Cutting device

A technology for cutting nozzles and cutting oxygen, which is applied in the direction of gas fuel burners, combustion methods, combustion types, etc., can solve the problems of wasting gas and oxygen, flame dispersion, and kerf width, and achieve less dross hanging, flame concentration, and noise reduction. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

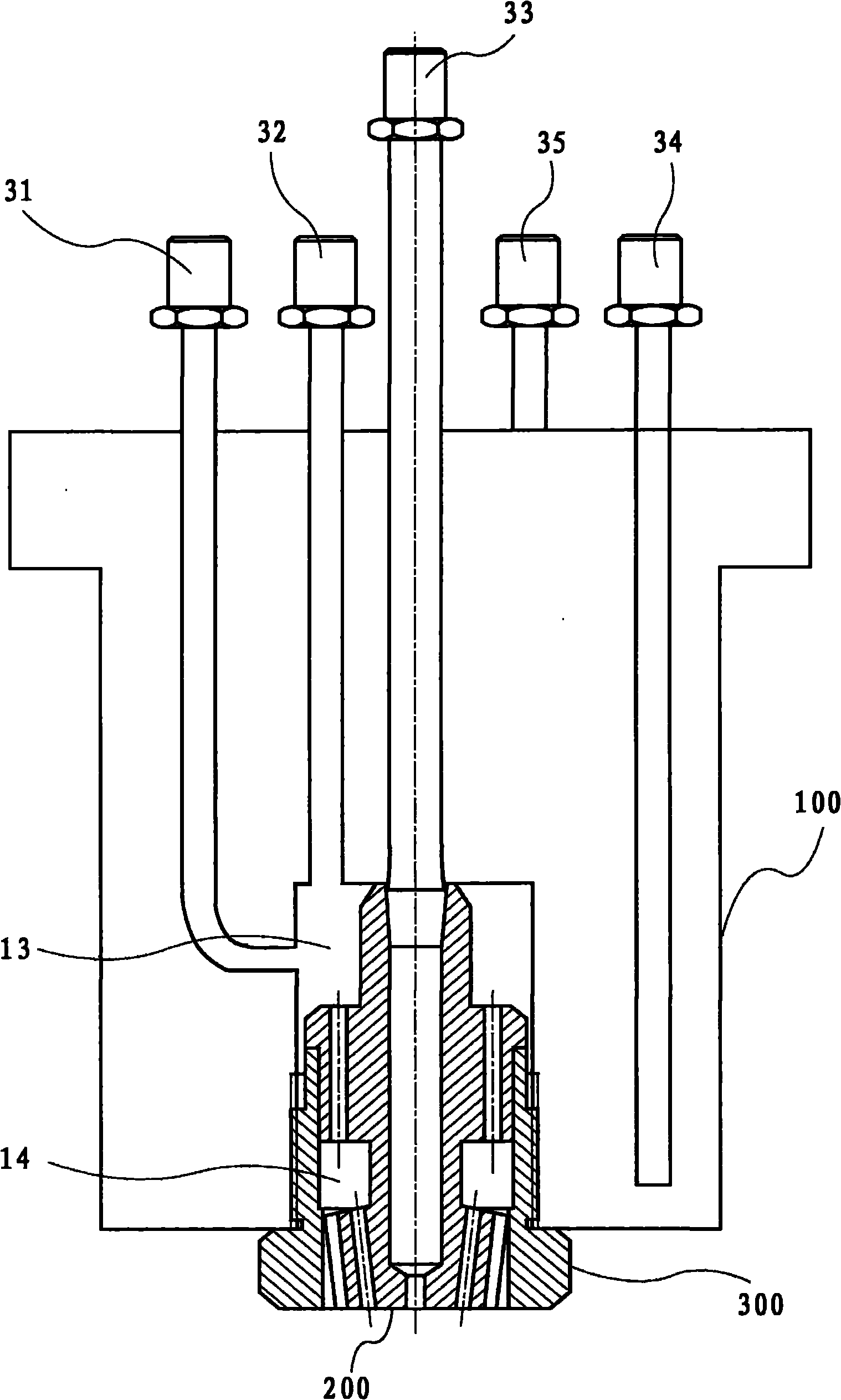

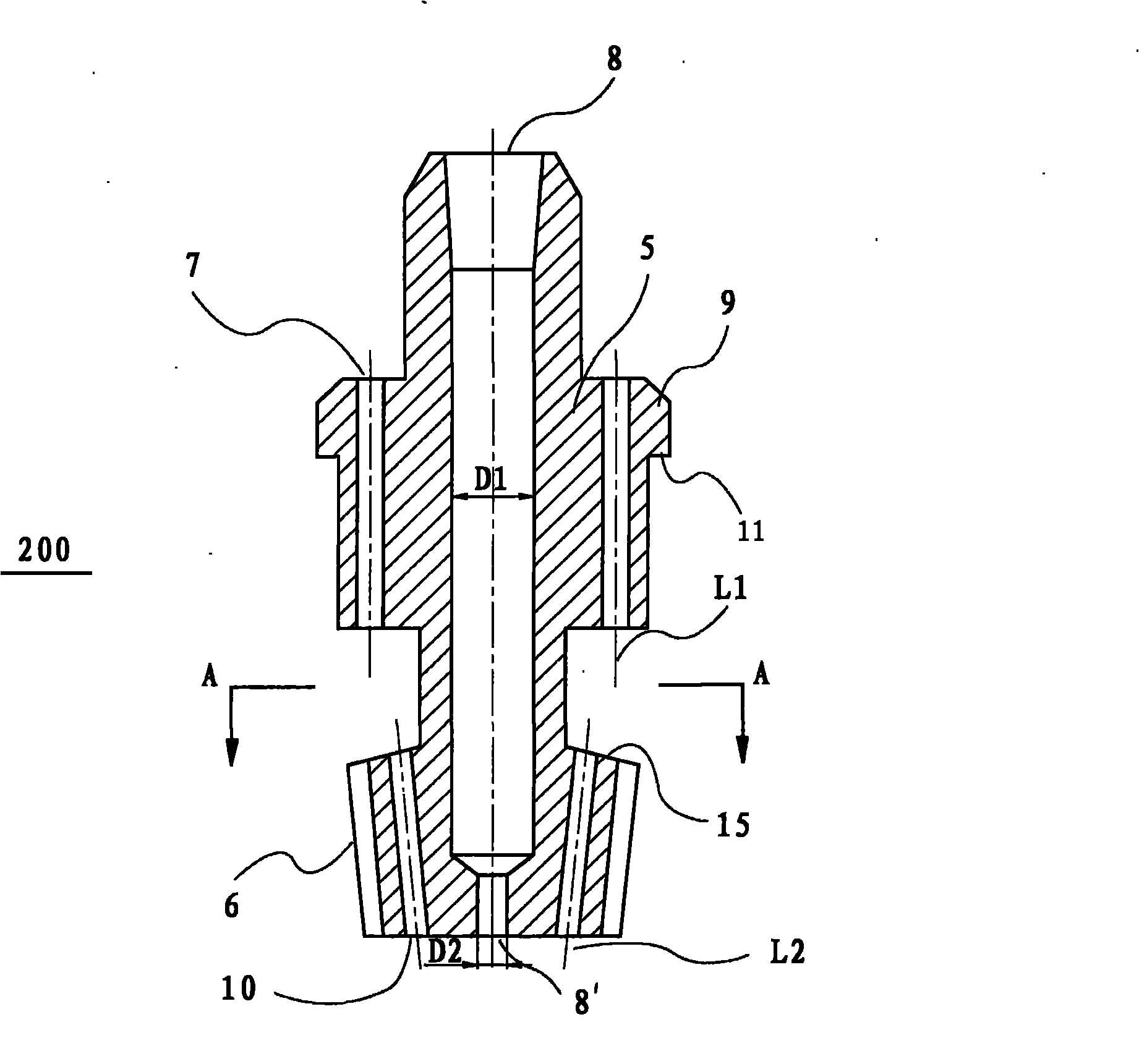

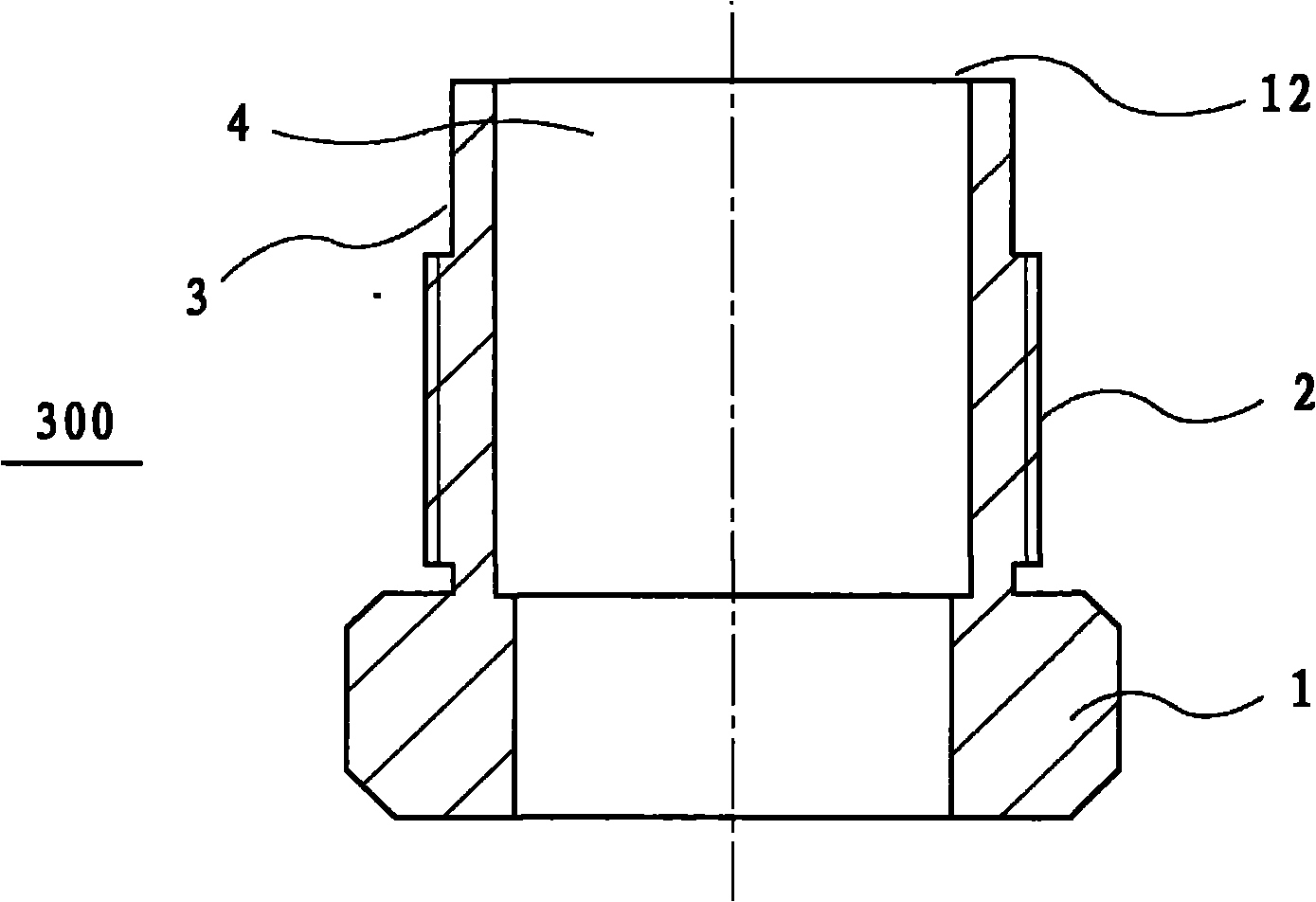

[0047]The flame cutting of steel (also called oxygen cutting) uses a gas flame (hereinafter referred to as preheating flame) to heat the surface of the steel to the ignition point and forms an activated state, and then sends high-purity, high-flow cutting oxygen to make the steel The iron in the oxygen atmosphere burns to generate iron oxide slag and releases a lot of heat at the same time. With the help of these combustion heat and slag, the lower layer of steel and the front edge of the cut are continuously heated to reach the ignition point until the bottom of the workpiece. At the same time, the momentum of the cutting oxygen flow blows off the slag, thereby forming an incision to cut the steel. Therefore, from a macro perspective, oxygen cutting is a processing method that combines the chemical process of burning iron in steel (in a broad sense, metal) in high-purity oxygen and the physical process of removing slag by cutting oxygen flow. Embodiments of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com