Flame cutting device and method for track beam

A technology for flame cutting and rail beams, which is applied to gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high spare parts cost, high labor intensity, and high billet loss, so as to reduce the cost of spare parts and reduce the labor load , the effect of labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

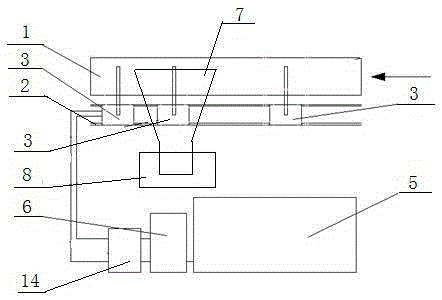

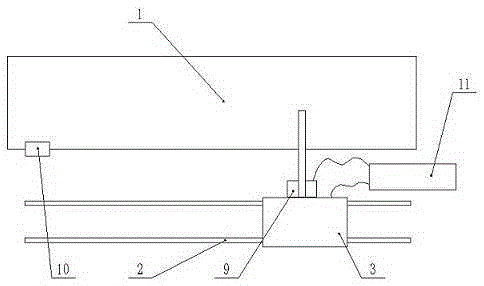

[0038] This embodiment provides a rail beam flame cutting device, such as figure 1 and figure 2 As shown, it includes a mobile cutting trolley system, a gas supply system and a waste recycling device. The mobile cutting trolley system is composed of a trolley track 2 set in front of the rail beam roller table 1 and a trolley 3 on the trolley track 2. Installed on the trolley 3 There is a flame cutting torch 4; the gas supply system includes a gas generator 5 and a safety cabinet 6 connected by stainless steel pipes, and the safety cabinet 6 is connected to the flame cutting torch 4 on the trolley 3 through a hose; the waste recycling device includes an inclined chute 7 and waste Basket 8 and inclined chute 7 are arranged directly below rail beam roller table 1, and waste basket 8 is positioned at the slope end of inclined chute 7 directly below.

[0039] Flame cutting includes flame cutting of other gases including alkanes. The following is an example of oxyhydrogen flame cu...

Embodiment 2

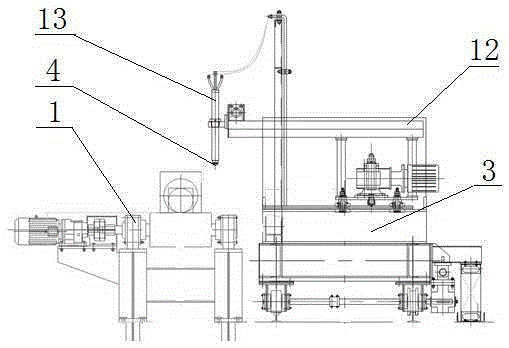

[0044] This embodiment describes the specific structure of the trolley 3 and the specific distribution of the trolley 3 and the rail beam roller table 1, as image 3 , 4 , 5, in this embodiment, the dolly 2 includes wheels, a vehicle frame and a power drive motor on the vehicle frame, and the first telescopic body 12 is also fixed on the vehicle frame, and the first telescopic body 12 is horizontally arranged and perpendicular to In the direction of the roller table of the rail beam roller table 1, the end of the first telescopic body 12 is connected to the second telescopic body 13, and the second telescopic body 13 is vertically arranged and perpendicular to the direction of the roller table of the rail beam roller table 1. The end portions of the two telescopic bodies 13 are equipped with flame cutting torches 4 .

[0045] The movement of the trolley 3 on the trolley track 2 is mainly completed by the power drive motor of the cutting trolley. The flame cutting gun 4 has th...

Embodiment 3

[0053] Inclined chute 7 is the inclined plane that steel plate is laid, and steel plate edge has limit baffle to prevent scrap steel from slipping to both sides; Set with lugs.

[0054] The inclined chute 7 is placed directly below the rail beam track foundation pit, so as to ensure that each cut section can accurately fall in the inclined chute 7 to facilitate recovery. The waste basket 8 is placed on the end of the inclined surface of the inclined chute 7 to ensure that each waste section that slides through the inclined chute 7 can slide into the waste basket 8 . When the volume of the waste basket 8 is fully loaded, the motor is operated to move the waste basket 8 along the pre-laid basket track to the range of row hoisting, and a new waste basket 8 is replaced by hoisting lugs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com