Global automatically controlled hydraulic jacking device and jacking method thereof

A jacking device and jacking technology, applied in the direction of hoisting device, fluid pressure actuating device, hoisting device, etc., can solve the problems of low work efficiency and complicated operation, and achieve improved work efficiency, simple operation, and strong system reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

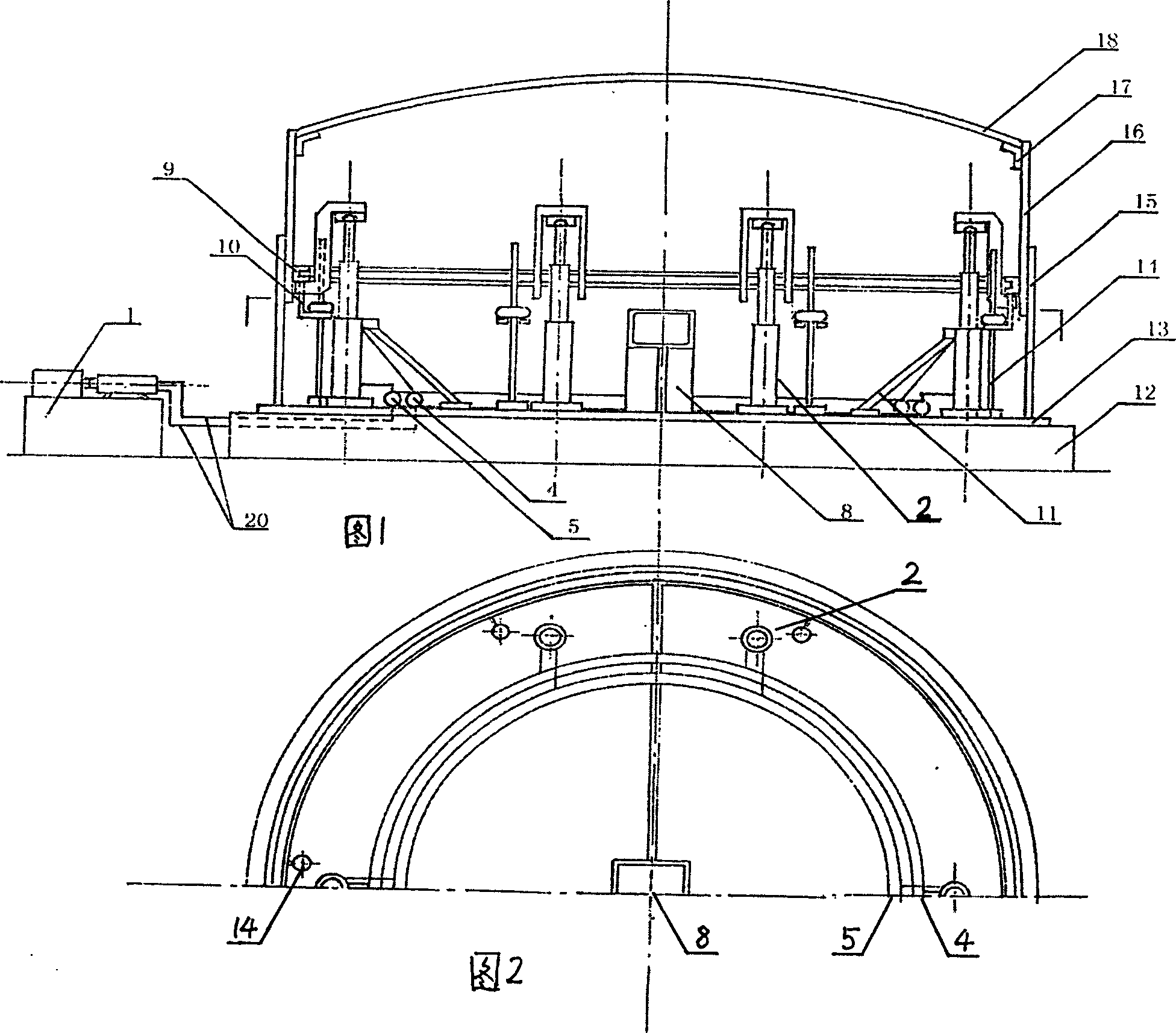

[0024] Below in conjunction with accompanying drawing and embodiment (3000 cubic meter oil tank jacking), the present invention is described in further detail, but the scope of implementation of the present invention, mode are not limited thereto.

