Laser cutting method based on inner carving

A laser cutting and laser technology, applied in the field of laser processing and laser cutting of "transparent" hard and brittle materials, can solve the problems of expensive system, low efficiency, glass or sapphire thickness can not be too thick, etc., to achieve smooth section and cutting efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

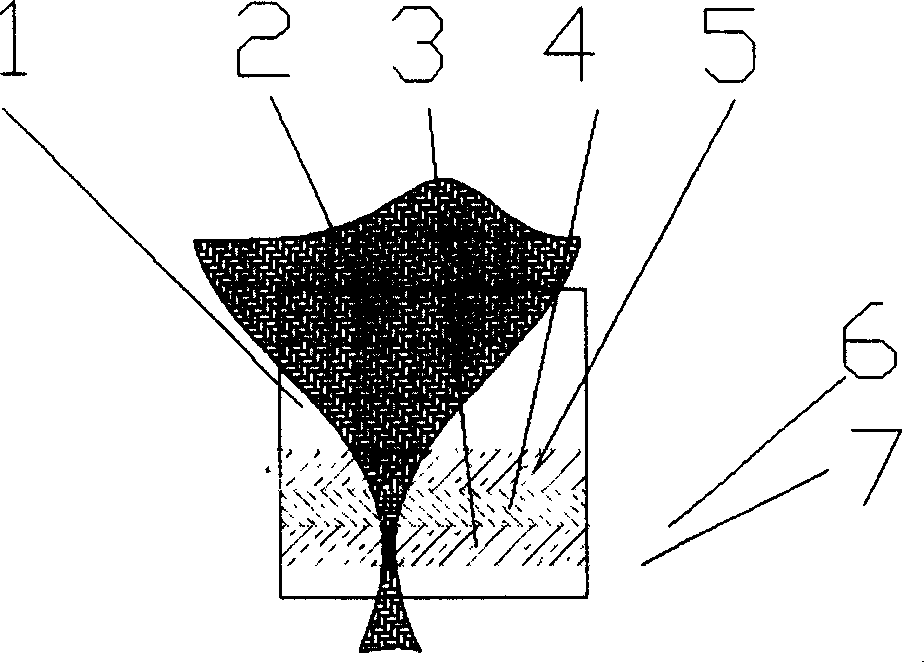

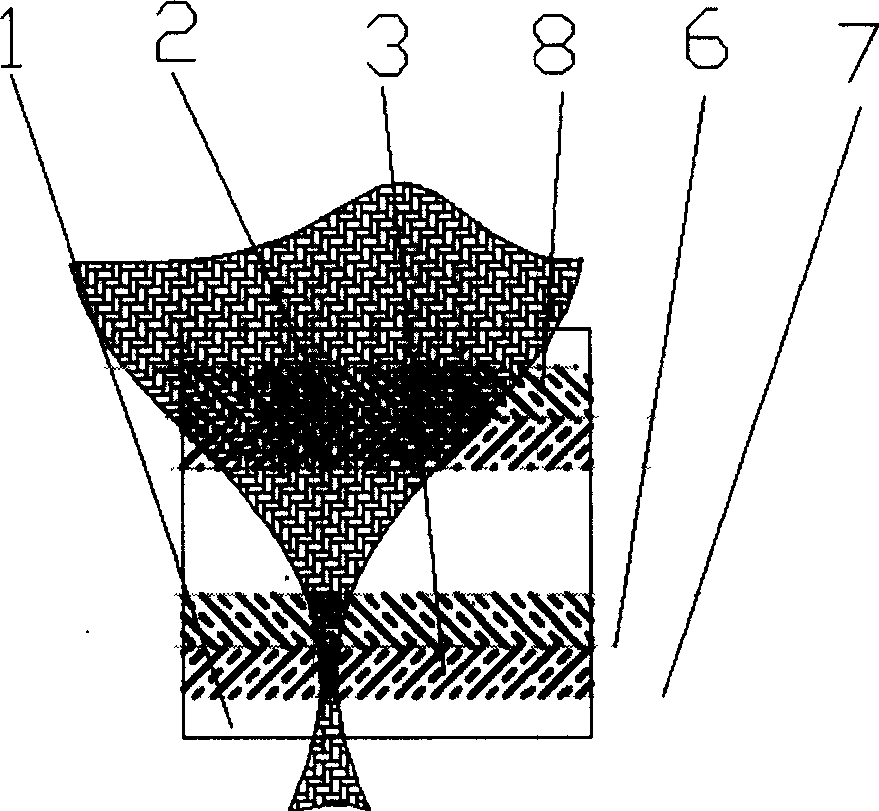

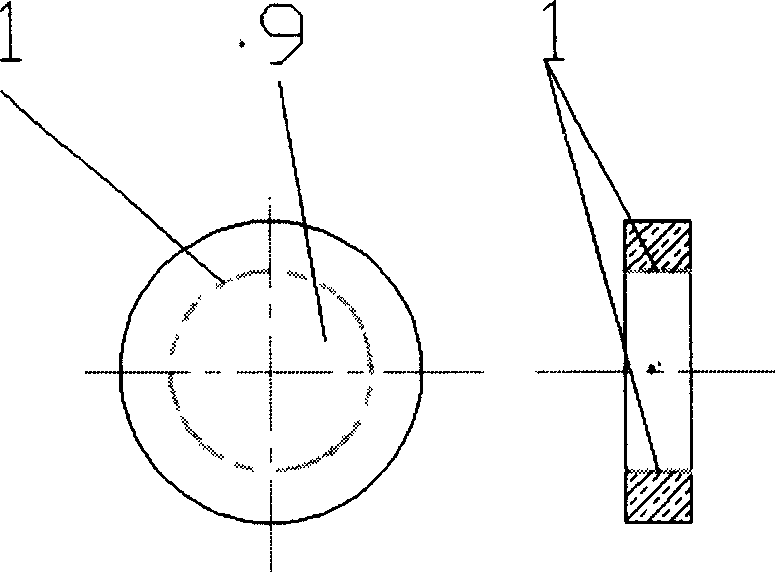

[0015] See figure 1 As shown, this is an embodiment of a laser cutting method based on internal engraving of the present invention. The material to be cut is colorless and transparent sapphire, which is almost transparent to ultraviolet light. It is a hard and brittle material, and it is difficult to cut efficiently by traditional methods. A 355nm UV Q-switched solid-state laser is used, with an average power of 4 watts at a pulse repetition frequency of 30KHz, a pulse width of 9ns, and single-mode. Among them, 1 is the surface to be cut, and 2 is the Gaussian ultraviolet beam, which is focused on the surface to be cut of the material to be cut, and its focal spot has a certain depth of focus, and its length is between 6 and 7. Since the laser peak power density exceeds the destruction threshold of sapphire, each laser pulse creates a detonation point at the laser focus inside the sapphire. When the laser focus moves horizontally in the cutting surface, a "cutting line" 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com