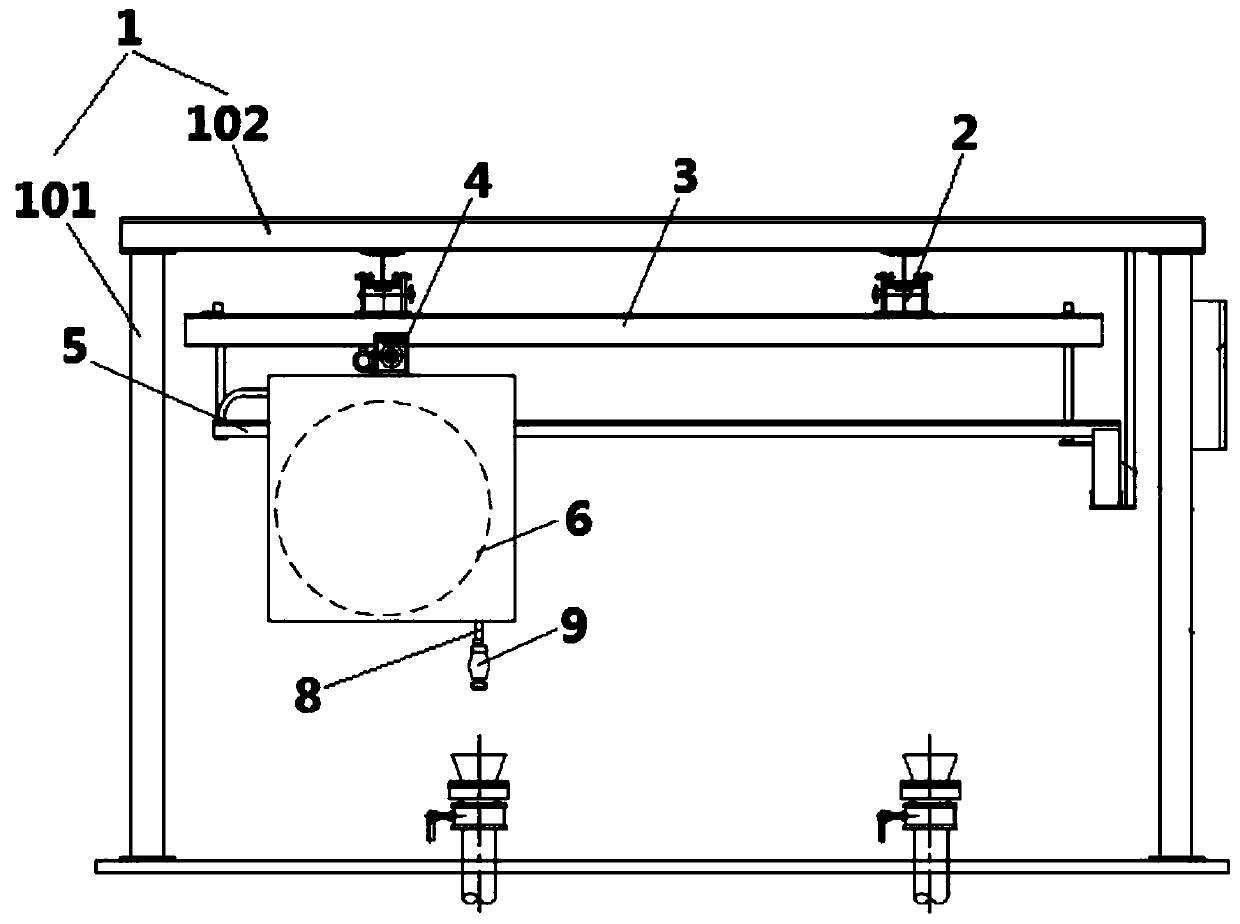

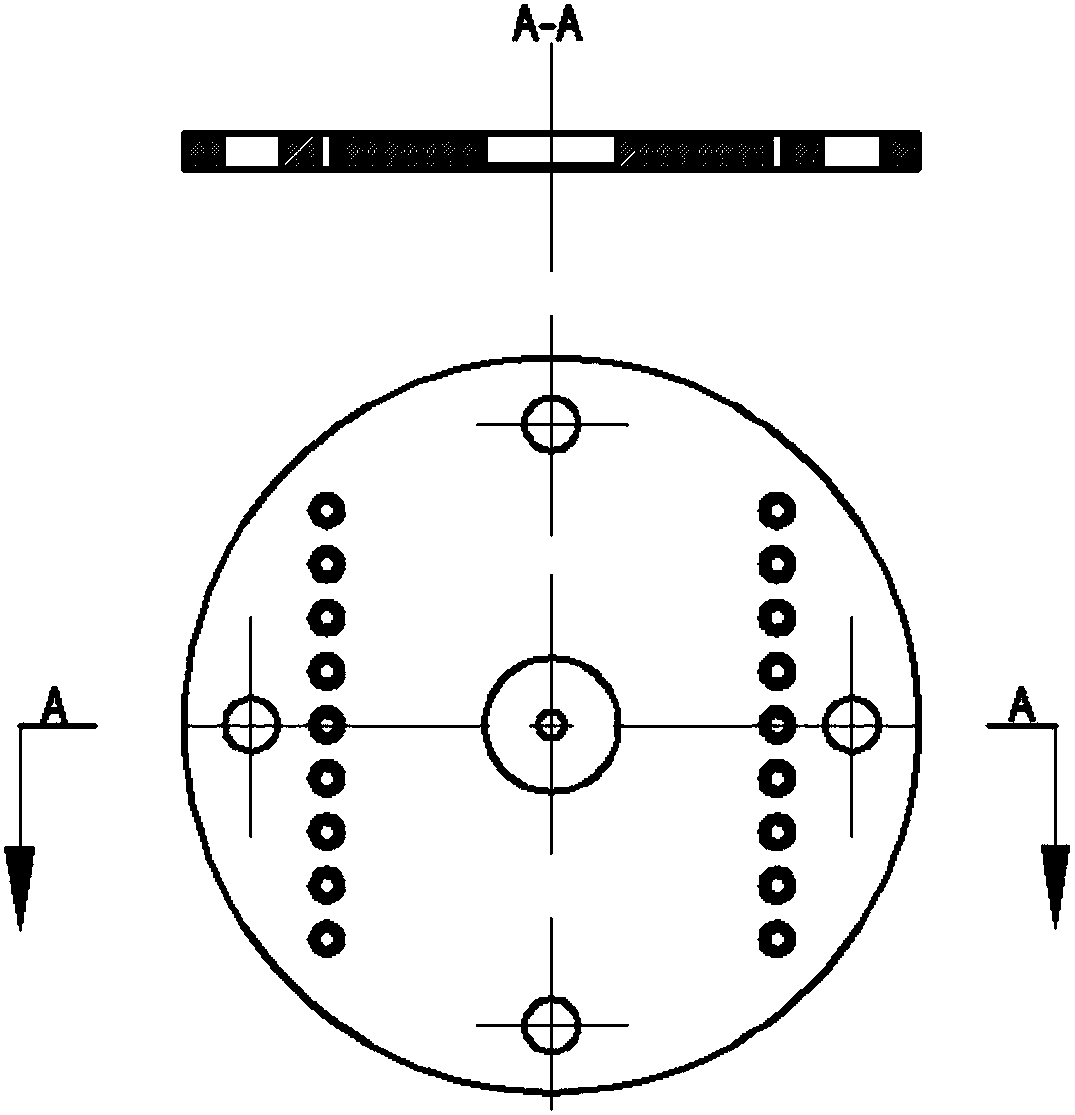

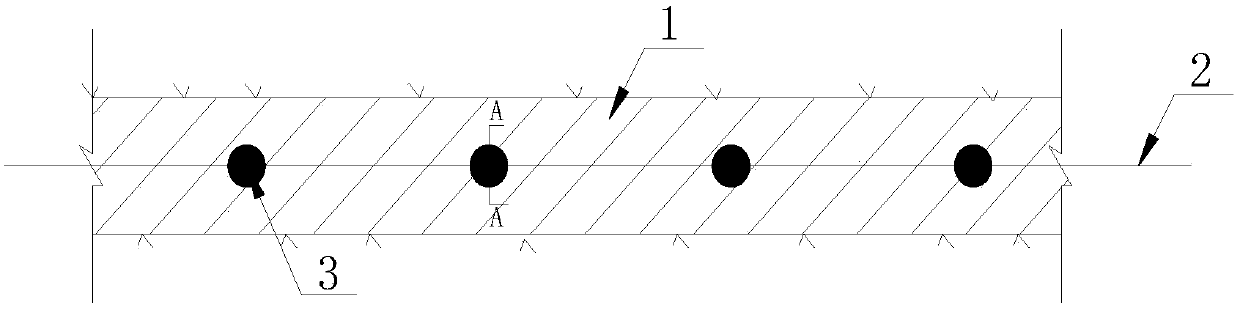

Test device for simulation of near-fault seismic oscillation initiated by reverse fault strike-slip movement

ActiveCN107271128ASimple structureReduce testing costsVibration testingClassical mechanicsTest figure

The present invention discloses a test device for simulation of near-fault seismic oscillation initiated by reverse fault strike-slip movement. The device comprises a cube structure test box body with an opening at the upper surface, and a movable baffle plate is arranged at the lower portion of the surface of one side of the test box body; the upper portion of the movable baffle plate is provided with an embedded plate extended into the test box body, and the movable baffle plate can slide along the embedded plate and the lower surface of the test box body; the test box body is internally provided with a simulation fault communicating the upper surface and the lower surface; a simulation tunnel passing through the simulation fault is arranged at the upper portion of the internal portion of the test box body; an upper disc is arranged between one side, close to the movable baffle plate, of the simulation fault and the inner surface of the test box body, and a lower disc is arranged between one side, far away from the movable baffle plate, of the simulation fault and the inner surface of the test box body; and a plurality of serial pressure-sensitive micro-explosion devices are arranged at the lower portion of the simulation tunnel in the simulation fault. The test device for simulation of near-fault seismic oscillation initiated by reverse fault strike-slip movement can really simulate the seismogenic mechanism of the near-fault seismic oscillation under the effect of the simulation reverse fault strike-slip effect, the test result is accurate, and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

Laser cutting method based on inner carving

ActiveCN101386112AEasy to cutReduce cutting efficiencyGlass severing apparatusLaser beam welding apparatusLaser processingLaser cutting

The invention pertains to the filed of laser processing and discloses a laser cutting method based on internal carving. The key feature of the invention is that laser penetrates through cutting material and focuses on the interior of the cutting material to be cut, and then the bottom of the cutting material to be cut is processed in a layered and bottom-up manner to obtain a cutting section in a'micro explosion' way, thereby cutting transparent and translucent crisp and hard materials with high efficiency and high quality.

