Laser drilling control method

A control method and laser drilling technology, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of affecting processing, non-linkage, difficult to cut or form notches, etc., to improve processing efficiency and reduce control time. , the effect of smooth section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

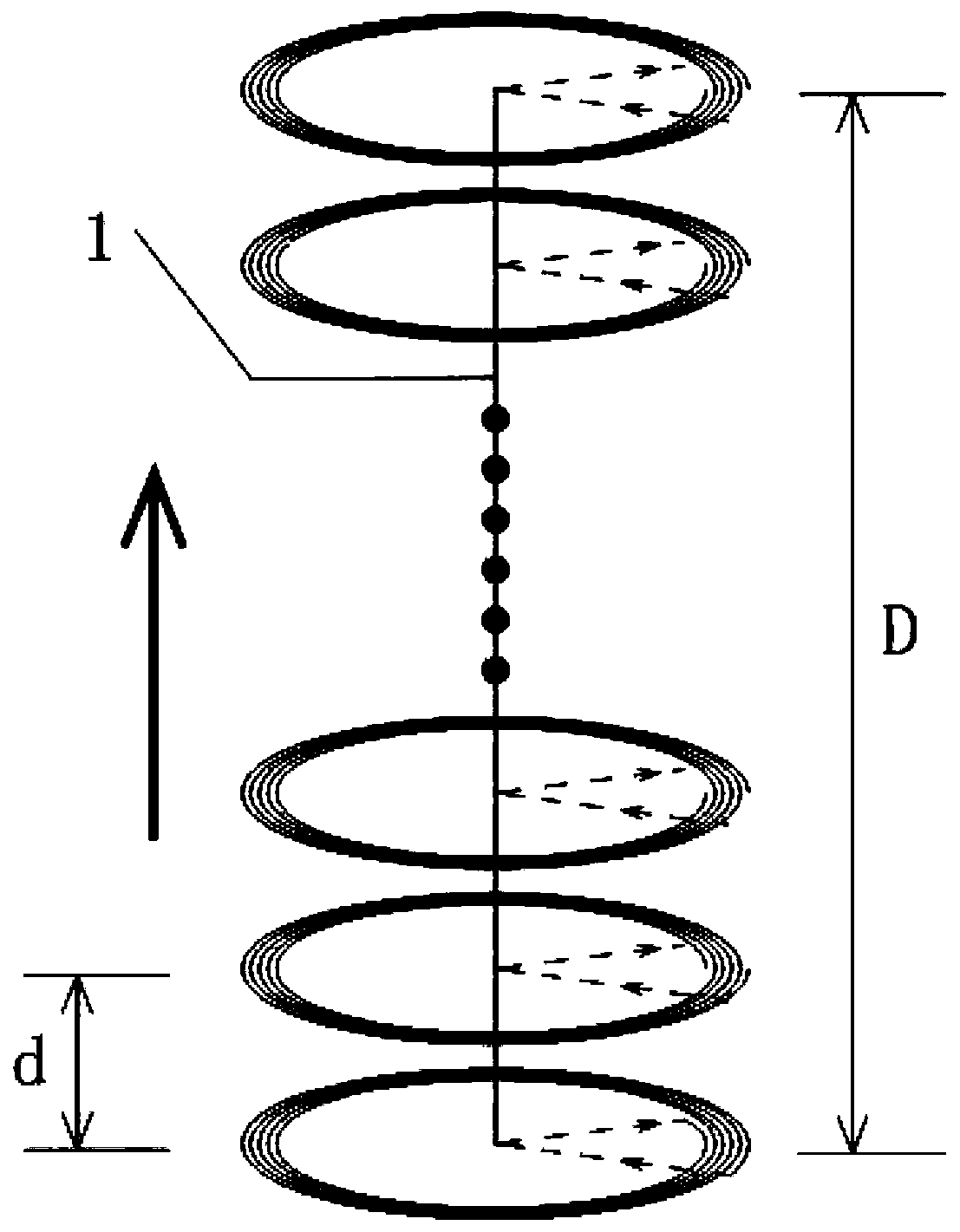

[0038] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0039] The hardware basis of the present invention:

[0040] 1. The processing object of the present invention is especially suitable for transparent and fragile solid materials, such as ordinary untempered glass drilling, high-purity quartz drilling, solar antireflection and hard glass drilling, etc. The control method of the present invention revolves around processing such materials;

[0041] 2. The present invention needs to use a low-pulse-width green laser or an ultraviolet laser as the light source for processing. After setting appropriate laser parameters, the laser can directly vaporize the raw materials near the focus;

[0042] 3. The present invention needs to use a 3D galvanometer as a scanning tool.

