Patents

Literature

71results about How to "Smooth section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

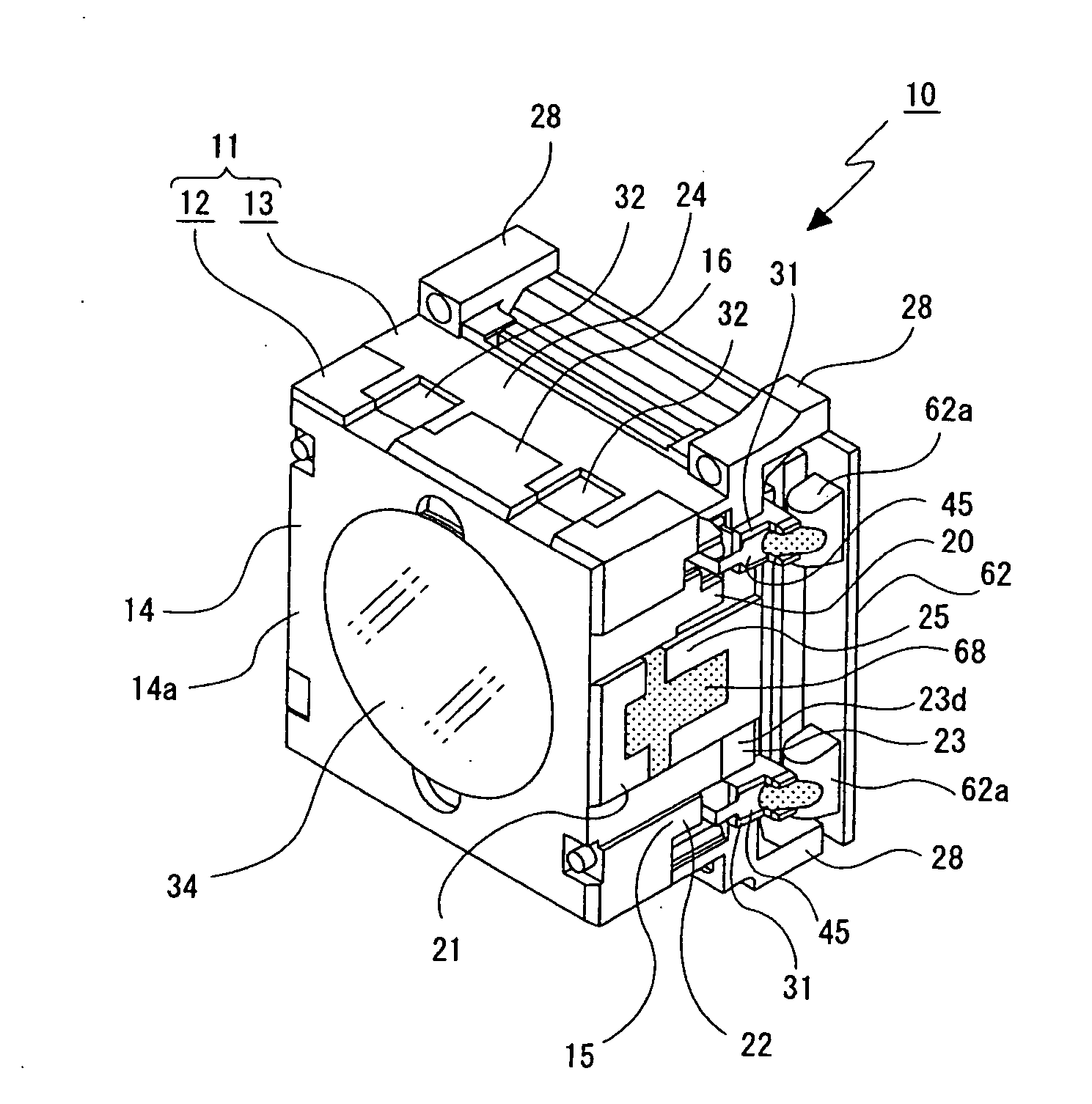

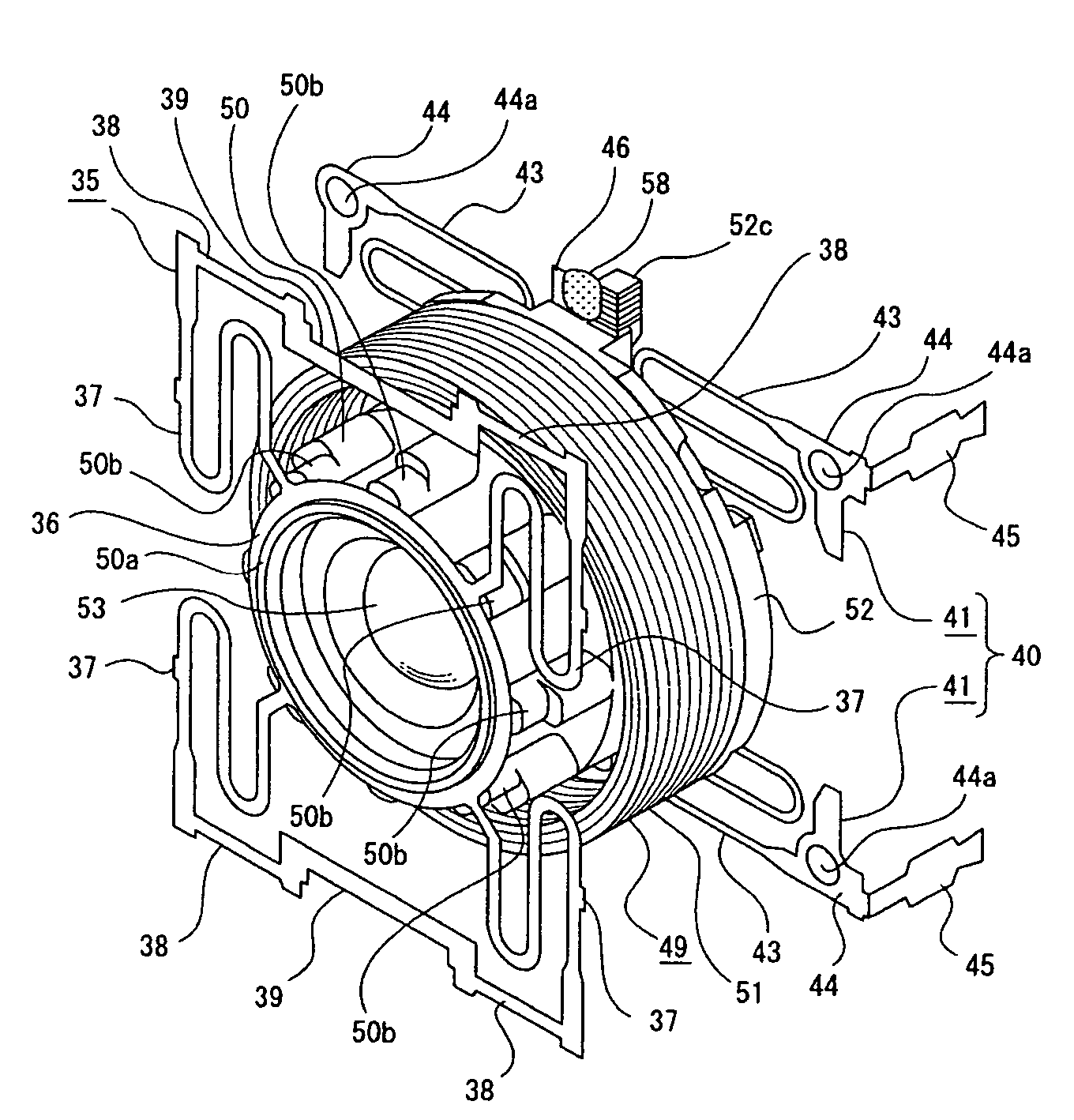

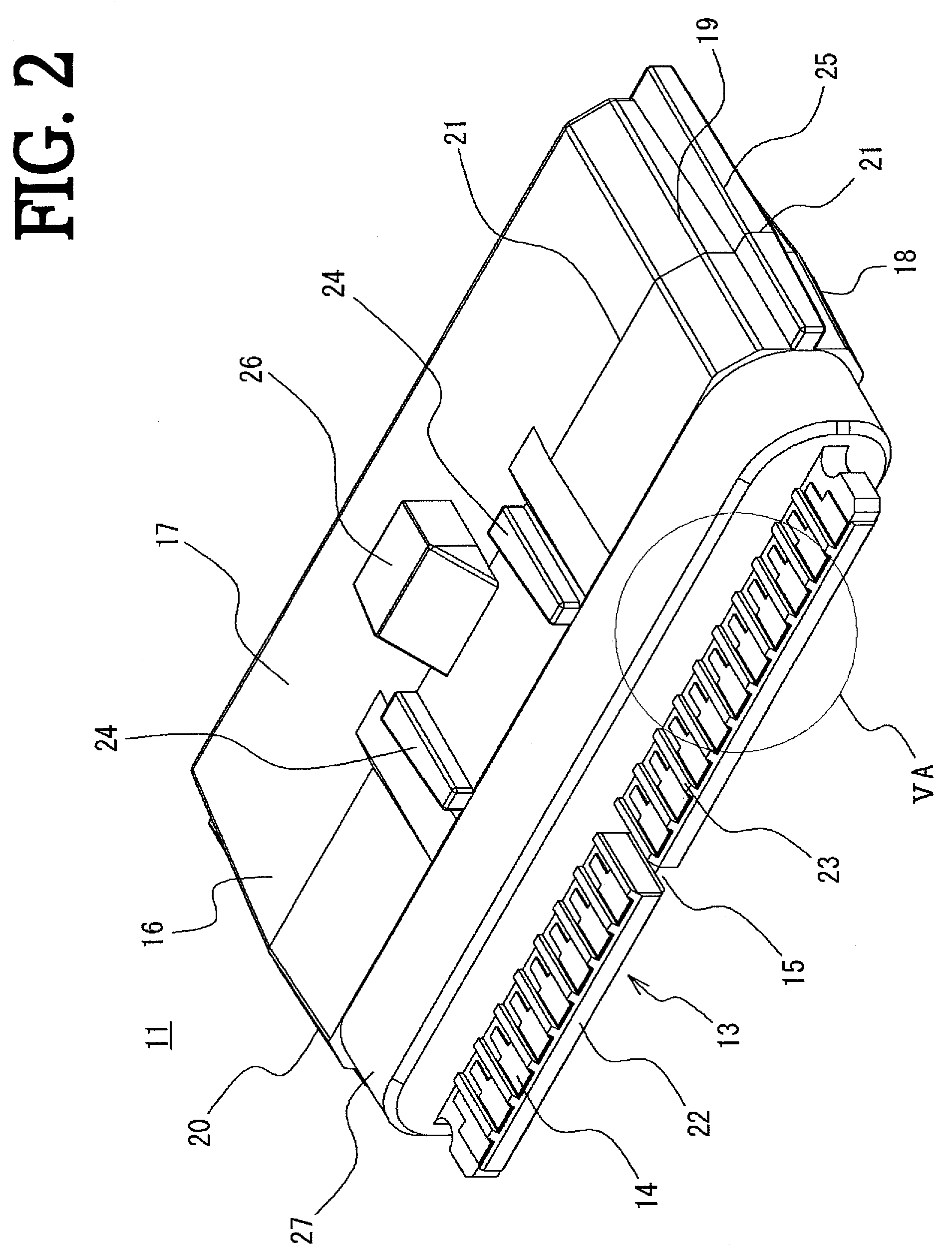

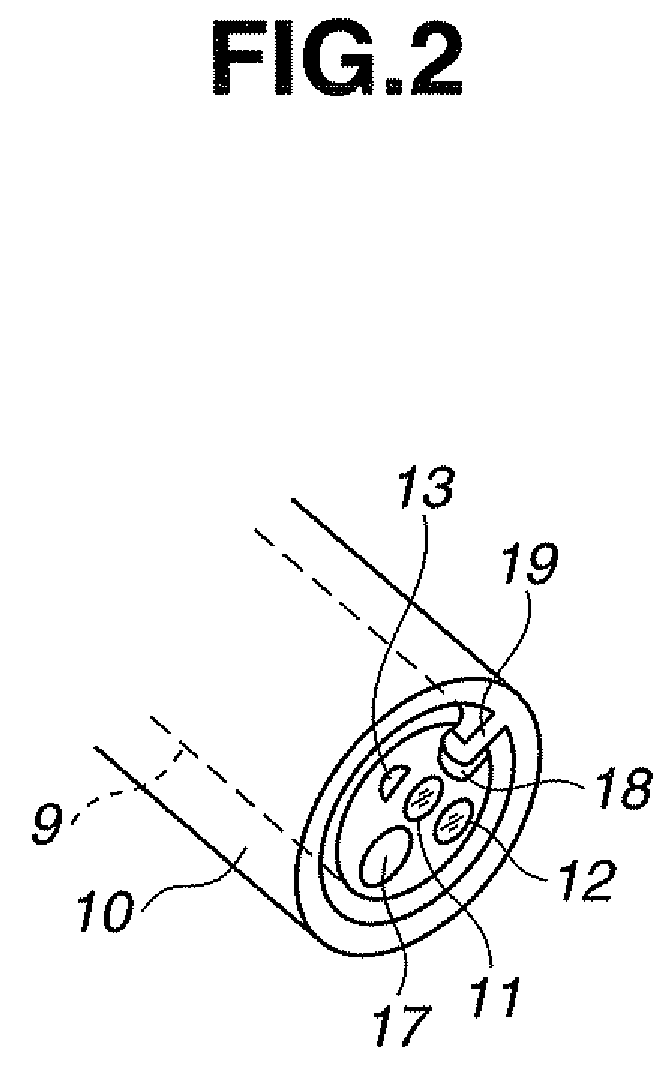

Lens unit and imaging apparatus

ActiveUS20060181748A1Small sizeQuality improvementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersOptical axisEngineering

A lens unit includes: a lens barrel; a movable section including a movable lens and configured to be moved in an optical axis direction relative to the lens barrel; a linear actuator configured to move the movable section in the optical axis direction; and a biasing blade spring including a holding portion for holding the movable section, a plurality of spring portions capable of being elastically deformed and biasing the movable section in the optical axis direction, and an attachment portion to be attached to the lens barrel. The plurality of spring portions of the biasing blade spring are configured to restraint a movement force produced at the movable section in a plane orthogonal to the optical axis.

Owner:SONY CORP

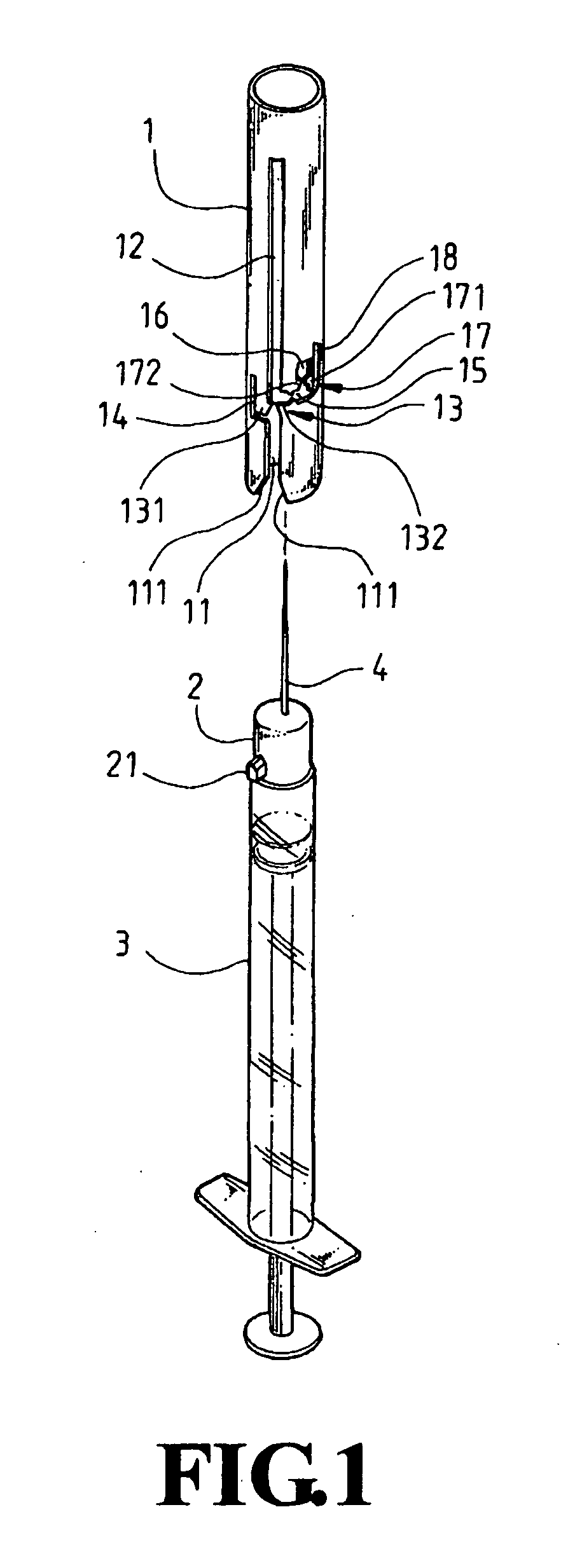

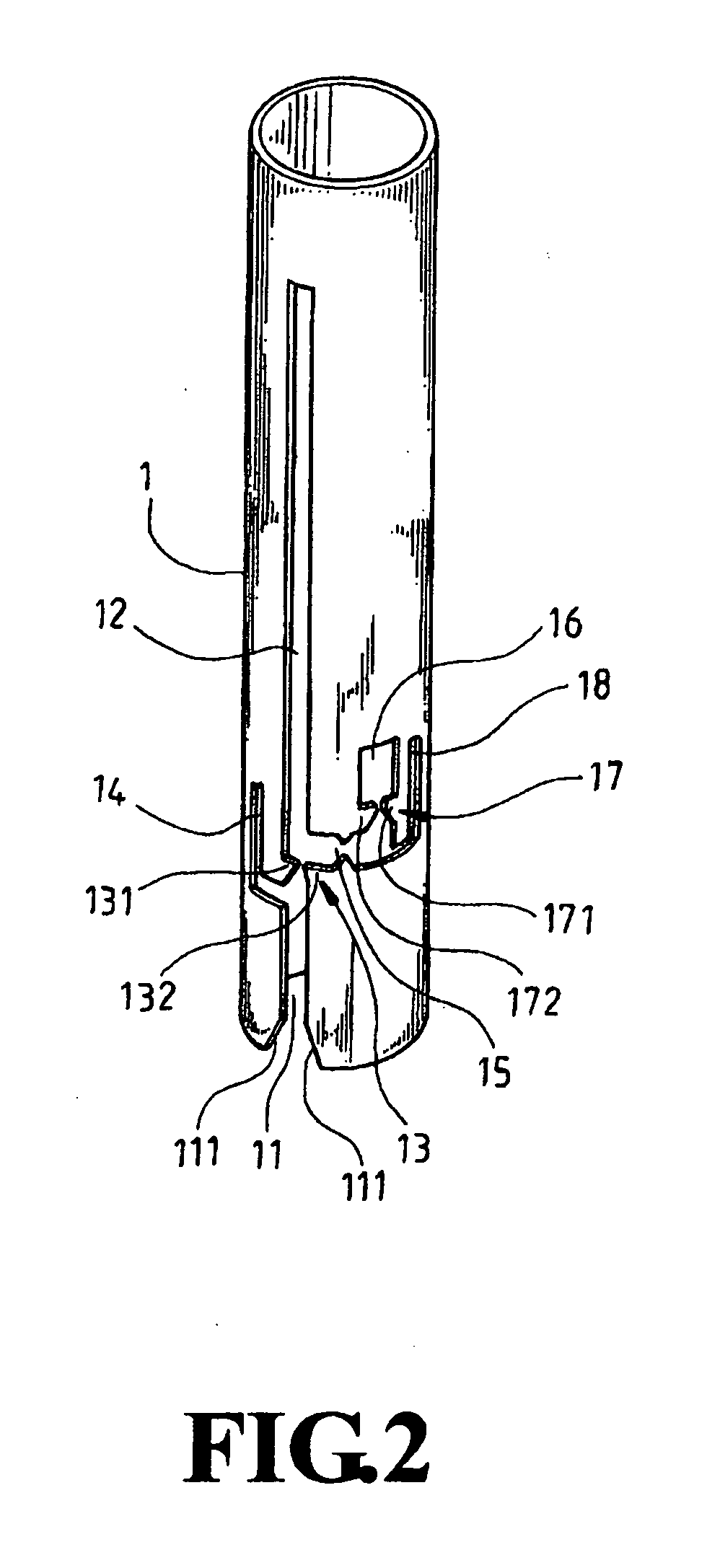

Safety structure for covering syringe needle

A safety structure for covering a syringe needle includes a safety sleeve and a hub provided with a sideward projection. The safety sleeve is fitted around the hub and provided with an axial sliding slot, a locating slot laterally extended from the sliding slot, a locating hole located at a bottom of the locating slot behind a locating section, and two opposing protrusions located in the locating slot between the sliding slot and the locating section. When the projection is abutted on a bottom of the sliding slot, the needle is exposed from the safety sleeve; when the projection is reversibly located behind the two opposing protrusions, the needle is temporarily enclosed in the safety sleeve and protected against contamination; and when the projection is moved behind the locating section into the locating hole, the needle is permanently enclosed in the safety sleeve without the risk of stabbing a user.

Owner:FORMOSA MEDICAL DEVICES

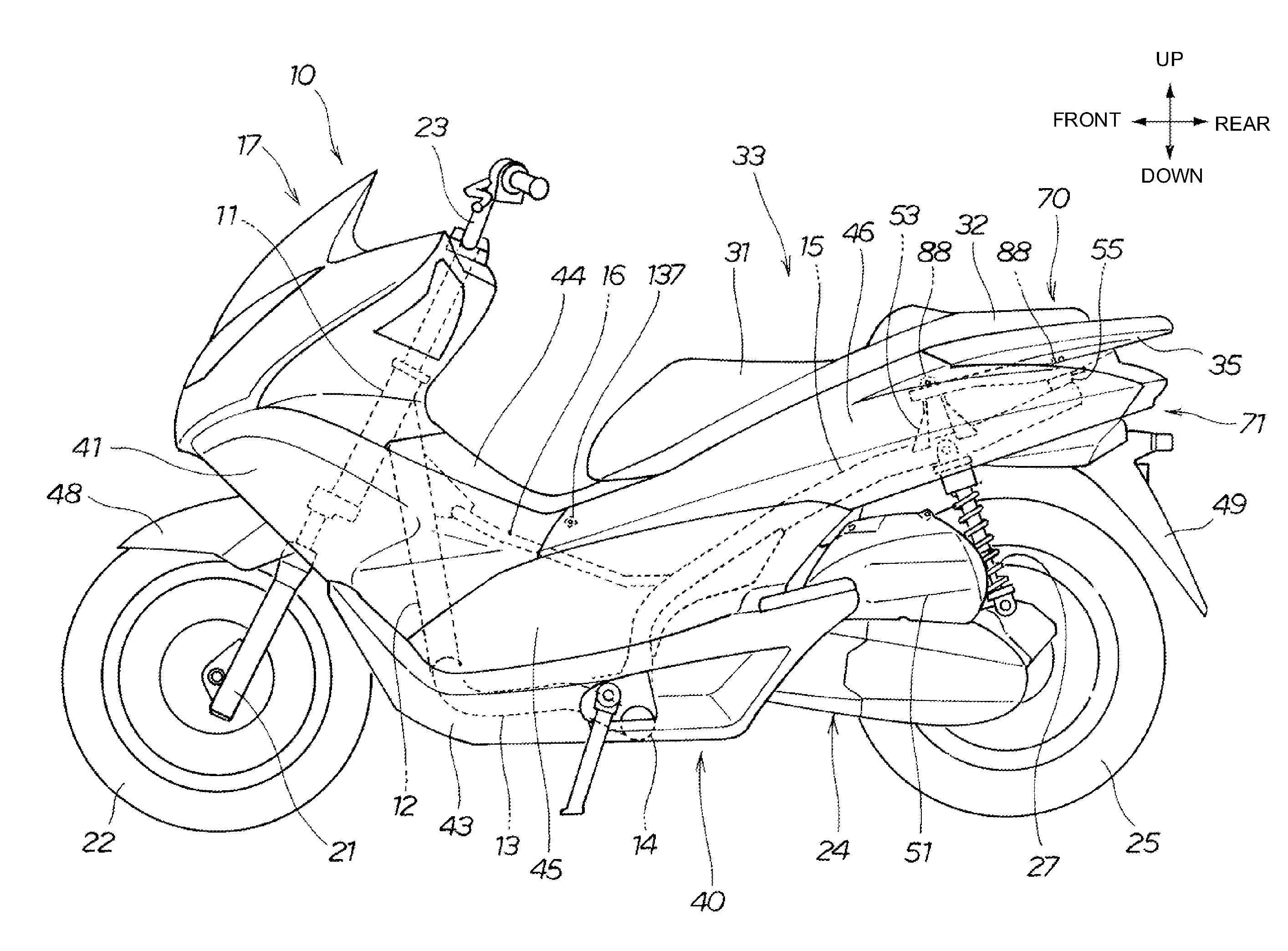

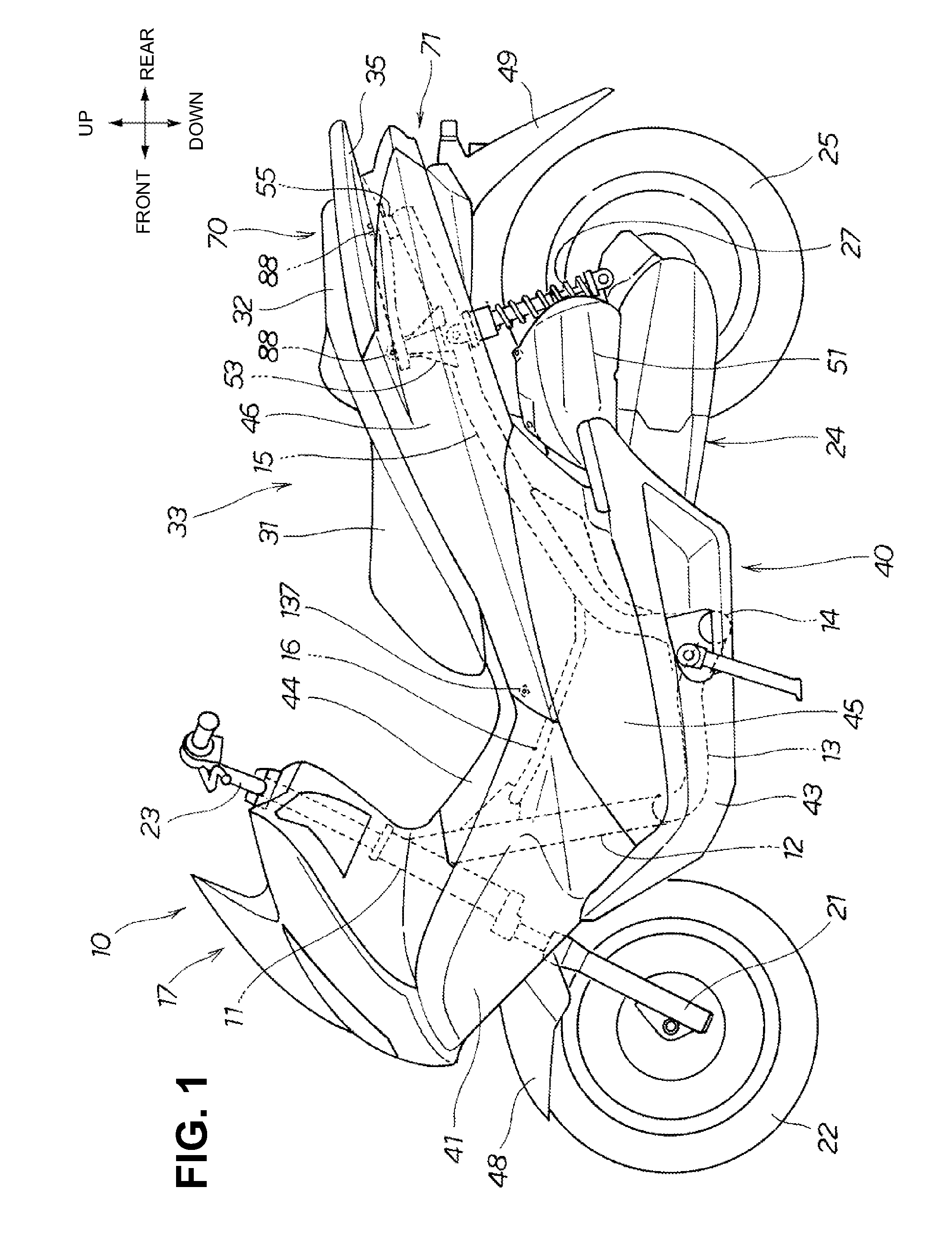

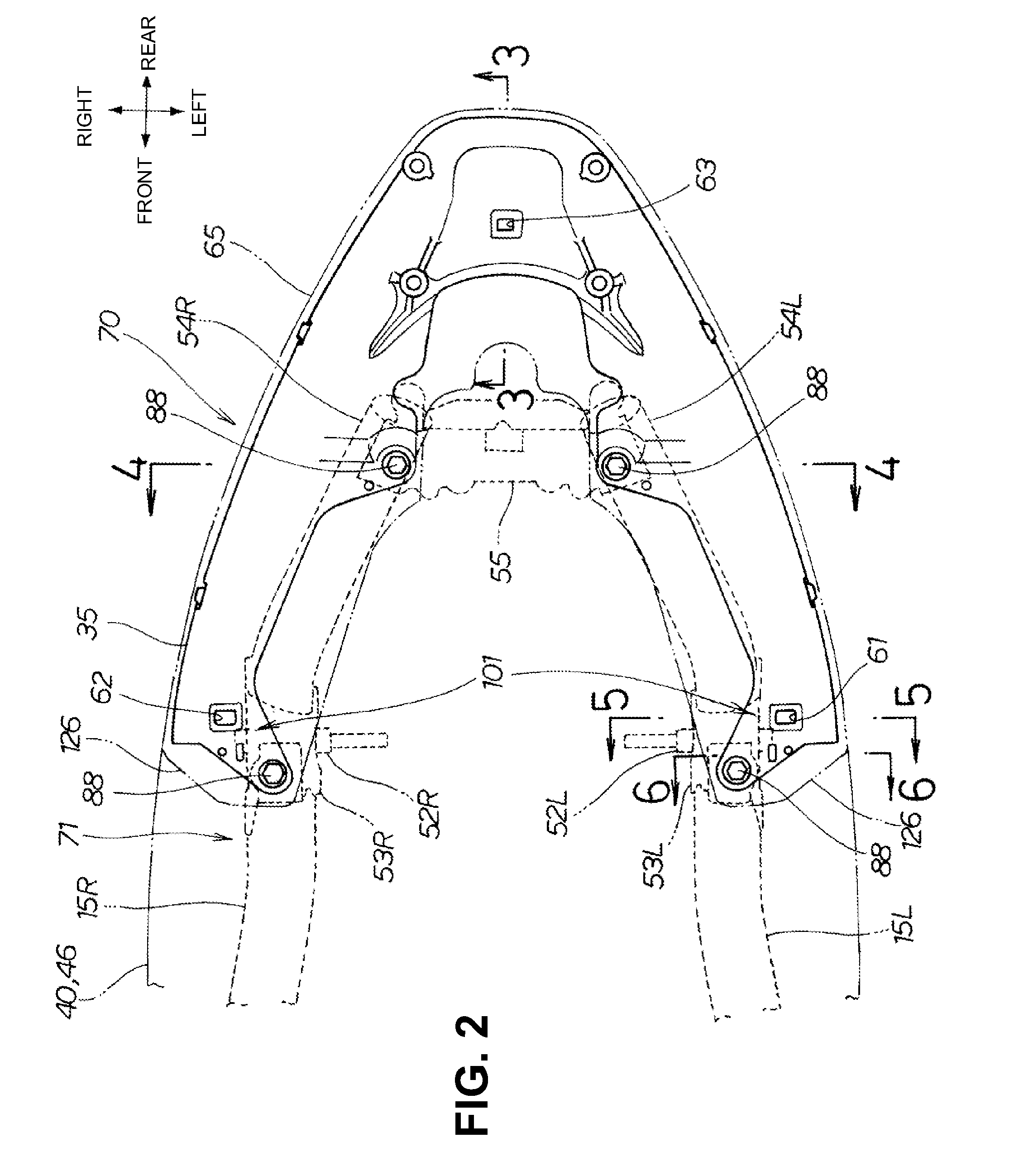

Rear body structure for a vehicle, and vehicle incorporating same

InactiveUS20110074183A1Improve assembly accuracyGood lookingVehicle seatsMotorised scootersAutomotive engineeringBody frame

A rear body structure for a vehicle includes a body cover for covering a vehicle body, a rear grip member attached to a vehicle body frame and configured to be gripped by an occupant of the vehicle during operation of the vehicle, and a rear grip cover attached to and covering the rear grip member. A portion of the body cover overlaps a top surface of the rear grip member. The rear grip member is provided with a body cover positioning section for positioning the body cover thereon. The rear grip cover is arranged above the body cover positioning section of the rear grip member for providing covering thereto. Such vehicle rear body structure provides an improvement in the outward appearance of a rear body structure of a vehicle.