Owner:INNO LASER TECH CORP LTD +1

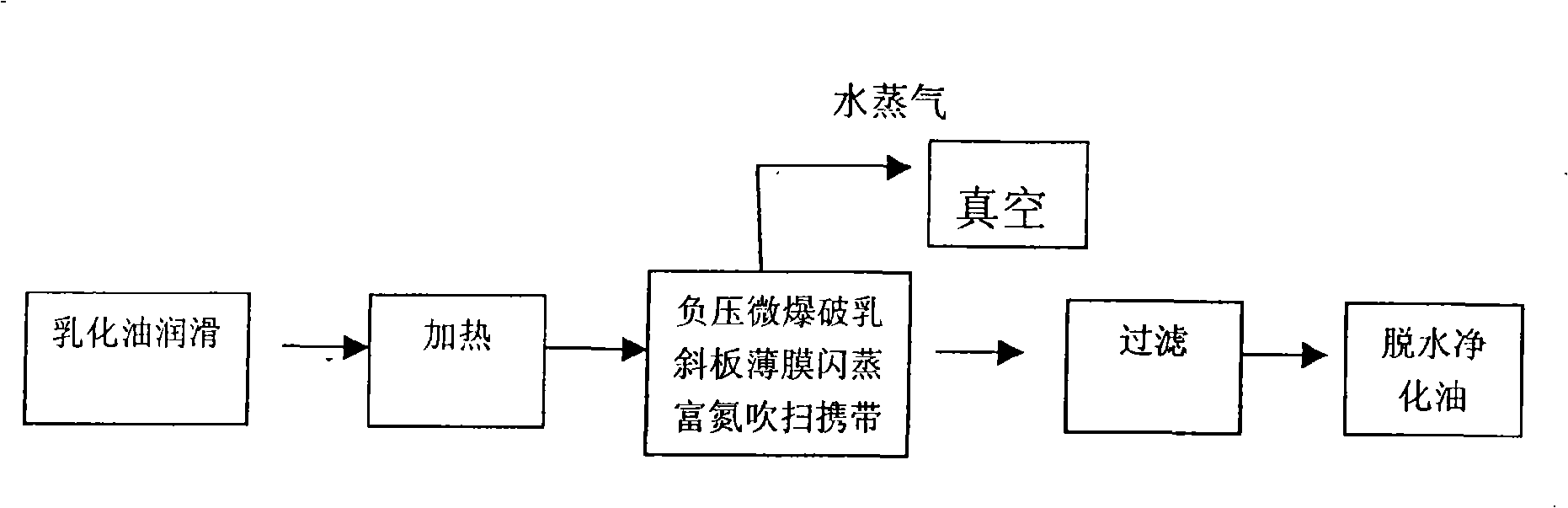

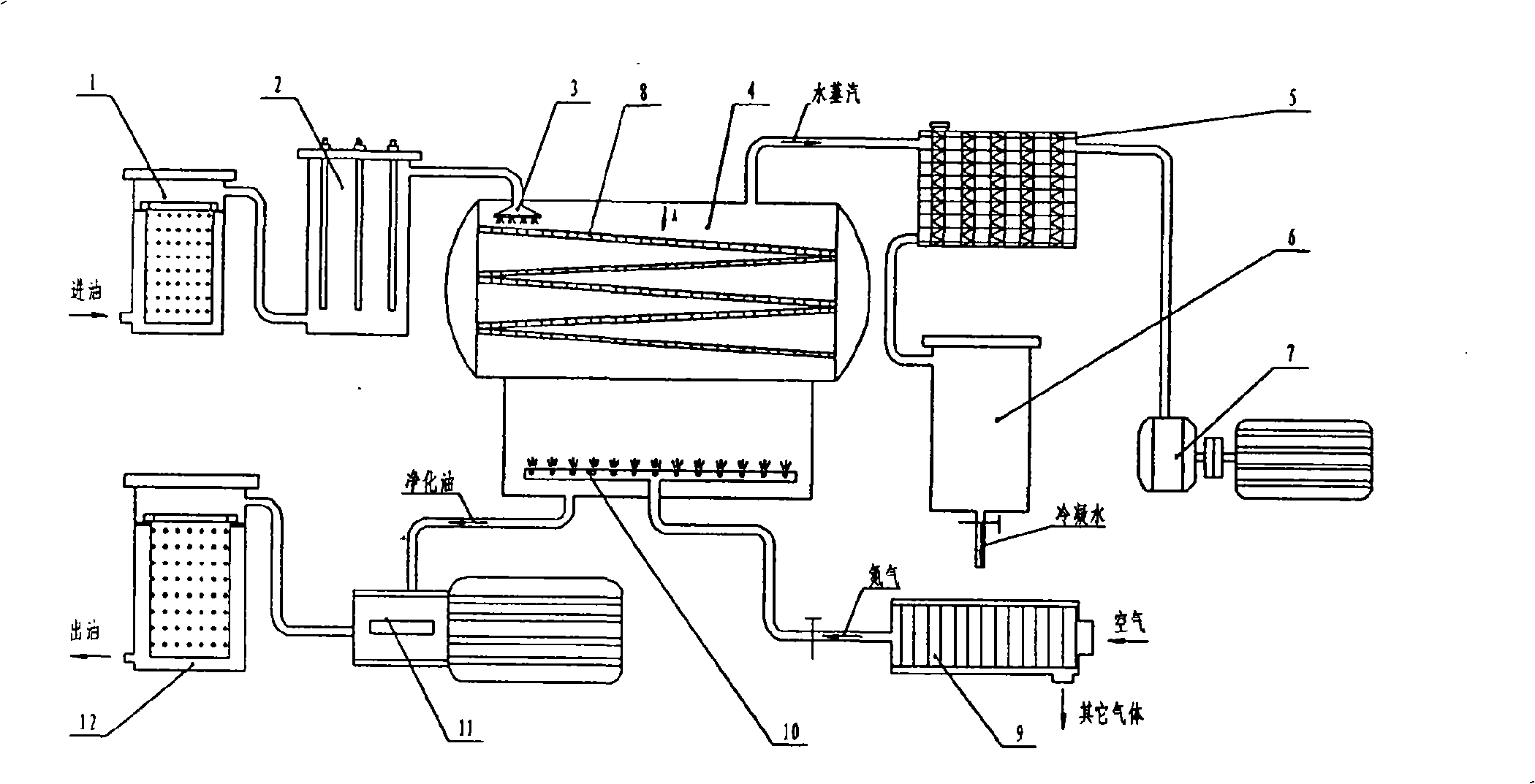

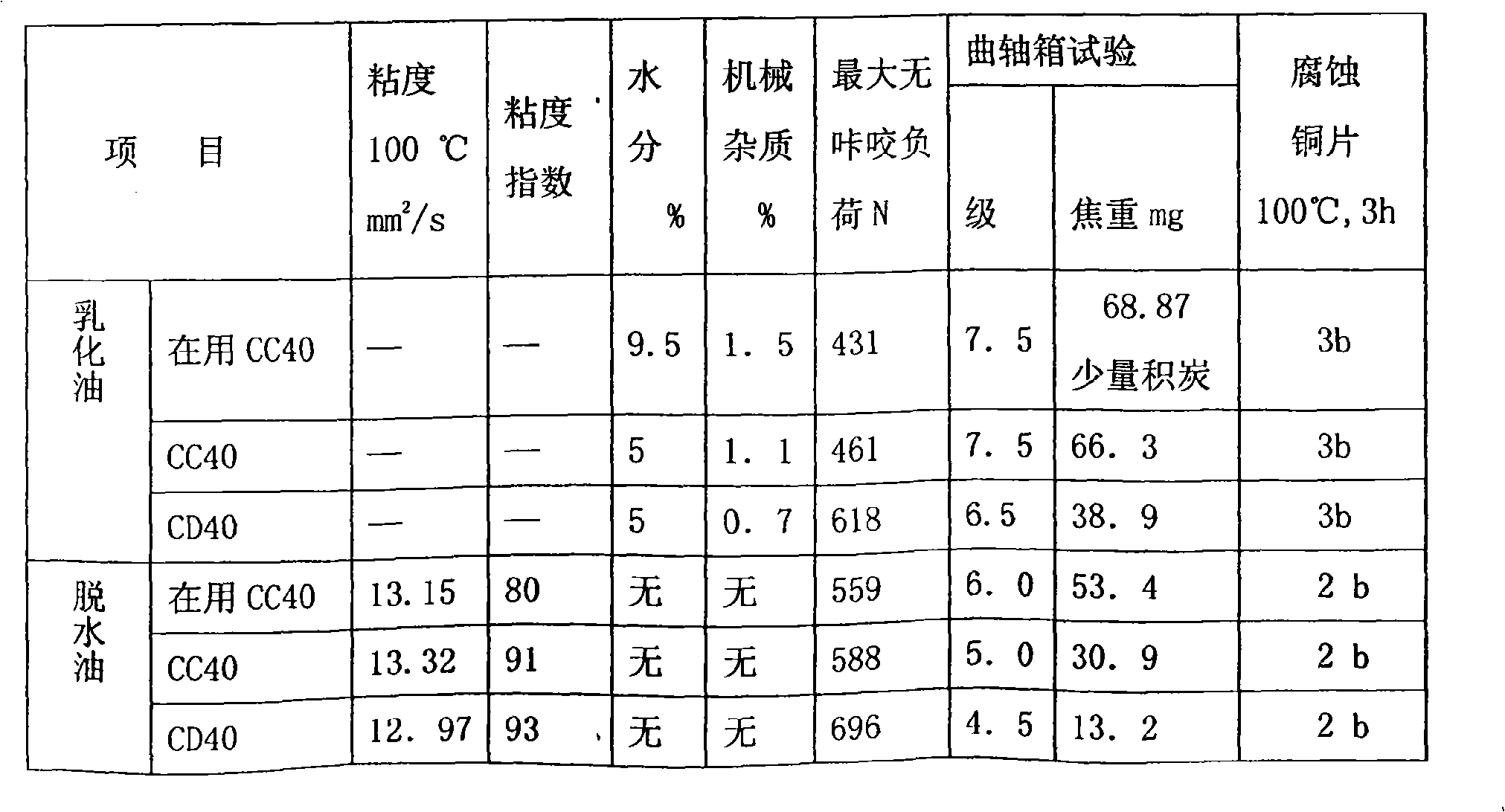

Lubricating oil composite dewatering technique

InactiveCN101265416AEffective protectionPrevent oxidationHydrocarbon oil dewatering/demulsificationFiltrationWater vapor

The invention relates to a lubricating oil composite dehydration process, which comprises the following steps: a vacuum pump is started to form the negative pressure in a composite dehydration device; emulsified lubricating oil is filtered, and the emulsified lubricating oil enters into a coarse filter under the negative pressure effect formed in the composite dehydration device; the emulsifying lubricating oil is heated, and the temperature is controlled within 40 to 80 DEG C; negative pressure micro explosion demulsification is performed, the emulsified lubricating oil after heating is sprayed into the composite dehydration device, the water in liquid beads wrapped by oil is quickly evaporated under the negative pressure, micro explosion is produced to form vapor which is taken out; microporous inclined plate film flash evaporation is performed; nitrogen-enriched air lancing carrying evaporation is performed; the lubricating oil after the filtration and the evaporation can be used continuously. The lubricating oil composite dehydration process has the advantages that the film infiltration technology is applied to concentrate the nitrogen in the air, to perform effective protection for the oil product during the oil and water separation process, and to prevent the lubricating oil from being oxidated; the negative pressure formed in the composite dehydration device is utilized to absorb the nitrogen gas, and the cost is reduced.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

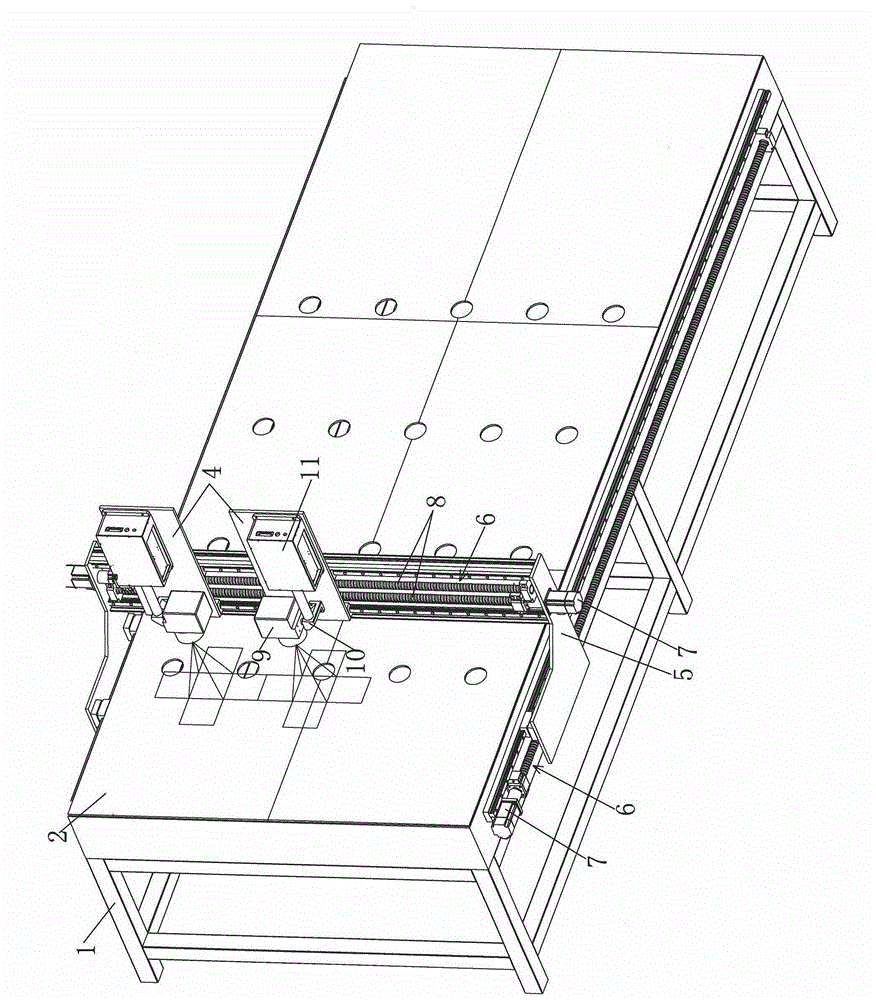

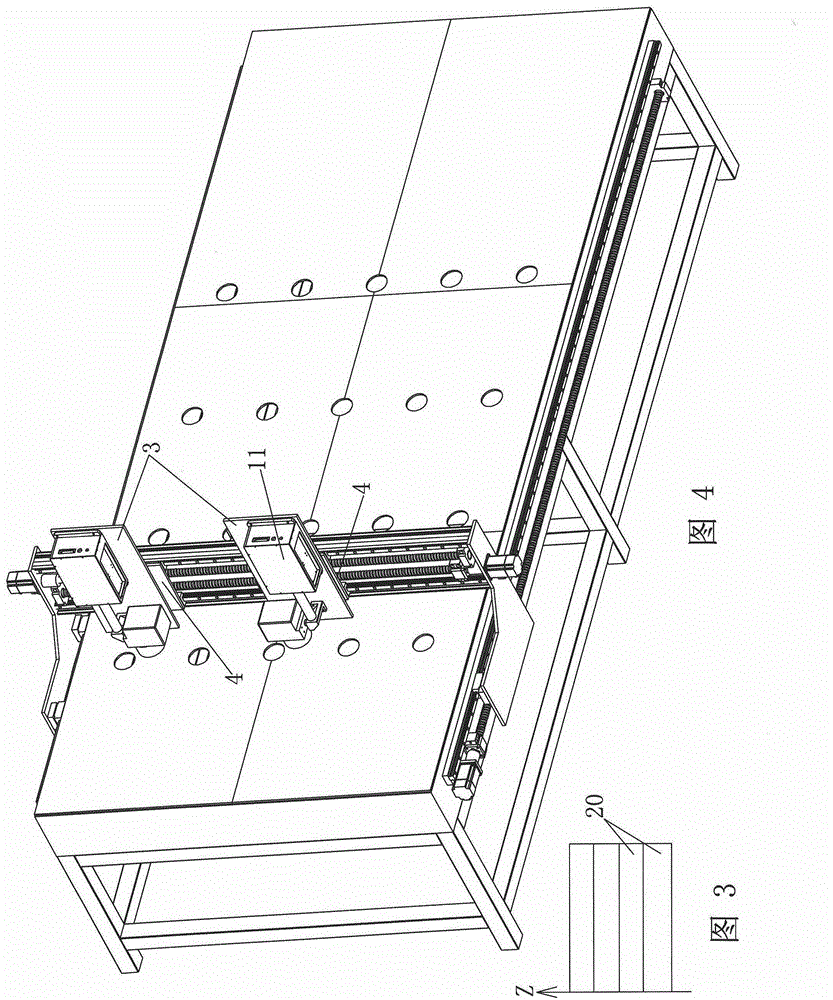

Method and device for improving efficiency in engraving three-dimensional images in large-area flat glass

ActiveCN104907703AImprove engraving efficiencyHigh speedWelding/soldering/cutting articlesMetal working apparatusFlat glassEngraving

The invention discloses a method and a device for improving efficiency in engraving three-dimensional images in large-area flat glass. The method includes: adopting more than two high-speed galvanometers to deflect more than two branches of laser to control positions of laser focusing points; forming micro-explosion points inside the flat glass to acquire the three-dimensional images inside and outside the glass. The device based on the method comprises a support, a glass placement platform, a movable positioning mechanism and high-speed galvanometer systems, the glass placement platform is arranged in the support, the movable positioning mechanism comprises at least two X-direction moving platforms and one Y-direction moving platform, the X-direction moving platforms are connected with the Y-direction moving platform, the movable positioning mechanism is connected with the support and positioned above the glass placement platform, and the high-speed galvanometer systems are arranged on the X-direction moving platforms. The high-speed galvanometer systems are adopted for image engraving of the flat glass at the same time, so that engraving efficiency can be improved substantially.

Owner:ZHEJIANG HOLY LASER TECH CO LTD

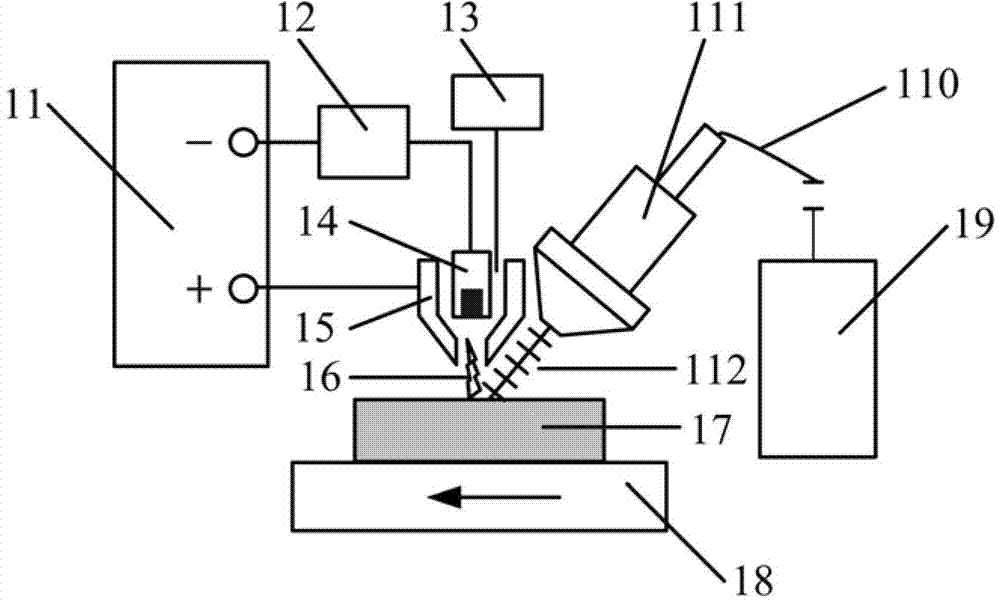

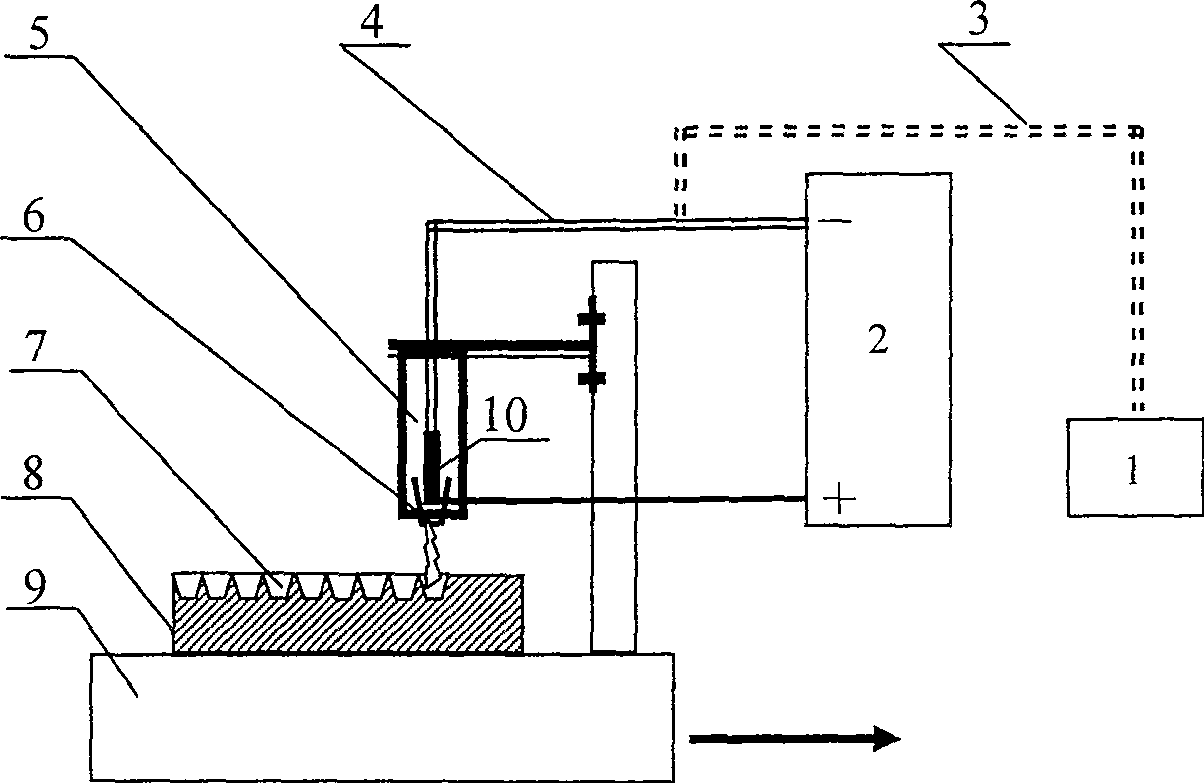

Laser heating auxiliary arc striking micro-explosion processing method and device for engineering ceramic material

InactiveCN102950387AControl outputImprove quality and efficiencyLaser beam welding apparatusMaterial removalSpray nozzle

The invention relates to a laser heating auxiliary arc striking micro-explosion processing method and a laser heating auxiliary arc striking micro-explosion processing device for an engineering ceramic material, and belongs to the technical field of the processing of hard and brittle materials. The method comprises the following steps of: focusing a laser beam, and then, obliquely irradiating the laser beam on the surface of a work piece to be processed; vertically aligning a jet nozzle of an arc striking micro-explosion generator with the surface of the work piece downwards; and enabling the work piece to continuously perform a feed movement along with a working platform, carrying out laser preheating first, raising the temperature of a micro cell to the softening temperature of the ceramic material, and then, carrying out arc striking micro-explosion processing until the processing of the engineering ceramic work piece to be processed is finished. The system mainly comprises a special pulse power supply, a pulse controller, a numeric control three-dimensional working platform, a micro-explosion generator, a gas supply device, a medium-low power laser apparatus, an optical fiber and a laser head. By using the laser heating auxiliary arc striking micro-explosion processing method and the laser heating auxiliary arc striking micro-explosion processing device, the material removal efficiency of the arc striking micro-explosion processing method is improved; the processing damage is reduced; and the practical application of the arc striking micro-explosion processing method in the processing of the engineering ceramic material is further promoted.