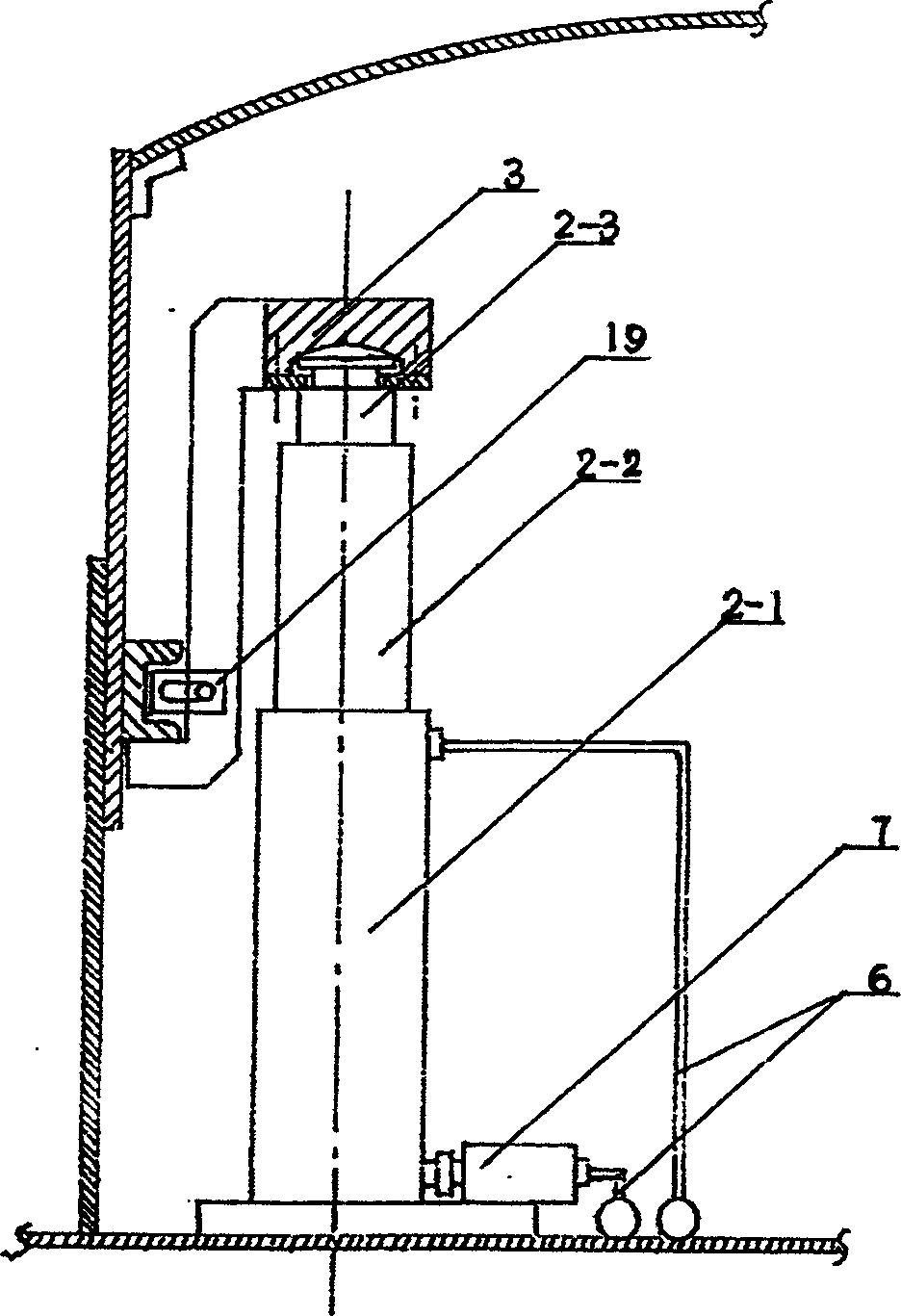

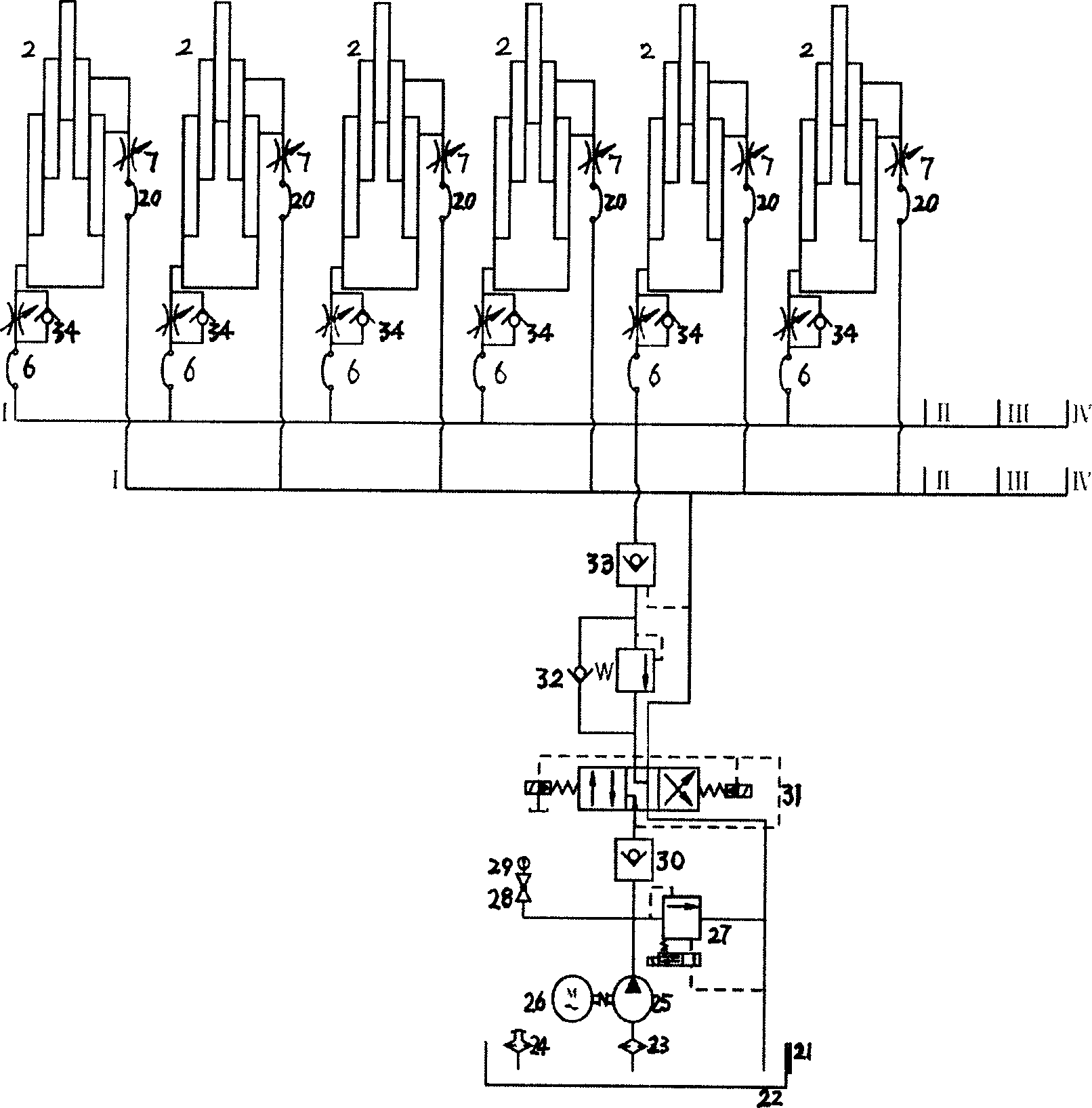

[0025] As shown in Figures 1, 2 and 3, the whole process automatic control hydraulic jacking device of the present invention consists of two parts, a hydraulic system and an automatic control system. The hydraulic system consists of a hydraulic station 1 and 10 hydraulic cylinders 2. The hydraulic cylinder 2 belongs to the jacking actuator and adopts a double-acting telescopic hydraulic cylinder, including a cylinder body 2-1 and a two-stage telescopic cylinder 2-2 nested with each other. , 2-3 composition (wherein, one-stage cylinder D=150, L=1000, two-stage cylinder D=100, L=1050); Hydraulic cylinder 2 side walls are fixed with support frame 11; Hydraulic cylinder 2 tops are equipped with self-positioning Jacking bracket 3 (spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com