Owner:HONDA MOTOR CO LTD

Lens unit and imaging apparatus

ActiveUS7450834B2Quality improvementSmooth sectionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersCamera lensOptical axis

A lens unit includes: a lens barrel; a movable section including a movable lens and configured to be moved in an optical axis direction relative to the lens barrel; a linear actuator configured to move the movable section in the optical axis direction; and a biasing blade spring including a holding portion for holding the movable section, a plurality of spring portions capable of being elastically deformed and biasing the movable section in the optical axis direction, and an attachment portion to be attached to the lens barrel. The plurality of spring portions of the biasing blade spring are configured to restraint a movement force produced at the movable section in a plane orthogonal to the optical axis.

Owner:SONY CORP

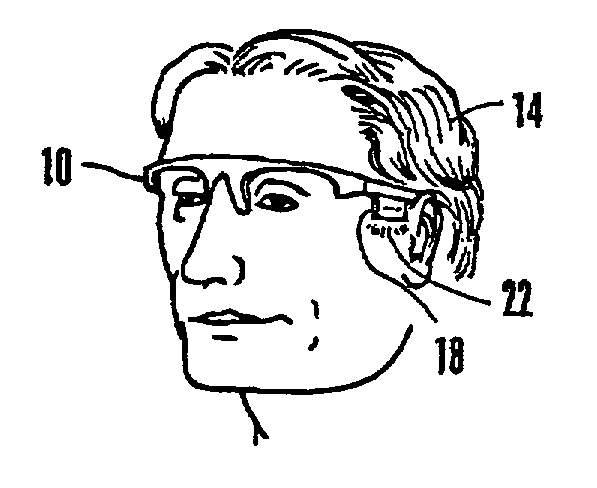

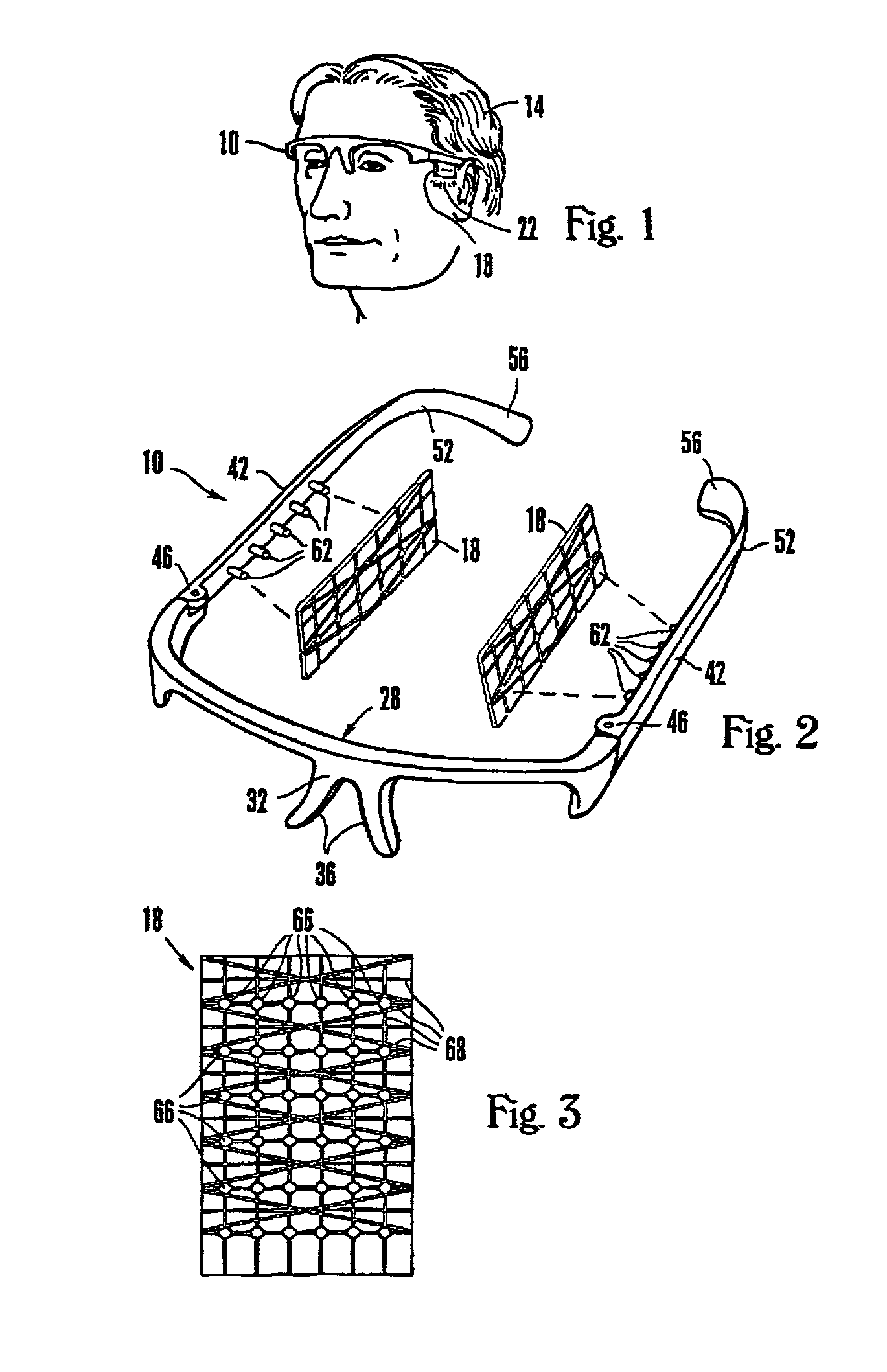

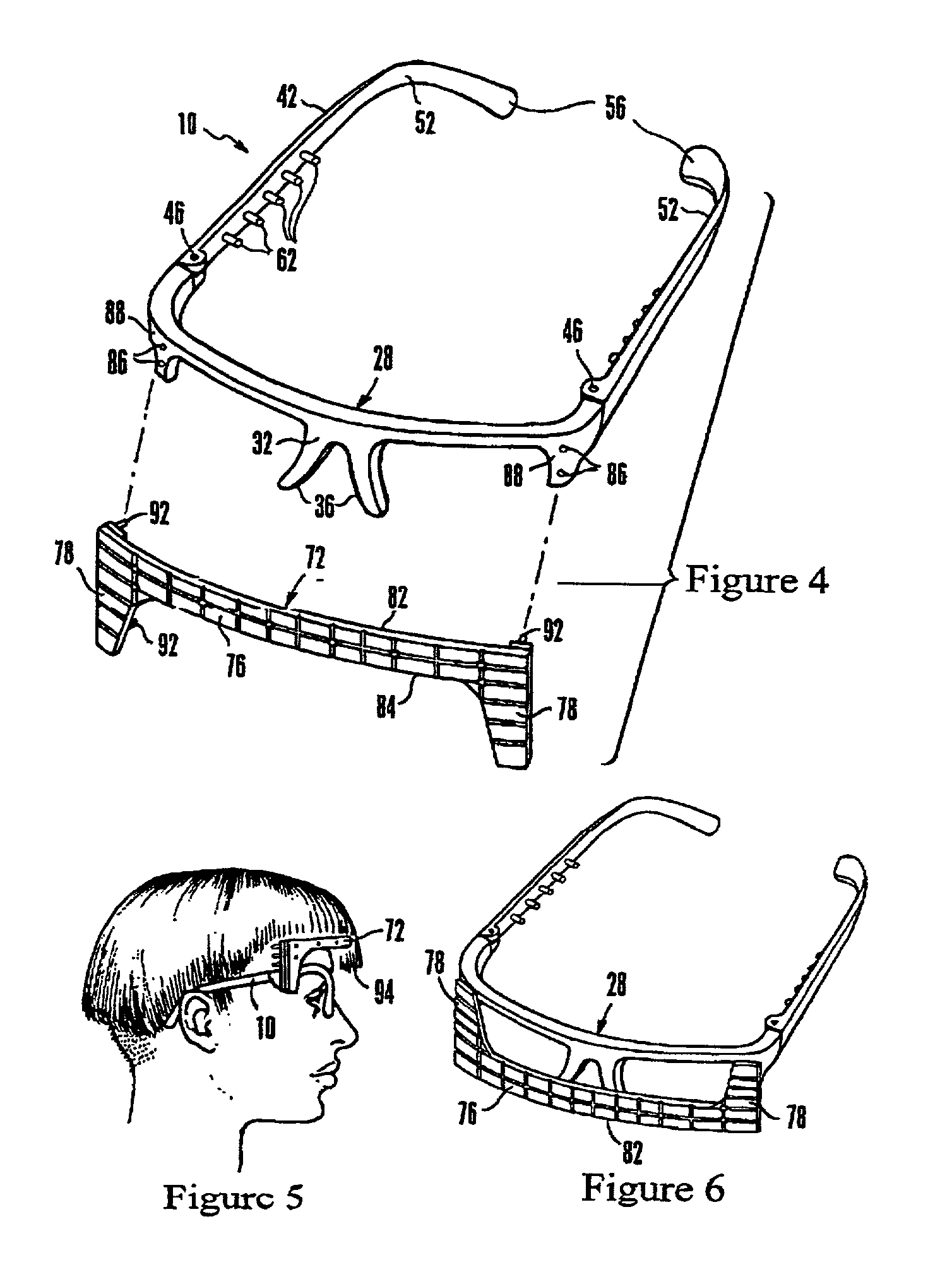

Hair trim guide

Owner:VACKER TRESE J

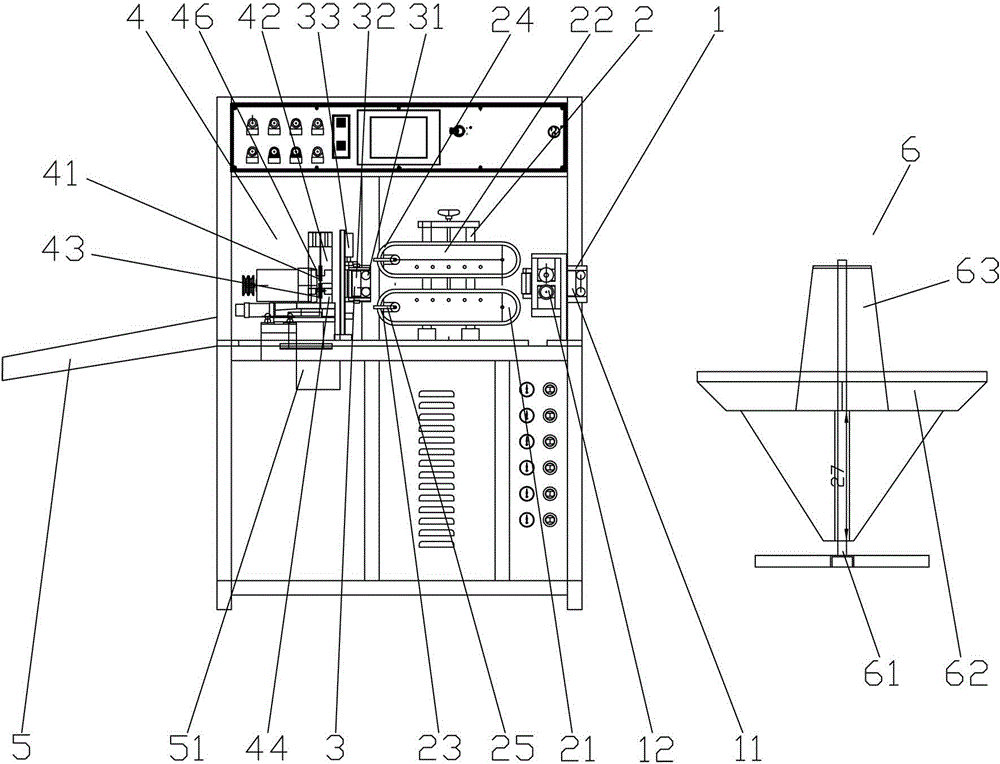

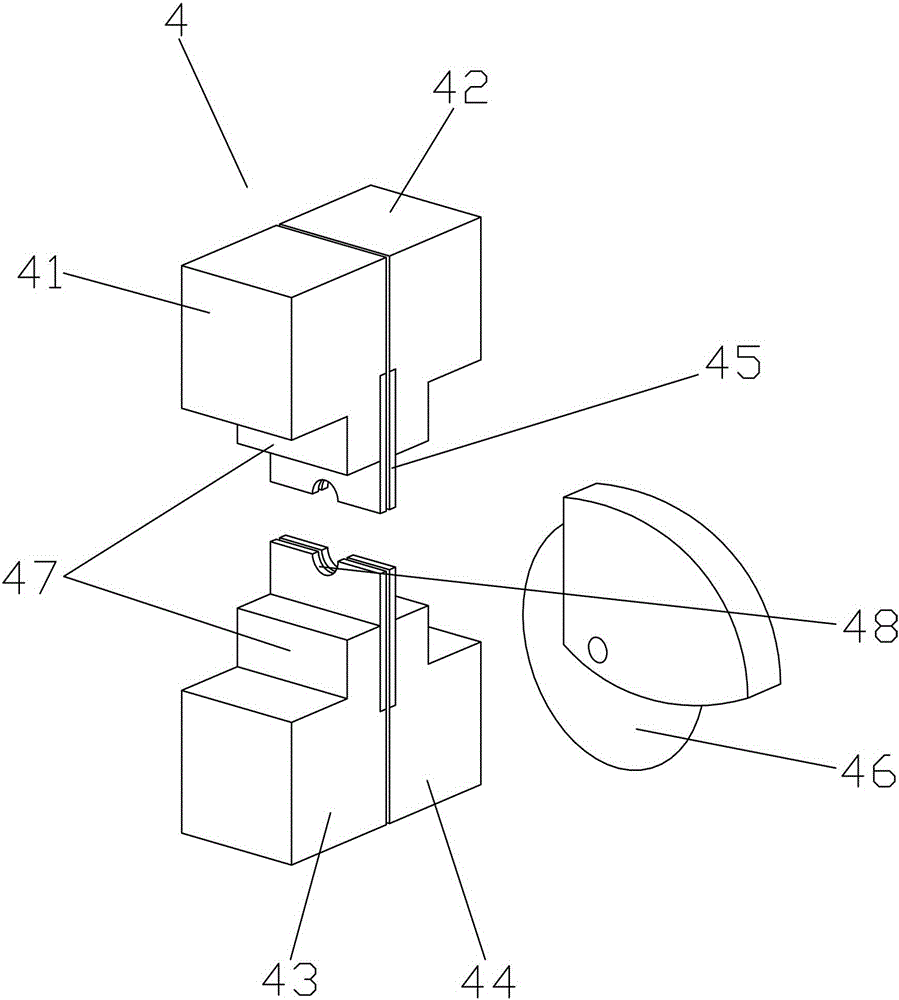

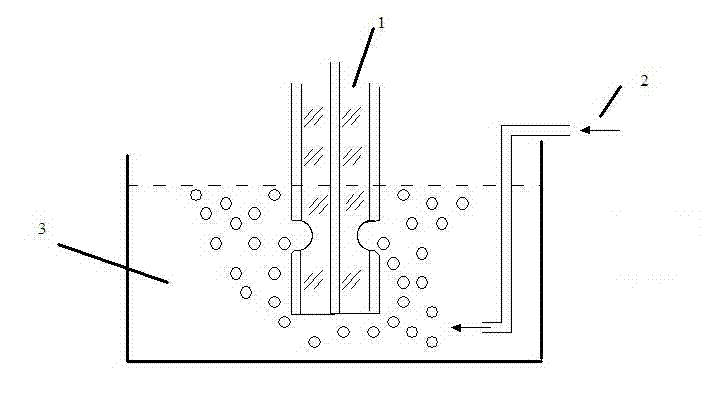

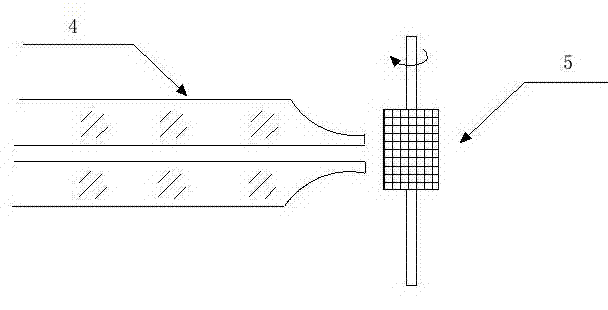

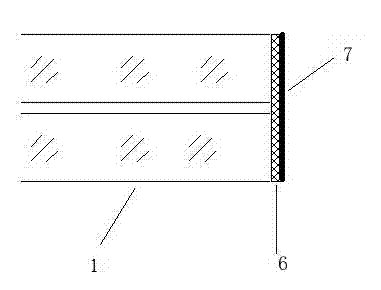

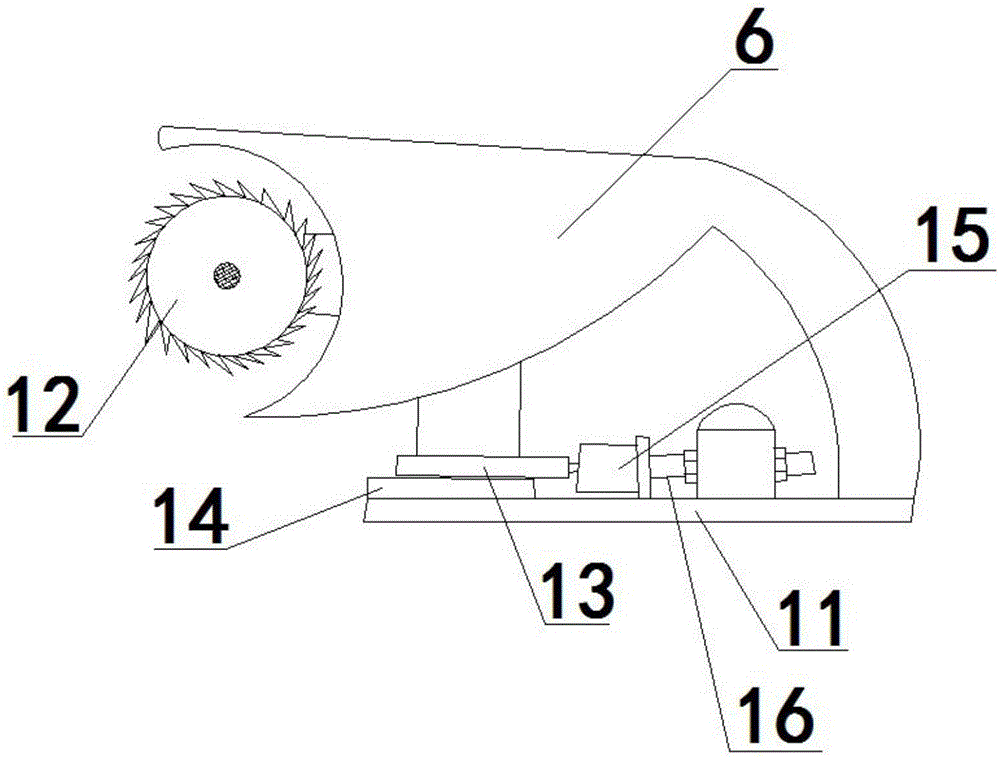

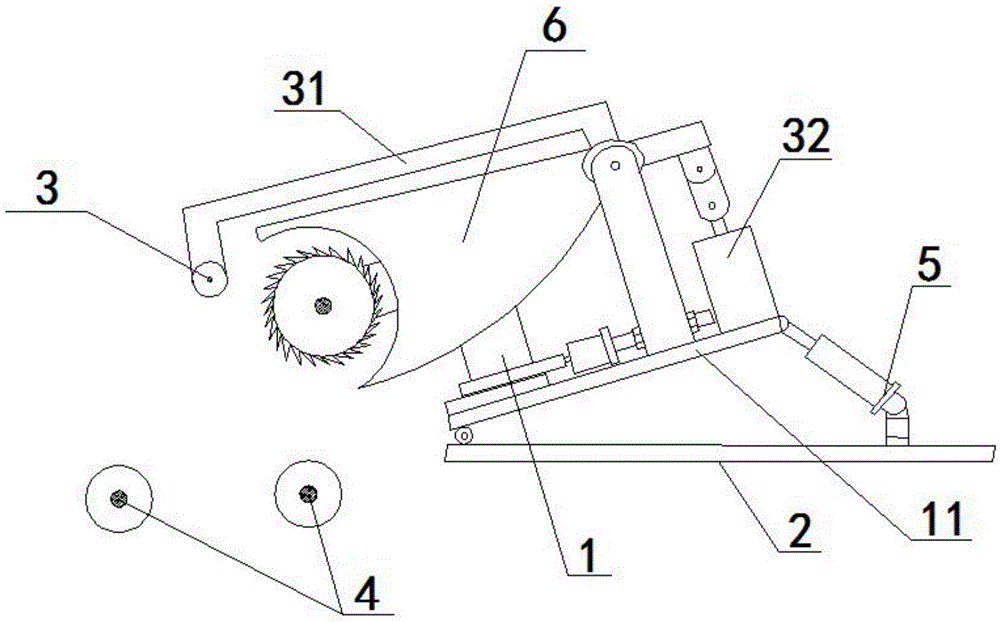

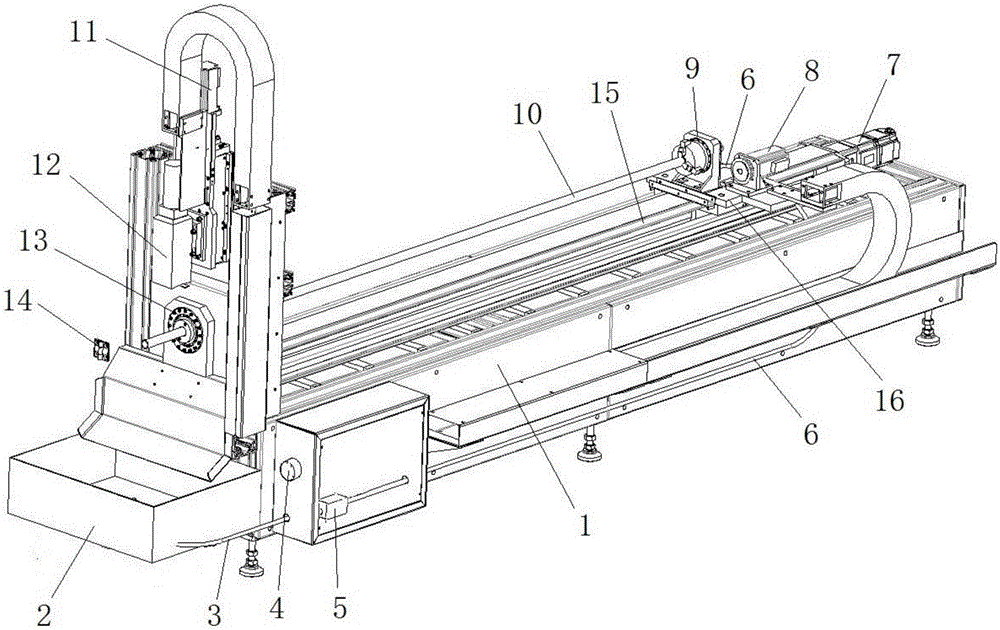

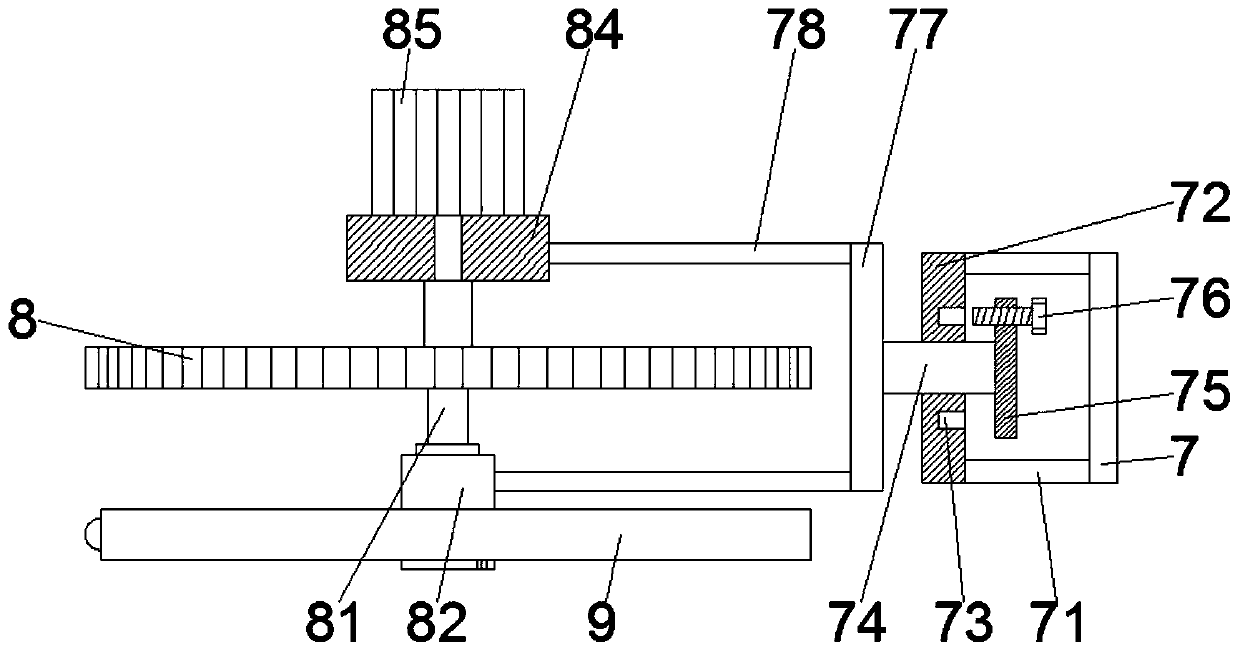

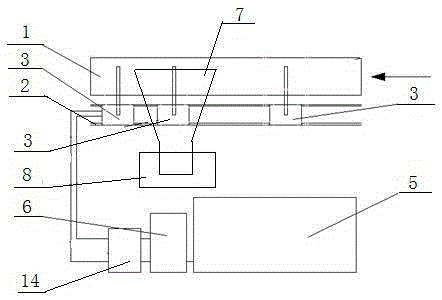

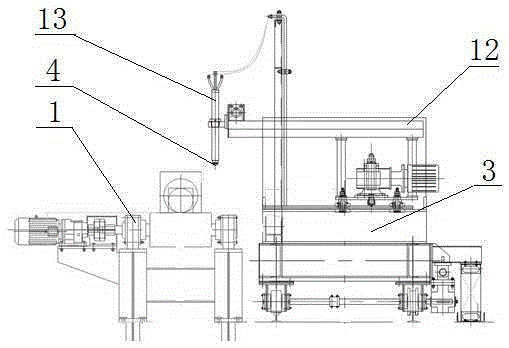

Automatic fusing cutting machine for stainless steel woven polytetrafluoroethylene tubes

The invention discloses an automatic fusing cutting machine for stainless steel woven polytetrafluoroethylene tubes. The machine comprises a wire feeding and pressing module, a belt wheel wire pressing module, a guiding wire pressing module and a fusing module in sequence from right to left. The fusing module comprises a left upper pressing block, a right upper pressing block, a left lower pressing block and a right lower pressing block, wherein the left upper pressing block and the right upper pressing block can slide vertically and move horizontally; the left lower pressing block and the right lower pressing block can move horizontally; the pipeline passing workstation positions among the left upper pressing block, the right upper pressing block, the left lower pressing block and the right lower pressing block are each provided with a dismountable fusing conductive copper knife installed vertically; a vertically installed saw blade is installed in front of the pipeline passing workstation position of the fusing module. For the characteristics of woven hoses, through the reasonable structural improvement, especially the design of combination of the pressing blocks and the saw blade, steel wire layers of the woven hoses are fused through the combination of the pressing blocks, then the saw blade cuts off tubes on the inner layers, the woven hoses are pulled broken when the combination of the pressing blocks is in a heating state, and therefore the steel wires do not explode without external force when fused, and it is ensured that the fracture surfaces after fusing are tidier and smoother.

Owner:FOSHAN HAOBANG MACHINERY CO LTD

Manufacture method for cutting liquid crystal display panel

ActiveCN102225841ALess prone to transverse cracksSmooth sectionEdge grinding machinesGlass severing apparatusEpoxyLiquid-crystal display

The invention discloses a manufacture method for cutting a liquid crystal display panel. A mode of chemical thinning liquid thinning glass is used for thinning a cutting frame of the liquid crystal display panel, a diamond grinding head is used for reconditioning a cutting plane, the reconditioned section is blocked by an epoxy resin, and edge sealing is performed by a metal film. The section cutby the method has the advantages of smooth flat, no stress and difficult cracking, and is capable of manufacturing the panels with any section shapes, wherein the thickness of the edge sealing glue-line is less than 0.2mm, thereby an ultra-narrow seam spliced screen with the width of seam-line of less than 1mm can be manufactured.