Owner:田欣利 +1

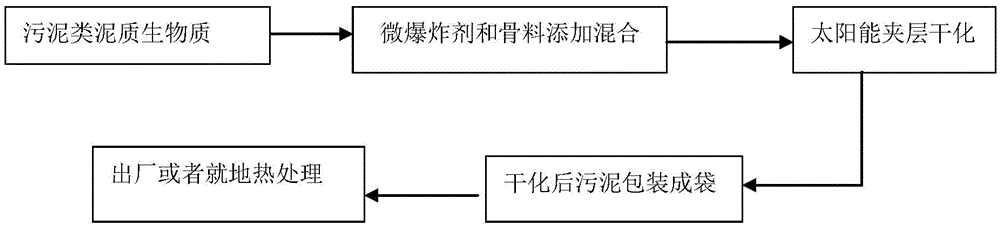

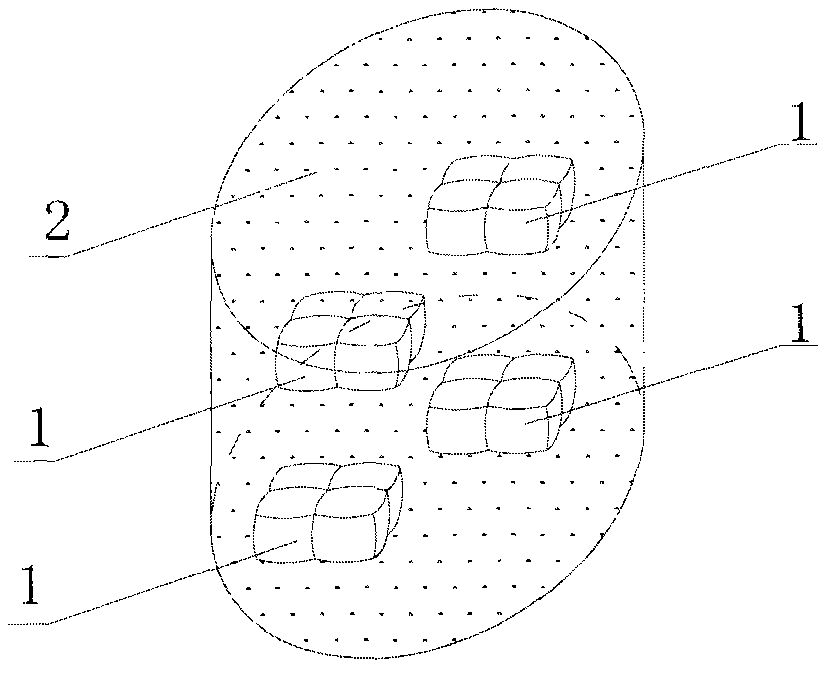

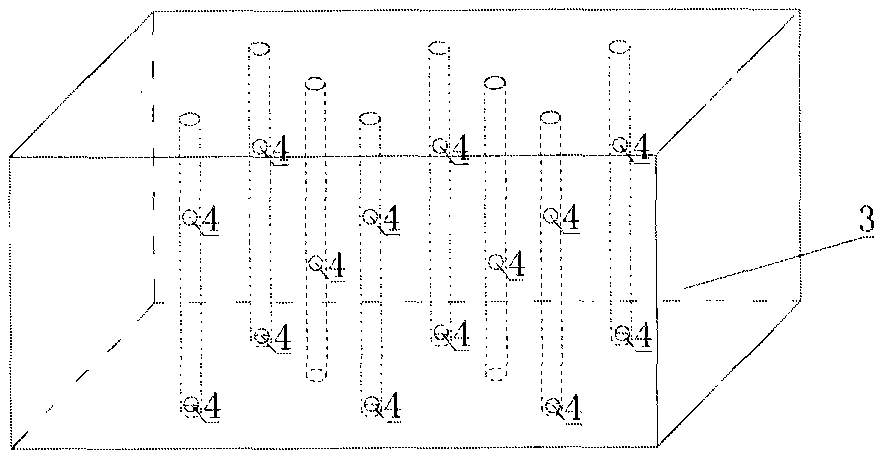

Activated carbon preparation method of sludge type argillaceous biomass

ActiveCN105523555APromote formationGood removal effectSludge treatment by de-watering/drying/thickeningCarbon compoundsSolar dryingWater vapor

The invention discloses an activated carbon preparation method of a sludge type argillaceous biomass. The method comprises: carrying out a process of constructing and conditioning micro-explosion agent / aggregate, a process of solar sandwich drying and a process of activation two-stage pyrolysis; uniformly mixing the sludge obtained after dehydration of the sludge type argillaceous biomass, the micro-explosion agent and the aggregate in a mass ratio of 8.5:0.5:1.0-6:2:2 of a dry basis, then carrying out distribution, carrying out drying in a solar sandwich drying system, then carrying out two-stage pyrolysis in a pyrolysis furnace, controlling the temperature of the initial carbonization stage at 230 DEG C for 20 minutes, then raising the temperature to 400 DEG C at a rate of 20-40 DEG C / min, making a stop for 30-60minutes, and introducing water vapor into a water vapor activation stage at a flow rate of 0.1-1L / (min.G), wherein the pyrolysis final temperature is 550-650 DEG C, the residence time is 20-60 minutes, the EET of the formed activated carbon is 200-500m2 / g, and the particle size is less than 20mm; and the micro-explosion agent is one or more of ammonium nitrate, potassium ammonium nitrate and calcium ammonium nitrate, and the aggregate is a waste circuit board. The preparation method disclosed by the invention comprehensively uses solar drying, micro-explosion agent swelling pore-forming and waste resin to construct a framework, and thereby improving the solar drying efficiency of the sludge and the quality of the activated carbon.

Owner:SHANGHAI JIAO TONG UNIV

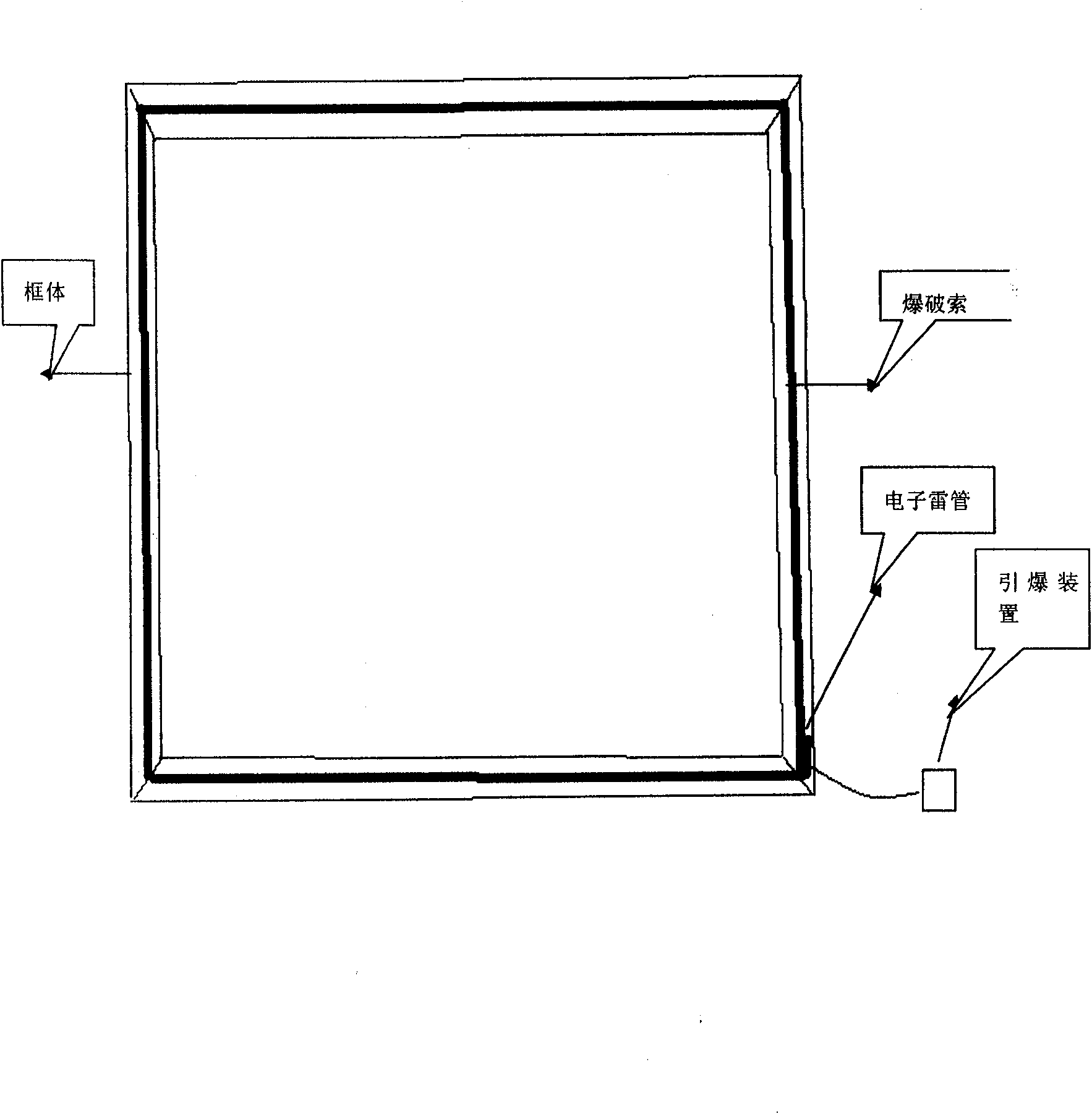

Door and window frame with explosion device

InactiveCN101649710ASafe escapeNo additional destructive powerBlastingSealing arrangementsEngineeringSTI Outpatient

The invention relates to a door and window frame device which has an explosion function, can be used under the conditions of emergency escape, and the like, can explode a door plate or window glass inthe frame momentarily to escape and is widely used for various buildings and vehicles. A circular groove or a hole is arranged in the middle of the frame body of the door and window frame or the selfmaterial of a seal strip, an explosion cable is inlaid into the circular groove or the hole, the device comprises one or a plurality of micro explosion electronic exploders which are connected with the explosion cable, and an electronic exploder leading wire is communicated to a special explosion device of an emergency control device. The door and window frame can separate the door and window frame body and a fixed object momentarily in an emergency and obtain valuable escape time for people to escape in dangerous environment. Because the electronic exploders are adopted to carry out double-code explosion and different specifications of charging explosion cables, the door and window frame device can safely deviate fixed objects made of different materials from the door and window frame body, can not generate excess destructive power and is a safe and effective novel emergency door and window device.

Owner:高浩钧

Micro-explosion soil remediation method

InactiveCN104275344AAchieve the purpose of repairContaminated soil reclamationAmbient technologyFenton reagent

Belonging to the environmental technology field, the invention provides a micro-explosion soil remediation method, which enables a soil remediation agent to rapidly and fully disperse into polluted soil. Commonly used soil remediation chemicals include oxidizing agents and reducing agents, like potassium permanganate, low concentration hydrogen peroxide, a Fenton reagent, iron powder, surfactants and a variety of composite remediation agents. The micro-explosion soil remediation method aims to enhance the dispersion sufficiency and dispersion speed of chemicals in soil, enable rapid and full dispersion of chemicals into polluted soil and achieve a high degree of dispersion. The remediation method is especially suitable for conditional in-situ soil remediation engineering.

Owner:ESD CHINA LTD

Automatic dish-washing machine

The invention relates to the kitchen ware field, in particular to an automatic dish-washing machine. The automatic dish-washing machine comprises a shell body, a high pressure water pump, a water injection nozzle, an ultrasonic generator and a rotary containing basket set, wherein the high pressure water pump, the water injection nozzle, the ultrasonic generator and the rotary containing basket set are located inside the shell body; the water injection nozzle is connected with the high pressure water pump; the water injection nozzle faces towards the containing basket set. Since the ultrasonic generator is arranged inside the automatic dish-washing machine, ultrasonic waves generated by the ultrasonic generator generate intense micro explosions and shock waves when passing through a liquid medium, and the micro explosions and the shock waves damage dirt on the surface of tableware and make the dirt be removed from the cleaned surface. Since the ultrasonic waves can penetrate through solid matter to make the whole liquid medium vibrate and generate cavitation bubbles, the cleaning method is free of dead corners which cannot be cleaned. After the automatic dish-washing machine is connected with a tap water pipe, tap water is pressurized by the high pressure water pump and then ejected from the water injection nozzle to the containing basket set which contains the tableware, the containing basket set keeps rotating, the high-pressure tap water is ejected to the tableware and then ejected back so as to remove fallen oil dirt, as a result, dead corner positions of the tableware are cleaned, and an excellent cleaning effect is achieved.

Owner:黄和昌

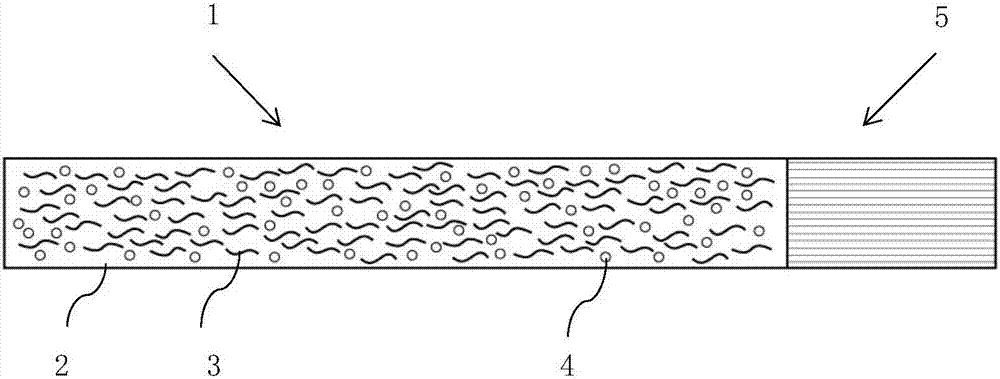

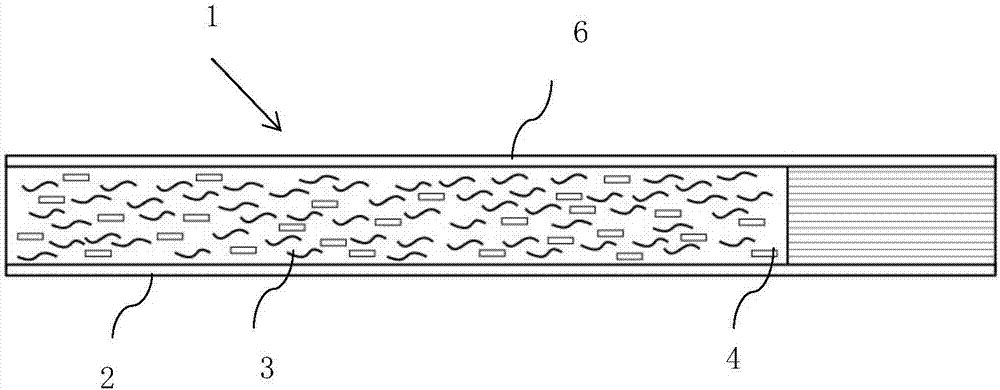

Micro-explosion micro-capsule for smoke product and smoke product including same

The invention discloses a micro-exploitation micro-capsule for a smoke product and a smoke product including the same. The micro-explosion micro-capsule can be filled into a smoke product body and is formed by a capsule wall and aerosol generation substance; when the smoke product burns, the temperature of a fervor combustion area enables the aerosol generation substance of the micro-explosion micro-capsule around the combustion area to vaporize, until the micro-capsule explode and occur fusion deformation; and aerosol produced by the aerosol generation substance can be spilled out form the capsule wall. The combustion material in the smoke product body can be carbonaceous fuel free of nicotine; the micro-explosion micro-capsule can be filled into the smoke product; and safe smoke products can be provided for smokers.

