Method for cutting of bonded substrate

A technology for bonding substrates and benchmarks. It is used in optics, glass manufacturing equipment, instruments, etc. It can solve problems such as poor substrates, movement, and incomplete separation of glass, and achieve the effect of improving separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, methods, steps, Features and their functions are described in detail below.

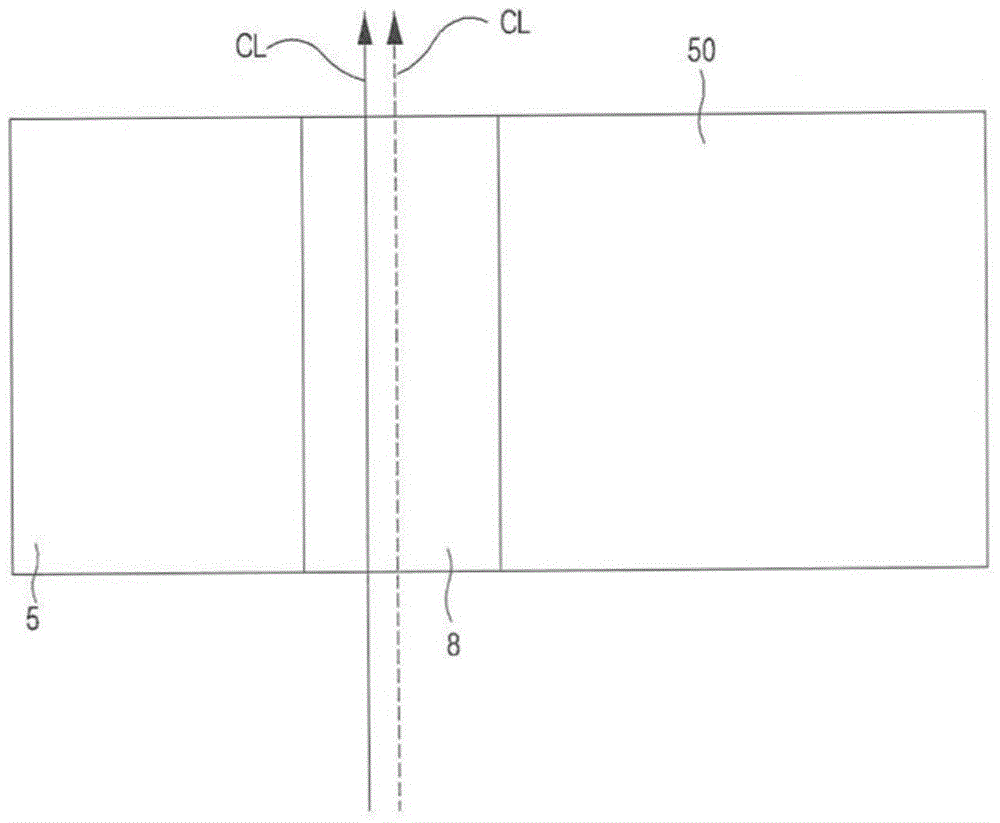

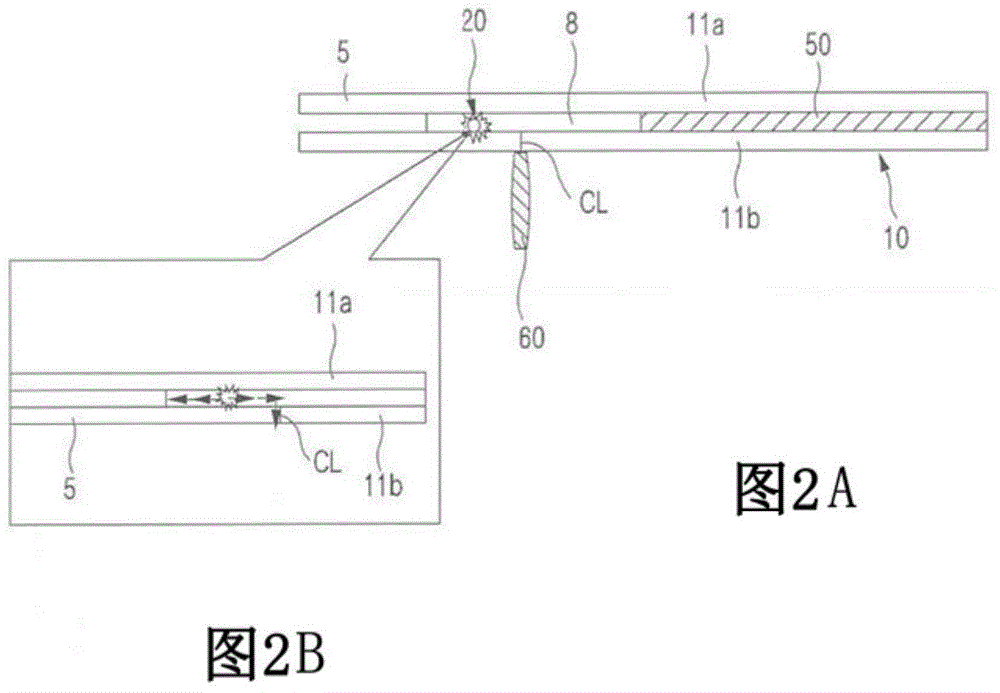

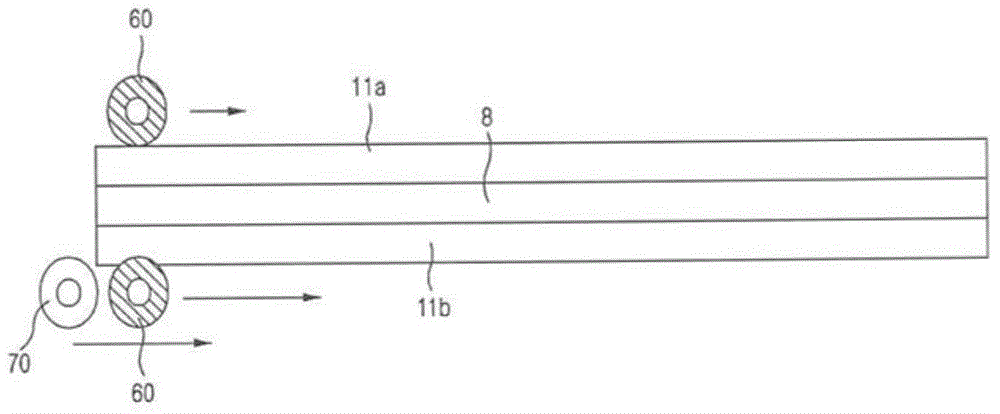

[0036] like figure 1 , Figure 2A and Figure 2B As shown, the bonded substrate 10 of this embodiment includes an upper glass portion 11a and a lower glass portion 11b, and a liquid crystal portion 50 is formed between the upper glass portion 11a and the lower glass portion 11b. Further, the outer periphery of the liquid crystal portion 50 is sealed with the sealing portion 8 so that the liquid crystal portion 50 does not leak liquid to the outside of the bonded substrate 10 .

[0037] In the frame portion of the bonded substrate 10 , there is an end material portion 5 which is an unnecessary portion. The sealing portion 8 is also included between the frame portions of the upper glass portion 11 a and the lower glass por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com