Owner:西藏贝珠亚电子科技有限公司

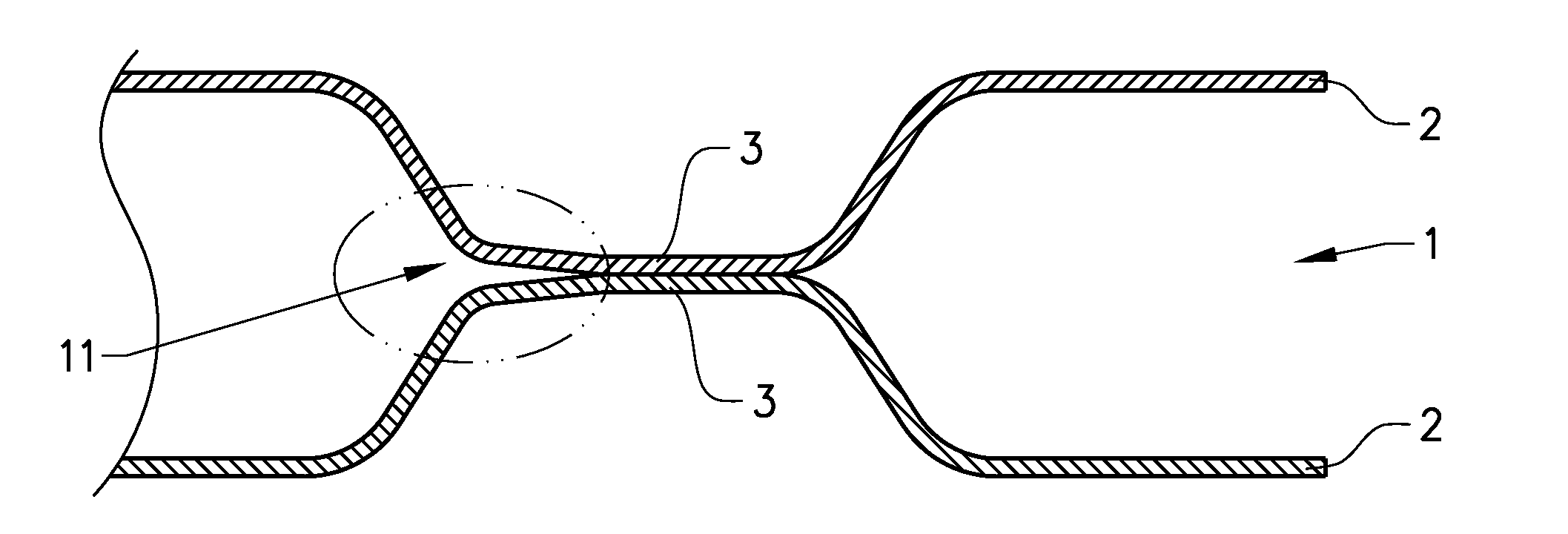

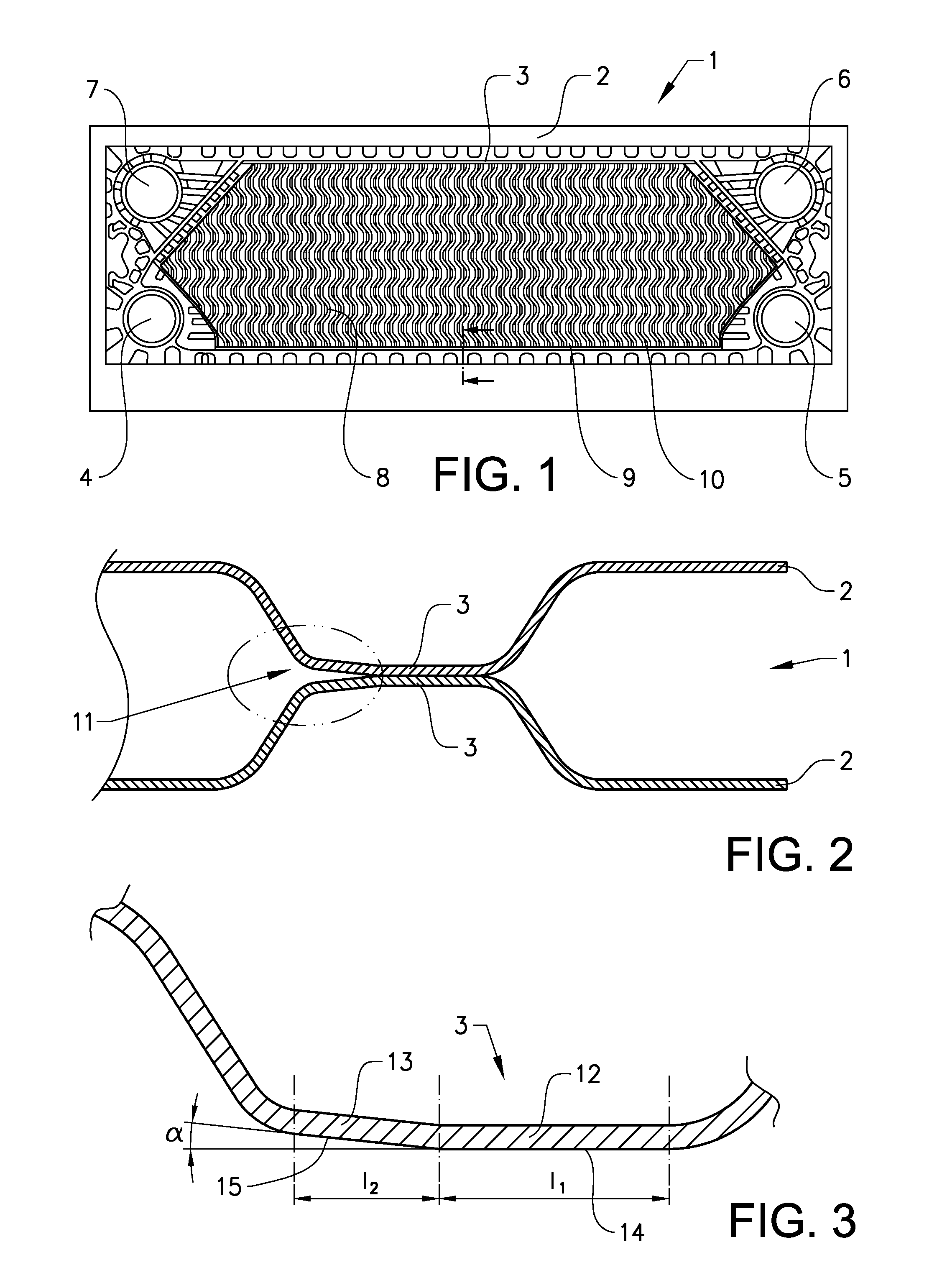

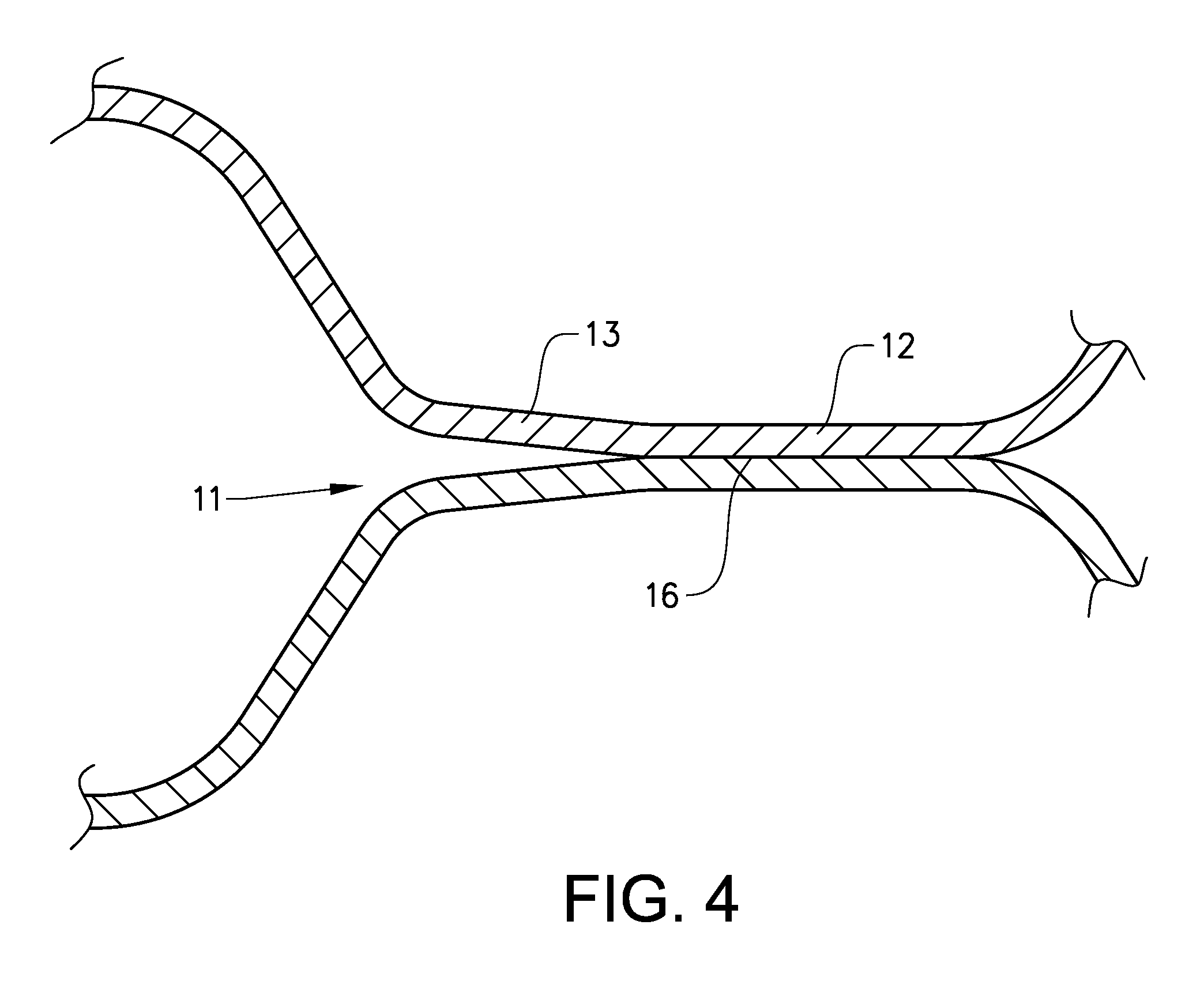

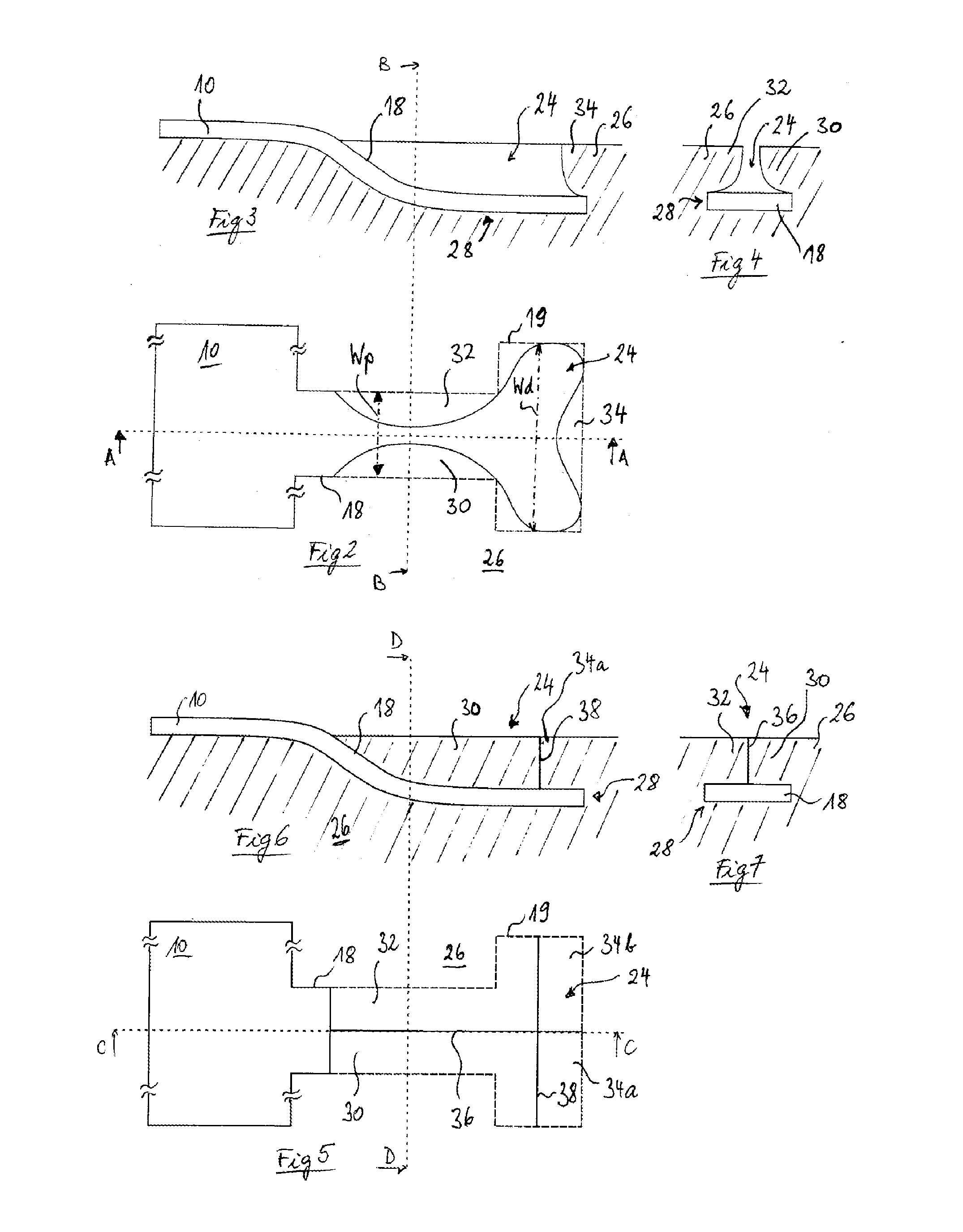

Heat Exchanger

ActiveUS20100258288A1Smooth sectionEasy to assembleSoldering apparatusMetal working apparatusEngineeringRidge

A plate for the use in a heat exchanger cassette, where the plate comprises a corrugated pattern having a plurality of ridges (9) and valleys (10), and where the plate comprises a sealing gasket groove (3) encircling a heat transfer surface (8) that will be part of a contact-free fluid channel when two cassettes comprising at least one plate each are positioned adjacent each other, wherein the sealing gasket groove (3) comprises a base surface with a first, flat section (12) and a second, bent section (13), and where the bent section is angled with the angle α. The advantage of the inventive plate is that an airtight heat exchanger cassette can be obtained in an easy and cost-effective way.

Owner:ALFA LAVAL CORP AB

Fixed cutting device and paper tube smoothing mill comprising same

InactiveCN105034046AEliminate edge burrsReduce scrap rateMetal working apparatusWorking environmentControl unit

The invention relates to a cutting device used for cutting objects and a paper tube smoothing mill comprising the cutting device. The fixed cutting device comprises a rack, a roller wheel for bearing a paper tube, a cutting device and a control unit, wherein the cutting device and the roller wheel are arranged on the rack in a matched mode, and are electrically connected with the control unit respectively. The fixed cutting device has the beneficial effects that: a cutting saw of the cutting device is arranged to be a mechanism capable of controlling cutting depth by sliding front and back; rotation, in front and negative directions, of the cutting saw or the roller wheel is matched, so that a secondary cutting mode is applied, and therefore, influence on use or surface aesthetic extent due to the fact that burrs are generated on a cut surface of a cut part can be prevented; an air draft device for collecting chippings is arranged in a working area of the cutting device, so that the working environment can be kept sanitary; and the paper tube smoothing mill comprising the cutting device is simple to operate, and has cutting efficiency which is 2-5 times that of a circular knife.

Owner:许立国

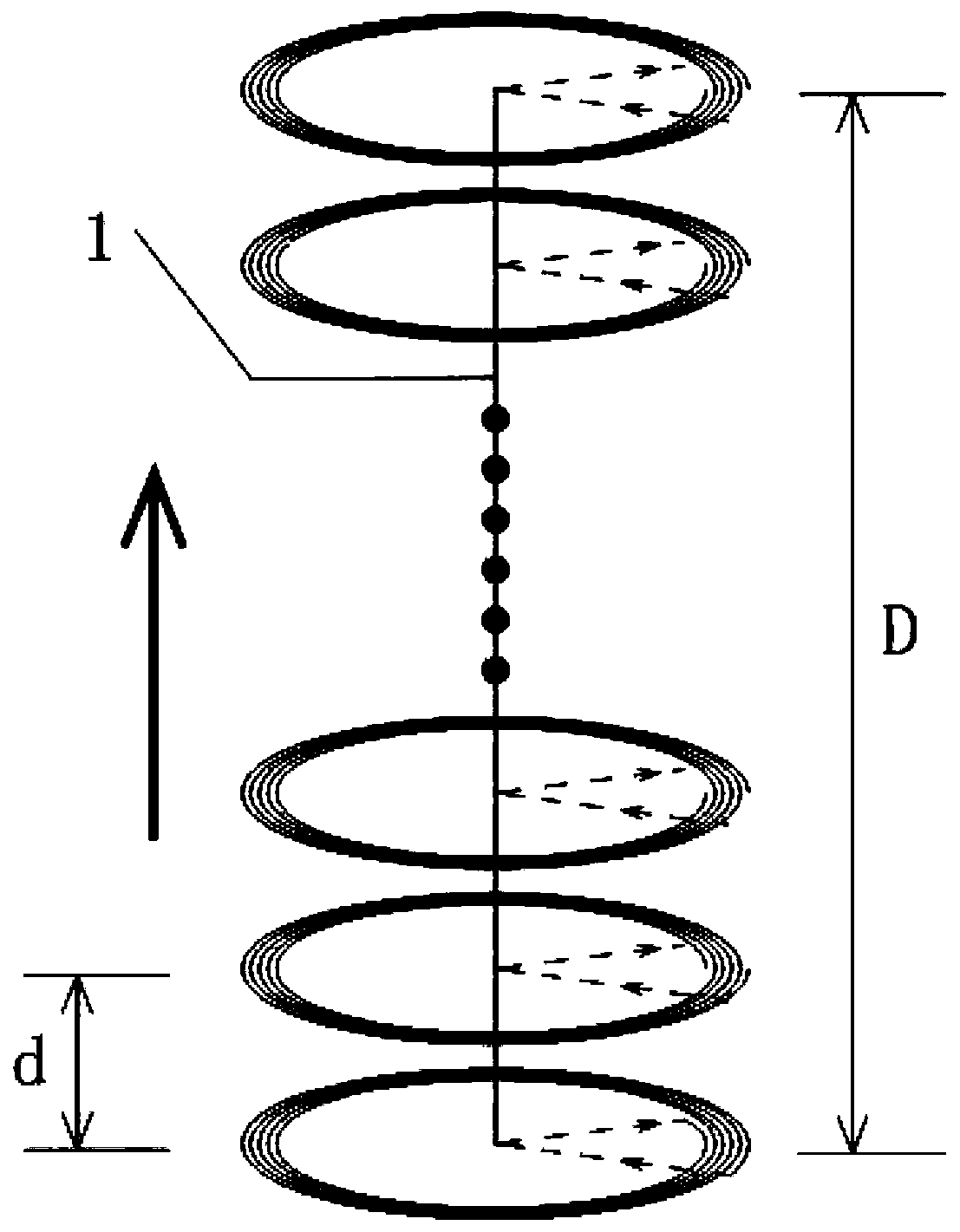

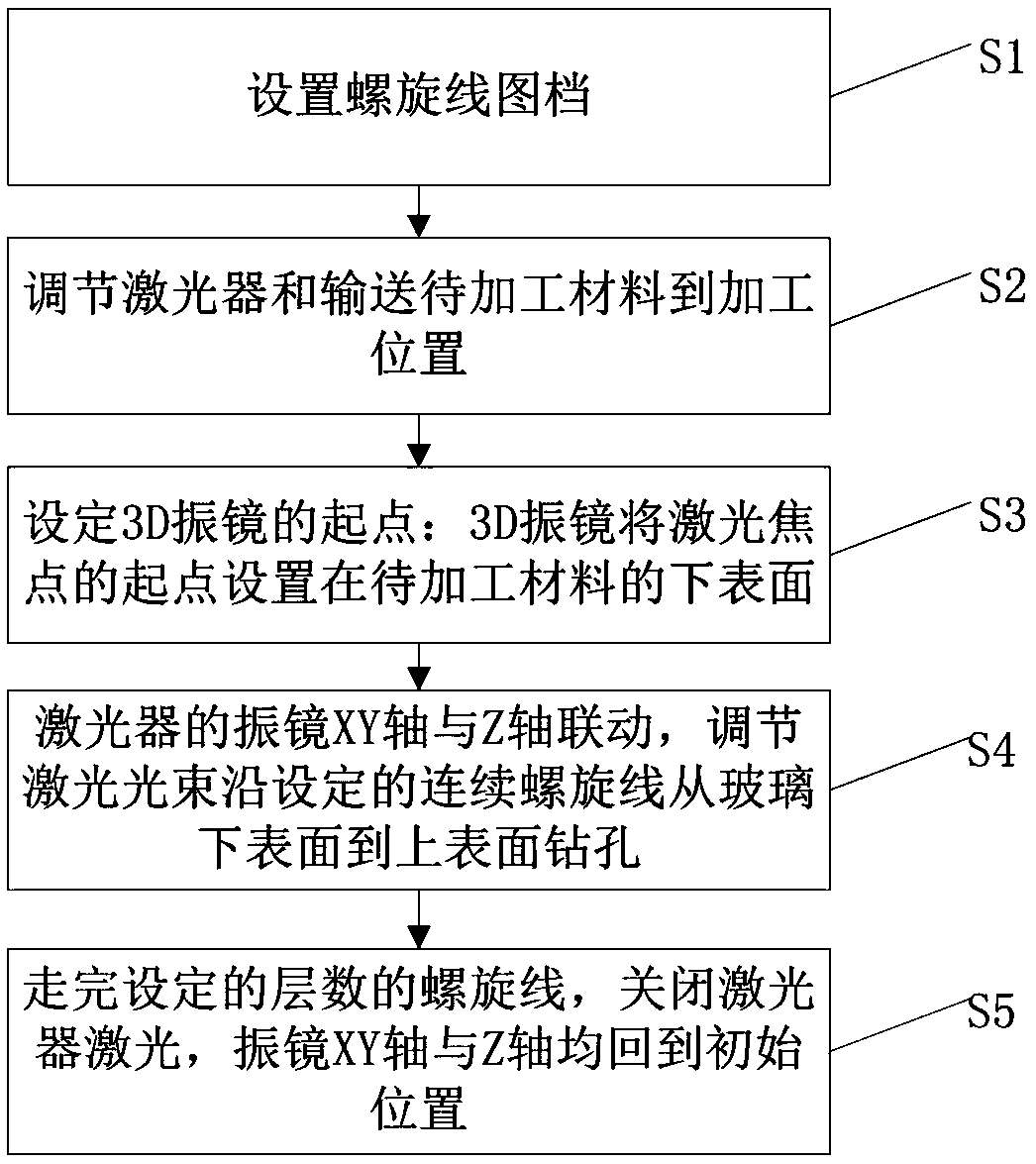

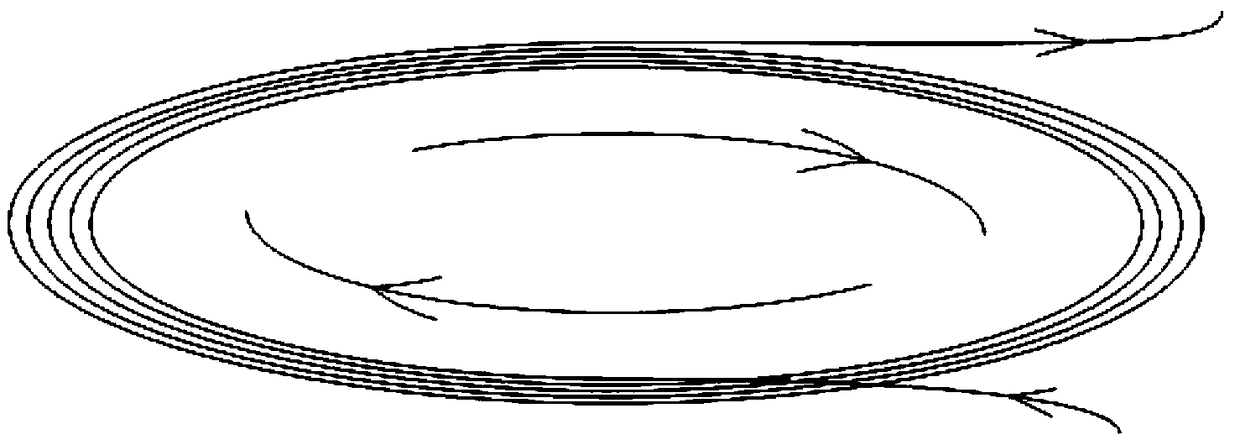

Laser drilling control method

ActiveCN109352190AShorten control timeImprove processing efficiencyLaser beam welding apparatusLaser processingOptoelectronics

The invention provides a laser drilling control method and belongs to the field of laser processing. The laser drilling control method comprises the following steps: arranging spiral line drawing archives; adjusting a laser and conveying a to-be-processed product to a processing position; setting the starting point of a 3D vibrating mirror, wherein the 3D vibrating mirror sets the starting point of the laser focal point on the lower surface of the to-be-processed product; linking the XY axis and Z axis of the vibrating mirror of the laser, and adjusting the laser beam to drill from the lower surface to the upper surface of glass along the set continuous spiral line; and travelling on the entire spiral line with set layers, turning off the laser, and enabling the XY axis and Z axis of the vibrating mirror to return to the initial position. The laser drilling control method has the following benefits: the processing efficiency is improved, a connecting knife edge for turning on and off laser is not formed from bottom up, and the fracture surface is smooth.