Owner:韩力

Cleaning agent for gasoline system

InactiveCN102108310AEmission reductionReduce pollutionLiquid carbonaceous fuelsFuel additivesCombustion chamberPreservative

The invention relates to a new cleaning agent for a gasoline system and belongs to the technical field of fuel additives. The cleaning agent for the gasoline system, which is provided by the invention, consists of a cleaning dispersant, a nano micro-explosion component, an antioxidation stabilizer, a preservative, an antifriction protective agent, a basic solvent and other components. The cleaning agent is treated by a microencapsulation process. The cleaning agent for the gasoline system can be used in gasoline engines to clean pollutants generated in combustion and deposits in oil paths and combustion chambers so as to save oil, protect environment and maintain automobiles.

Owner:北京红豪特高科技发展有限公司

Light-triggered tattoo process

A light-triggered tattoo process. A strong absorber of light energy and tattoo material are sandwiched under pressure between a skin region and a transparent window. Short pulses of light, at frequencies strongly absorbed by the strong absorber, illuminates the strong absorber through the window creating micro-explosions in the strong absorber that drive particles of the tattoo material into the skin region producing a tattoo.

Owner:TANG KENNETH Y +2

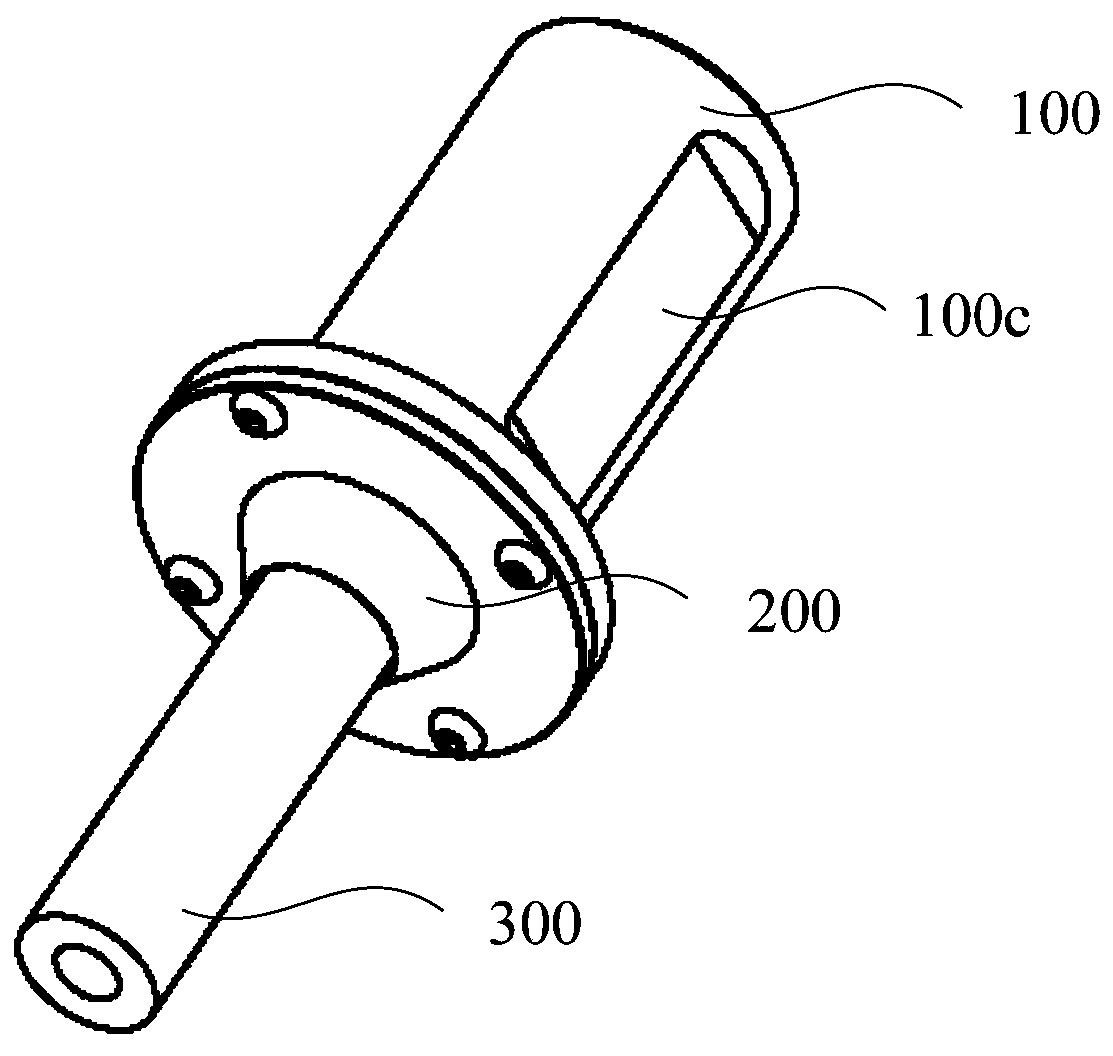

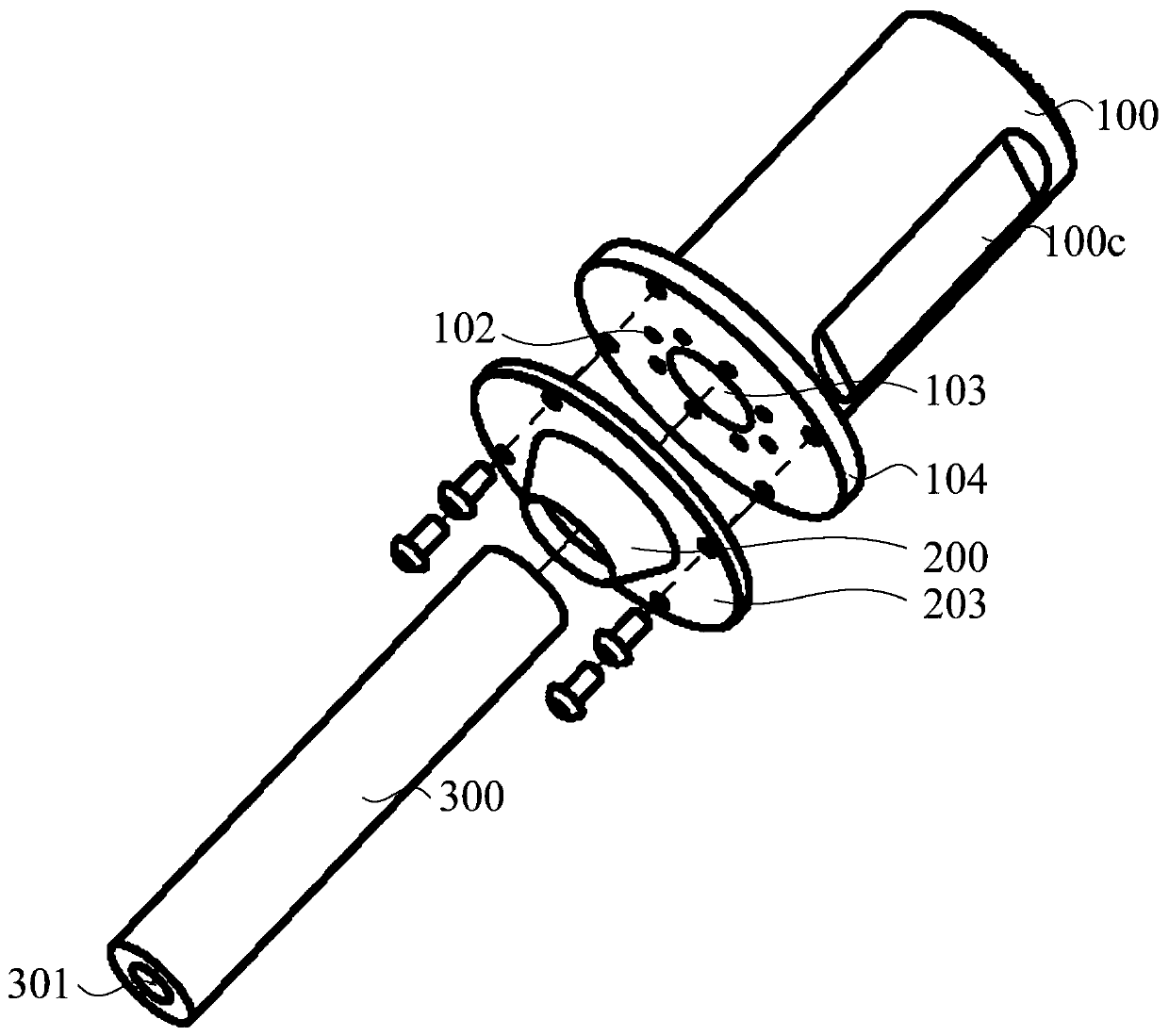

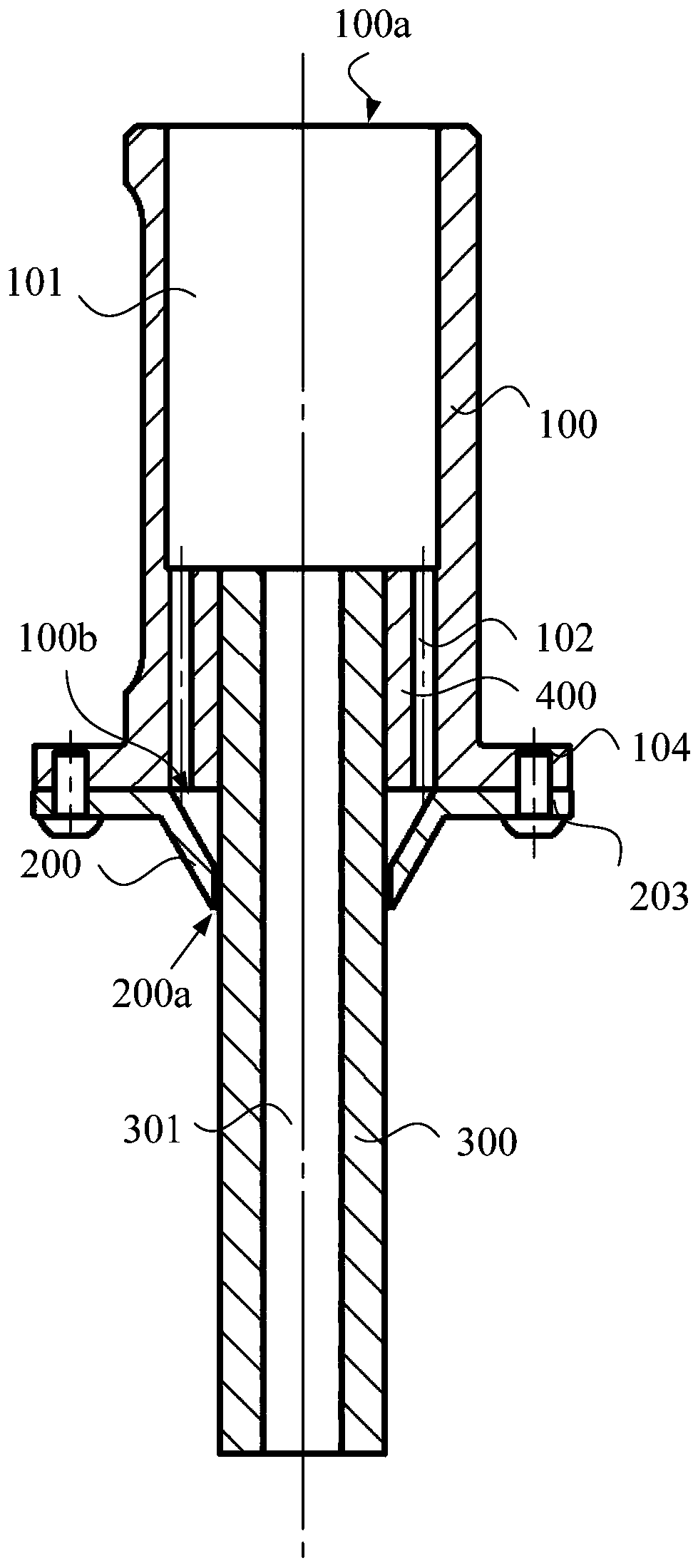

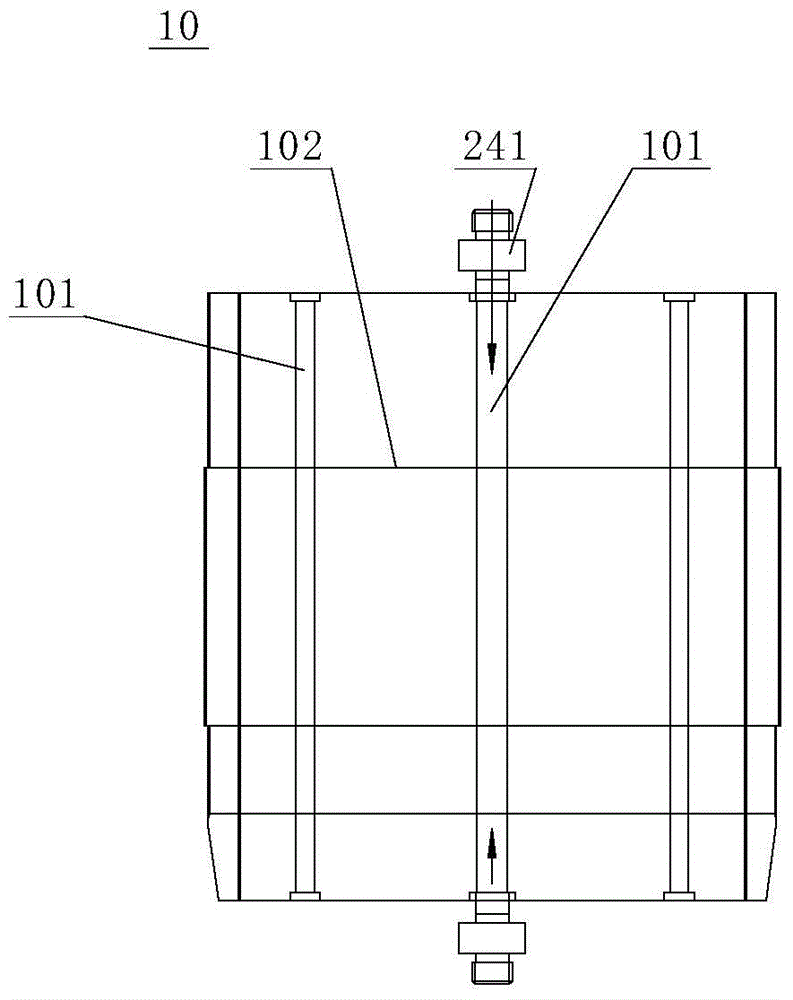

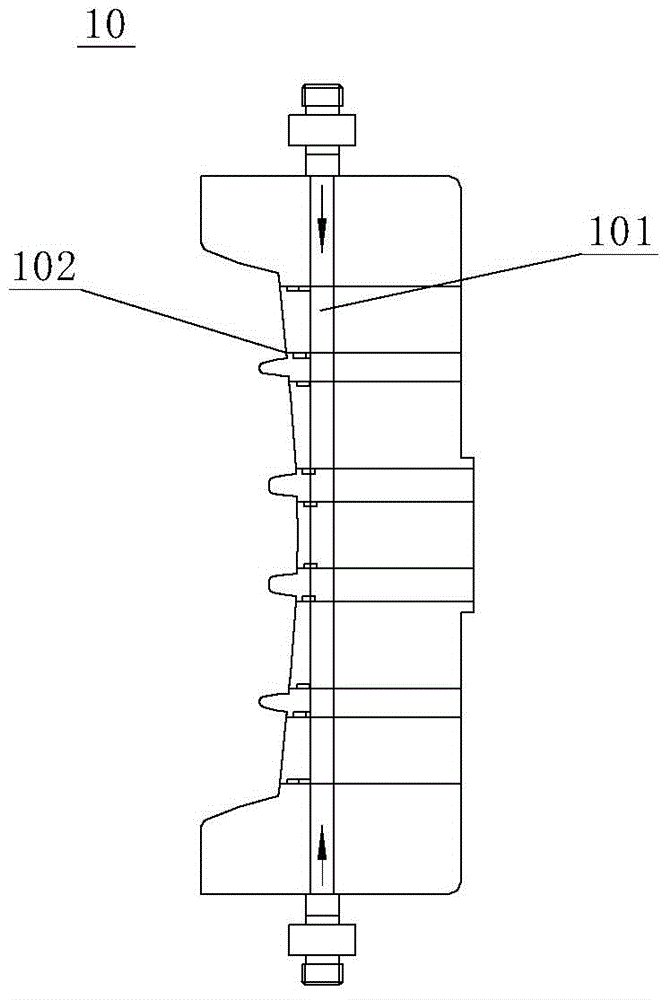

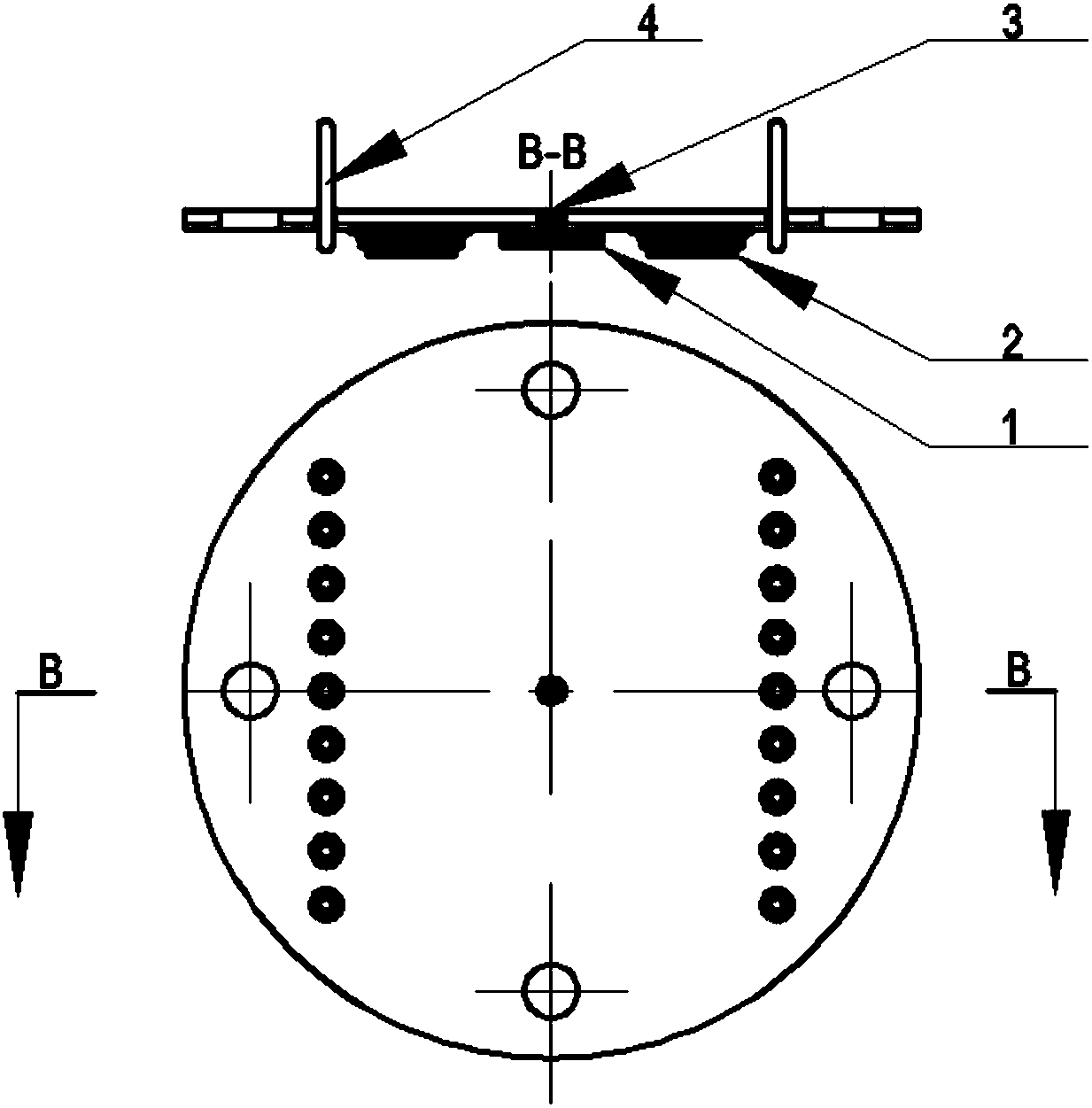

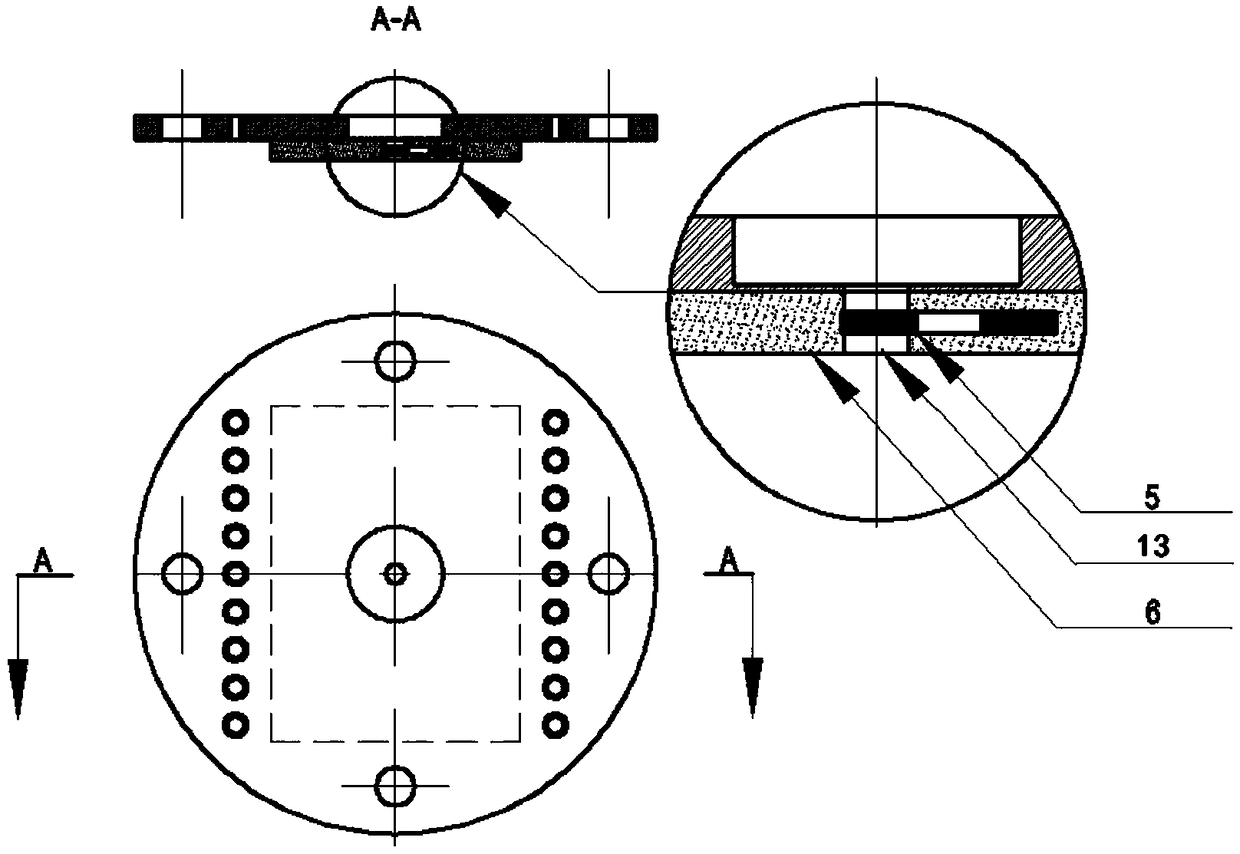

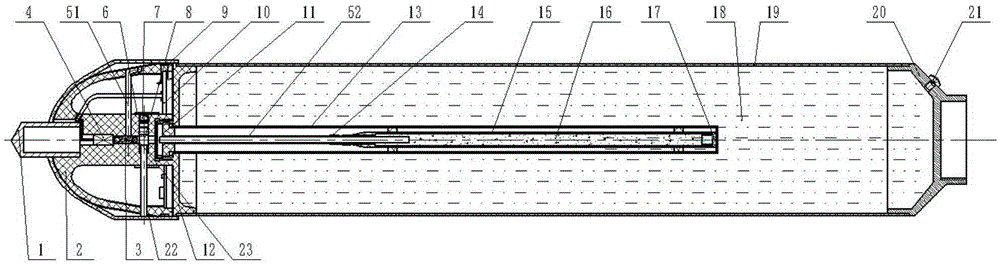

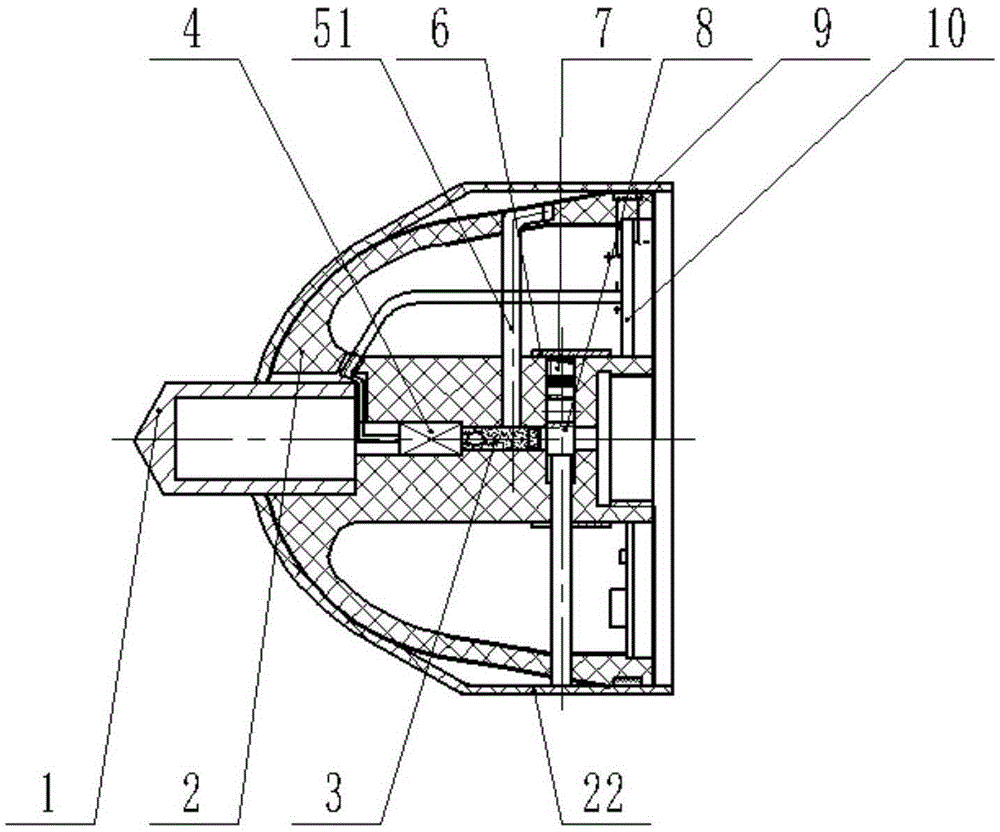

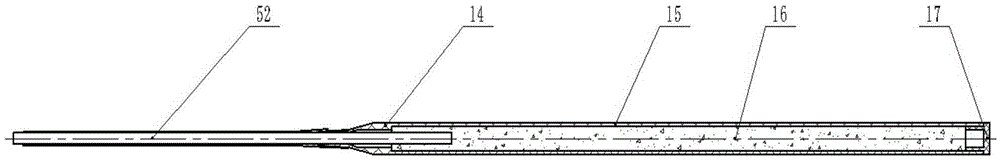

Electric arc micro-explosion internal and external flushing device and processing equipment

ActiveCN110238466ASimple structureGuaranteed supplyElectrical-based auxillary apparatusEngineeringMicro explosion

The invention discloses an electric arc micro-explosion internal and external flushing device and processing equipment. The electric arc micro-explosion internal and external flushing device comprises a knife rest body, a platform structure, a tool electrode and a liquid collecting cover. The knife rest body is provided with an inlet end and an outlet end which are oppositely arranged; the platform structure is fixed in the knife rest