Owner:SHENZHEN JIXIANGYUN TECH CO LTD

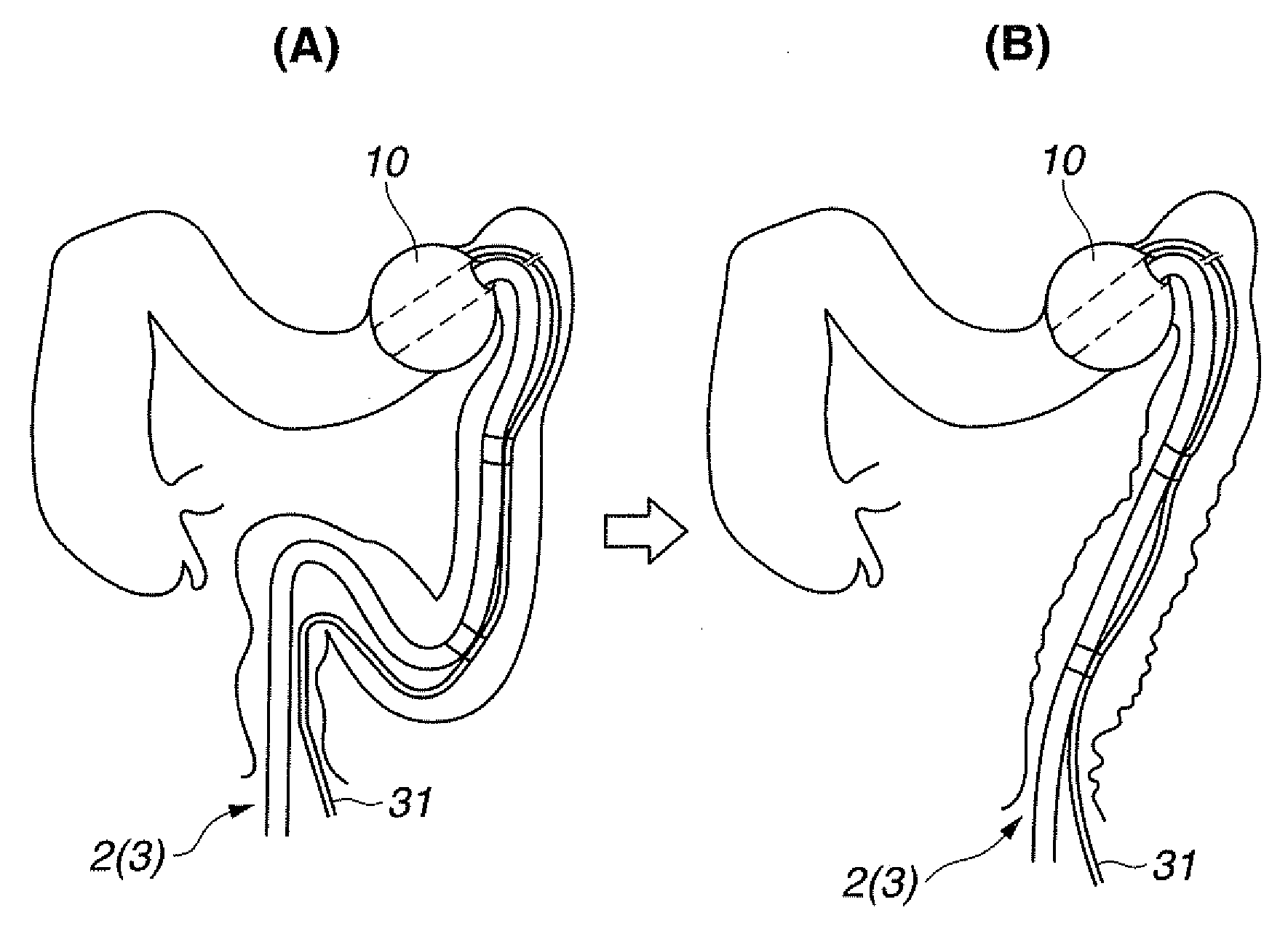

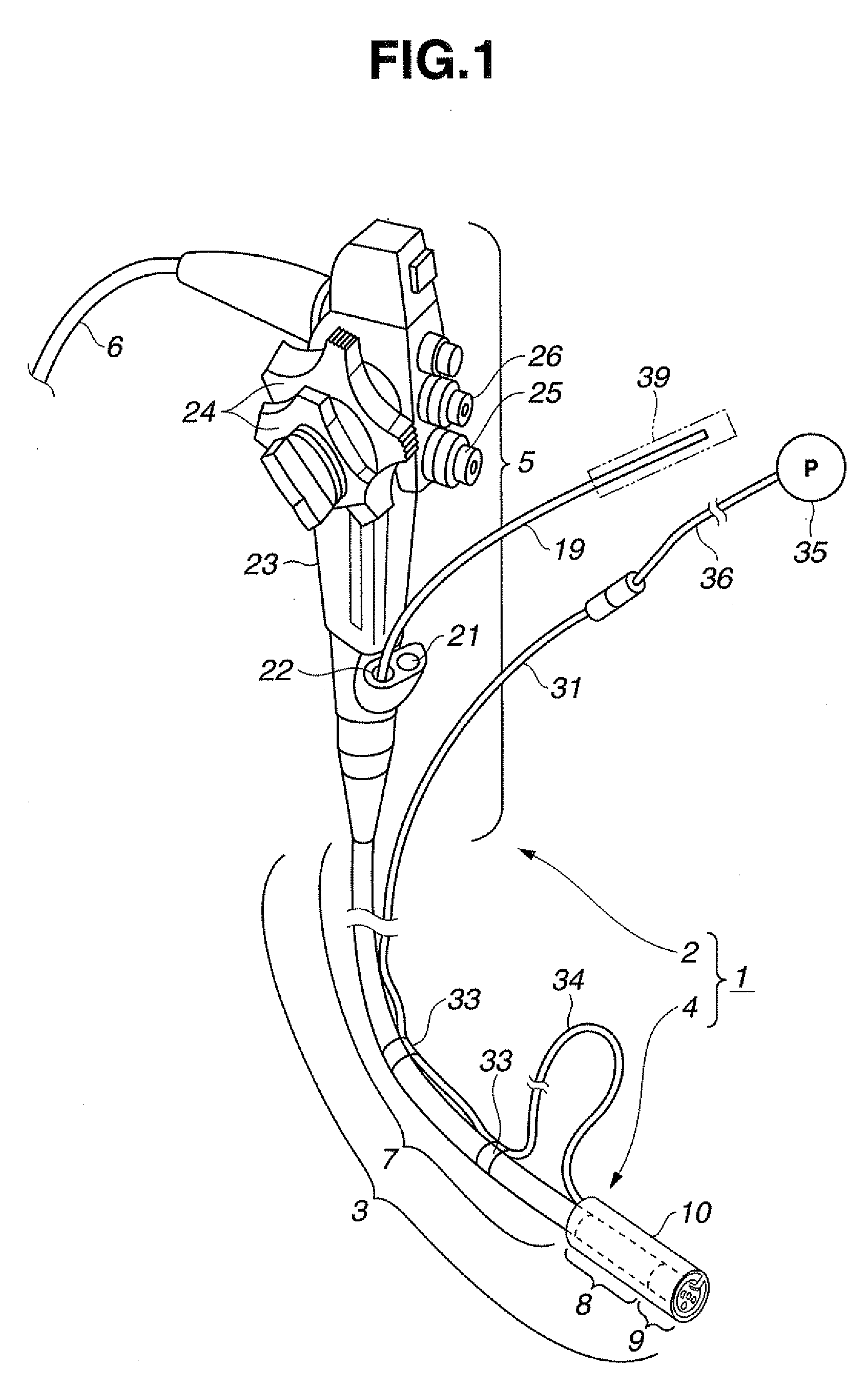

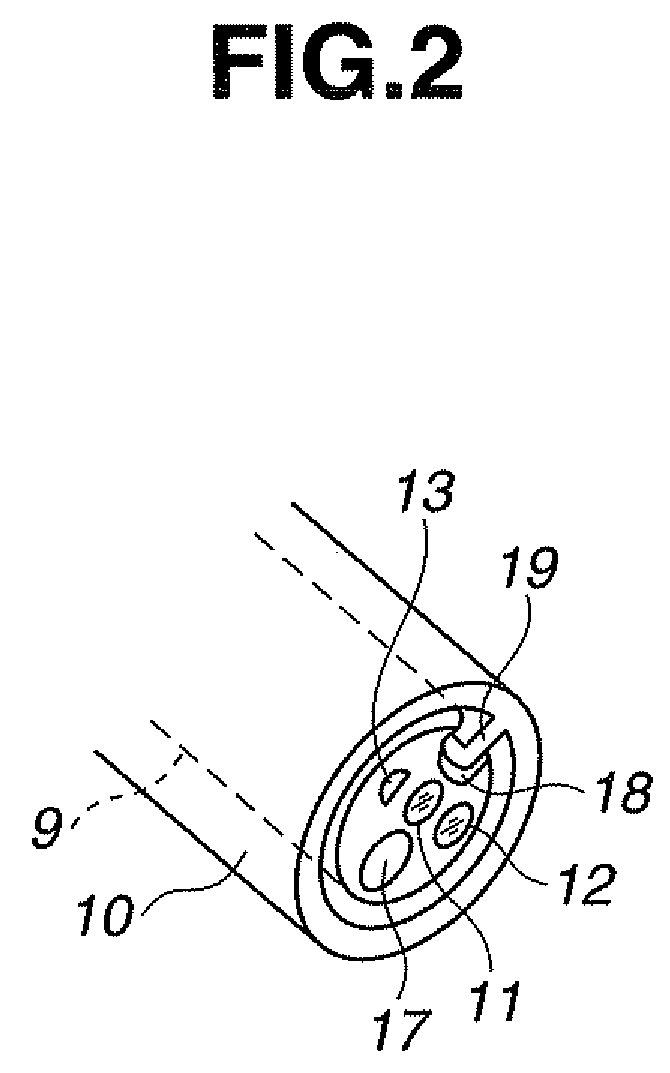

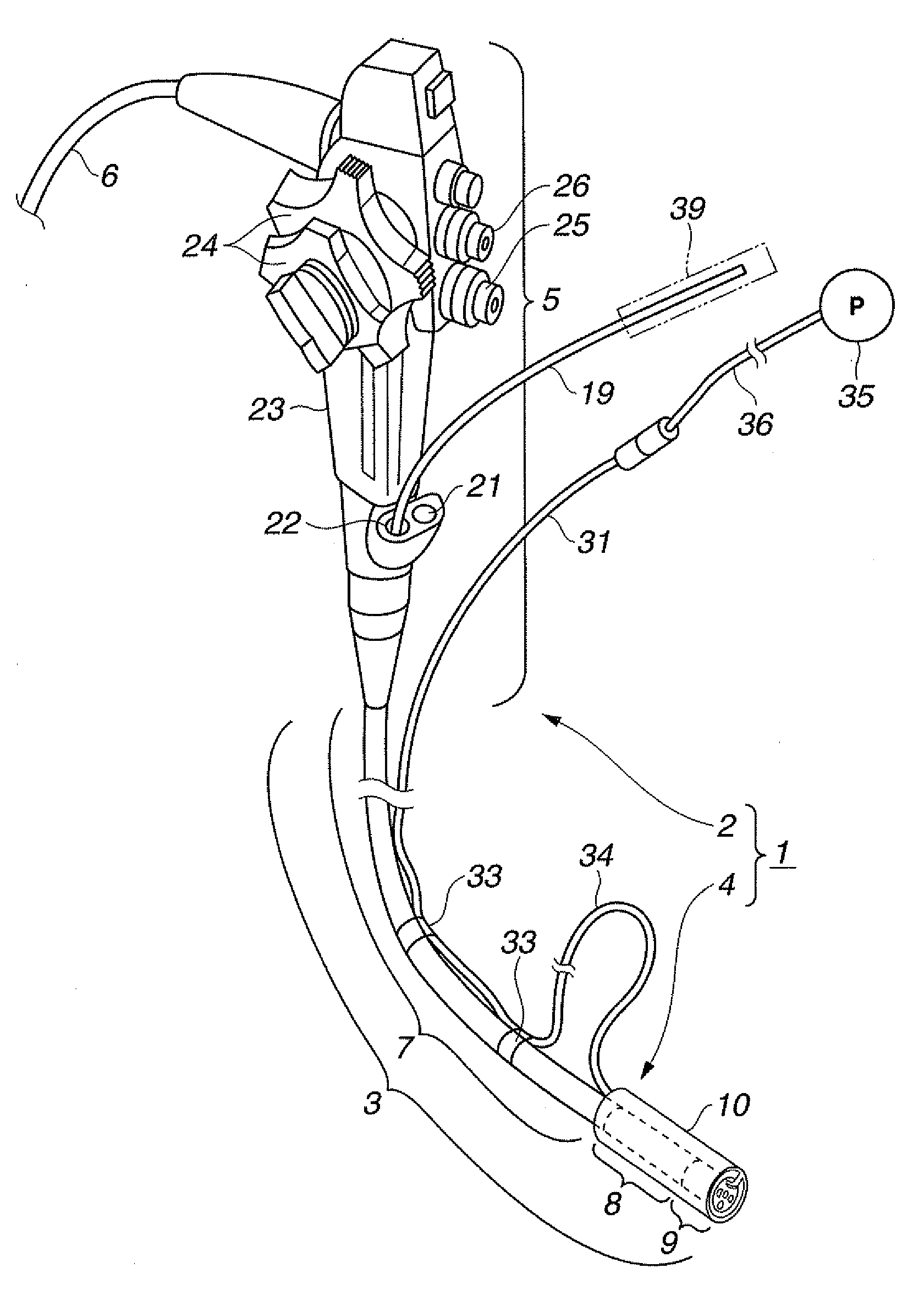

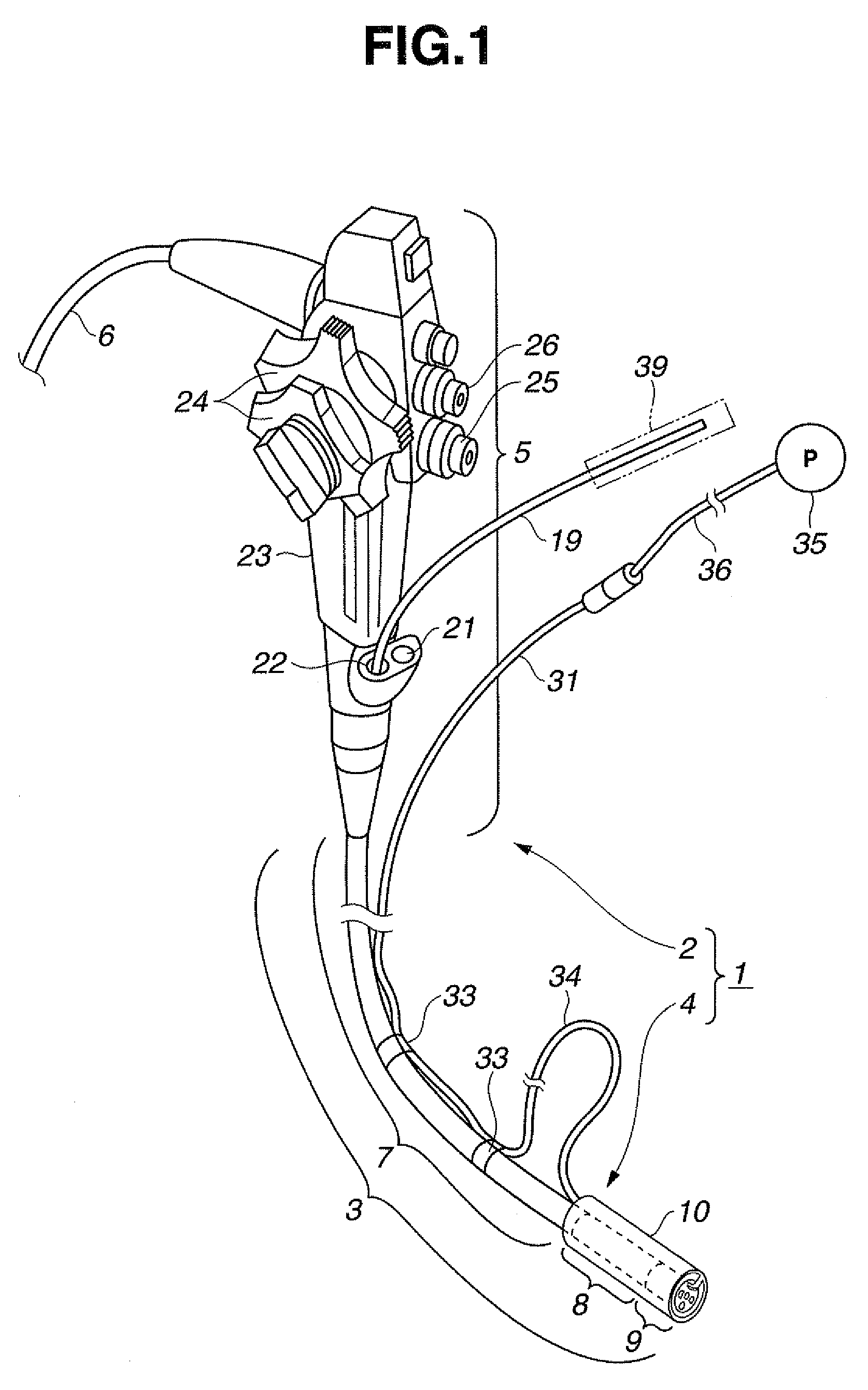

Endoscope insertion support tool and endoscope device

ActiveUS20090171156A1Smooth sectionEasily to smoothly insert insertionStentsBalloon catheterEndoscopeFluid supply

An endoscope insertion support tool includes an advancing and retracting member that is disposed in an insertion section of an endoscope, capable of advancing and retracting in a hollow passage, a distal end portion of which communicates with the outside, and has length projected from a distal end of the insertion section, a balloon member that includes an attaching portion attachable to an outer surface side of the insertion section of the endoscope and is connected to the distal end of the advancing and retracting member and capable of projecting from the distal end of the insertion section according to an advancing and retracting movement of the advancing and retracting member, and a fluid supplying and discharging unit including a conduit that is connected to the balloon member and inflates and deflates the balloon member according to supply and discharge of a fluid to and from the balloon member.

Owner:OLYMPUS CORP

Laser cutting device for small-aperture pipelines

InactiveCN106735941AEnsure the original shapeSeam smoothLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser cutting device for small-aperture pipelines. The laser cutting device for the small-aperture pipelines comprises a machine table, wherein a pipeline conveying mechanism is arranged above the machine table and used for controlling the translation and rotation of a pipeline; a laser cutting mechanism is arranged above the left side of the pipeline conveying mechanism; a material collecting water tank is arranged at the left side of the machine table and located below the laser cutting mechanism; the bottom of the material collecting water tank is provided with a water inlet pipe; the other end of the water inlet pipe is connected with a water inlet of a vacuum water pump arranged on the front of the machine table; a water outlet of the vacuum water pump is connected with a water outlet pipe; and the other end of the water outlet pipe is connected into the right end of the pipeline conveying mechanism and used for connecting an inner core at the right end of the pipeline. The laser cutting device for the small-aperture pipelines has the advantages that the precise machining of a product with any pipeline diameter in a region between 0.1mm and 20mm is realized, the kerf is neat, the fracture surface is smooth, high-temperature deformation produced during laser cutting is avoided, the initial shape of a machined material is ensured, the machining speed is raised, the structure is simple, and the manufacture cost is low.

Owner:SUZHOU TIANHONG LASER

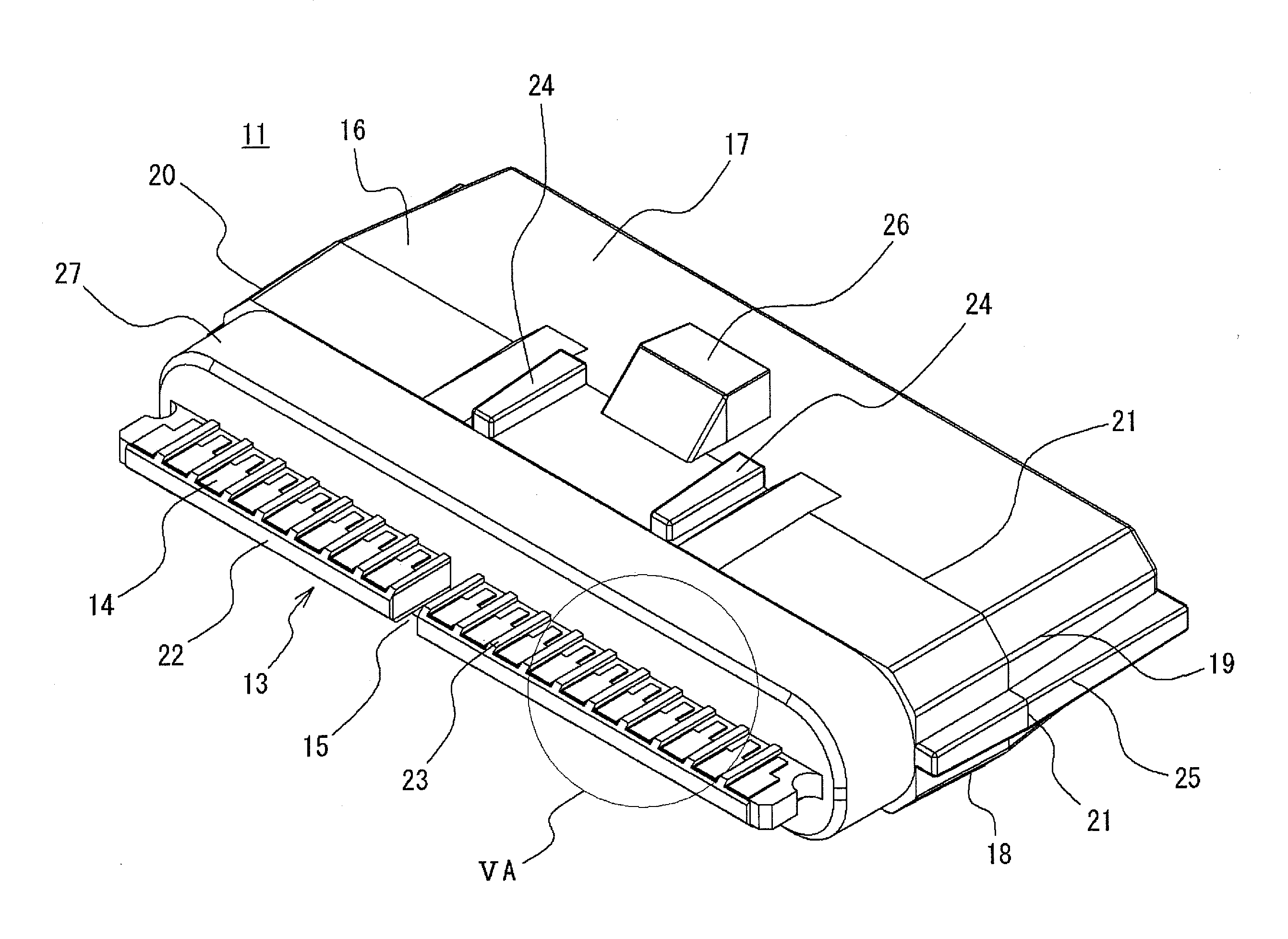

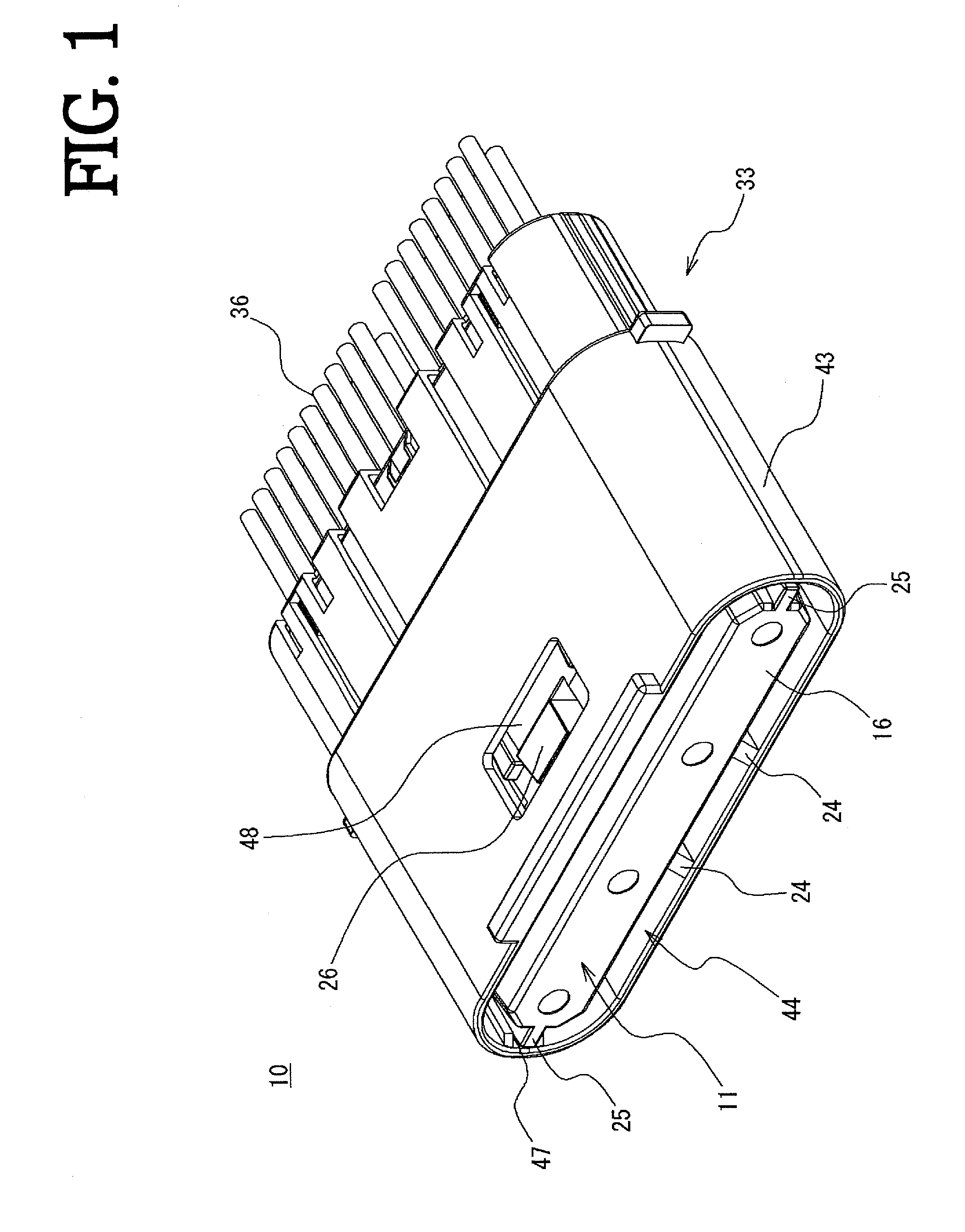

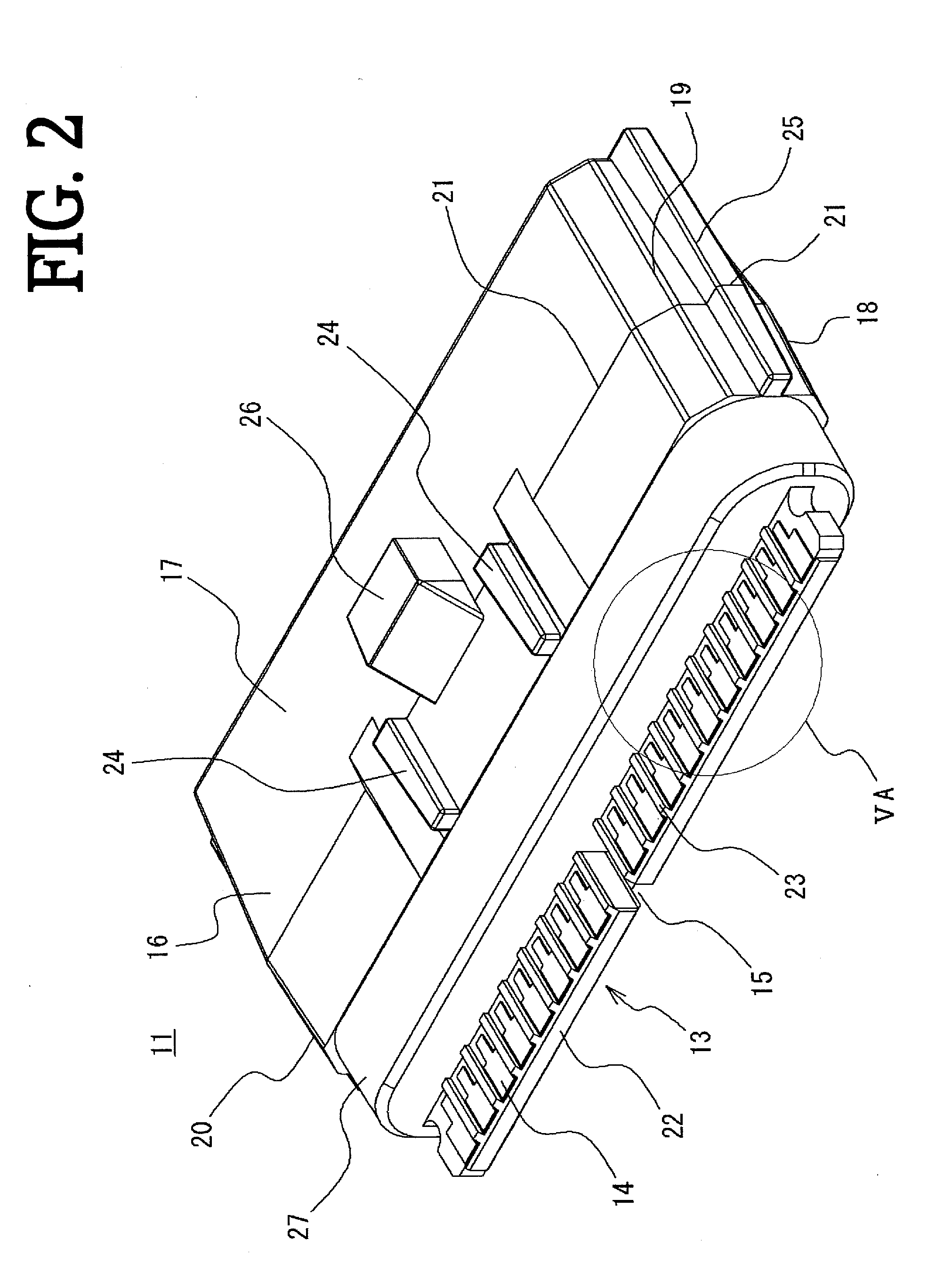

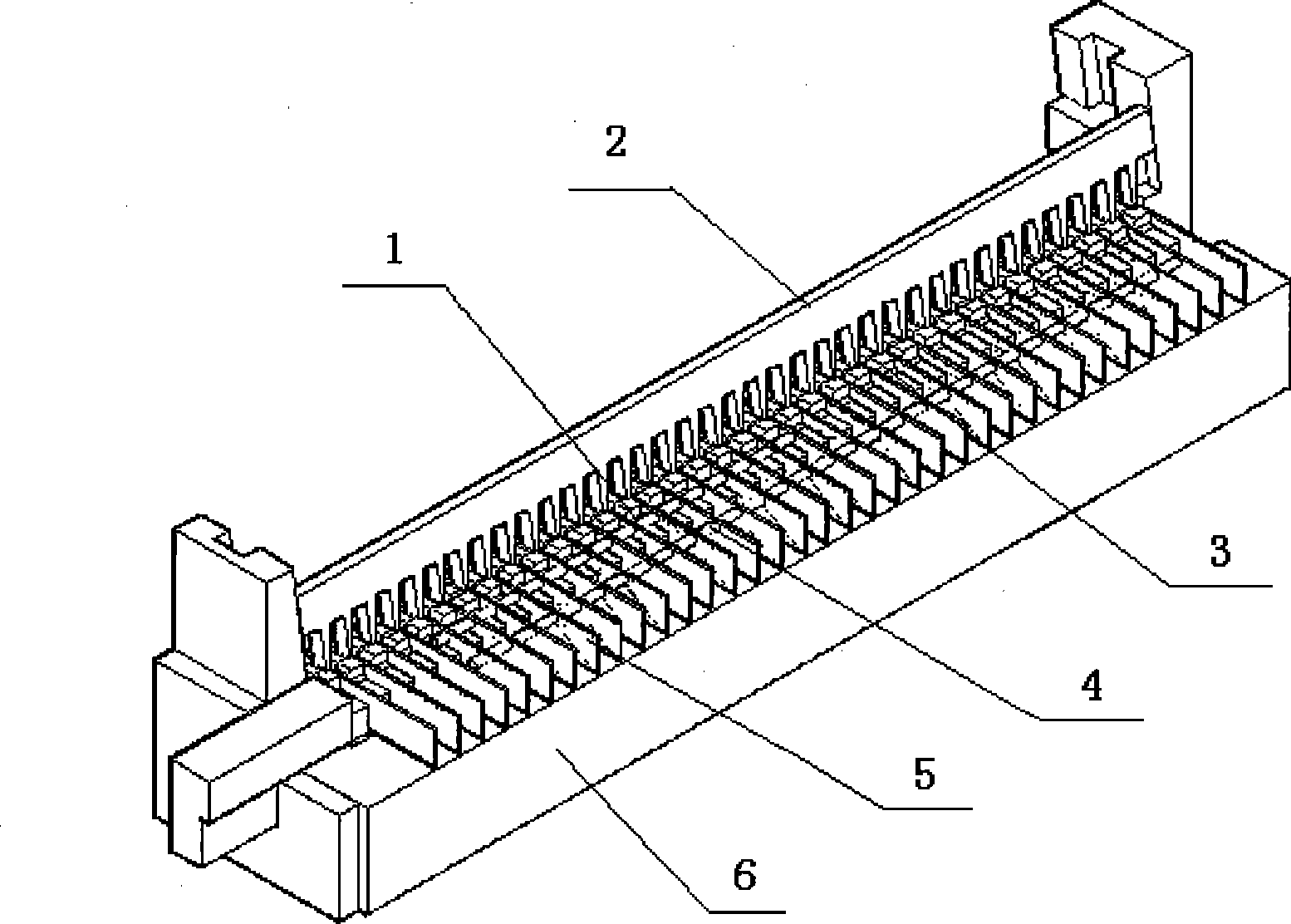

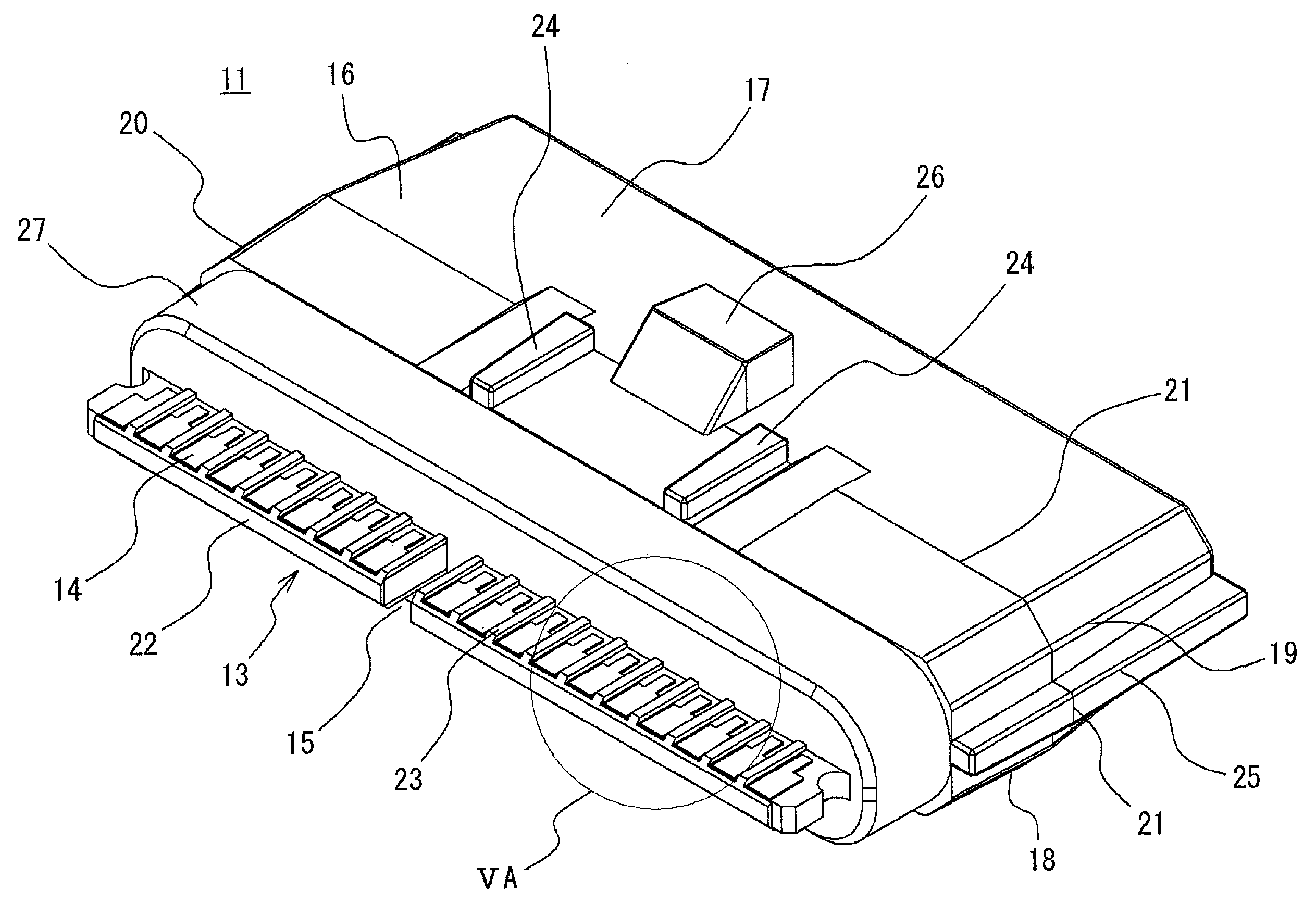

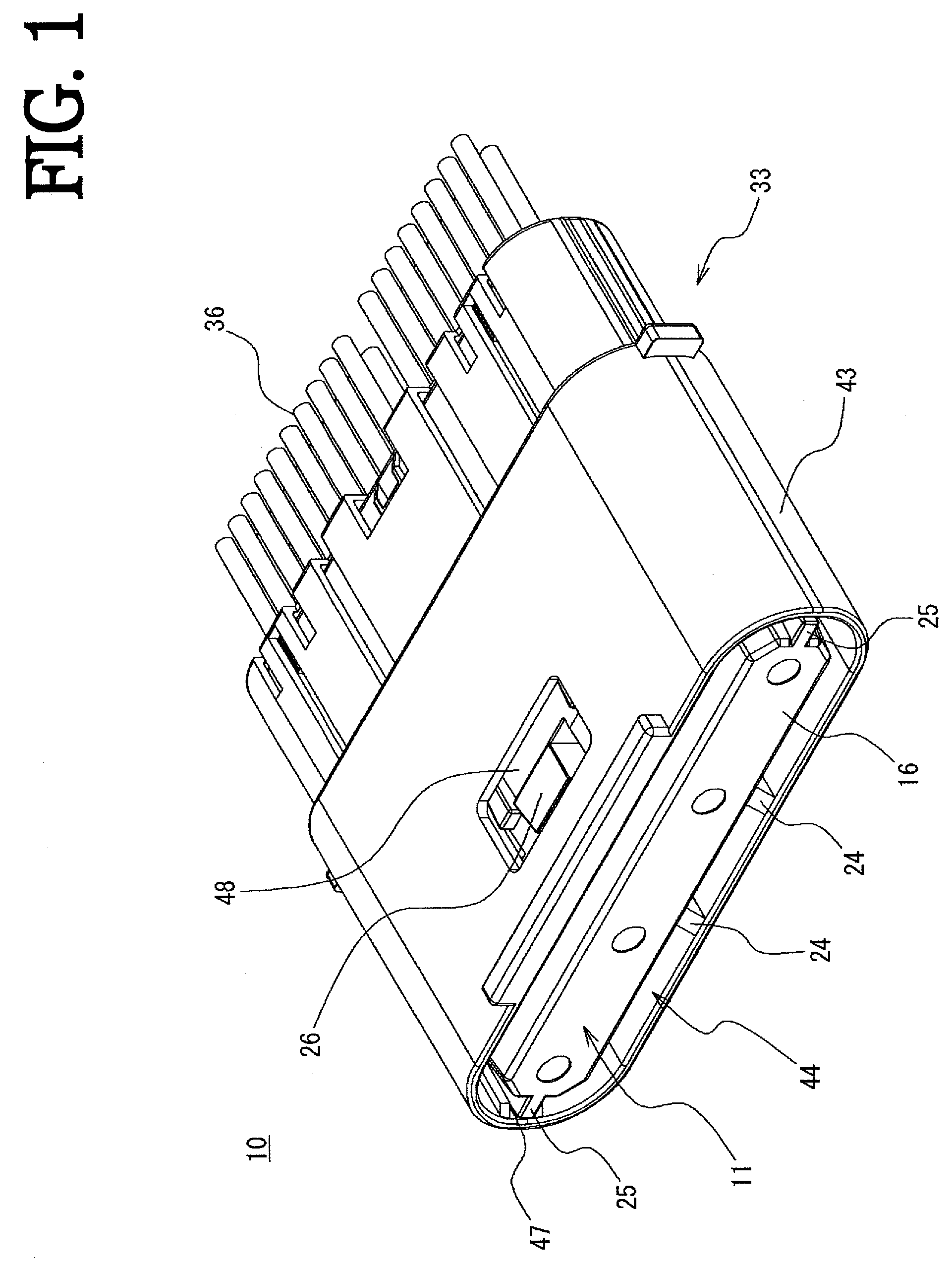

Card member, card edge connector, and method for manufacturing card member

InactiveUS20130288541A1Smooth fitting sectionNo unevennessElectrically conductive connectionsContact member assembly/disassemblyEngineeringSynthetic resin

A method for manufacturing a card member includes: preparing a substrate having a card edge section with card edge terminals to be connected to an opposing connector; preparing a fist mold and a second mold that have molding spaces for molding a resin molded section having a fitting section to be fitted with the opposing connector formed around the substrate; placing the substrate inside the molding spaces between the first mold and the second mold in such a way that the joining portion of the first mold and the second mold are disposed so as not to be overlapped with the portion where the fitting section is to be formed; injecting a synthetic resin material into the molding space to integrally form the resin molded section around the substrate. The method can provide a card member having an excellent watertightness.

Owner:JST MFG CO LTD

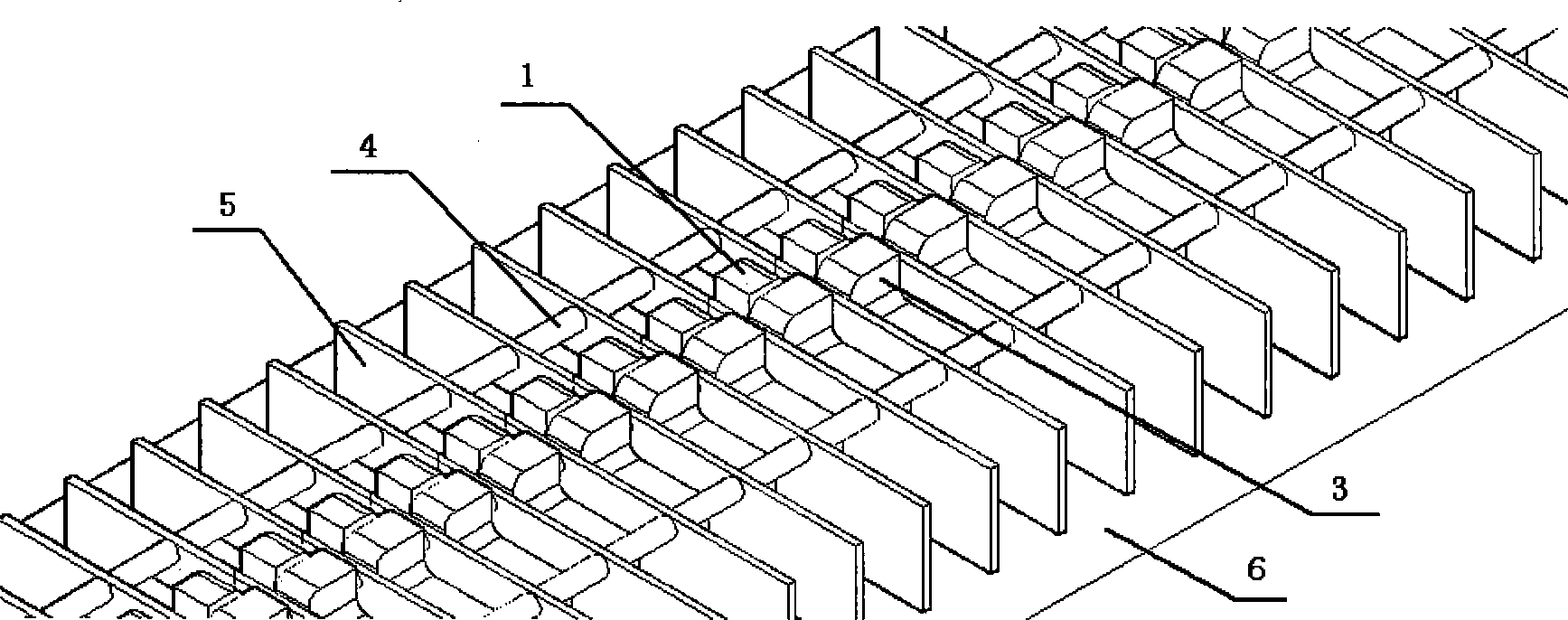

Cuneiform hold-down mechanism for steel grating gang tool shearing machine

ActiveCN101367140AEliminate voidsSmooth sectionShearing machinesPositioning apparatusAutomatic controlEngineering

The invention discloses a wedged pressing mechanism for the shearing of a steel grid plate combined tool. A combined tool consisting of a fixed cutting tool and a movable cutting tool is arranged on a tool rest, flat steel and a vertical transverse rod of the steel grid plate pass through the gap between the fixed cutting tool and the movable cutting tool, the back side of a blade of the fixed cutting tool is provided with a plurality of tilted grooves with wider upper part and narrower lower part, and the flat steel passes through the inside of the tilted groove. A wedged pressing plate corresponding to the tilted grooves is arranged above the fixed cutting tool, and the wedged pressing plate can extend to the bottom of the gap formed by the flat steel and one side of the tilted groove from top to bottom. The invention makes use of the wedged pressing mechanism above the fixed cutting tool to press tightly the flat steel of the steel grid plate to the blade along the direction of the tilted groove so as to eliminate the gap of the flat steel in the combined tool. The pressing and lifting actions of the wedged pressing mechanism are achieved when performing shearing, and the gap is adjusted by an automatic control mechanism of the shearing machine, thus the section after shearing has the advantages of tidiness, smoothness, and straight flat steel.

Owner:溧阳常大技术转移中心有限公司

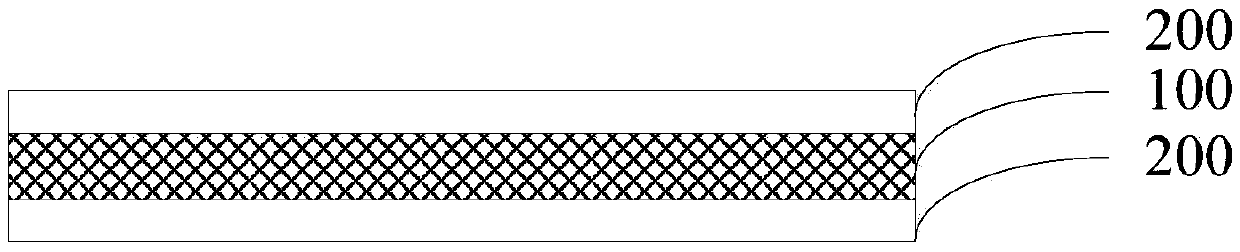

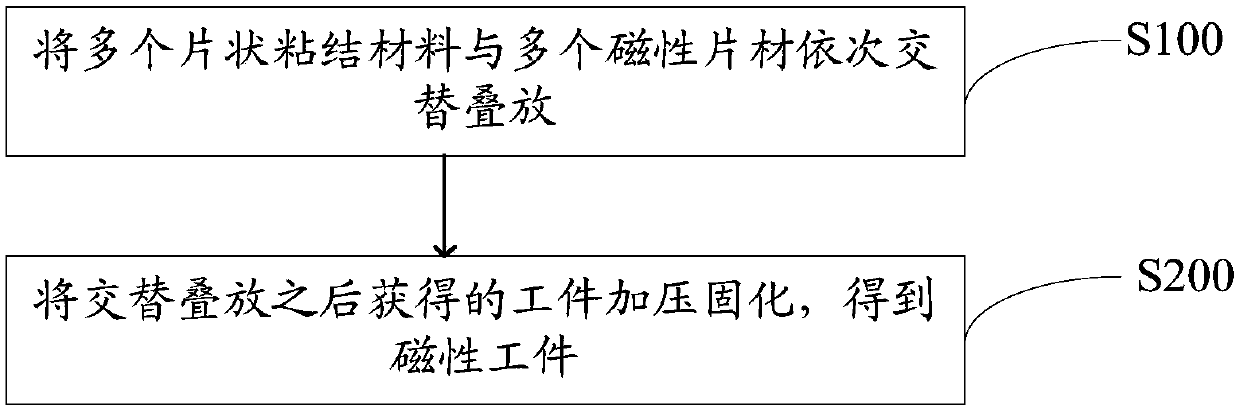

Sheet bonding material and magnetic workpiece and preparation method and application thereof

InactiveCN109686530ASimple structureUniform thicknessFilm/foil adhesivesPermanent magnetsNanotechnology

The invention provides a sheet bonding material and a magnetic workpiece and a preparation method and application thereof, and relates to the field of magnetic material bonding. The sheet bonding material comprises an insulating layer and glue layers disposed on the two opposite surfaces of the insulating layer. The inventor finds that the sheet bonding material has a simple structure, a uniform thickness, easy control of the thickness of the sheet bonding material, no bubbles and excellent bonding and insulating effects.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

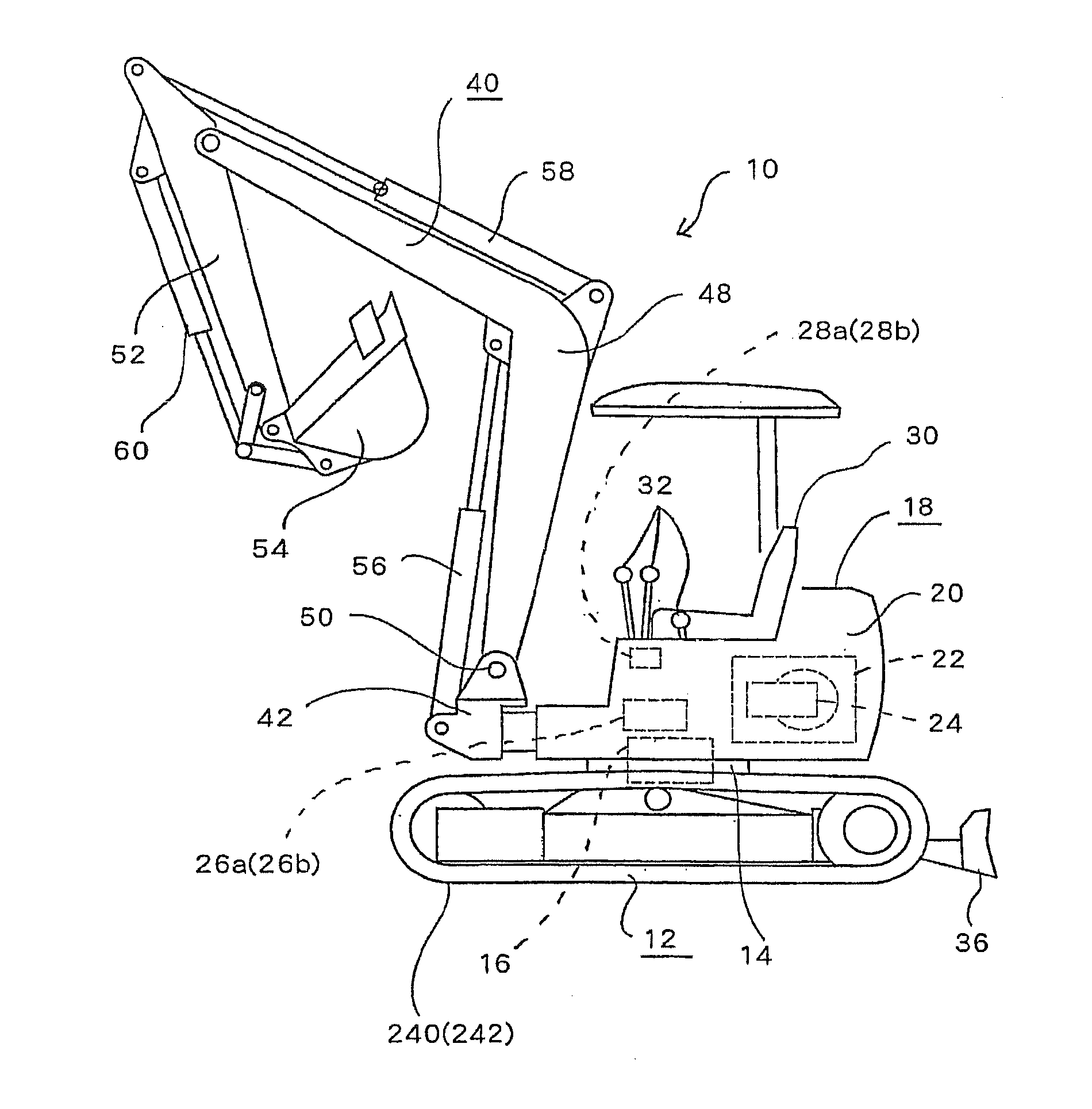

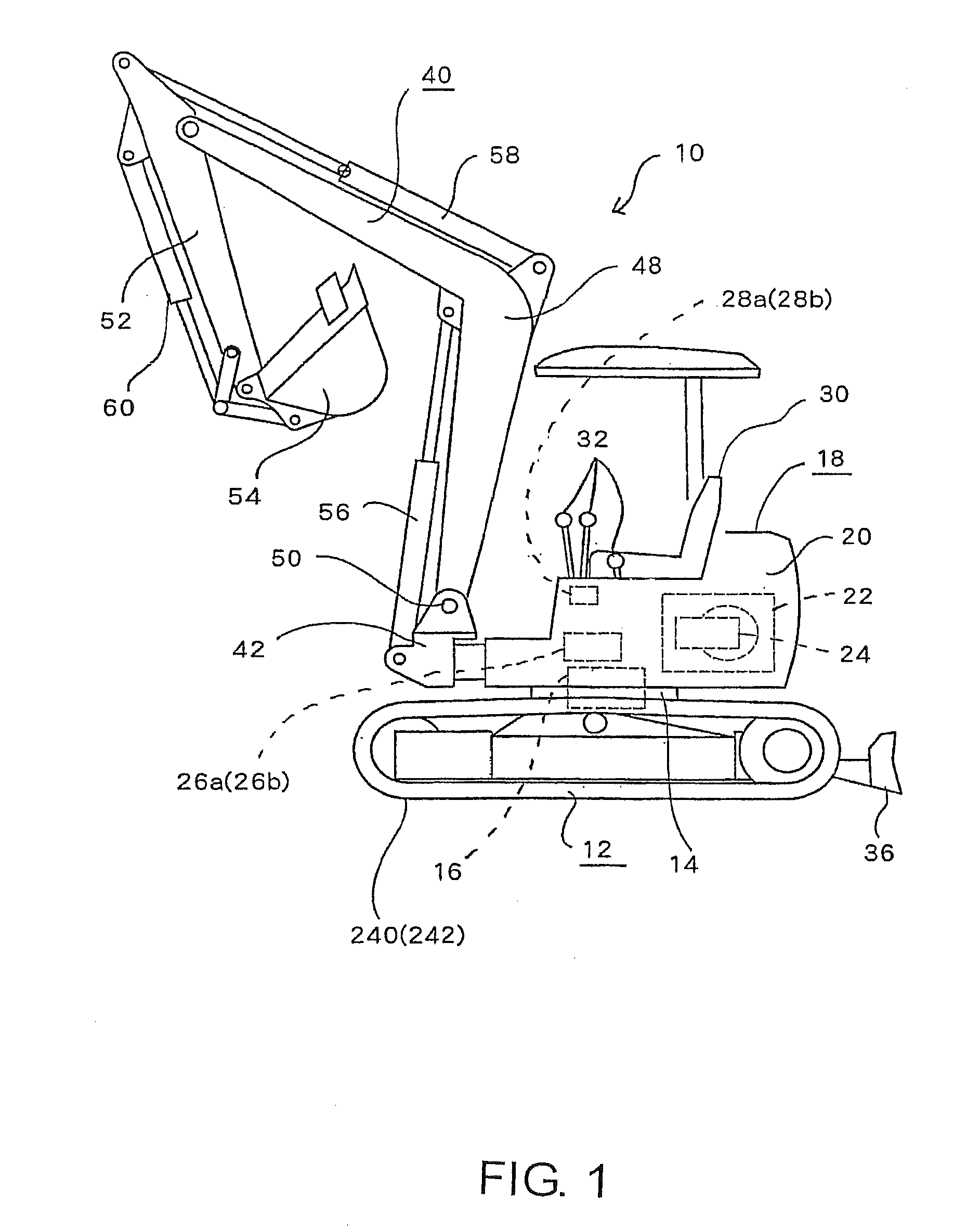

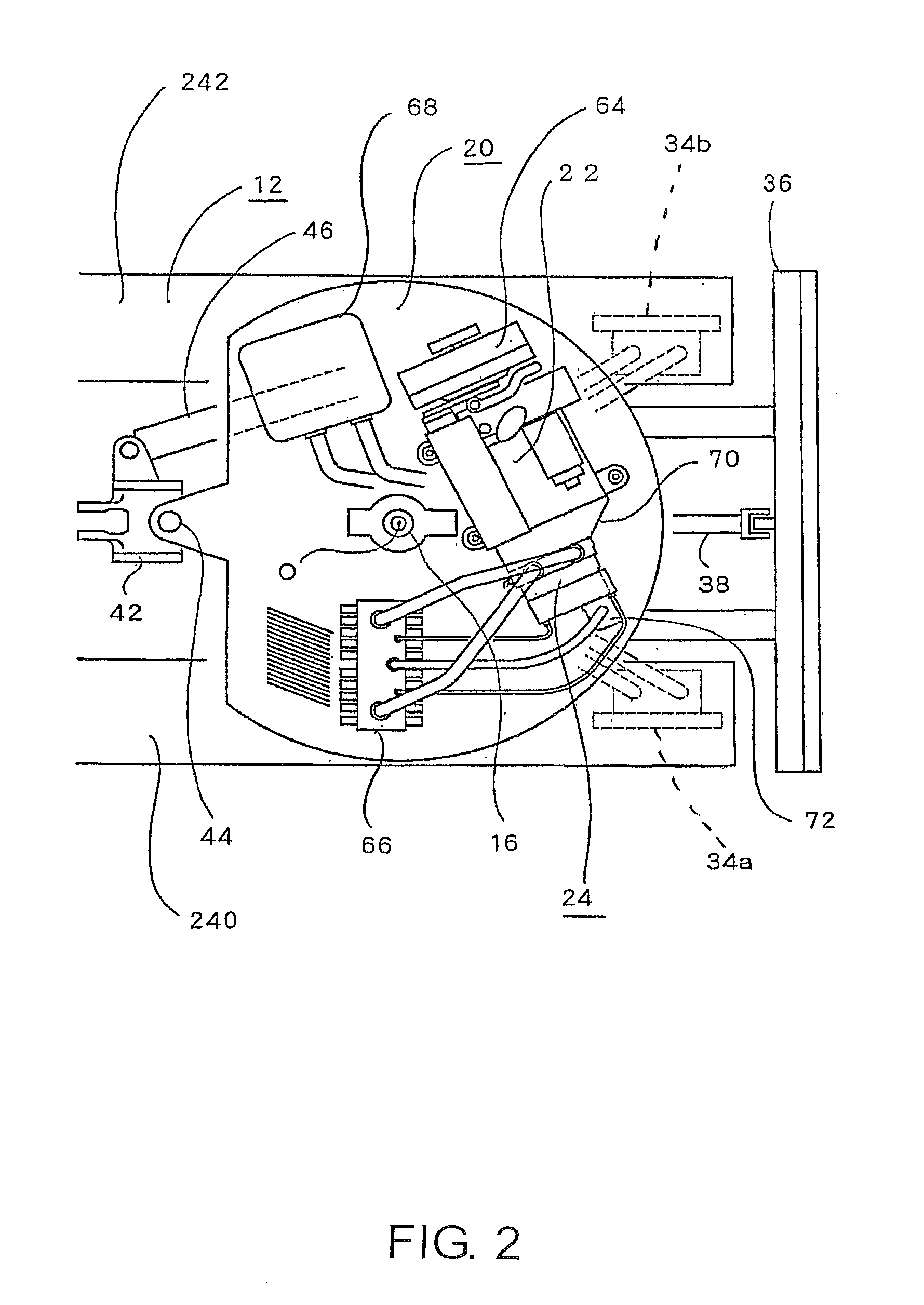

Hydraulically-powered working vehicle

InactiveUS20120097460A1Cost reductionReduce power lossFluid-pressure actuator testingServomotor componentsActuatorControl theory

A hydraulically powered working vehicle includes a turning section provided at an upper side of a travel unit capable of turning, and hydraulic circuits for the working vehicle. The hydraulic circuit for the working vehicle has a first actuator group including a one side traveling motor, a first variable capacity pump for driving the first actuator group, a second actuator group including an other side traveling motor and a turning motor, and a second variable capacity pump for driving the second actuator group. The second variable capacity pump is set so that a maximum value for discharge capacity per unit time becomes large compared to that of the first variable capacity pump.