body, a liquid cavity is formed between the platform structure and the inlet end, a mounting channel is formed in the platform structure, and an outer flushing fluid channel is formed in the platform structure; the tool electrode is arranged in the mounting channel, an inner flushing fluid channel is formed in the tool electrode, one end of the inner flushing fluid flow channel communicates with the liquid cavity, and the other end of the inner flushing fluid flow channel penetrates through the tail end of the tool electrode; and the liquid collecting cover sleeves the periphery of the tool electrode, and one end of the liquid collecting cover communicates with the outer flushing fluid channel, the other end of the liquid collecting cover and the side wall of the tool electrode are enclosed to form an annular gap, and the minimum value of the total area of the cross section of the outer flushing fluid channel is larger than that of the annular gap. According to the technical scheme, the processing efficiency of arc micro-explosion processing is improved, and the processing effect is improved.

Owner:SHENZHEN AEROSPACE SCI ADVANCED MATERIALS CO LTD

Micro-explosion atomization oil gun

The invention discloses a micro-explosion atomization oil gun, belonging to the field of thermal energy power. The micro-explosion atomization oil gun comprises an oil interface, a gas interface, an oil chamber and a gas chamber, wherein the oil chamber is communicated with the oil interface; the gas chamber is communicated with the gas interface; the oil chamber is communicated with an inner tube; the gas chamber is communicated with an outer tube; flow mixers are arranged at the front ends of the inner tube and the outer tube; the flow mixers are communicated with the front end of the inner tube through a small copper pad; the flow mixers are communicated with the front end of the outer tube through an air pipe interface; the front ends of the flow mixers are connected with a premixing chamber through a larger copper pad; and an atomization head is communicated with the front end of the premixing chamber. The micro-explosion atomization oil gun has the beneficial effects of small automation granularity and combustion sufficiency, so that the combustion efficiency is increased, the combustion oil is saved, the pollutants in combustion products are reduced, and the automation head is unlikely to be blocked and coked.