Owner:KANZAKI KOKYUKOKI MFG +1

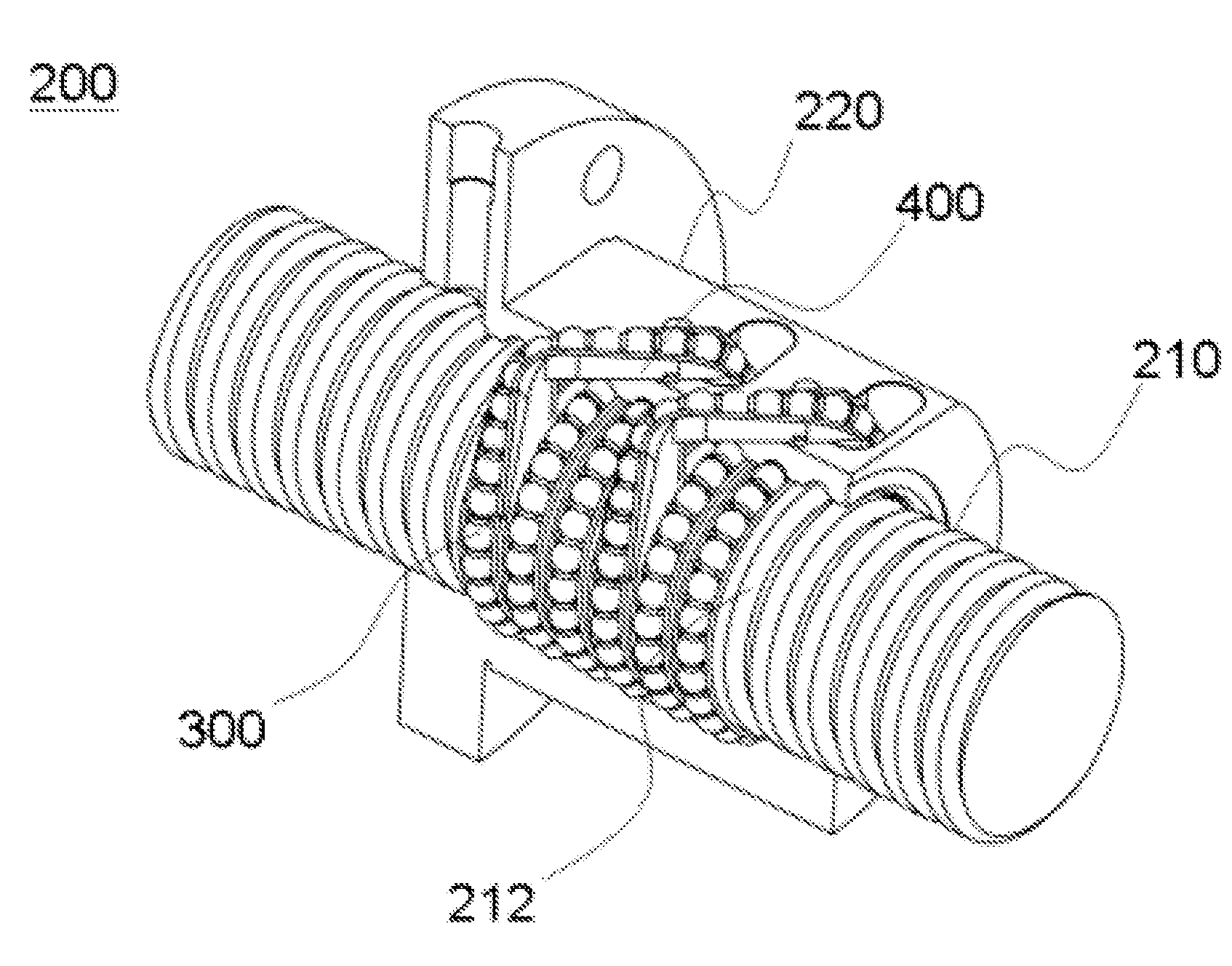

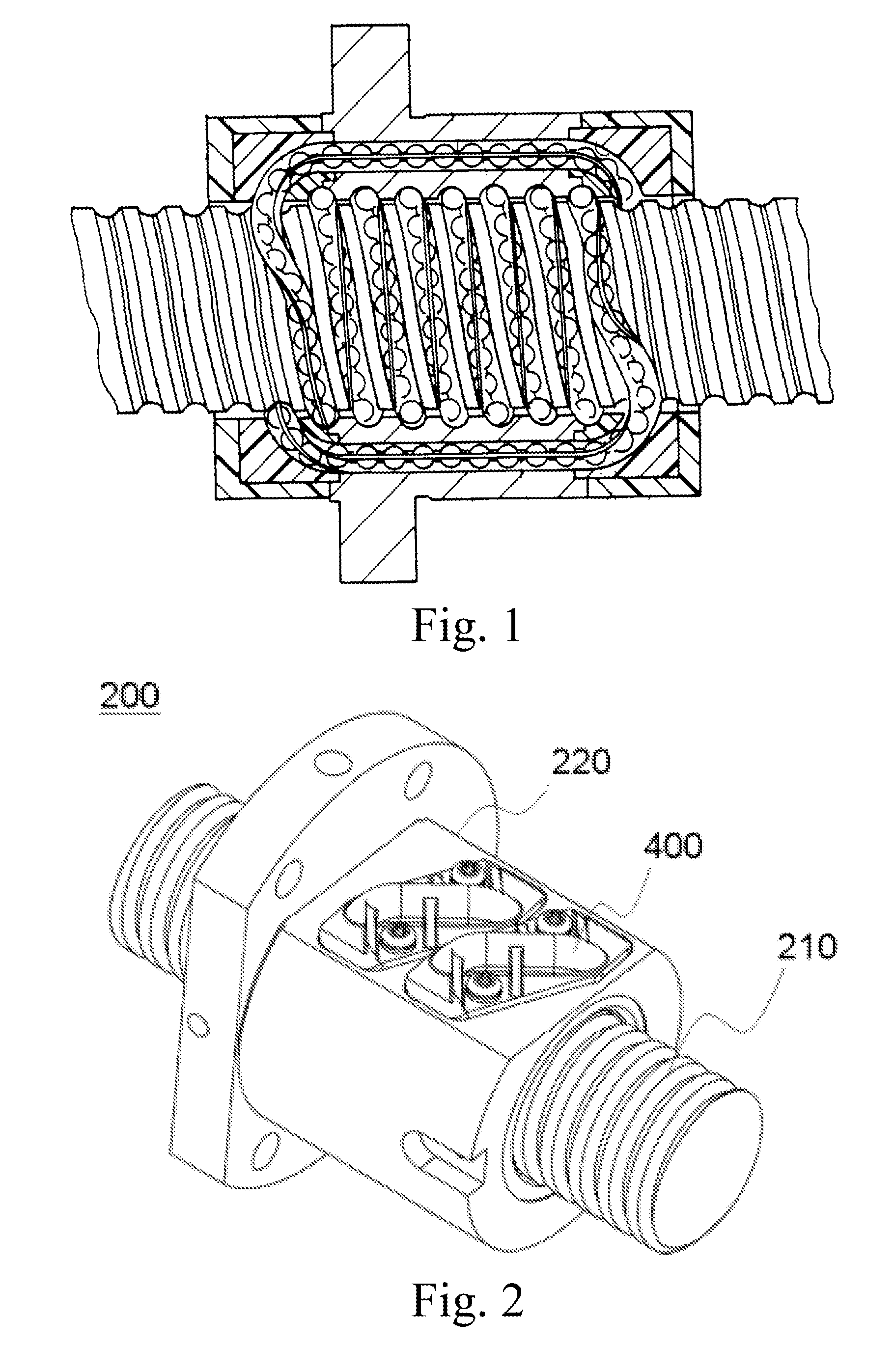

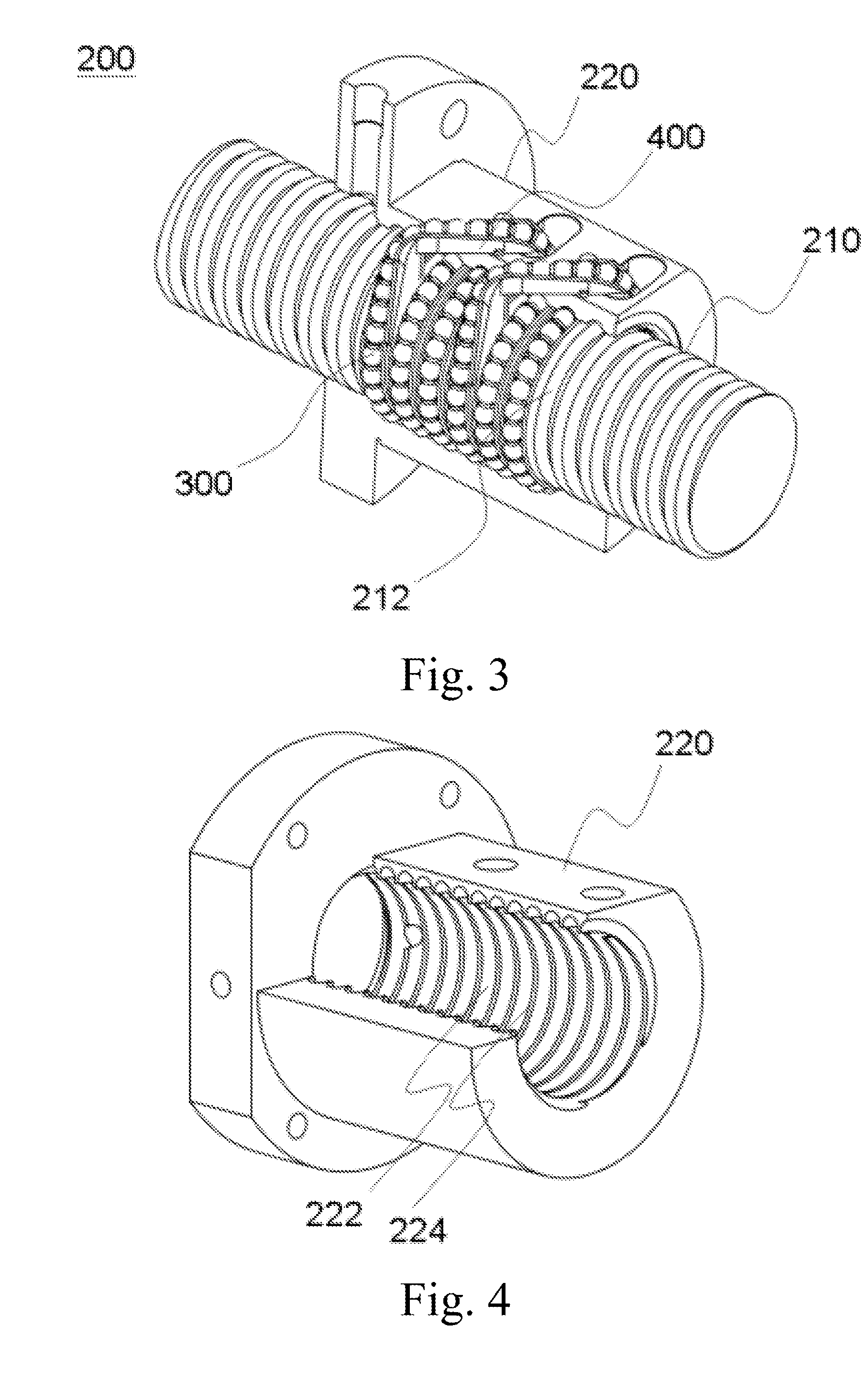

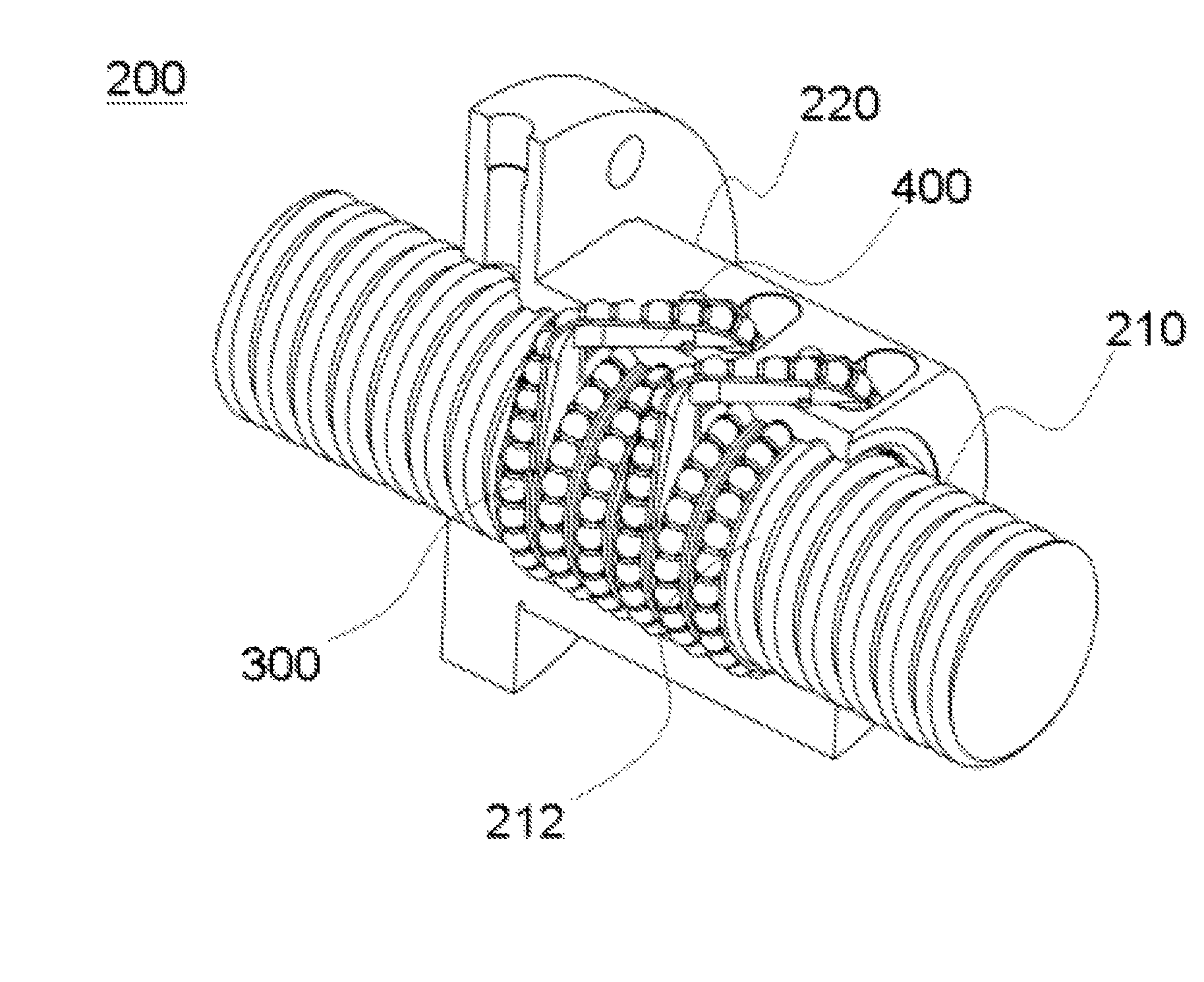

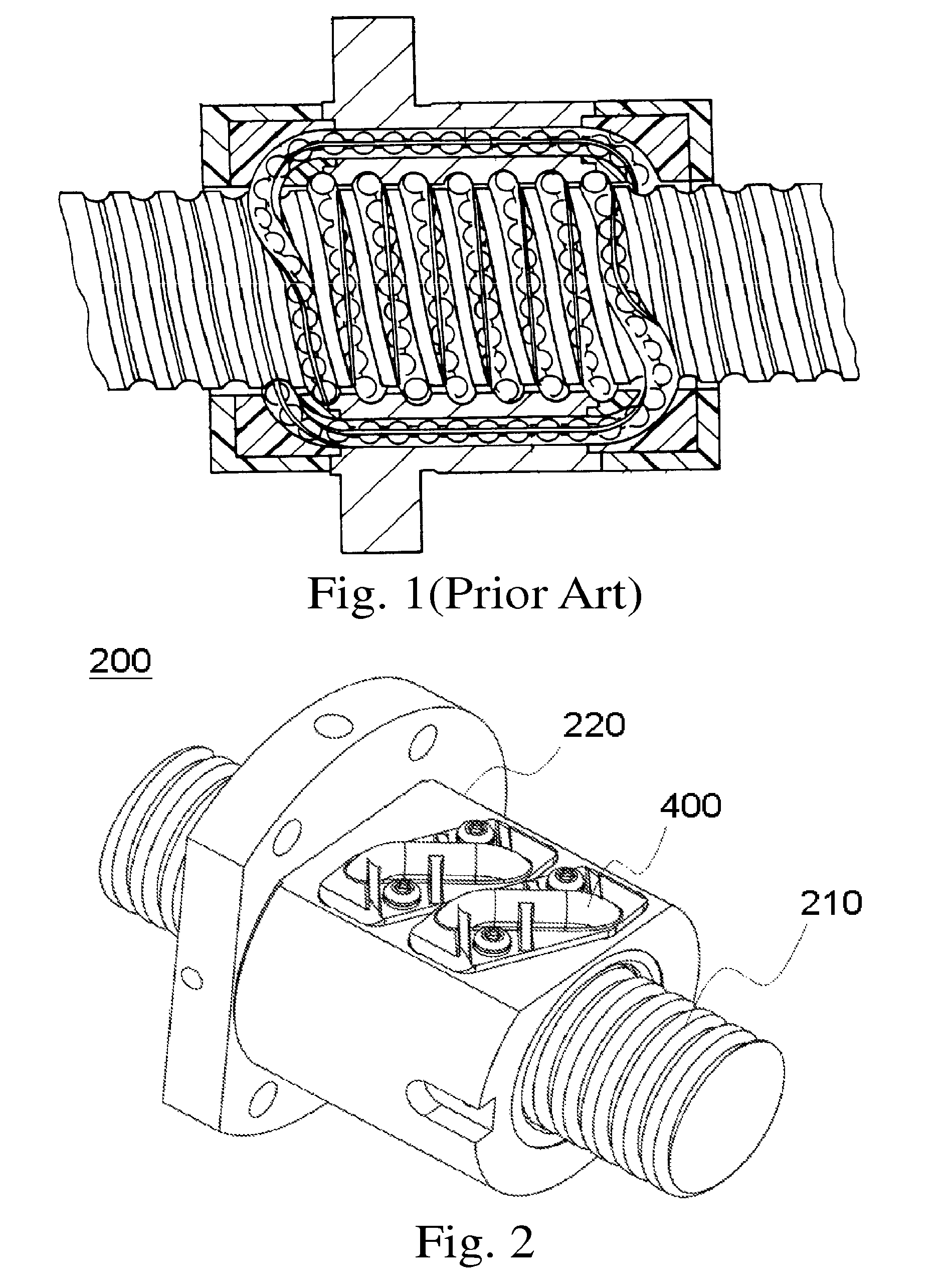

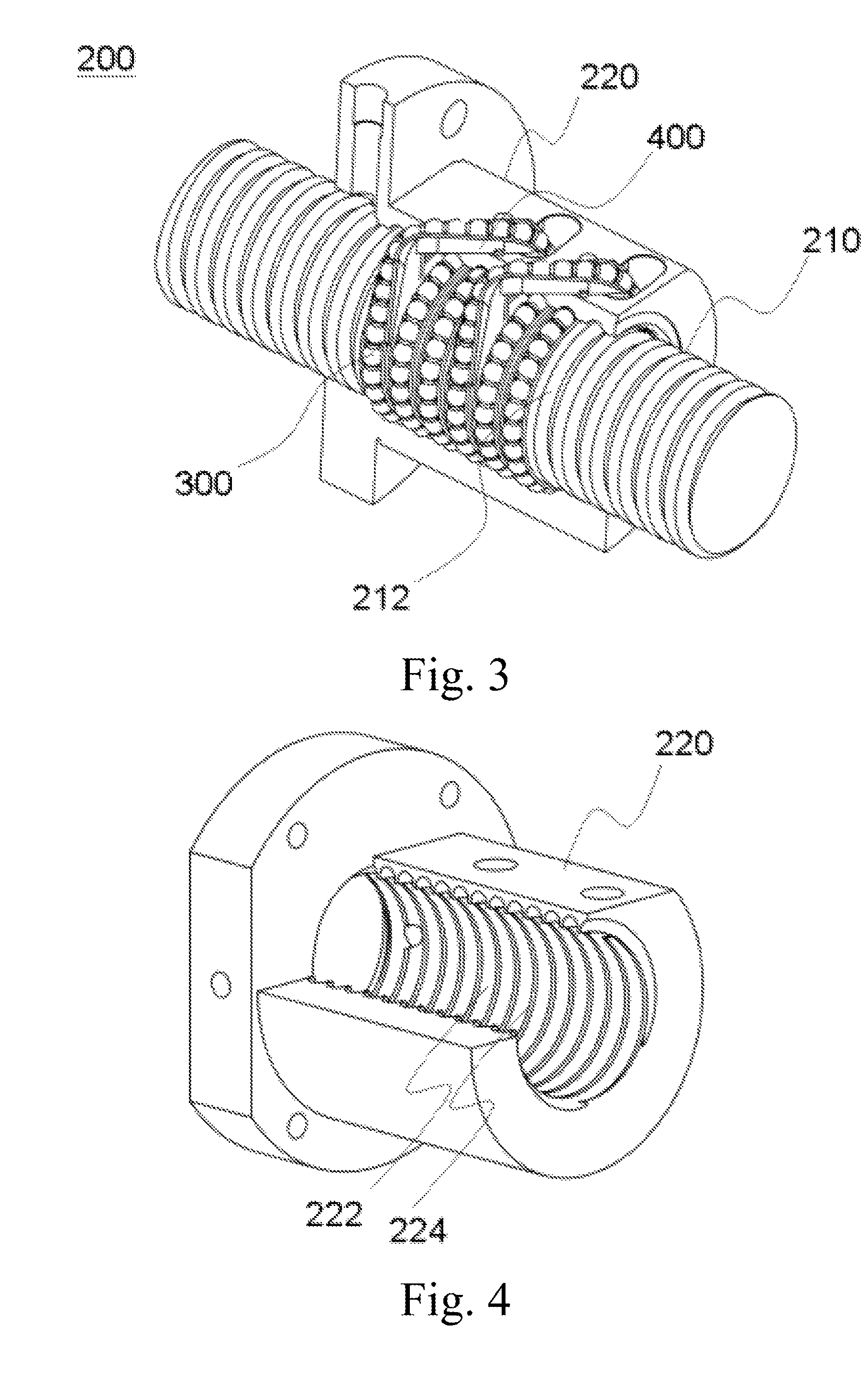

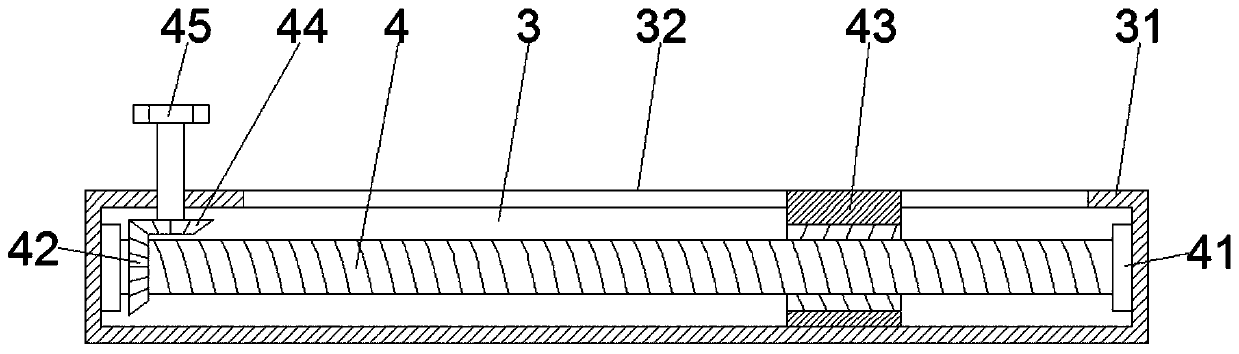

Ball screw module

ActiveUS20100050802A1Improve performanceHigh precisionPortable liftingToothed gearingsEngineeringBall screw

Provided is a ball screw module including a screw shaft, a nut member, a ball connector, and a circulating device inside the nut member. The screw shaft and the nut member constitute a first load rolling groove. The circulating device, being connected with the first load rolling groove, has a first turning section and a second turning section, and includes a first guiding groove and a second guiding groove. The first guiding groove has a radius of curvature greater than that of the second guiding groove when the ball connector passes the first turning section. The first guiding groove has the radius of curvature smaller than that of the second guiding groove when the ball connector passes the second turning section.

Owner:HIWIN TECH

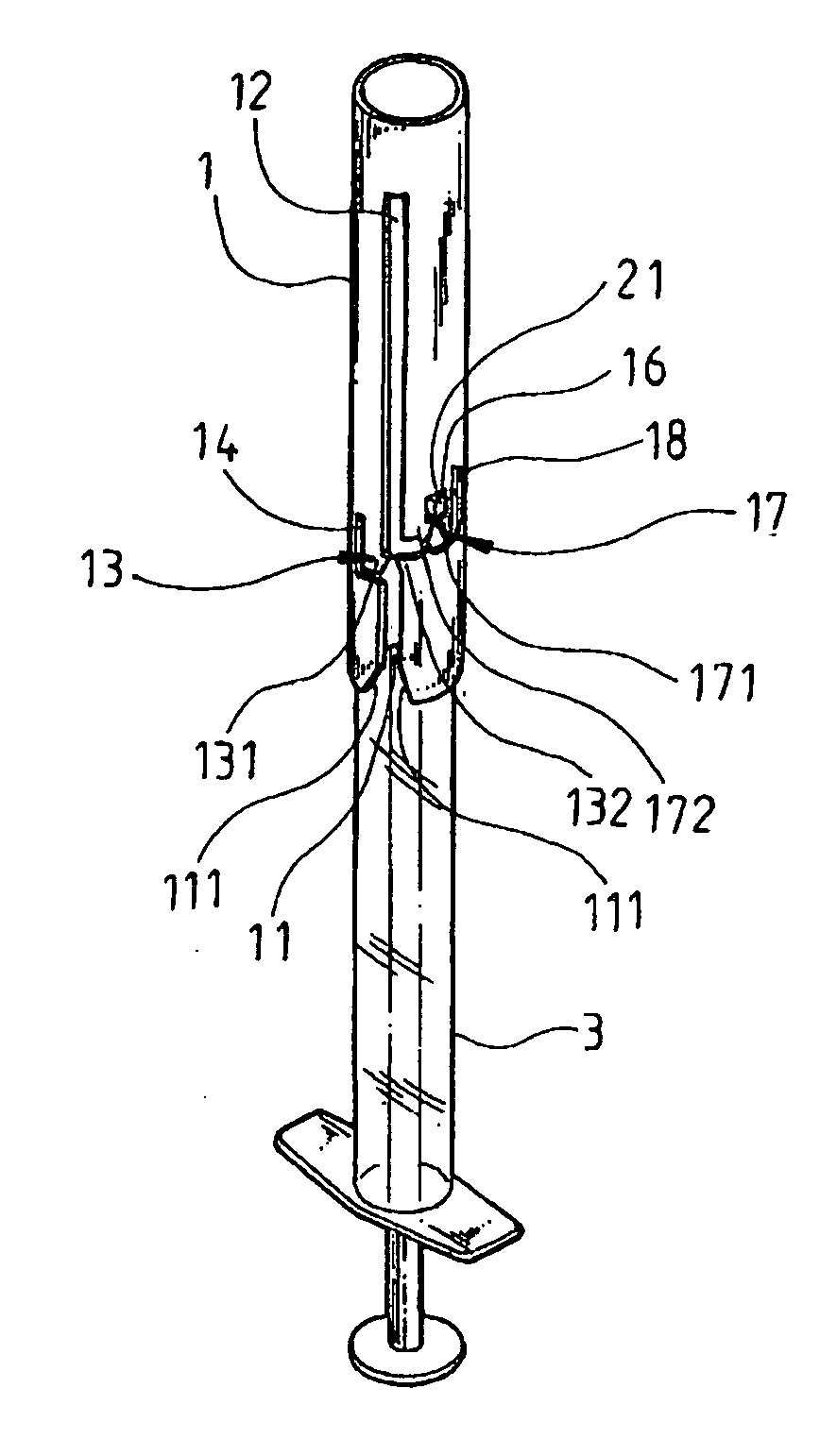

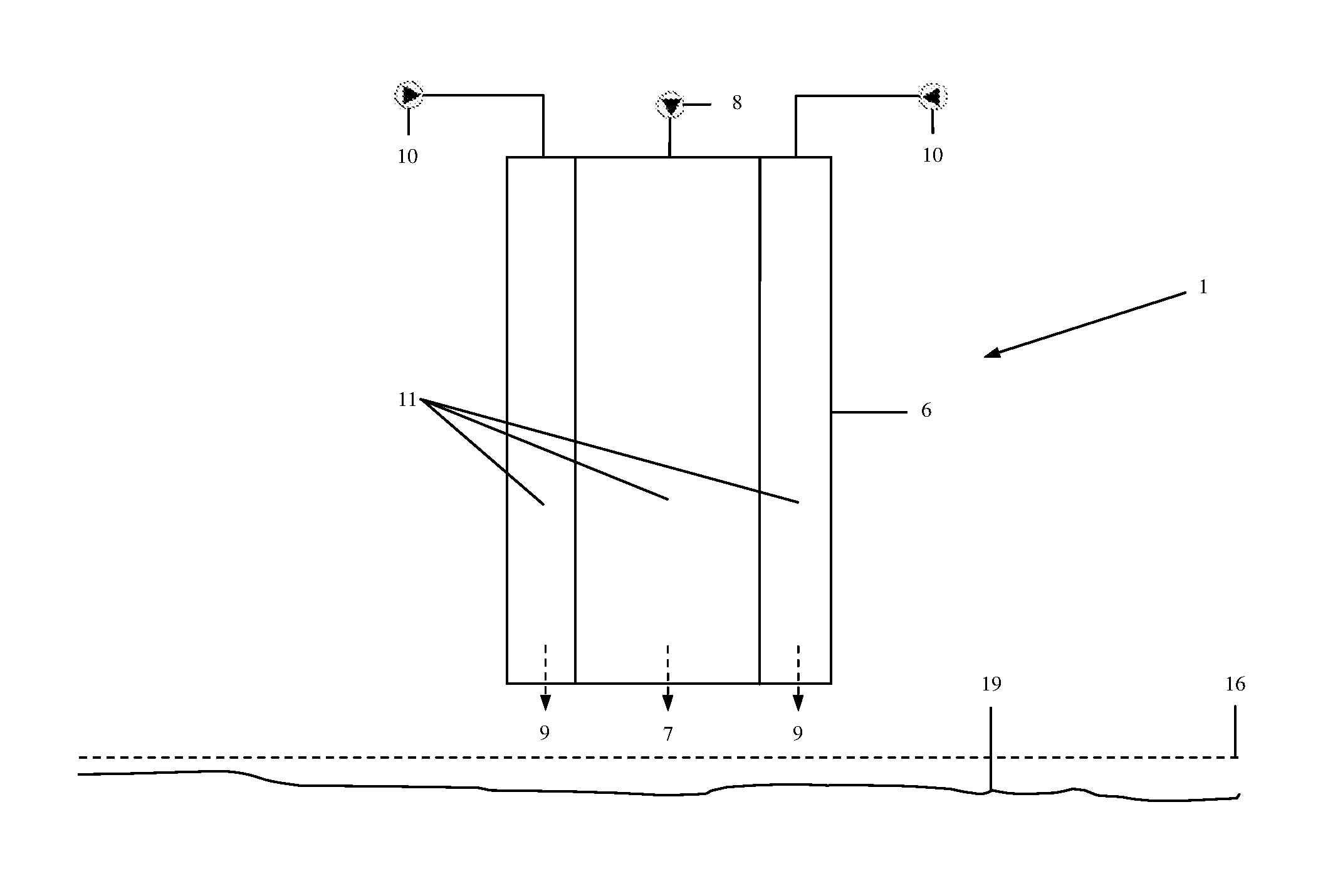

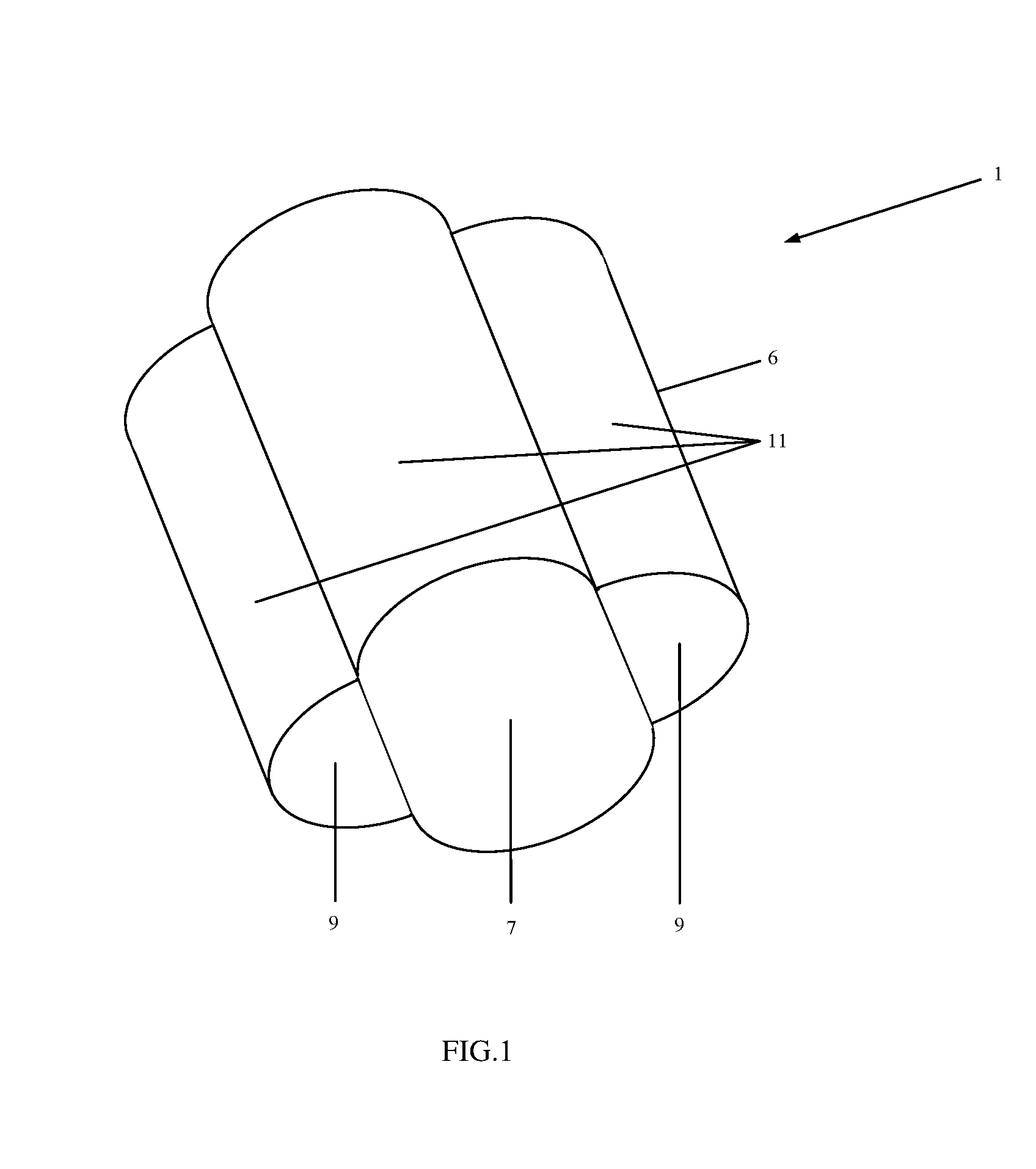

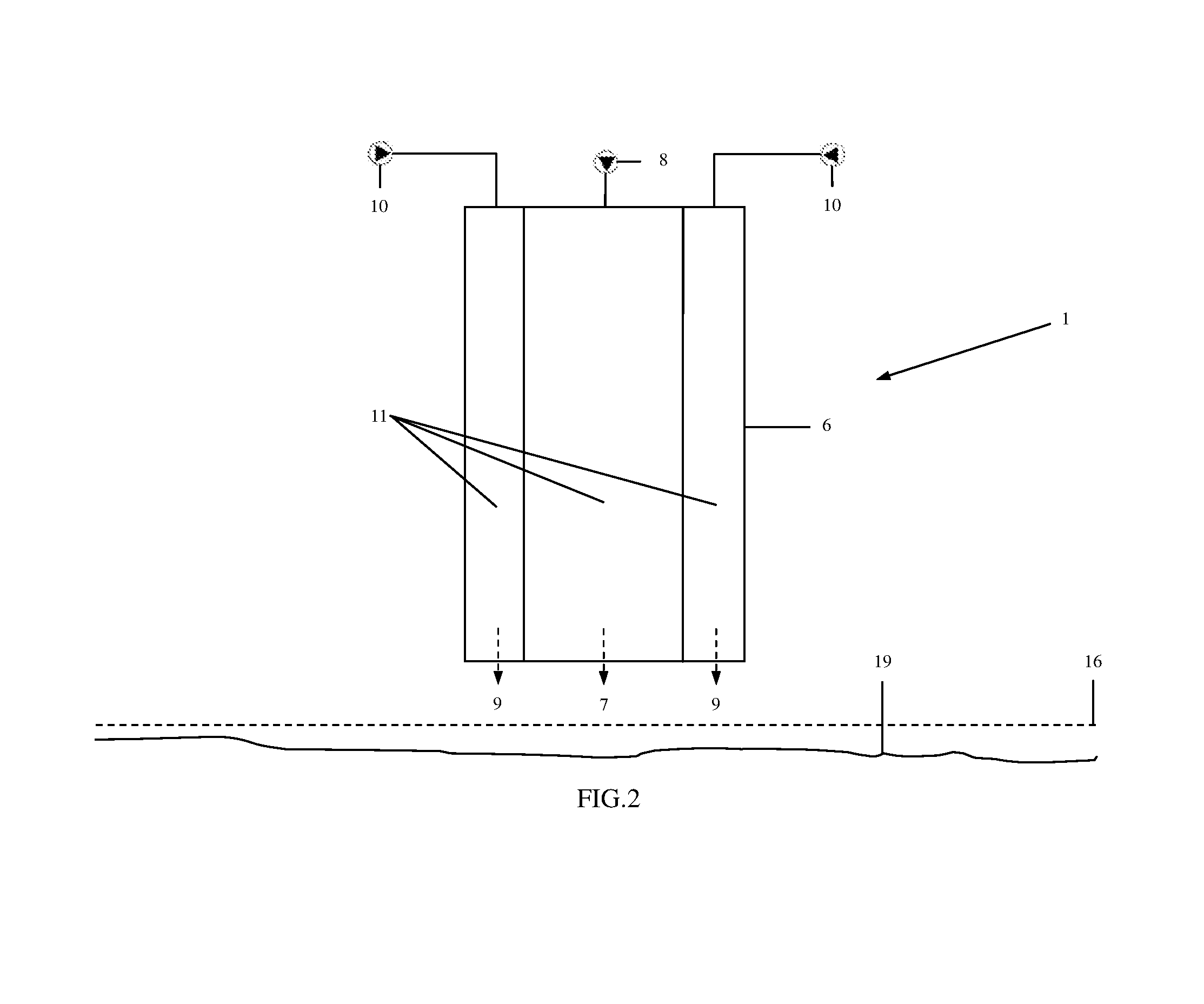

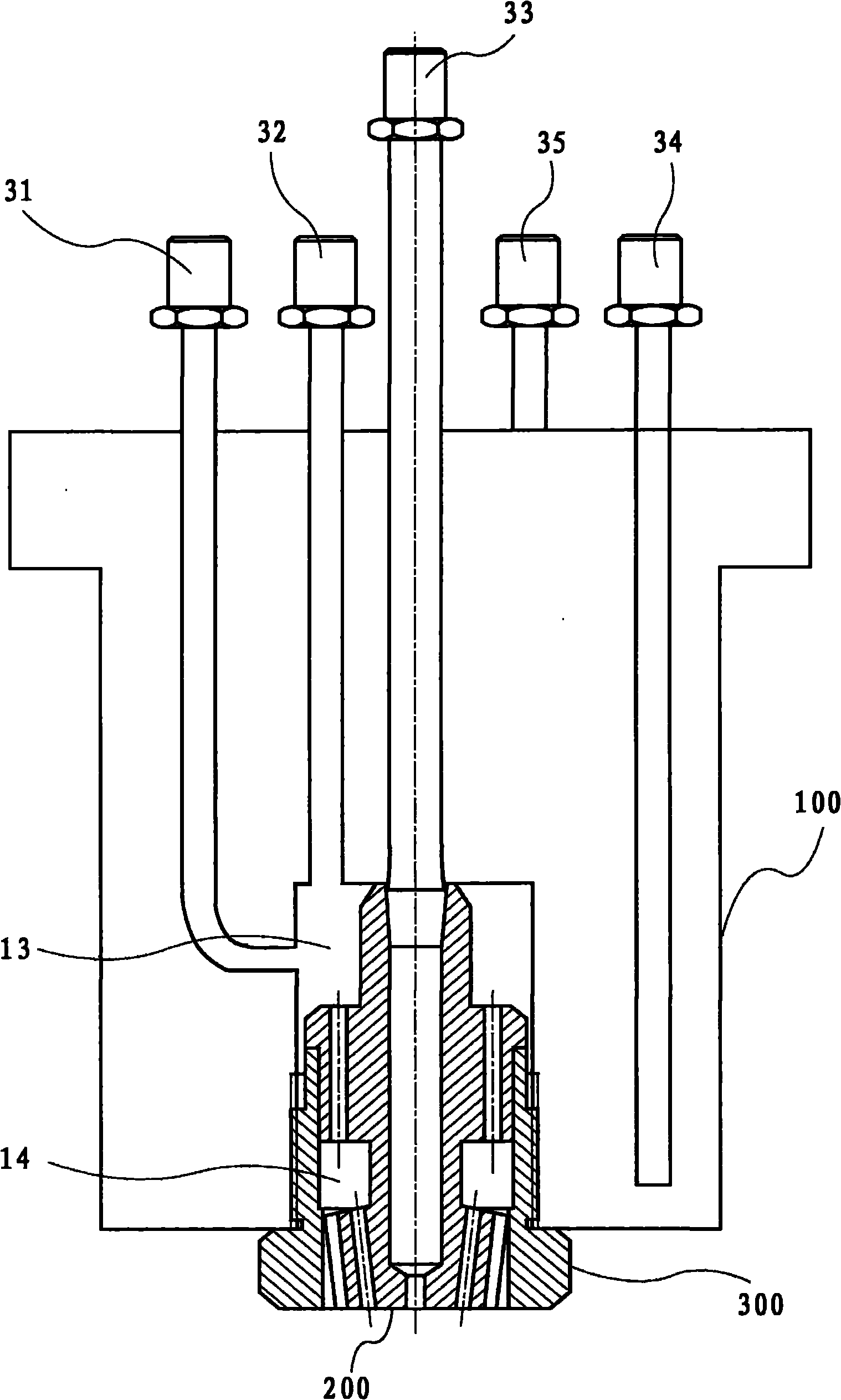

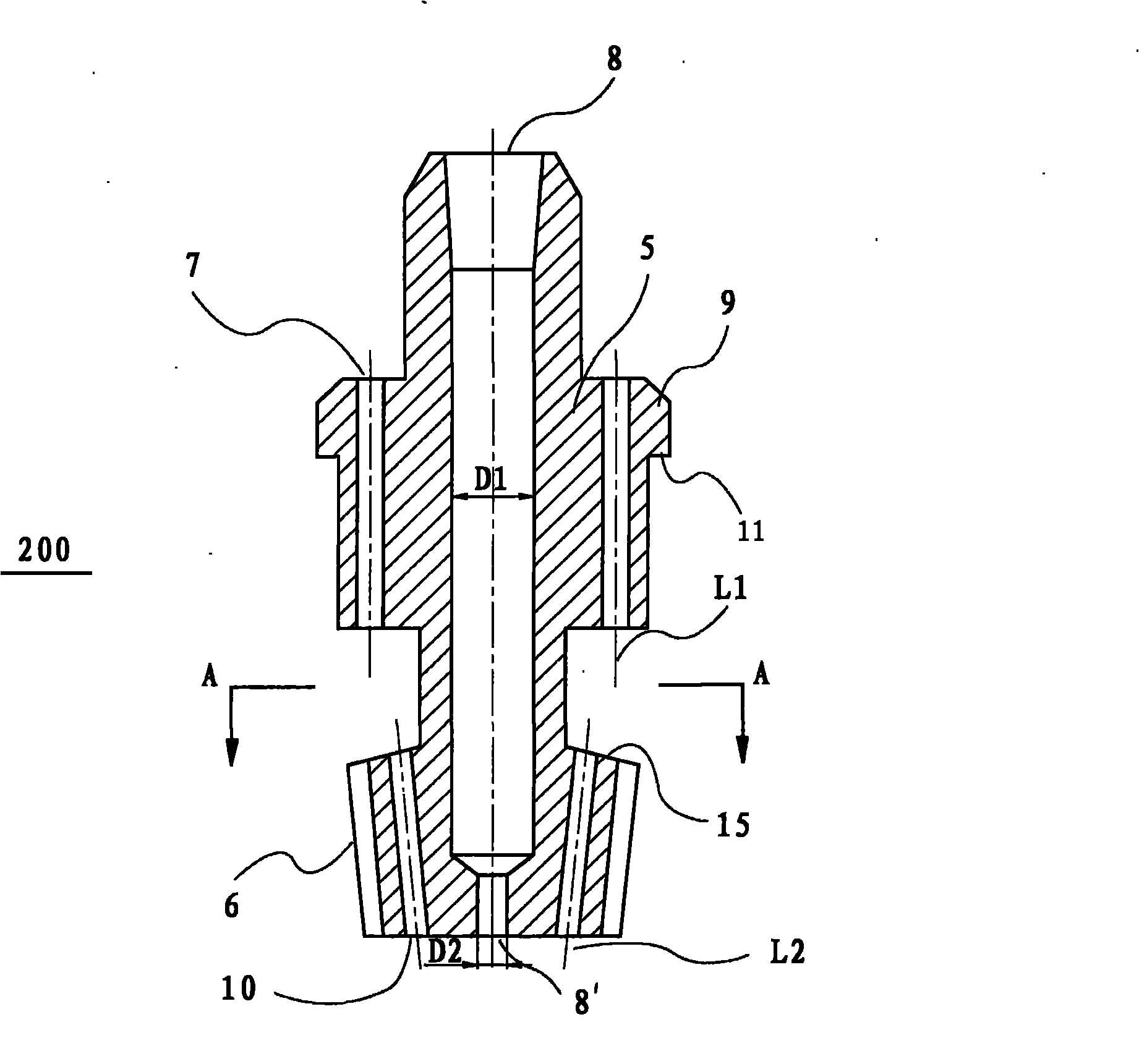

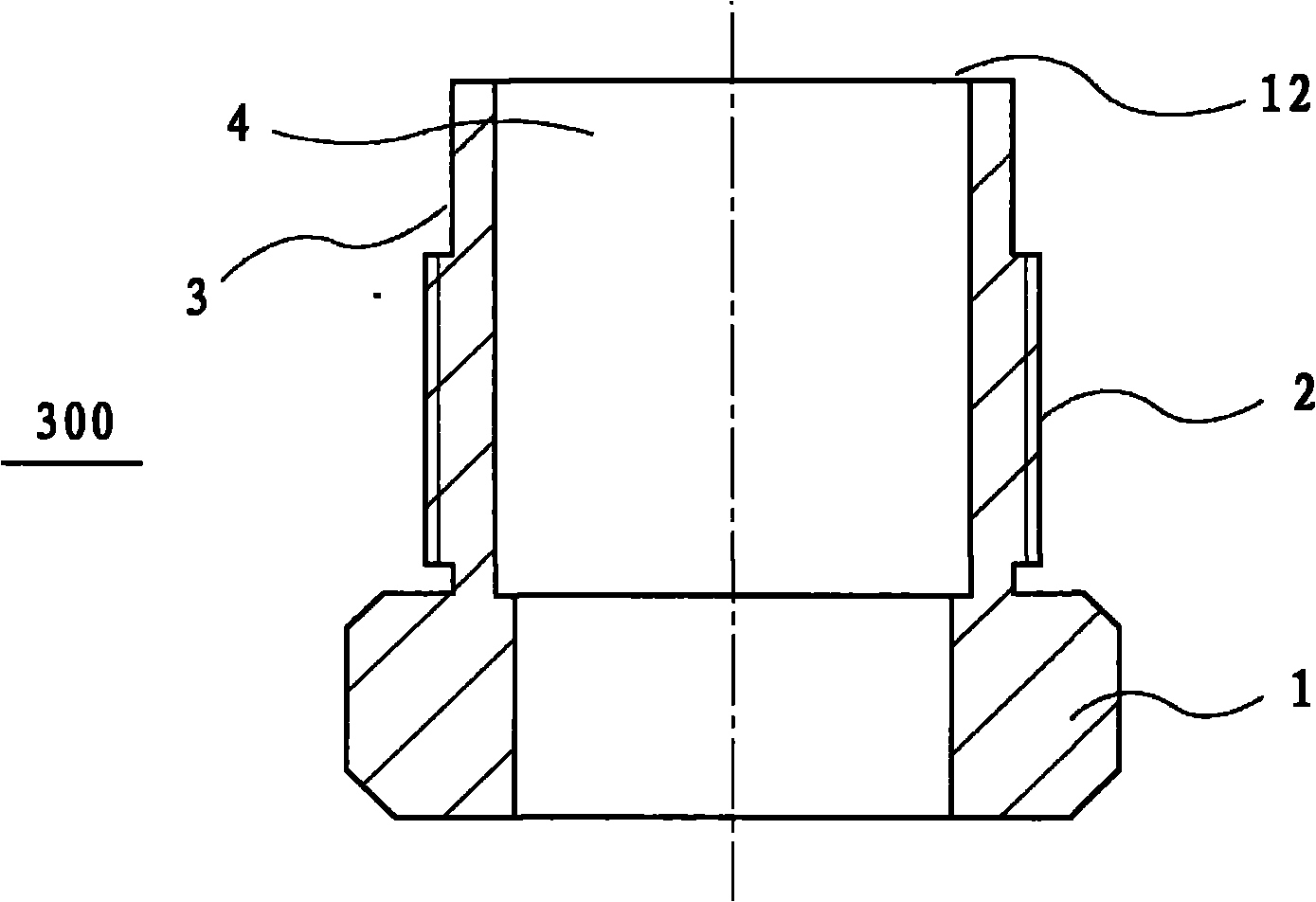

Method of installing a foundation in the sea bed and such foundation

ActiveUS20150010365A1Equally distributedSmooth sectionArtificial islandsWind motor supports/mountsPositive pressureHorizontal axis

The invention relates to a seabed foundation (1) for an offshore facility, comprising a primary pressure chamber (7) connected to a primary pump (8) and one or more secondary pressure chambers (9) connected to one or more secondary pumps (10). According to an embodiment of the invention, said primary pump is a suction pump and said secondary pump is a pressure pump. The invention further relates to a method (12) of installing said foundation on the seabed (19), which comprises the steps of activating (14) said primary pump to create negative pressure in the primary pressure chamber (7), so that the foundation sinks into the seabed, and activating (15) said one or more secondary pumps (10) to create positive pressures in the secondary pressure chambers (9), so as to control the alignment of the foundation with respect to a substantially horizontal axis (16) during the sinking into the seabed.

Owner:UNIVERSAL FOUND

Card member, card edge connector, and method for manufacturing card member

InactiveUS9293839B2No unevennessImprove propertiesContact member assembly/disassemblyCoupling contact membersShell moldingEngineering

A method for manufacturing a card member includes: preparing a substrate having a card edge section with card edge terminals to be connected to an opposing connector; preparing a fist mold and a second mold that have molding spaces for molding a resin molded section having a fitting section to be fitted with the opposing connector formed around the substrate; placing the substrate inside the molding spaces between the first mold and the second mold in such a way that the joining portion of the first mold and the second mold are disposed so as not to be overlapped with the portion where the fitting section is to be formed; injecting a synthetic resin material into the molding space to integrally form the resin molded section around the substrate. The method can provide a card member having an excellent watertightness.

Owner:JST MFG CO LTD

Ball screw module

ActiveUS7908938B2Improve performanceHigh precisionPortable liftingToothed gearingsBall screwEngineering

Provided is a ball screw module including a screw shaft, a nut member, a ball connector, and a circulating device inside the nut member. The screw shaft and the nut member constitute a first load rolling groove. The circulating device, being connected with the first load rolling groove, has a first turning section and a second turning section, and includes a first guiding groove and a second guiding groove. The first guiding groove has a radius of curvature greater than that of the second guiding groove when the ball connector passes the first turning section. The first guiding groove has the radius of curvature smaller than that of the second guiding groove when the ball connector passes the second turning section.

Owner:HIWIN TECH

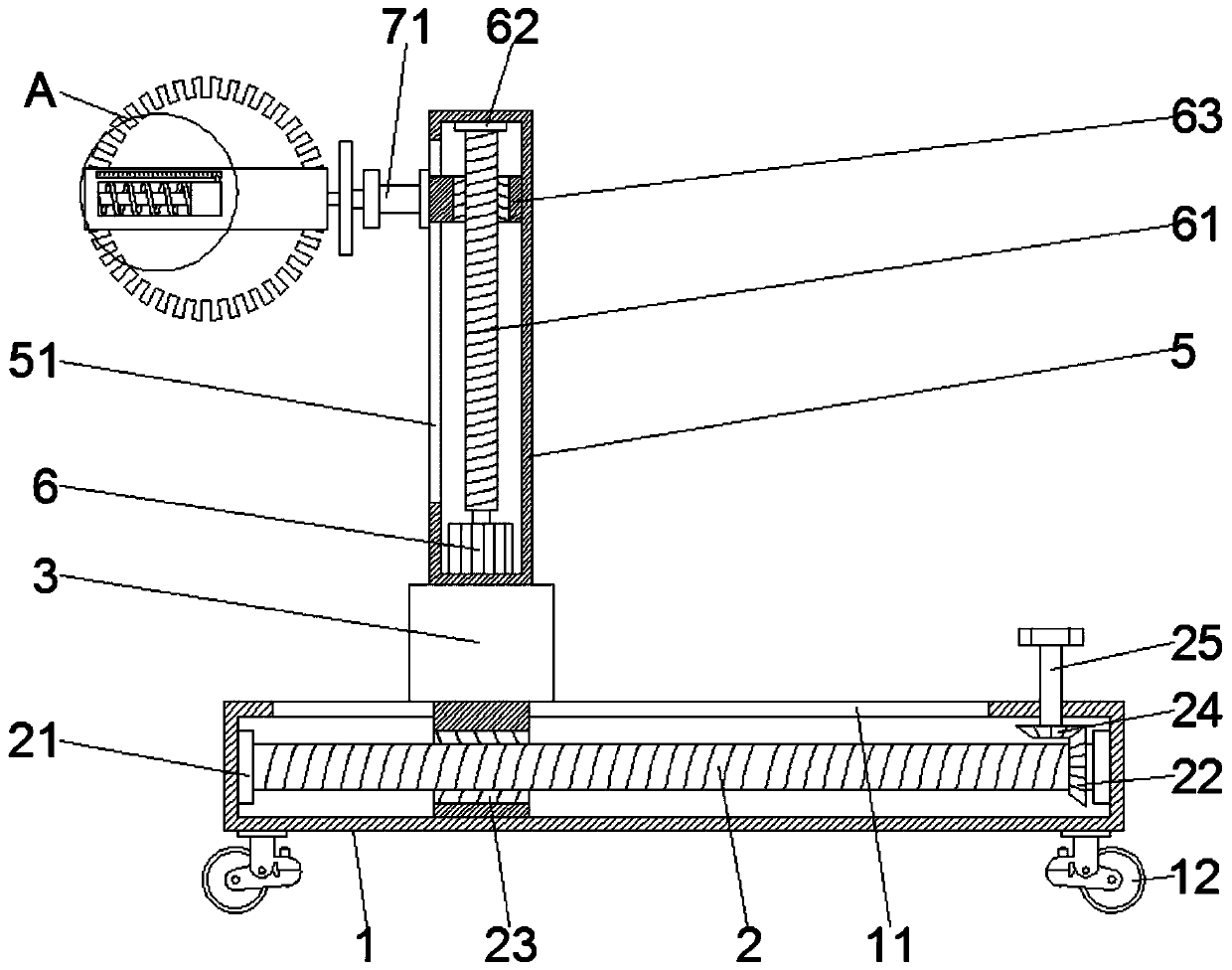

Novel wall cutting machine for home decoration

PendingCN111168866AAccurate locationNeat sectionWorking accessoriesStone-like material working toolsMachineHome improvement

The invention discloses a novel wall cutting machine for home decoration. The novel wall cutting machine comprises a bottom plate, wherein a sliding groove I is transversely formed in the upper end ofthe bottom plate, a threaded rod I is transversely arranged in the bottom plate, the left end and the right end of the threaded rod I are rotatably connected to the inner wall of the bottom plate, abevel gear I is arranged at the outer surface of the threaded rod I in a sleeving mode, and the bevel gear I is located on the right side of the sliding groove I; a bevel gear II is arranged in the bottom plate, the bevel gear II meshes with the bevel gear I, a threaded sleeve I is arranged on the outer surface of the threaded rod I in a sleeving mode, and the threaded sleeve I is located in the sliding groove I; and a movable device is longitudinally arranged at the upper end of the threaded sleeve I, and the movable device comprises a hollow plate and a threaded rod II, a sliding groove II is longitudinally formed at the upper end of the hollow plate, the threaded rod II is longitudinally arranged in the hollow plate, the front end and the rear end of the threaded rod II are rotationallyconnected to the inner wall of the hollow plate. According to the novel wall cutting machine for the home decoration, the position of a cutting opening is accurate, the cross section is neat, and theposition of a pointer on a dial gauge is observed, so that the depth of cutting the wall surface of a cutting wheel is quickly known, and meanwhile, the device further can cut the wall surface transversely and longitudinally.

Owner:SHANGHAI BETTER HOME DECORATION ENG CO LTD

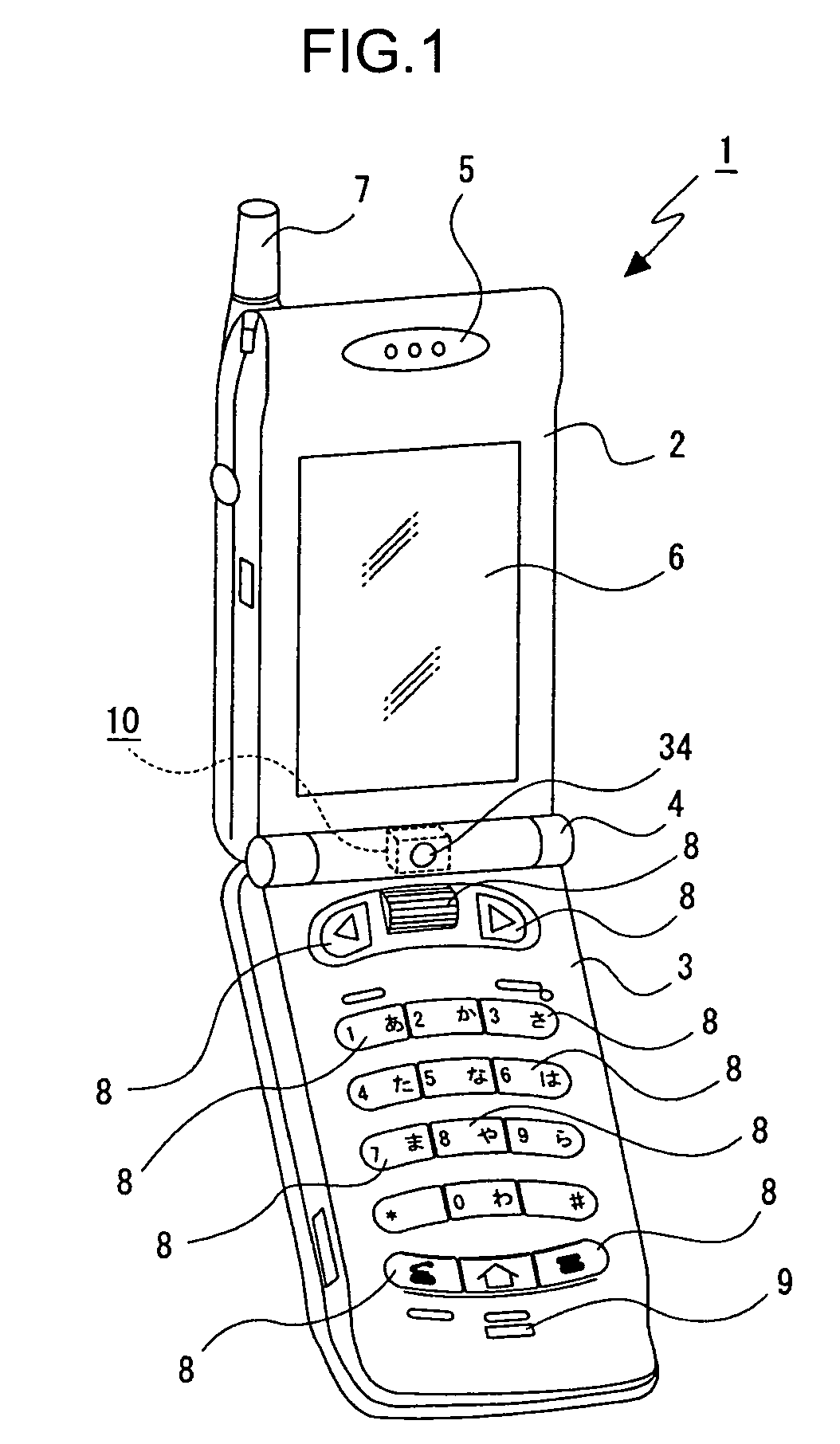

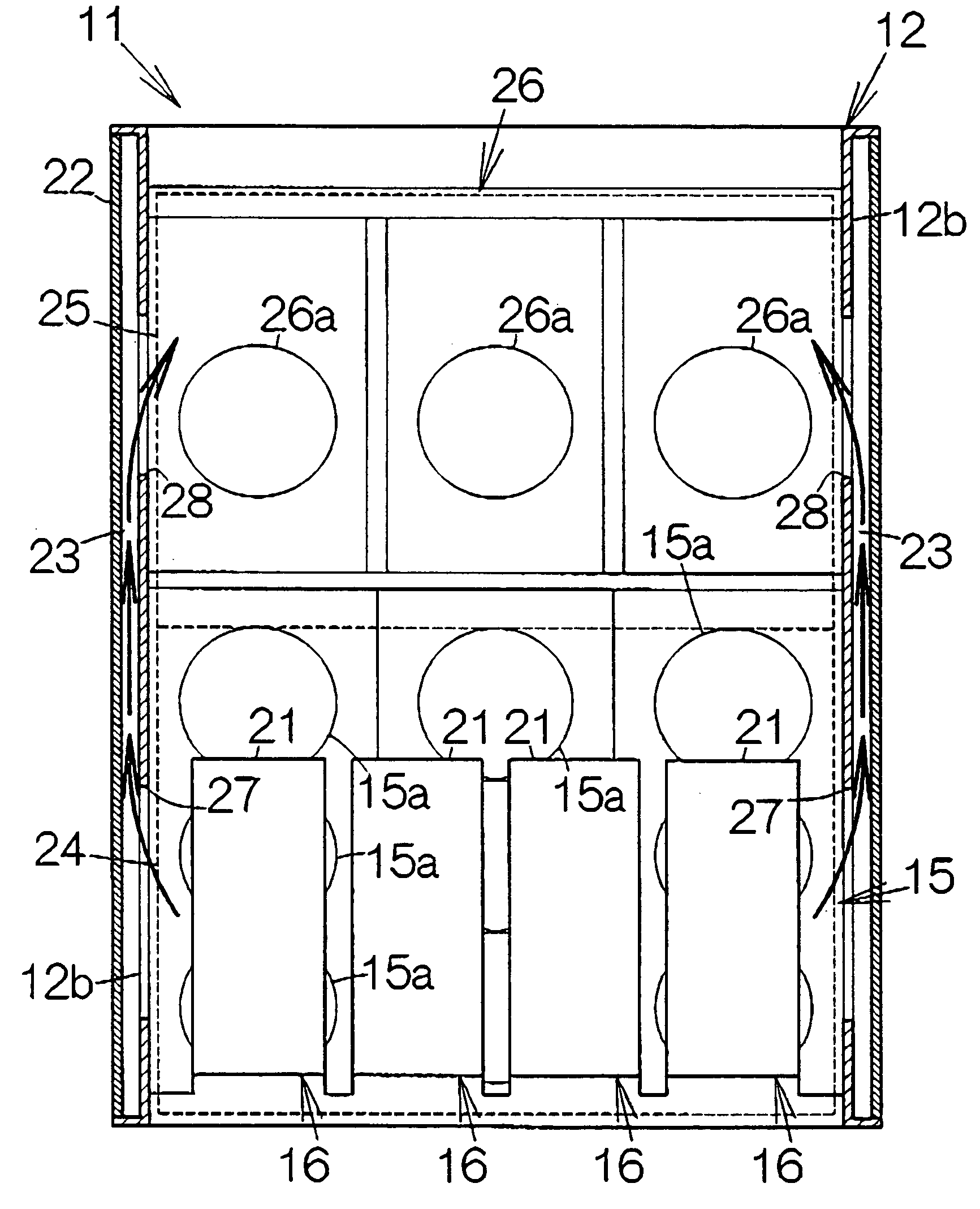

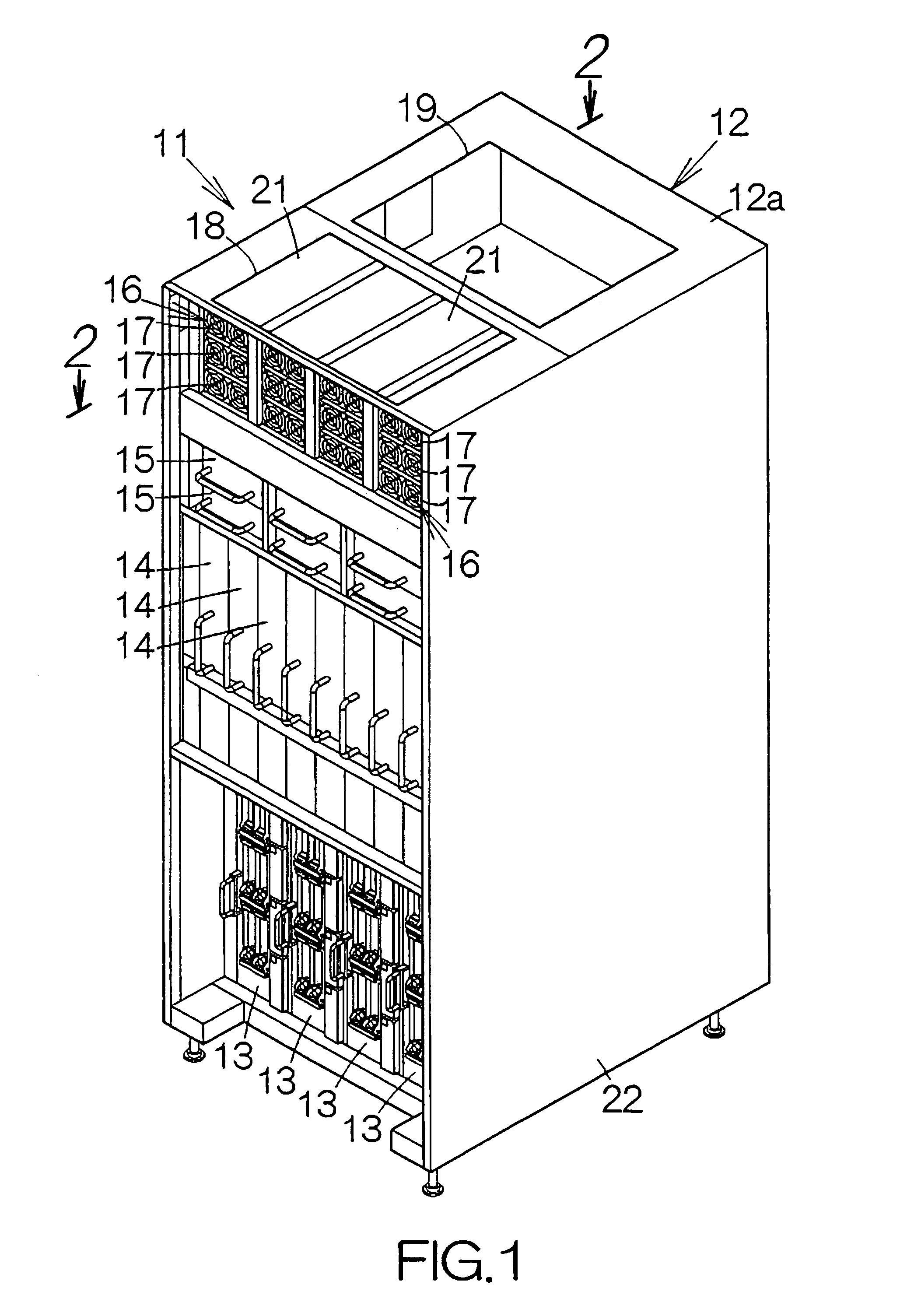

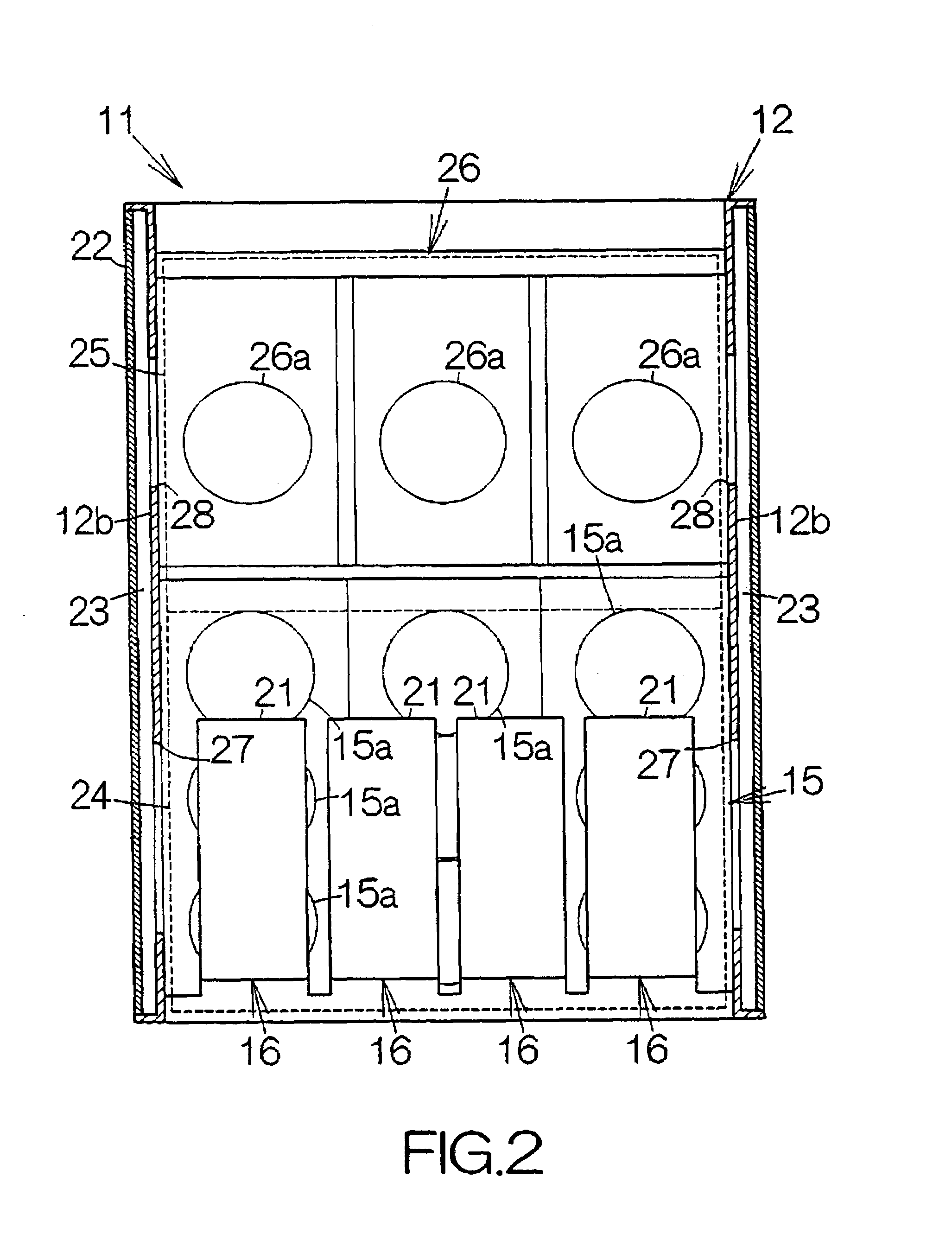

Electronic apparatus

ActiveUS7365977B2Even airflowImprove air flowCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringElectronic equipment

Owner:FUJITSU LTD

Endoscope insertion support tool and endoscope device

ActiveUS8147401B2Smooth sectionEasily to smoothly insert insertionStentsBalloon catheterCatheterEndoscope

Owner:OLYMPUS CORP

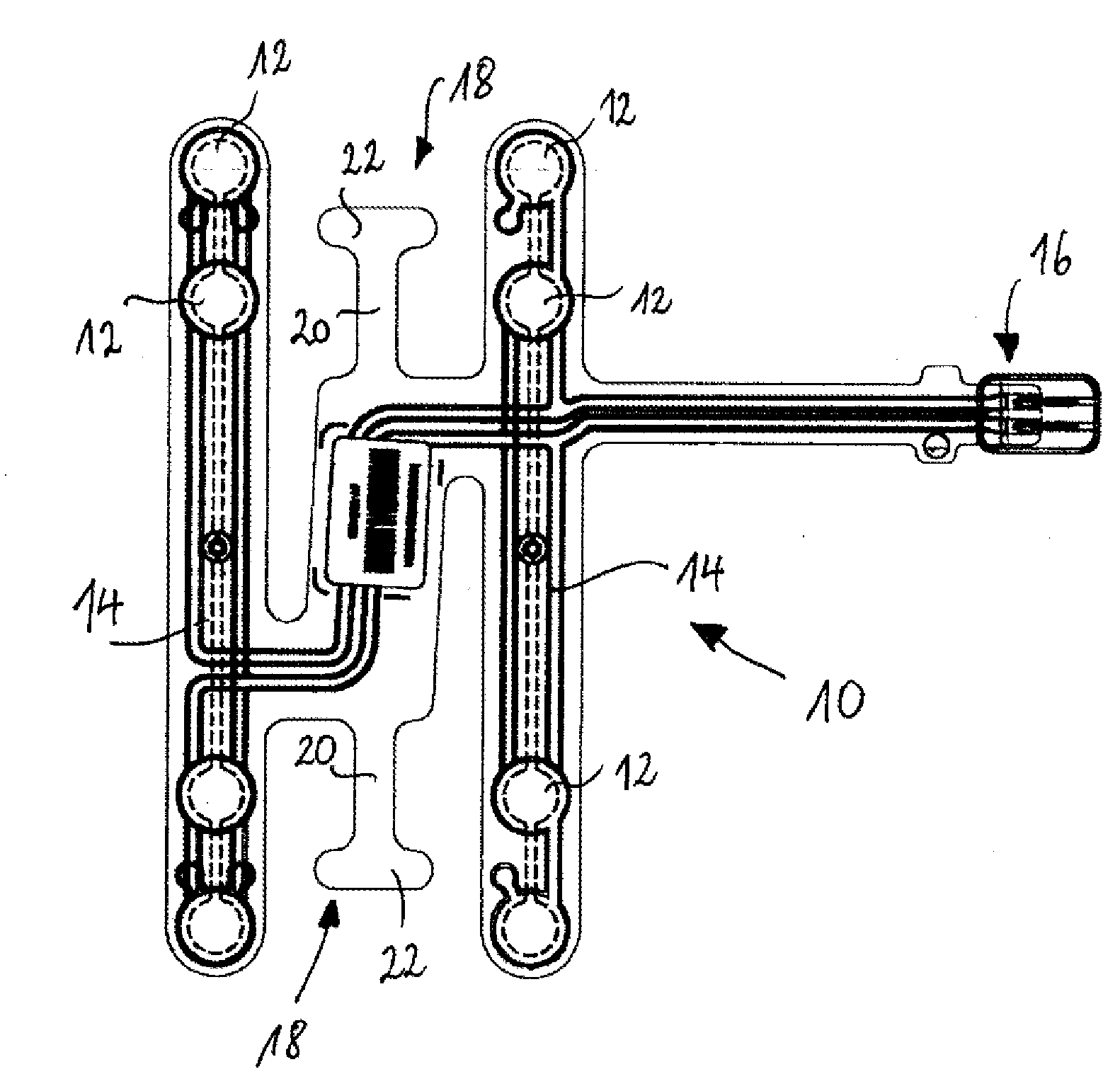

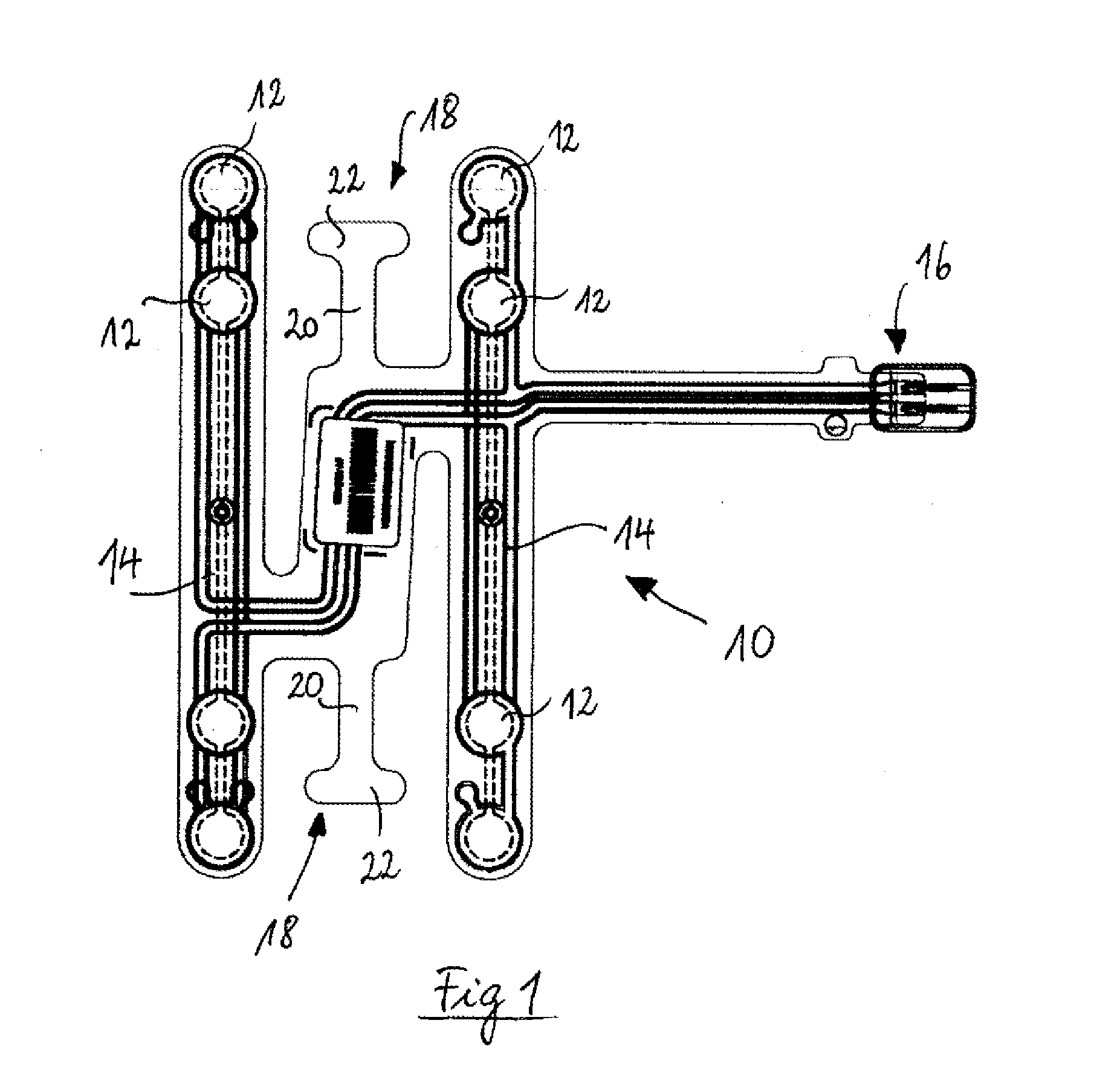

Seat Foam with Sensor Mat

ActiveUS20080252117A1Precise positioningSecurely holdVehicle seatsPedestrian/occupant safety arrangementMechanical engineering

In an assembly of a seat foam and a sensor mat, the seat foam has at least one incision and the sensor mat has at least one anchor tab adapted to be inserted into the at least one incision, thereby securely holding the sensor mat on a surface of the seat foam, where the seat foam includes at least one retaining element at the incision for retaining the anchor tab in the incision.

Owner:IEE INT ELECTRONICS & ENG SA

Cutting device

InactiveCN101968222AAdvanced technologyFast cutting speedGaseous fuel burnerEngineeringEnergy consumption

The invention discloses a cutting device which comprises a cutting gun body and a cutting nozzle, wherein, the cutting nozzle comprises a cutting nozzle core and a cutting nozzle sleeve; the cutting nozzle core comprises a nozzle core body, a cutting oxygen channel, a first boss, a first preheating hole, a second preheating hole and a preheating tank, and the cutting nozzle sleeve comprises a nozzle core assembling hole; the cutting nozzle core is assembled in the cutting nozzle sleeve, and the cutting nozzle core and the cutting nozzle sleeve are integrally assembled in the cutting gun body; and the cutting gun body comprises a gas pipe, a preheating oxygen pipe and a cutting oxygen pipe, and the cutting oxygen pipe is communicated with the cutting oxygen channel of the cutting nozzle core. The cutting device has the following technical effects of concentrated flame, fast cutting speed, bright and clean section, narrow slots, less steel and energy consumption, no black smoke during the cutting process, environmental protection and small noise.