Owner:徐州艾迪科技有限公司

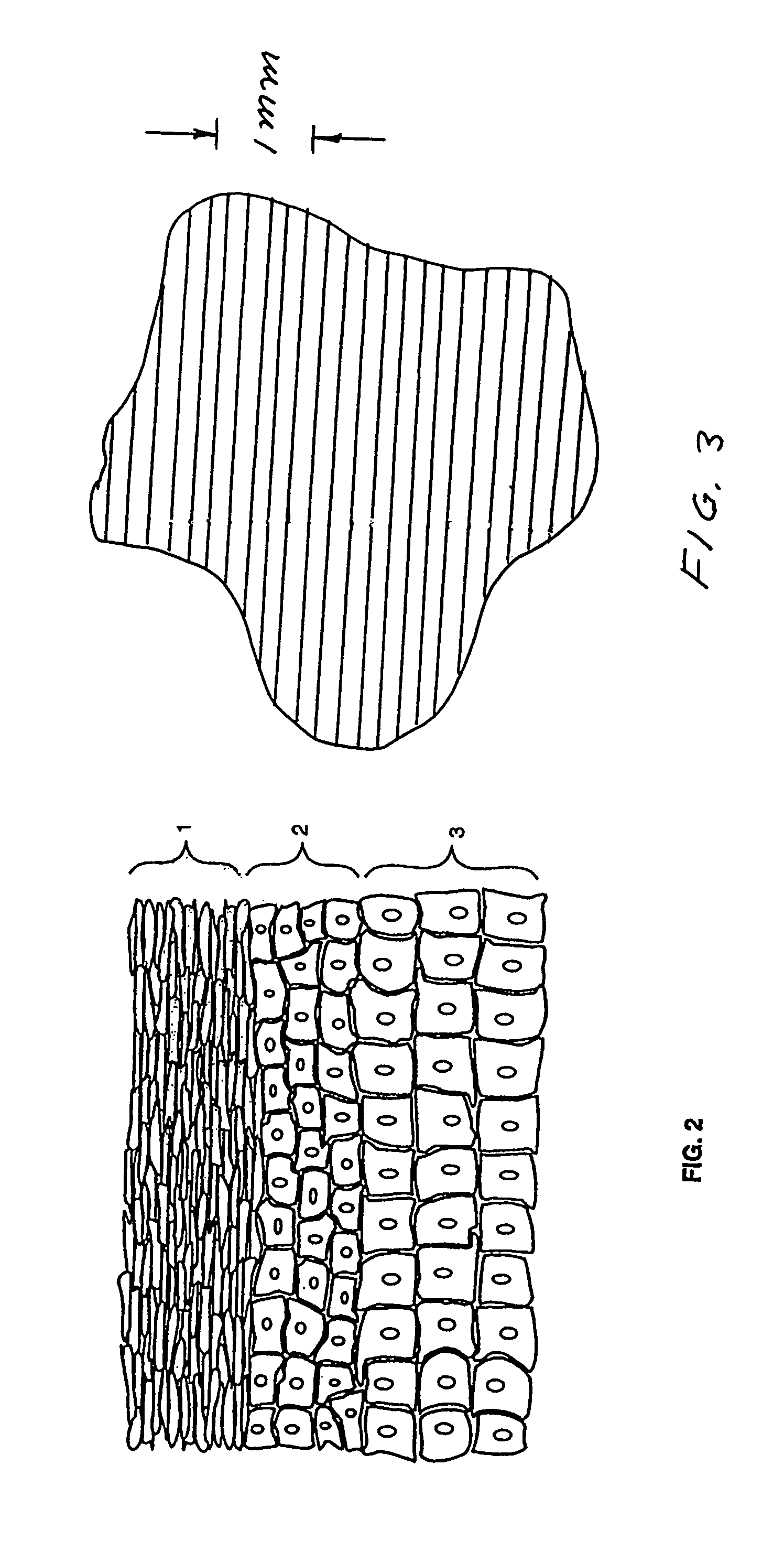

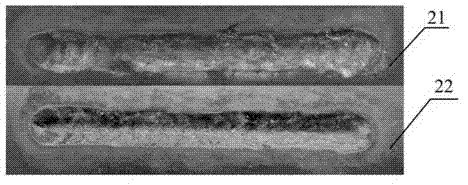

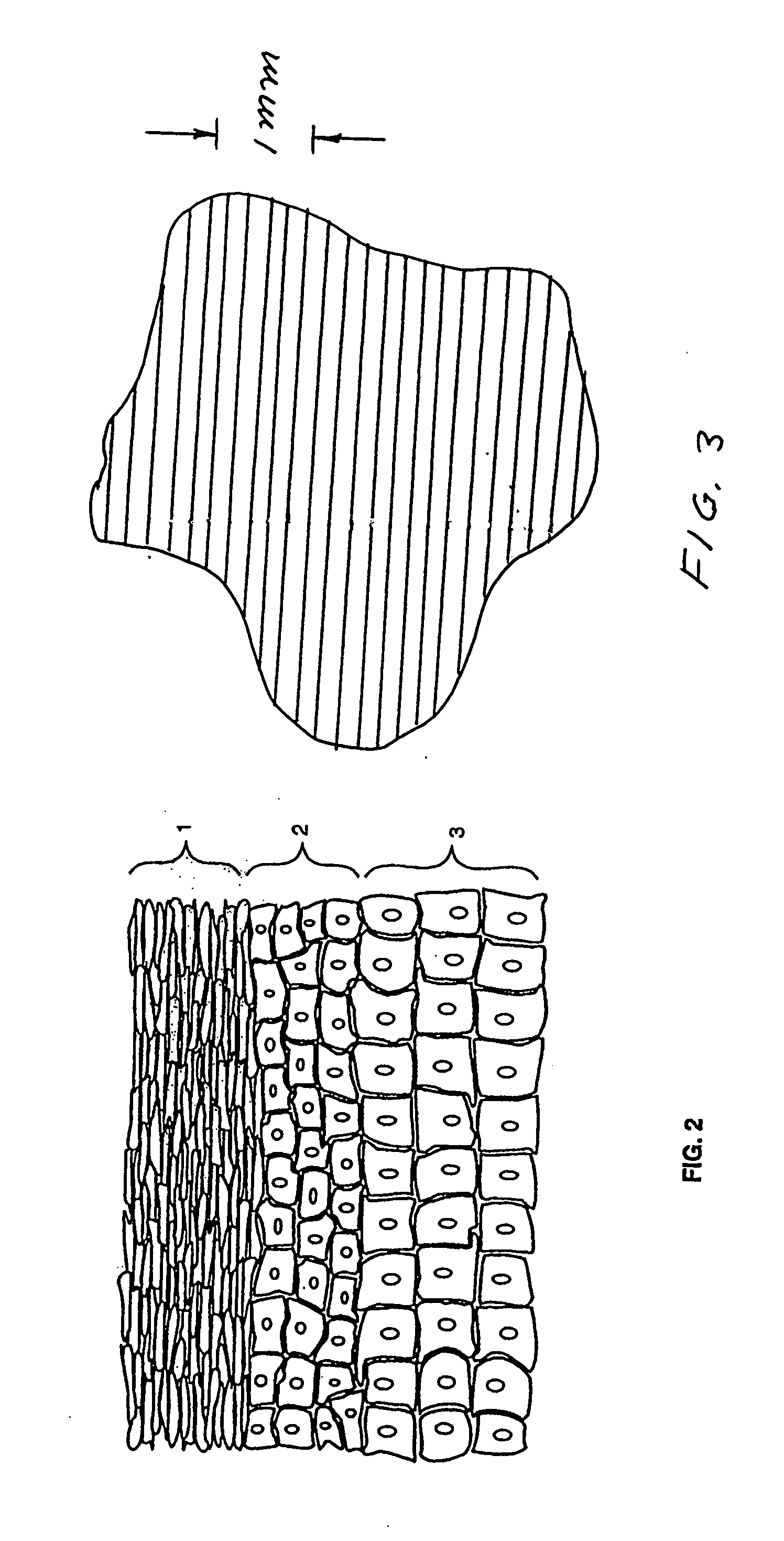

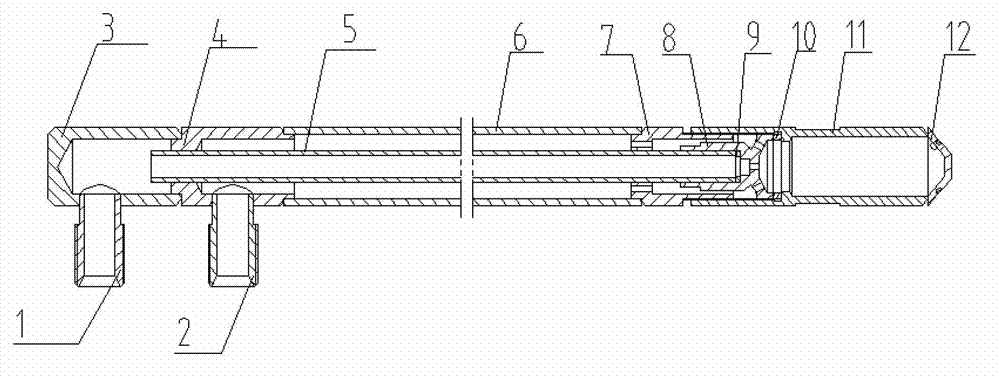

Method for utilizing micro-explosion of electrode striking arc to process engineering ceramics and device thereof

The invention relates to a method for utilizing the micro-explosion of an electrode striking arc to process engineering ceramics and a device thereof, and belongs to the technical filed of non-traditional machining. The method is that a micro-explosion bombardment wave generated by the electrode striking arc is used for being targeted at the surface of a ceramic workpiece; the surface of the ceramic workpiece is eroded to form a circular concave pit with 1-2 mm diameter and 0.01-1 mm depth, so as to realize the removal and the processing of the surface of the workpieces. The device comprises an air-compressor, a special impulse power supply, a numerical control three dimensions working table and a bombardment wave launcher, wherein, the compressed air output by the air-compressor is led into the inner cavity of the bombardment wave launcher through the cathode power supply duct of the special impulse power supply; the cathode of the special impulse power supply is connected with a core pole of the bombardment wave launcher; the anode of the special impulse power supply is connected with the nozzle of the bombardment wave launcher; and the nozzle of the bombardment wave launcher opens towards the table-board of the numerical control three dimensions working table. The invention has remarkable advantages of simple structure, low price, easy control on parameters, and capability of realizing the processing of a heteromorphic curved surface.

Owner:田欣利 +1

Multiple-effect fuel oil saving agent for assembling high-energy substance by nano water

InactiveCN101016478AImprove physical activityHigh calorific valueHydrocarbon oils refiningNitro compoundAlcohol

The invention discloses a multiple-effect fuel fuel-saving agent with nanometer water to assemble energetic material in liquid phase nanometer technical domain, which is characterized by the following: its oil-saving mechanism distinguishes with traditional additive; it chooses water (gasifying micro explosion function), energetic nitro group compound (energetic flame accelerating function) and polyatomic alcohol amine (dispersing modify function) as raw material; it produces fuel-saving agent through liquid phase nanometer technology.

Owner:孙文志

Nanometer heat-conducting water solution for use in car cooling system

InactiveUS7374698B2Speed up micro-explosionImprove cooling effectOther chemical processesMixing methodsLimescaleHeat conducting

A nanometer heat-conducting water solution for use in a car cooling system is disclosed. The nanometer heat-conducting water solution is formed by mixing a AlO2 solution (1.1 vol %) having 3-10 nanometer scale materials with a TiO2 solution (1.1 vol %) having 3-10 nanometer scale materials, wherein the obtained solution is then mixed with a diluent (93 vol %), and dispersing agents (3.43 vol %) and an emulsifying agent (1.37 vol %) are thereafter added so as to disperse the AlO2 solution and the TiO2 solution in the diluent uniformly. When the obtained stable nanometer heat-conducting water solution is added to a water tank of the car, the TiO2 cleans limescale and the emulsifying agent adheres to wall surfaces of water jackets to allow AlO2 to release energy continuously. Moreover, the nanometer scale materials speed up the micro-explosion of the cooling water so as to optimum the cooling effect and increase the heat-dispersing efficacy significantly.

Owner:WU CHING JUNG

Preparation method of modified cellulose insulating paper

ActiveCN108505374APromote productionGood for condensationPulp beating methodsPaper/cardboardSilanesHigh pressure

The invention relates to a preparation method of modified cellulose insulating paper, and belongs to the technical field of preparation of insulating materials. The preparation method comprises the steps of: firstly adopting micro-explosion to generates a pressure difference inside fiber during pressurization and instantaneous pressure releasing under the condition of maintaining intrinsic physical mechanical properties and complete appearance of birch fiber so as to form high-pressure airflow which impact from inside to outside inside the birch fiber, destroying cell walls, pit membranes andother weak tissue of the birch fiber so as to achieve preliminary fiber degradation, then mixing the obtained fiber after preliminary fiber degradation is conducted with tartaric acid, performing cooking at high temperature and high pressure, carrying out beating and oxidizing to obtain modified paper pulp, then utilizing a reaction of sodium silicate, hydrochloric acid and aminopropyl triethoxy silane so as to prepare modified nano silica, mixing the modified nano silica with the modified paper pulp, then carrying out papermaking, and performing a hot pressing reaction to obtain the modifiedcellulose insulating paper. The obtained insulating paper has good insulation performance, high mechanical strength and a broad application prospect.

Owner:江苏源清环保科技有限公司

High-fuel-efficiency biomass fuel

The invention relates to a high-fuel efficiency biomass fuel, and belongs to the field of fuels. According to the invention, octenyl succinic acid modified starch and bacterial cellulose are taken aswall materials, the surface of the wall materials is densified, so that the loss of effective ingredients in the processes of preparation and storage is effectively avoided, the effects of promoting combustion and improving fuel efficiency are achieved, the heat conductivity of the structure of the wall materials is improved; heat can be rapidly led into the inner part in the use process, and micro-explosion occurs to a micro-capsule structure; the occurrence of the micro-explosion, on one side, causes thermoresonance and produces secondary energy, so that the fuel can be completely burned rapidly at high temperature, and the fuel efficiency is further improved; the volume of magnesium oxide expands and shrinks in the use process, so that inner pores and melt materials in a system are redistributed, the excessive expansion of the volume of the fuel is avoided in the combustion process, and the product porosity is also effectively maintained. The invention solves the problems of low combustion efficiency and low use ratio of the current commonly-used biomass fuel.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

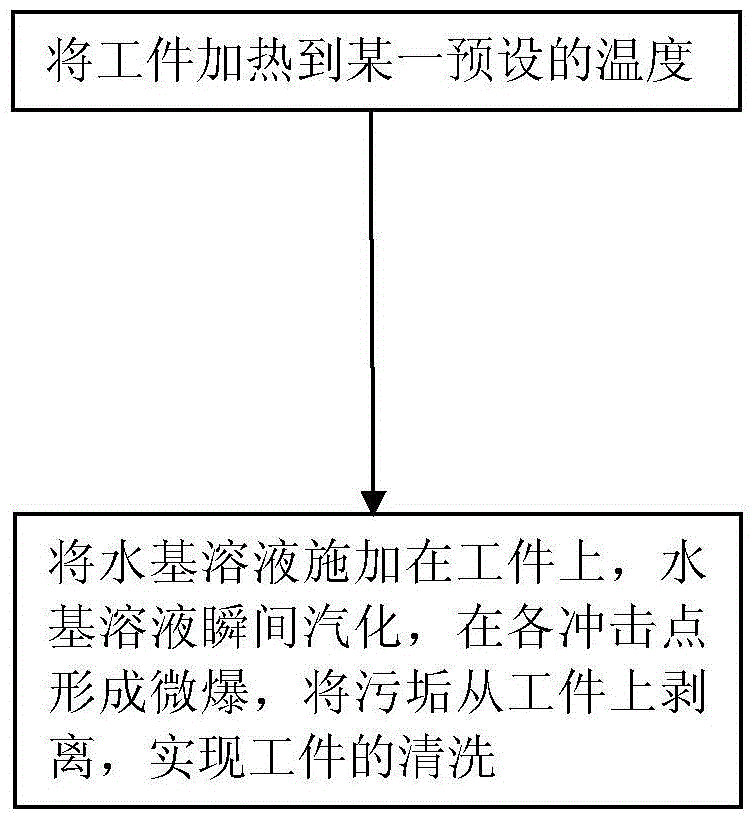

Method and equipment for cleaning workpiece and method and equipment for cleaning tire loose die

The invention provides a method and equipment for cleaning a workpiece and a method and equipment for cleaning a tire loose die. The method for cleaning the workpiece comprises the steps that the workpiece is heated to a preset temperature; and a water-based solution is applied to the workpiece and is instantly vaporized, micro explosion is formed at all impact points, dirt is stripped off from the workpiece, and the workpiece is cleaned. The equipment for cleaning the workpiece comprises a heating device and a cleaning device. The heating device is used for heating the workpiece to a preset temperature range. The cleaning device is used for applying the water-based solution to the workpiece, enabling the water-based solution to be vaporized instantly to form micro explosion at all the impact points, stripping off of the dirt from the workpiece and cleaning of the workpiece. Dirt on the surface of the workpiece can be cleaned off, and great breakthroughs are obtained in cleaning of micron-order or nano-scale clearances of the workpiece; and the beneficial effects that the cost is low, cleaning is easy, and dirt is thoroughly removed are achieved.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Method for promoting gradation landslide of landslide mass by adopting active manner

ActiveCN110029679AEliminate potential safety hazardsEnsure safetyExcavationsSoil preservationLandslideBlowing agent

The invention discloses a method for promoting gradation landslide of a landslide mass by adopting an active manner. The method comprises the following steps that 1, the location of each part of a landslide is determined; 2, zoning processing is conducted, specifically, according to the size of the landslide mass on a landslide bed, the landslide mass is divided into a plurality of sliding zone masses in the landslide direction; 3, holes are drilled; 4, an edge sliding zone mass slides off, specifically, one or more combinations of micro-explosion induction, water explosion induction, foamingagent application induction, high-pressure gas injection induction and non-contact induction are adopted for the holes drilled in the step 3, and thus the edge sliding zone mass slides off the landslide bed; and 5, the step 4 is repeated, and each adjacent sliding zone mass slides off the landslide bed one by one. According to the method for promoting gradation landslide of the landslide mass by adopting the active manner, the problem that existing prevention methods cannot eliminate potential safety hazards of the landslide mass can be solved, and the safety hazards are eliminated in time bythe gradation induction landslide.