Owner:河北煌剑节能技术有限公司

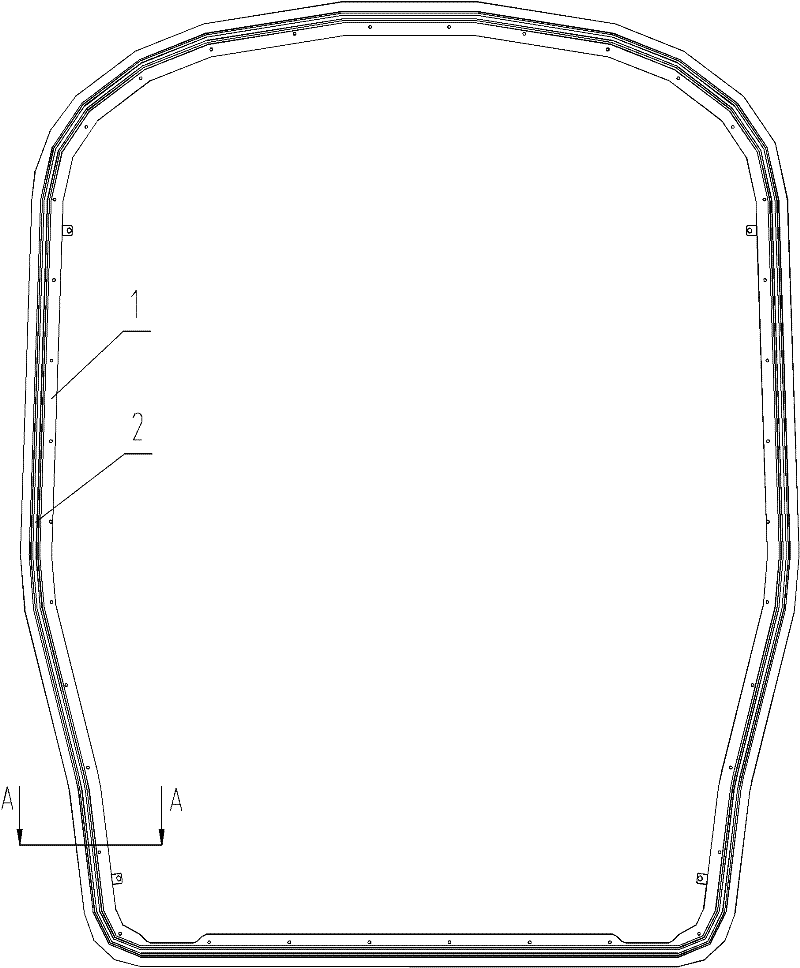

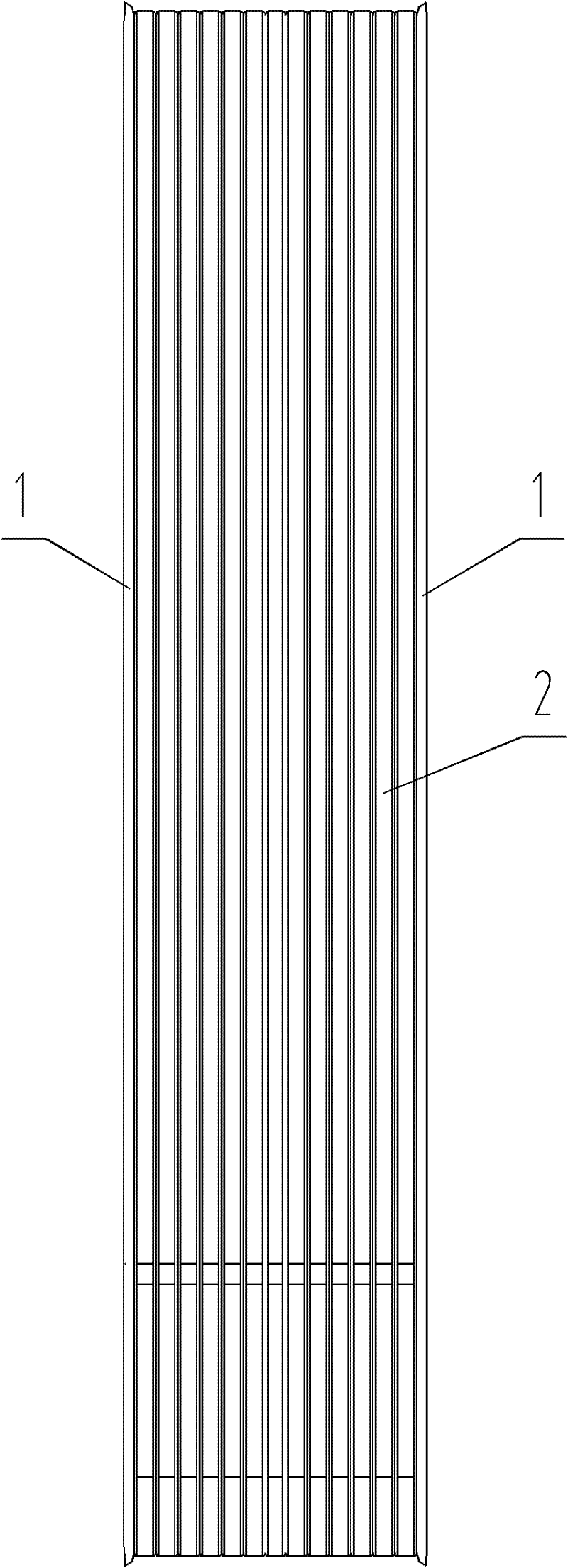

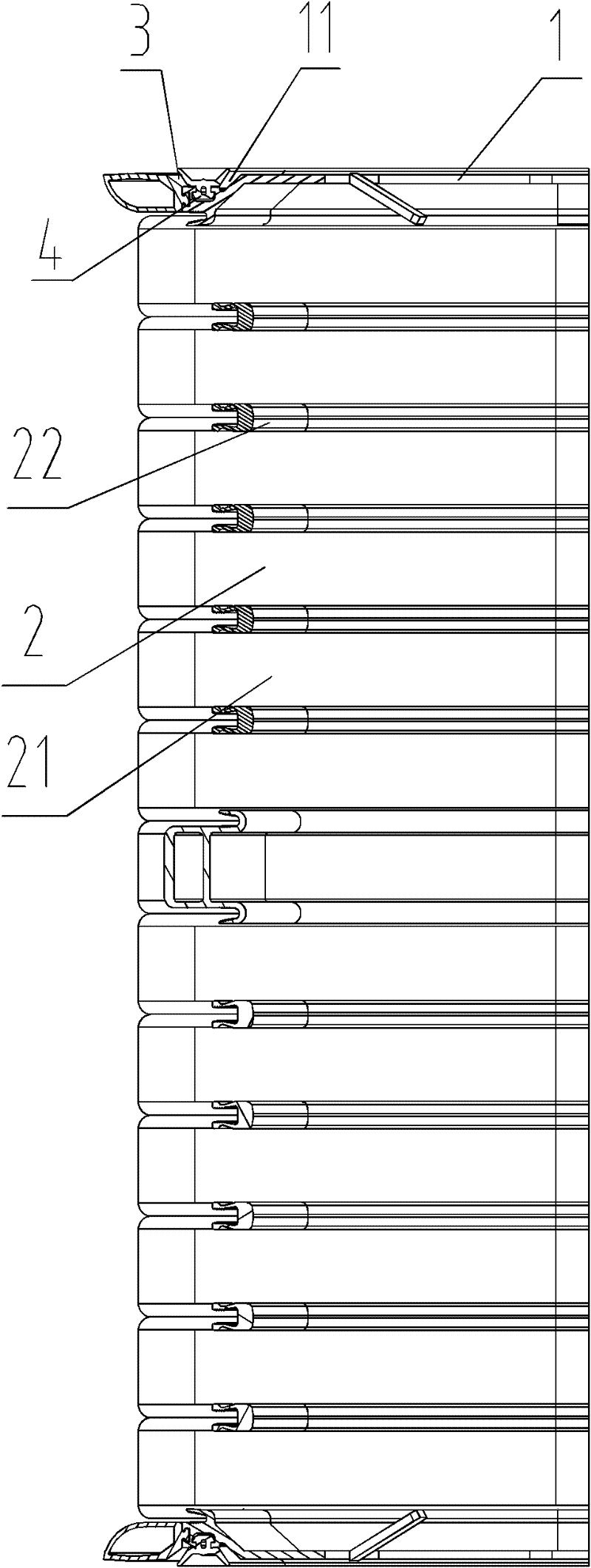

Totally-closed folding shed type external windshield

InactiveCN102556091ASmooth sectionSatisfy complex displacementAxle-box lubricationRailway bodiesEngineeringControl theory

The invention discloses a totally-closed folding shed type external windshield, which is used for connection between the ends of two high-speed railway vehicles and comprises two mounting frames. The two mounting frames are fixed to the ends of the two vehicles and closed along the outlines of the vehicle ends, a folding shed component is fixed between the two mounting frames, the outer face of each mounting frame is provided with an inner groove, a sealing groove is formed by each inner groove and the corresponding vehicle end face after the mounting frames are fixed to the ends of the vehicles, and a sealing strip is arranged in each sealing groove. The mounting frames of the external windshield are directly connected with the ends of the two vehicles, a gap between the end faces of two adjacent vehicles can be eliminated by means of the totally-closed structure, complex displacement of vehicles can be met by means of the foldable and retractable folding shed structure, a smoother section of the windshield is guaranteed in different road conditions, and accordingly air flow can flow along the external windshield smoothly, operating resistance, micro-pressure waves and pneumatic noise of a train can be effectively reduced, and comfortableness can be improved for passengers.

Owner:CHANGZHOU HUBOLA JINCHUANG TRAFFIC EQUIP

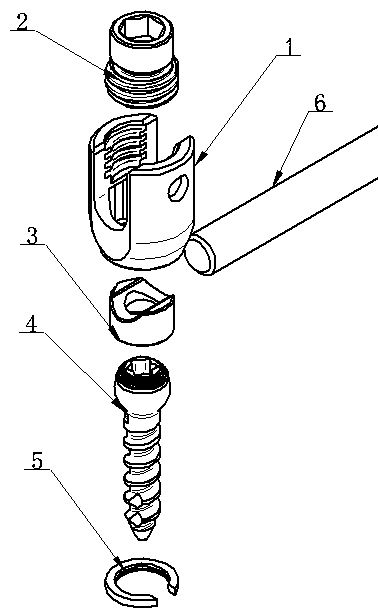

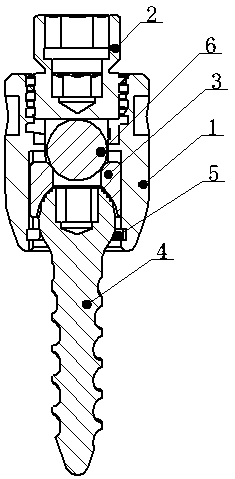

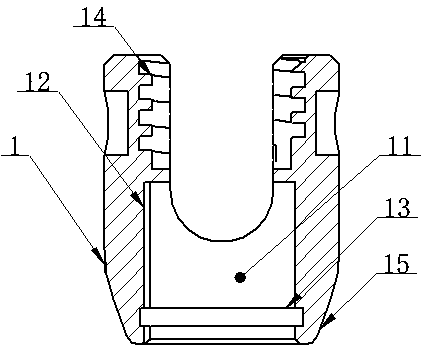

Polyaxial pedicle screw fixing device with self-breaking screw

PendingCN110123431AConsistent breaking torqueQuantifiable lockingInternal osteosythesisThoracolumbar spinePedicle screw fixation

The invention relates to a polyaxial pedicle screw fixing device with a self-breaking screw and belongs to the technical field of medical equipment. The fixing device is the main part of a spine and thoracolumbar spine posterior approach internal fixation system and used for fast assembling a pedicle screw and a fixing rod. The polyaxial pedicle screw fixing device comprises a screw seat, the self-breaking screw, a pressing block, a screw head and a C-shaped clamp ring and is characterized in that two symmetrically U-shaped grooves are arranged in the lateral wall of one side of the screw seat, an implanting hole is arranged inside the screw seat, an axial groove is arranged inside the implanting hole, the outer lateral wall of the pressing block is provided with a protrusion correspondingto the axial groove, the screw head and the pressing block are connected in a sleeved manner, the C-shaped clamp ring is embedded into an annular groove in the bottom of the screw seat, and self-breaking screw is connected with the upper portion of the screw seat through a rectangular thread. The polyaxial pedicle screw fixing device has the advantages that the device is simple to operate, capable of achieving fast fixing, capable transmitting large torque and capable of preventing the thread abrasion of the self-breaking screw, the twisting off torque of the self-breaking screw is consistent, quantification locking is achieved, and surgery efficiency and accuracy are increased.

Owner:山东新华联合骨科器材股份有限公司

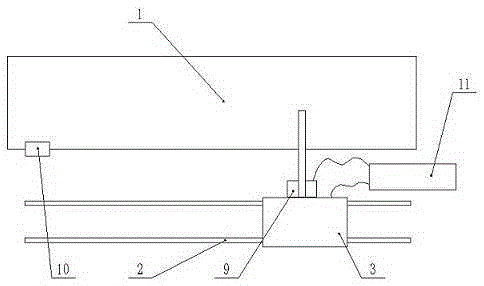

Flame cutting device and method for track beam

The invention discloses a flame cutting device and method for a track beam. According to the flame cutting device and method for the track beam, traditional saw blade cold cutting of the track rail is transformed into flame hot cutting. A hydrogen-oxygen generator (fuel gas generator) generates hydrogen-oxygen mixed gas used for cutting in the gas generation manner that gas is used while generated; the hydrogen-oxygen mixed gas is regulated through a safety device and an energy medium box; meanwhile, an auxiliary is regulated through the energy medium box; the hydrogen-oxygen mixed gas and the auxiliary are conveyed to a cutting gun on a trolley; and then the cutting gun is used for cutting work. According to the flame cutting device and method, the beneficial effects that the cutting section cut by hydrogen-oxygen flames is smooth, slag hanging does not exist, a cutting seam is small, the automation degree is high, and environmental pollution does not exist are utilized, the movable trolley and a waste recovery system which are designed for the track beam are combined, and therefore compared with traditional saw blade cutting, the flame cutting device and method have the beneficial effects of being low in cost, low in labor intensity, good in cutting quality and the like. The labor capacity of workers is reduced by improving the automation degree of the device, spare consumption and loss cost of steel billets of the cutting device are reduced, and the purpose of reducing production cost is achieved.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

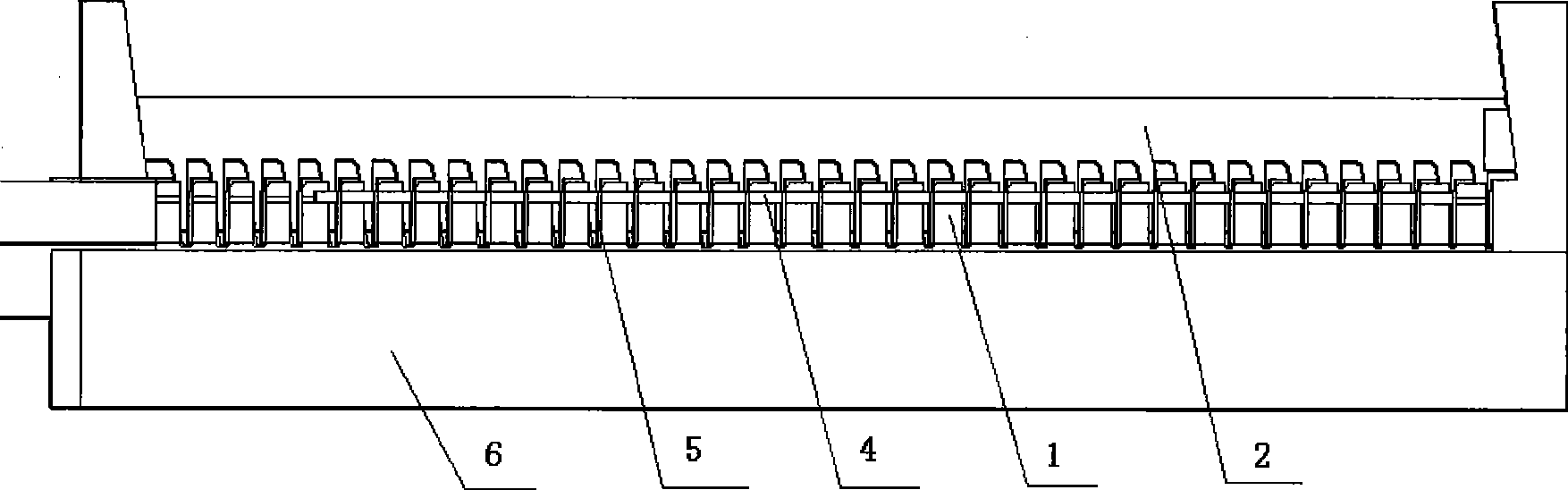

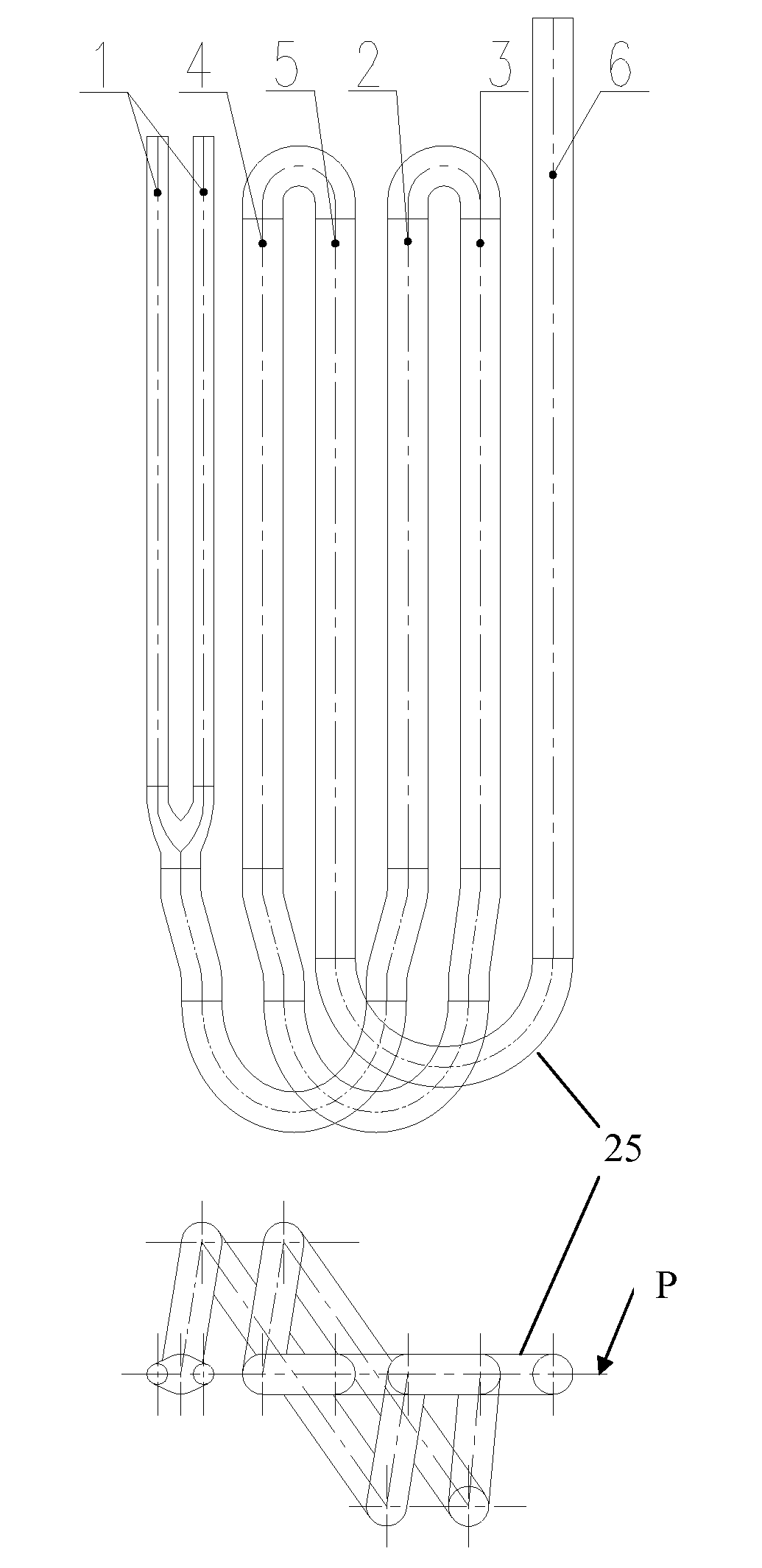

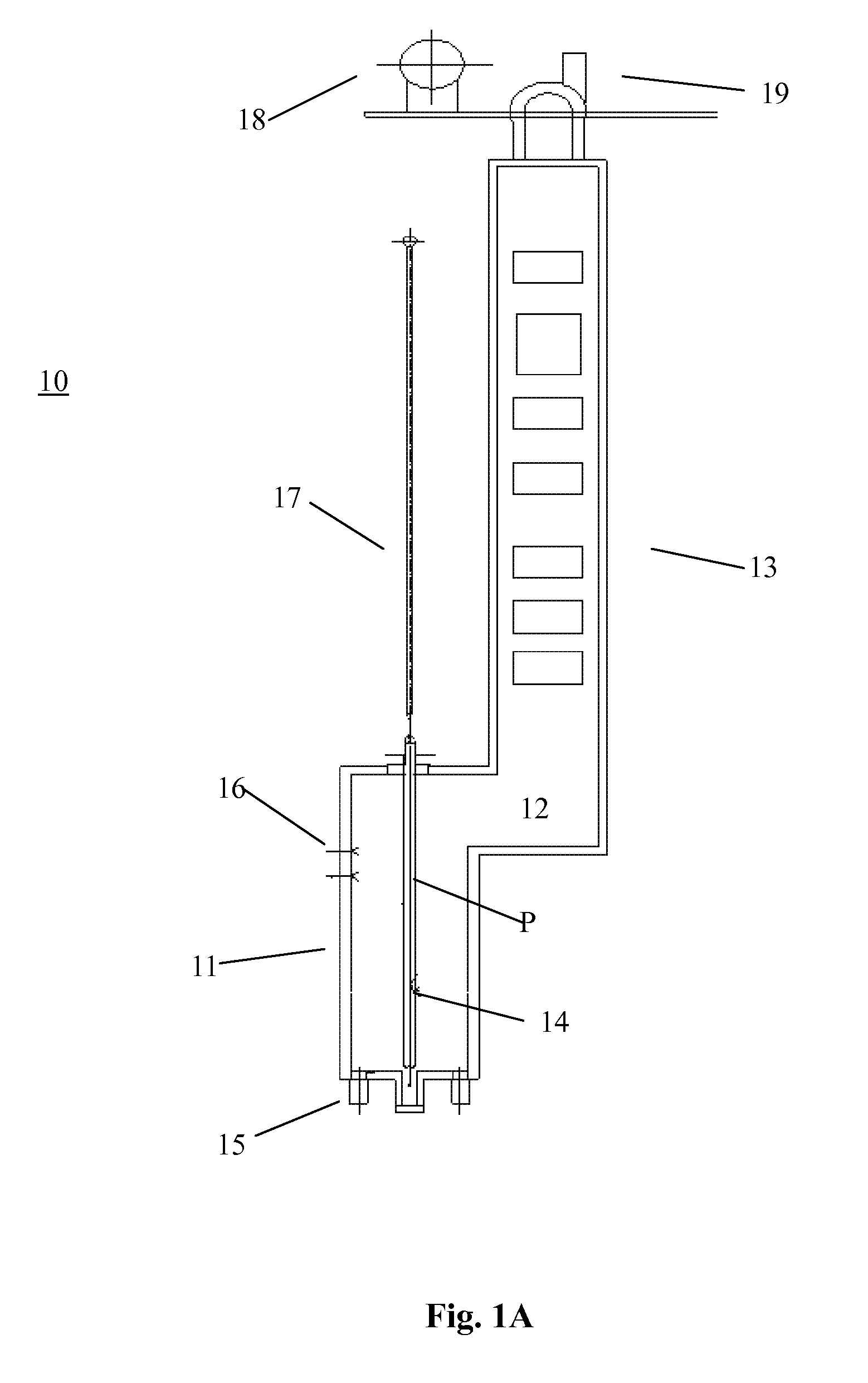

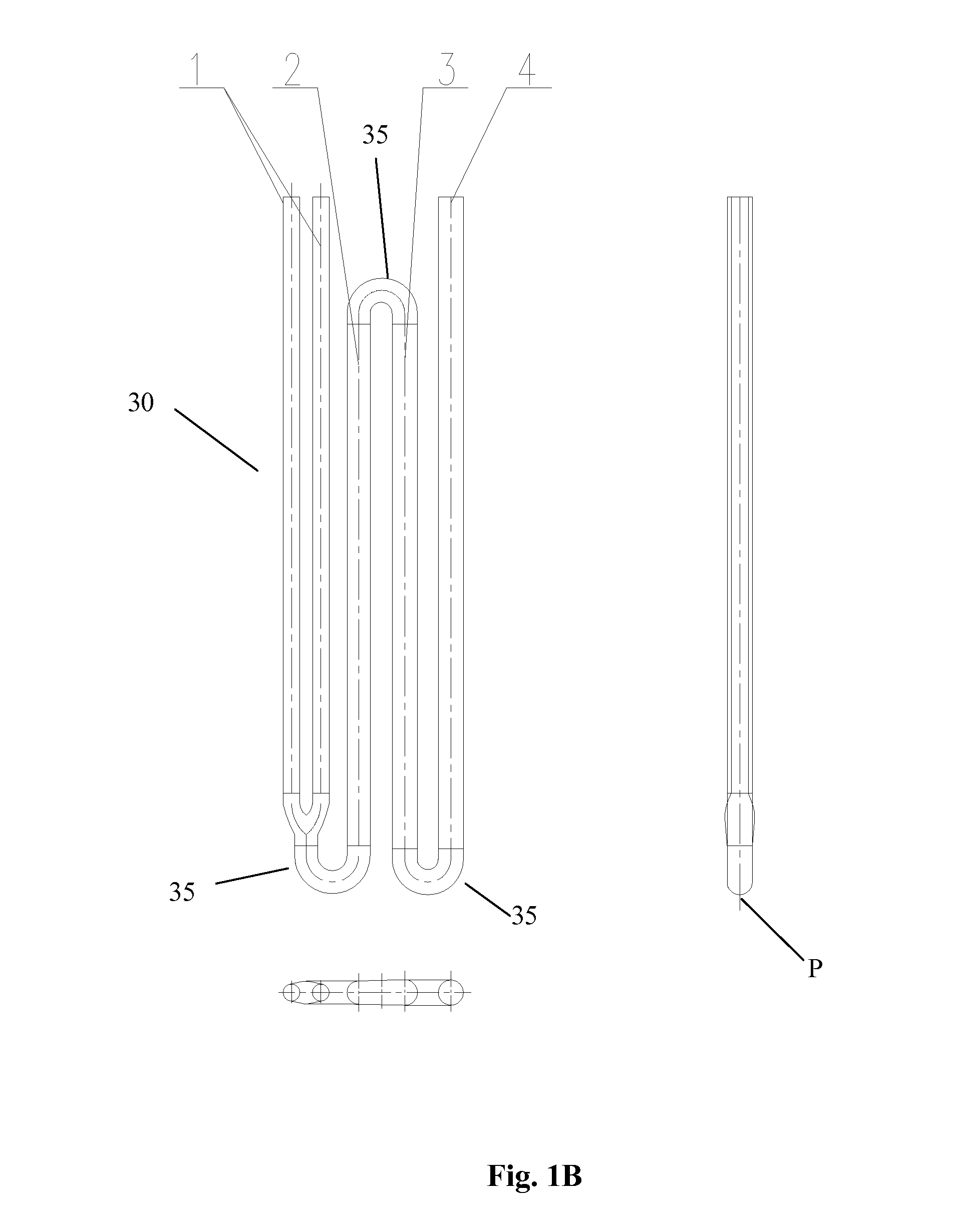

Ethylene Cracking Furnace With Multi-Pass Radiant Coil

ActiveUS20120219466A1Compact structureReduce influenceChemical/physical/physico-chemical processesHydrocarbon by hydrocarbon crackingPhysicsThermal radiation

The invention relates to an ethylene cracking furnace having a multi-pass radiant coil, comprising at least one radiant section. In the radiant section there are provided with bottom burners and / or sidewall burners, and at least one set of multi-pass radiant coil longitudinally arranged in the radiant section. The multi-pass radiant coil is a four- to ten-pass type radiant coil. At least one tube of the multi-pass radiant coil is arranged to be spatially adjacent to a tube which is not consecutive to said at least one tube. With this arrangement, the thermal radiation influence between tubes with high temperature can be reduced, so that the tubes with low temperature can absorb the radiation heat from the tubes with high temperature. Therefore, the surface temperature of the tubes with high temperature can be reduced, thus extending the lifetime of the radiant coil and the operational cycle of the cracking furnace.

Owner:CHINA PETROCHEMICAL CORP +2

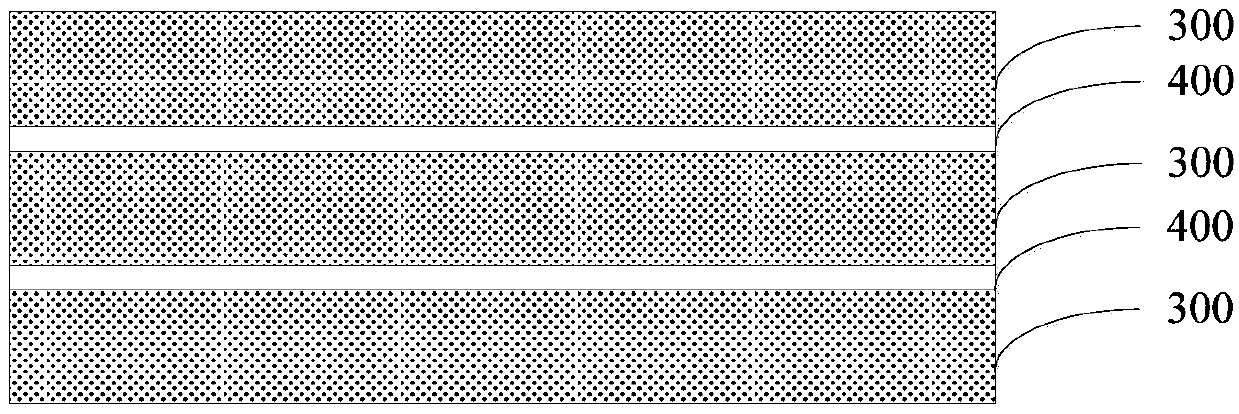

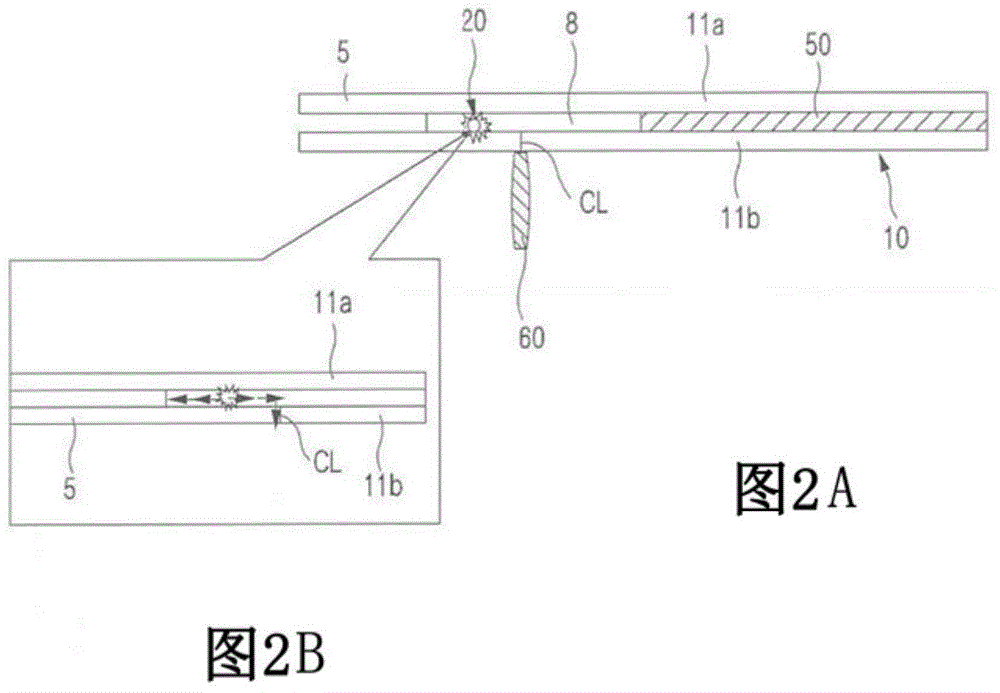

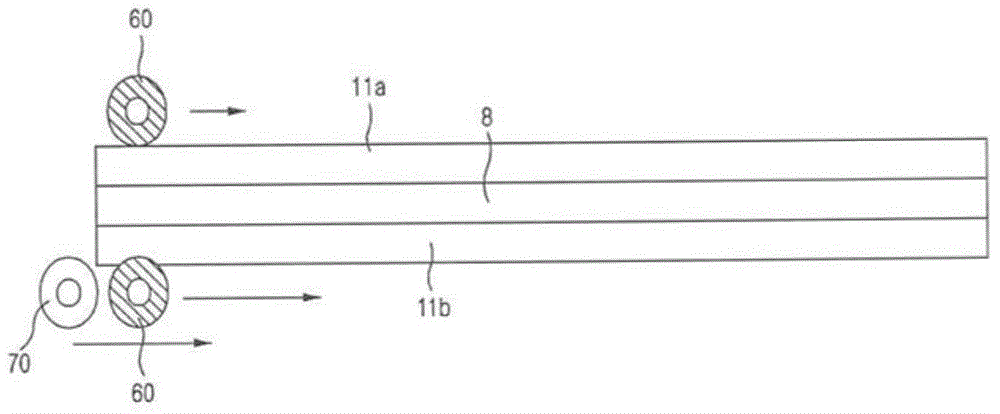

Method for cutting of bonded substrate

ActiveCN105314835AEasy to separateAvoid pollutionGlass severing apparatusNon-linear opticsEngineeringMechanical engineering

The present invention relates to a method for cutting of a bonded substrate, a useless material end part of the substrate can be furthest small when a liquid crystal substrate is cut, and a smooth cutting surface can be obtained. The method comprises the following steps of: scribing an upper glass part (11a) or a lower glass part (11b) on a sealing part (8) by using a scribe wheel (60) to form a scribe line (CL); irradiating laser to the sealing part (8) formed at the position isolated from the scribe line (CL) position with an interval to scribe; and scribing the residual glass parts without the scribe line (CL) by using the scribe wheel (60).

Owner:MITSUBOSHI DIAMOND IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com