Owner:CHINA THREE GORGES UNIV

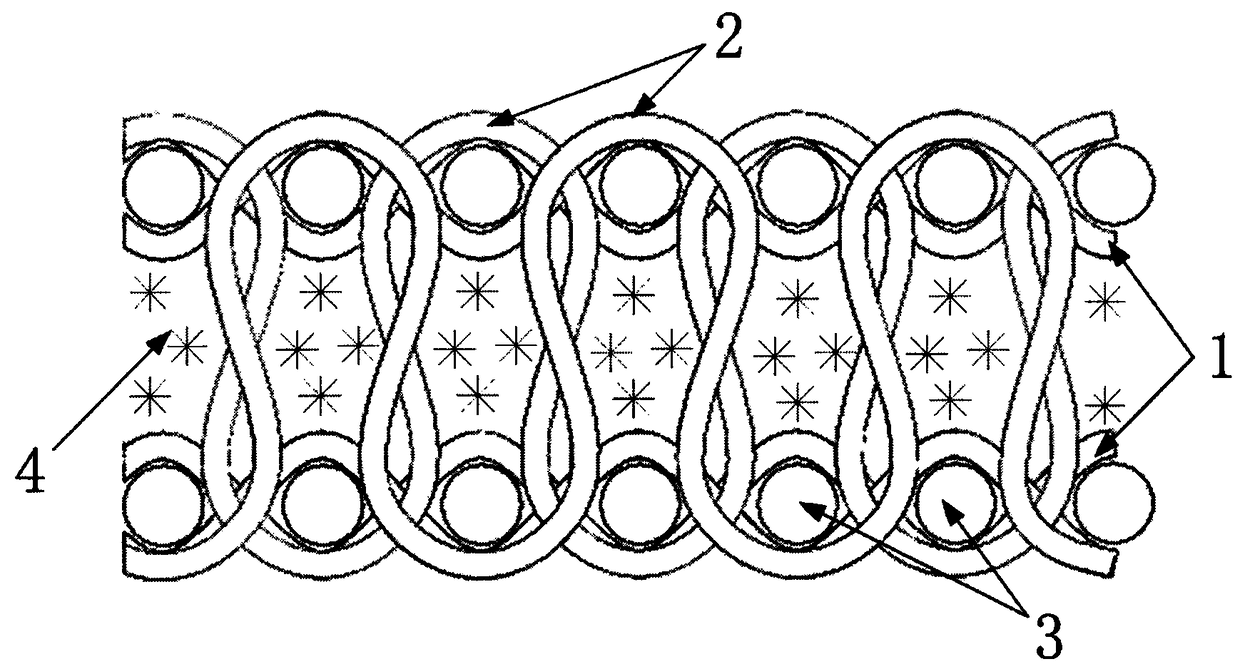

Filtering fabric having three-dimensional structure and preparation method thereof

InactiveCN108159781AStable structureLight in massMembrane filtersWoven fabricsDecompositionEngineering

The invention discloses a filtering fabric having three-dimensional structure and a preparation method thereof. The fabric comprises an upper surface yarn layer and a lower surface yarn layer composedof warp yarn and weft yarn, and a spacing layer composed of interval yarn between the upper surface yarn layer and the lower surface yarn layer, and a part between the spacing layer as well as the upper surface yarn layer and the lower surface yarn layer is filled with a filtering material. The preparation method comprises the following steps: weaving the upper surface yarn layer and the lower surface yarn layer, wherein each surface yarn layer comprises two layers of warp yarn and a layer of weft yarn, then employing two groups of spacing yarns for mutual interlacing, binding the upper surface yarn layer and the lower surface yarn layer to form an integral body; weaving a hollow spacing layer with the filler, after weaving, immersing the three-dimensional fabric in a mixed solution of araising agent and a compatilizer, performing immersing of the mixed solution in the filler for decomposition to generate the foams having micro explosion effect, gradually loosening and swelling the structure of the filler to fill the whole three-dimensional hollow structure, and obtaining the filtering fabric having three-dimensional structure. The three-dimensional interval fabric is taken as aframe support material, and provides an accommodation space and mechanical support for a fluffy carbon tube material.

Owner:DONGHUA UNIV

Spraying type dust blower

ActiveCN110857775AAvoid the problem of not being able to install the sootblowerPrecise positioningSolid removalSprayerSlag

The invention discloses a spraying type dust blower. A spraying pipe box and a travelling device for driving the spraying pipe box to travel front and back and left and right are included. The spraying pipe box is internally provided with a spraying hose wound around a hose rotation disc, a detection system, a guiding system and a cooling system. After sequentially passing through the systems, thespraying hose is output from a hose outlet in the bottom of the spraying pipe box and conveyed into a hearth which is about to be subjected to dust cleaning. High-pressure water sprayed out of a sprayer at the lower end of the spraying hose conducts strong cold-heat exchange with high-temperature caking slag on a high-temperature screen type overheater, the second flue film type wall heated faceand the third flue film type wall heated face within the purging range, accordingly, micro explosion happens to the caking slag position, the caking slag is cracked and falls off on the heated faces under the micro explosion action, and accordingly the effects of dust cleaning and slag removal are achieved.

Owner:WUHAN SANYU MACHINE CO LTD

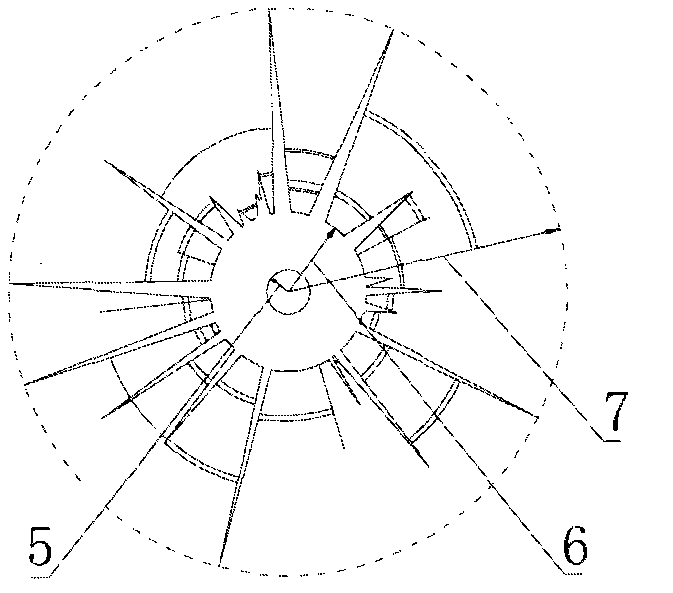

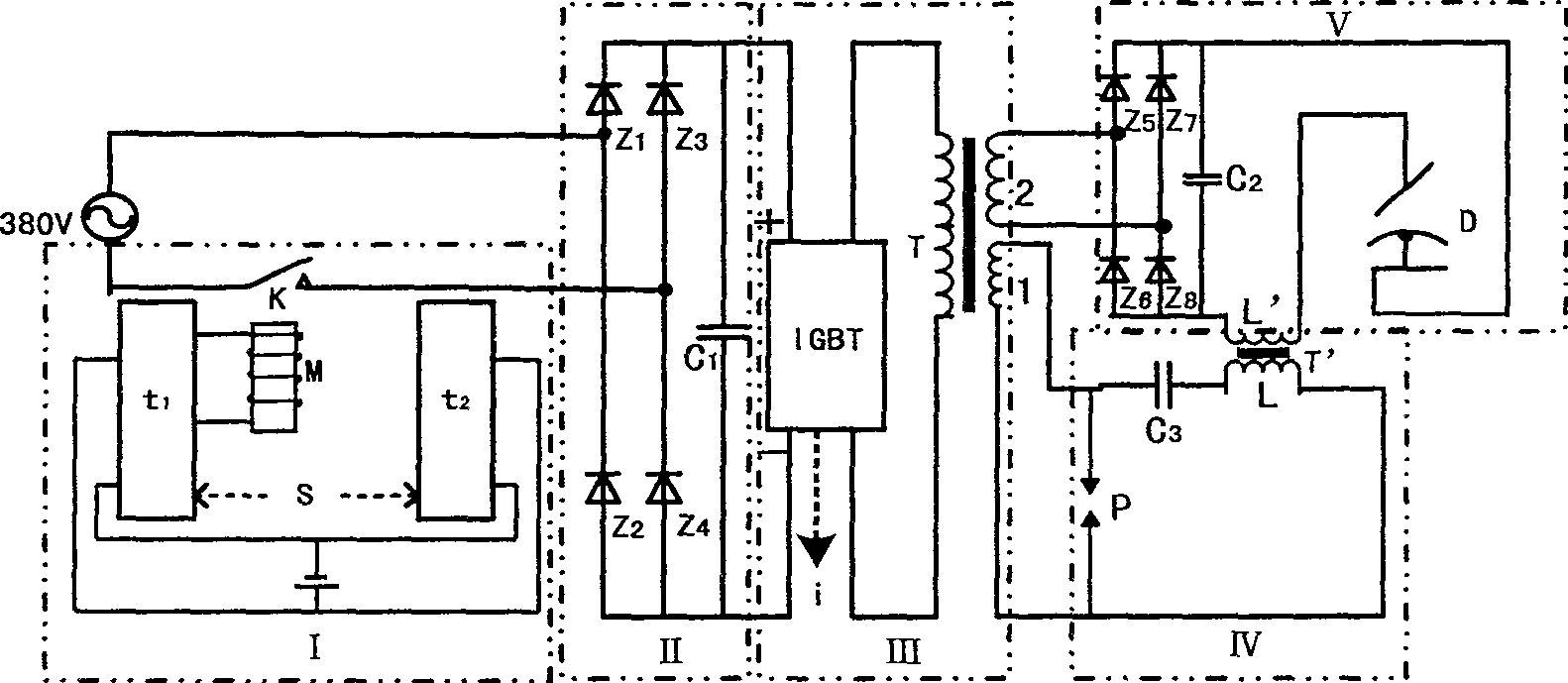

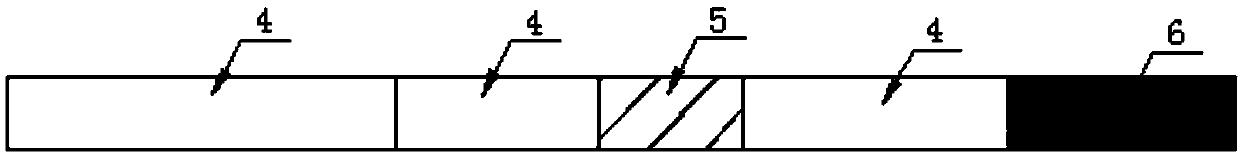

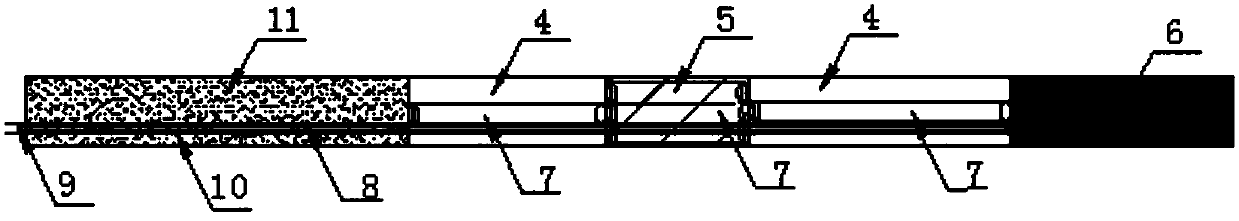

Micro-electro-mechanical system intelligent security explosion initiation device and preparation method thereof

PendingCN108592707AMeet needsWith anti-electromagnetic interferenceBlasting cartridgesElectromagnetic interferenceEngineering

The invention discloses a micro-electro-mechanical system intelligent security explosion initiation device and a preparation method thereof. The micro-electro-mechanical system intelligent security explosion initiation device comprises an explosion initiation system and a packaging shell. The packaging shell is arranged on the outer side of the explosion initiation system in a cladding manner to package the explosion initiation system. The explosion initiation system comprises a micro explosion initiation chip unit, a micro security unit, an initiation chemical and a contact pin. The micro explosion initiation chip unit and the micro security unit are connected through the contact pin to form an electric signal channel. The micro explosion initiation chip unit is arranged below the micro security unit. The initiation chemical is installed on the back side of the micro explosion initiation chip unit. Because a micro explosion initiation and explosion propagation sequence based on an in-situ micro chemical loading technology, and the micro security chip based on the MEMS technology are adopted, and a technology of ultra-thin flattening chip inlaid design is adopted, the micro-electro-mechanical system intelligent security explosion initiation device has the characteristics of being micro, intelligent, and resistant to overload and electromagnetic interference.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

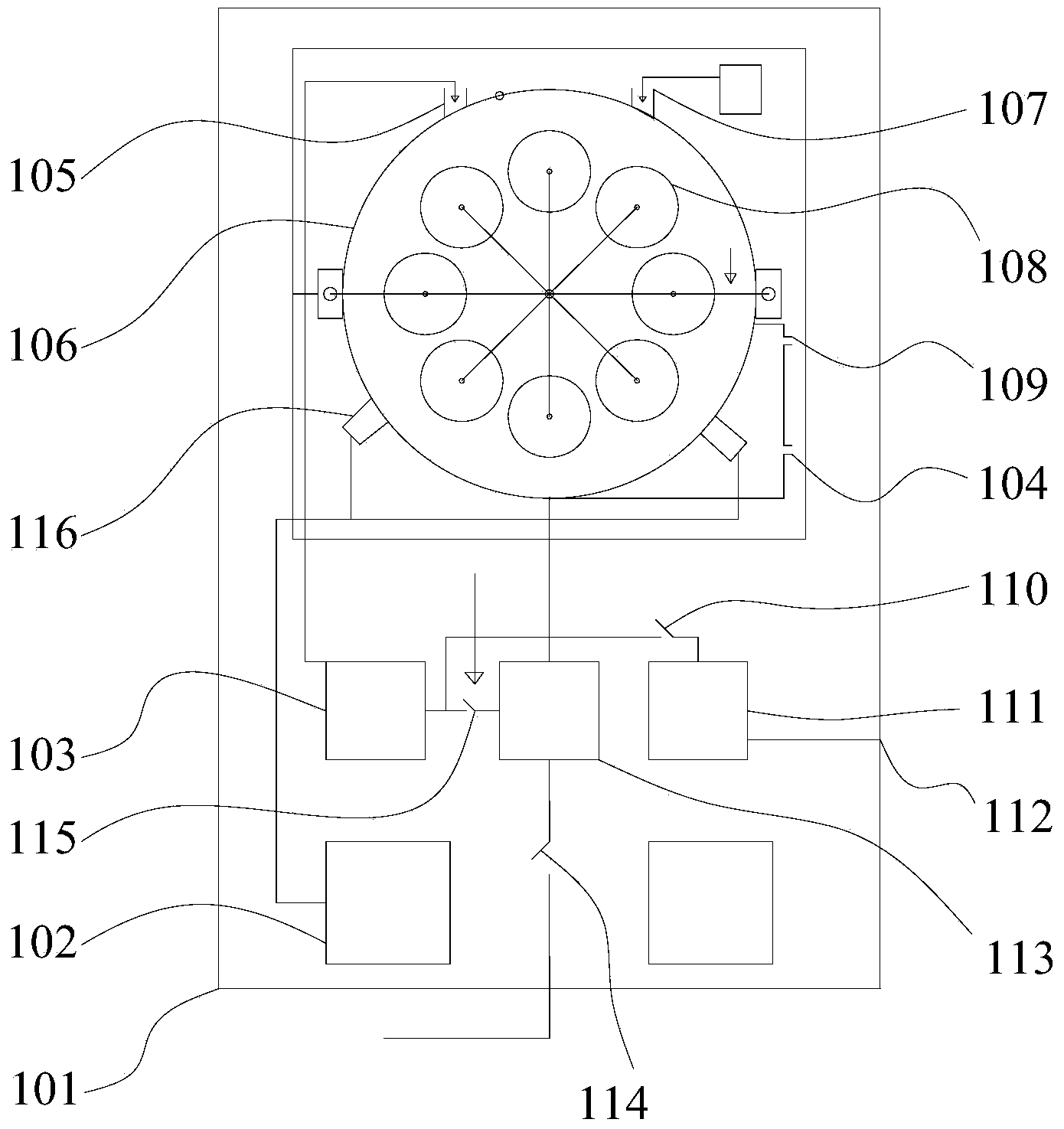

Acting part of water-based fire extinguishing bomb

ActiveCN105423828AReduce harmIncrease burn rateAmmunition projectilesFire rescueWater basedElectricity

The invention discloses an acting part of a water-based fire extinguishing bomb. The acting part comprises a detonating device and a bomb body device, wherein the detonating device comprises an impact head and a head screw; an explosive jar, an electric igniting head, an external ignition line, a secondary induction coil, an igniting control printed board and an insulation mechanism are arranged in the head screw; the secondary induction coil, the igniting control printed board and the electric igniting head are connected to achieve an electric detonating manner; the bomb body device comprises a central fixing tube, a micro-explosion throwing and spreading device, and a housing of which the two ends are provided with openings; the micro-explosion throwing and spreading device comprises an inner ignition line, a limiting hose and an explosive tube; the micro-explosion throwing and spreading device is positioned in the central fixing tube; one end of the central fixing tube is fixed to the opening of a front blocking cover through a pressing screw while the other end of the central fixing tube extends into the housing. According to the acting part of the water-based fire extinguishing bomb, the micro-explosion throwing and spreading structure is adopted, so that broken pieces can fly within a short distance after explosion, and the safety can be improved; an impacting and electric detonating manner is achieved in the detonating device, so that all launched fire extinguishing bombs can be detonated and exploded; the insulation mechanism is arranged and can greatly improve the safety of the fire extinguishing bombs during a storage process.

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

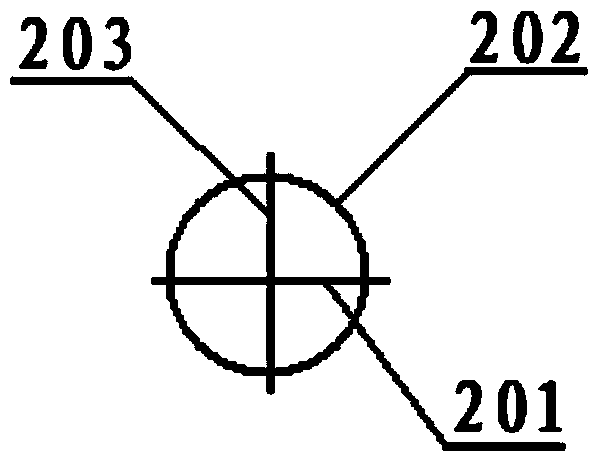

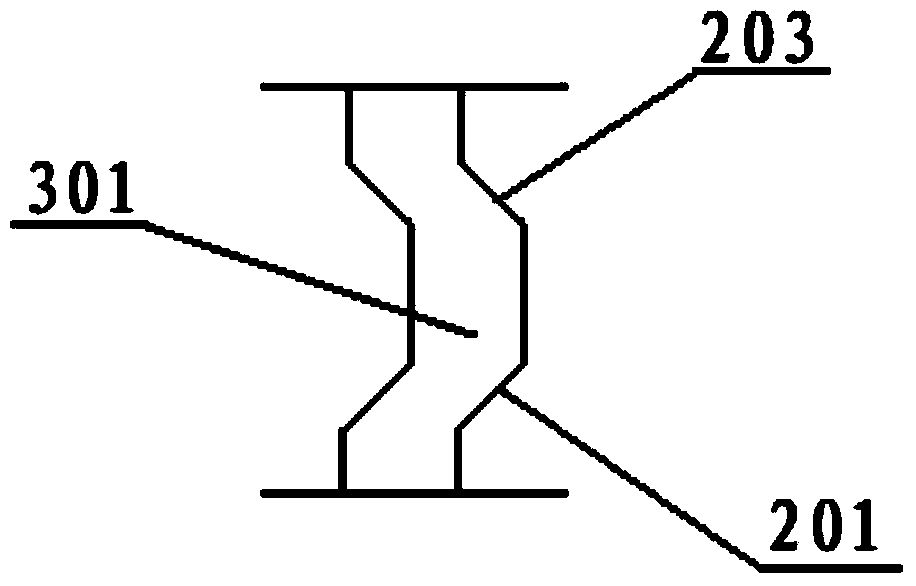

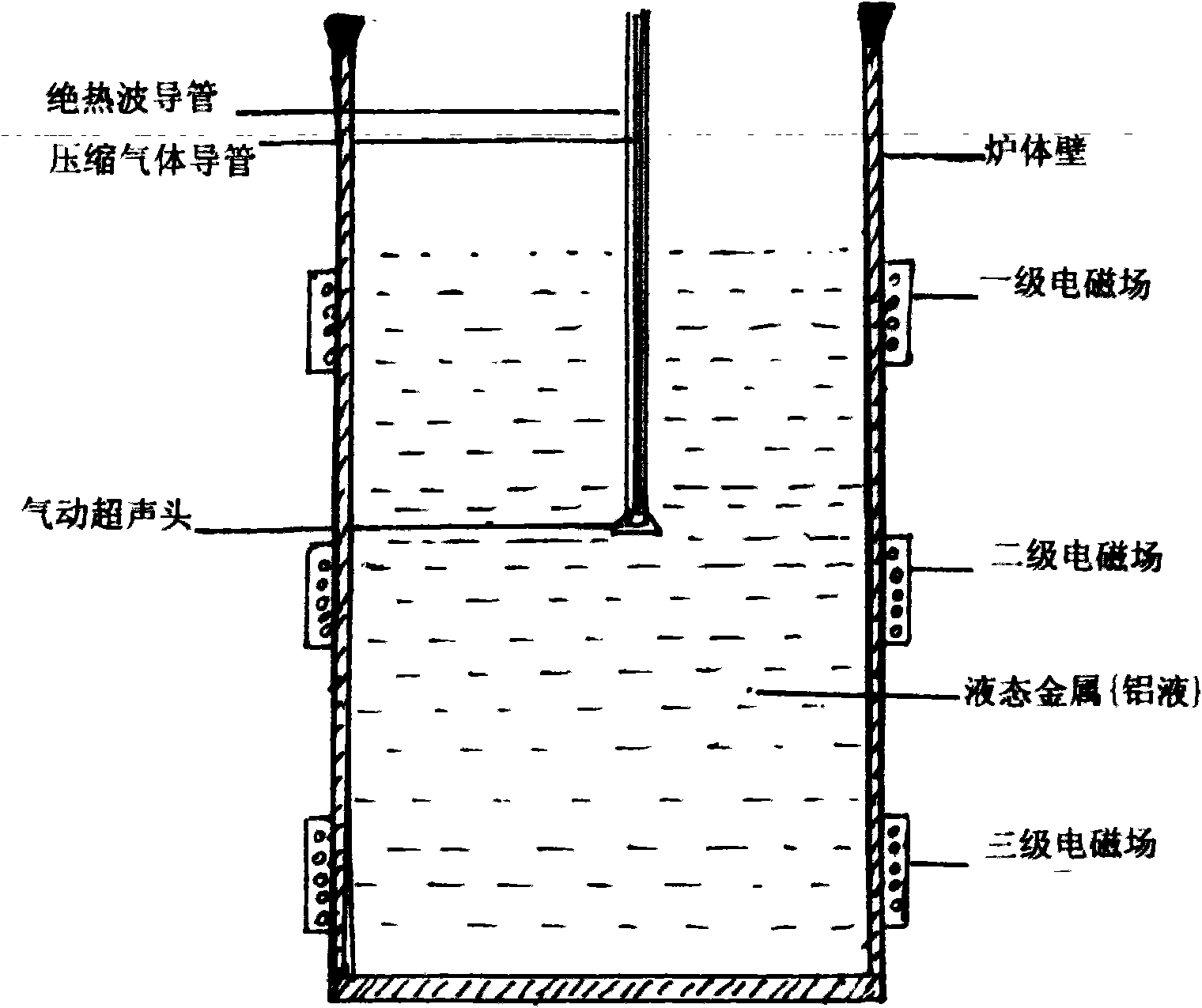

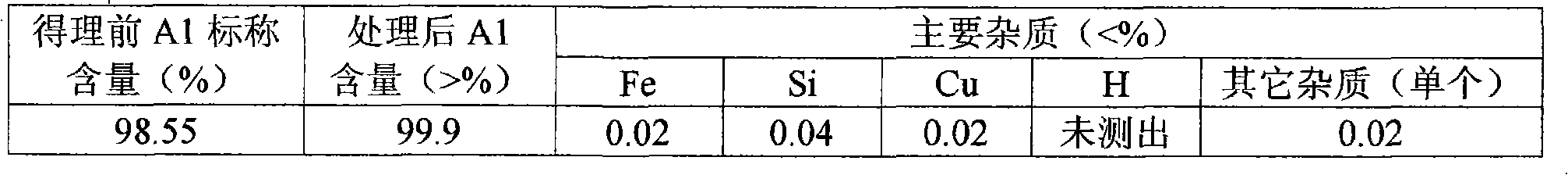

Application of ultrasonic and rotary electromagnetic field in aluminium melting refining

The invention discloses a physical synthesis field method of an ultrasonic and rotary electromagnetic field, which is used for smelting, purifying and dehydrogenating metal, removing metal impurities and non-metallic inclusions and improving metal crystal refinement so as to produce high-purity metal. In an impurity removing process, dielectric is not added, chlorine which is used for dehydrogenation is not communicated or fluorine-containing substances are added. In an aluminium melting refining purification experiment, the efficiency of the method is confirmed, and the device of the method is the ultrasonic and rotary electromagnetic field. The method is a synthetic physical field technology of a micro-explosion technology and a multidimensional layered continuous spiral line transient reversing vortex technology and is characterized in that the controllable layered large dispersity, the strong potential energy, the small-diameter bubble compression field and the gas explosion body trapping are used in metal (aluminum) liquid, and the functional effects of molecular collision, resonance, autorotation, glomeration, and the like are used. The method has high impurity removing speed, good effect and no pollution, saves energy and does not have an external publication report in the metal melting refining purification experiment.

Owner:梁保胜

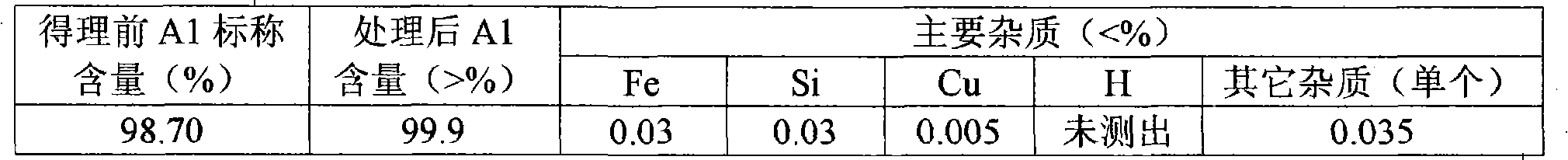

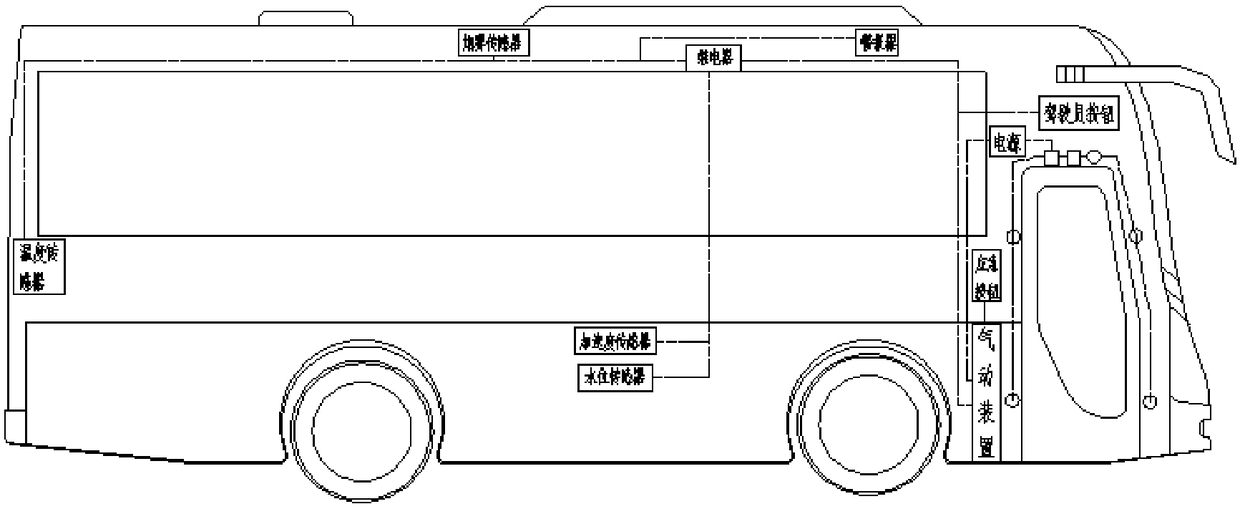

Multifunctional car door micro-explosion system

ActiveCN108407747APromote escapeSmall structural deformationPedestrian/occupant safety arrangementSignalling/lighting devicesStructural deformationControl system

The invention discloses a multifunctional car door micro-explosion system. When an emergency situation such as a fire, collision, falling into water or falling off a cliff occurs in a passenger car, adoor of the passenger car cannot be opened, and the micro-explosion system is triggered to act to open the door. The system is provided with a second set of mechanical door opening device. At the same time, an own two-way hydraulic damping device of the system can absorb part of energy of front impact and reduces structural deformation of the car. When a vehicle-mounted sensor detects the emergency situation or a driver presses a door opening button, a door opening system is operated and a car door sensor detects whether the door is open or not. When the door fails to open, the micro-explosive device is triggered to act to assist the door to fully open. When a control system of the micro-explosive device fails, the driver and passengers can open the door by operating a mechanical device.The multifunctional car door micro-explosion system can ensure the passengers to escape quickly, and the advantages of reliable escape and high realization are achieved.

Owner:CHANGAN UNIV

Construction technology for huge isolated boulders of alluvial granite in diaphragm wall construction

ActiveCN107702604AFast constructionFlexible construction organizationBlastingEngineeringGeological exploration

The invention discloses a construction technology for huge isolated boulders of an alluvial granite in diaphragm wall construction. The technology comprises the steps of drilling preparation, drillingdevice selection, hole diameter determination, advanced coaxial drilling, geological exploration and isolated boulder accurate blasting. According to the blasting design of the technology steps, accurate positioning and blasting of large isolated boulders can be realized, and meanwhile, full-section micro-explosive quantity micro-explosion treatment is carried out on smaller isolated boulders ina covering layer. According to the construction technology for the huge isolated boulders of the alluvial granite in diaphragm wall construction, the drilling precision is strictly controlled during drilling, and the stratum condition is recorded and analyzed in detail; aiming at different stratums, differential explosive configuration is adopted, meanwhile, accurate positioning is carried out onthe positions of the large isolated boulders, thus the used explosive amount is reduced and the explosive string manufacturing time is shortened, the construction period is saved, construction cost isreduced, unnecessary disturbance on the original stratum is avoided to the maximum extent in the meanwhile, and a guarantee for the stability of the construction of diaphragm wall slotted holes in the later stage.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

Processing method for automobile graphene material

The invention relates to a graphene material and particularly relates to a processing method for an automobile graphene material. The method comprises the following steps: pouring a sulfuric acid solution and a nitric acid solution into a container, mixing and then putting the container into a water tank of a water bath device; adding ice bags into the water tank, adding the graphene raw material and potassium permanganate powder into the container, heating the container and performing suction filtration on the solution in the container, thereby acquiring graphene oxide; taking the graphene oxide, placing into a micro-explosion reactor, adding a potassium permanganate solution and then adding hydrogen peroxide for completing the micro-explosion reaction, thereby acquiring a nanometer graphene oxide roll with a roll structure. According to the invention, the solutions are stirred and mixed and then the graphene raw material and the potassium permanganate are added and the ice bags are used for performing ice water bath, on the one hand, the ice bags are low in cost and high in operability, on the other hand, the ice bags are uniformly distributed in the water tank, the uniformity of the temperature is promoted and the solution is more sufficient, so that the high-performance nanometer graphene oxide roll can be acquired.

Owner:LIUZHOU SHENTONG AUTOMOBILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com