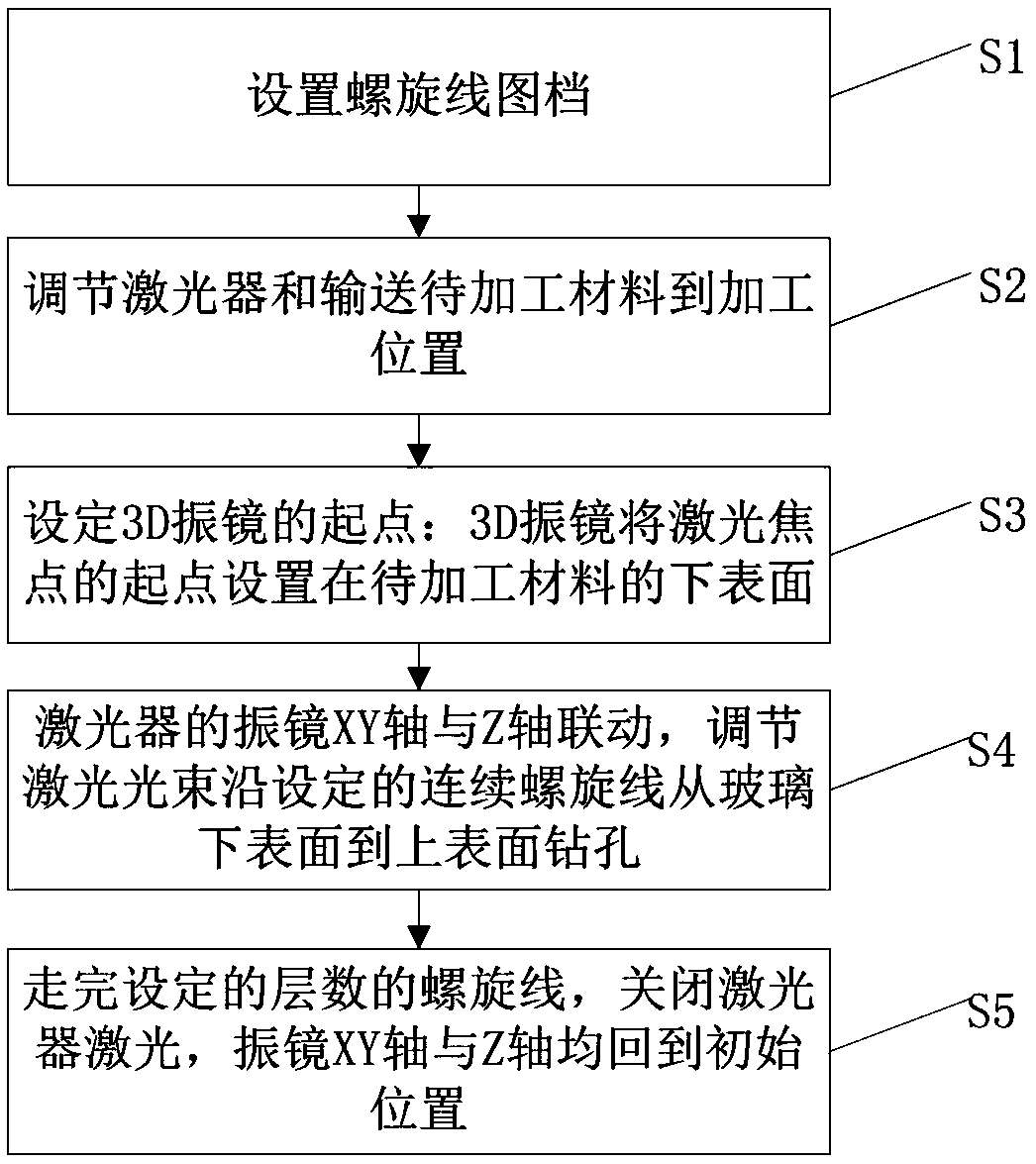

[0043] like figure 2 As shown, the present invention comprises the following steps:

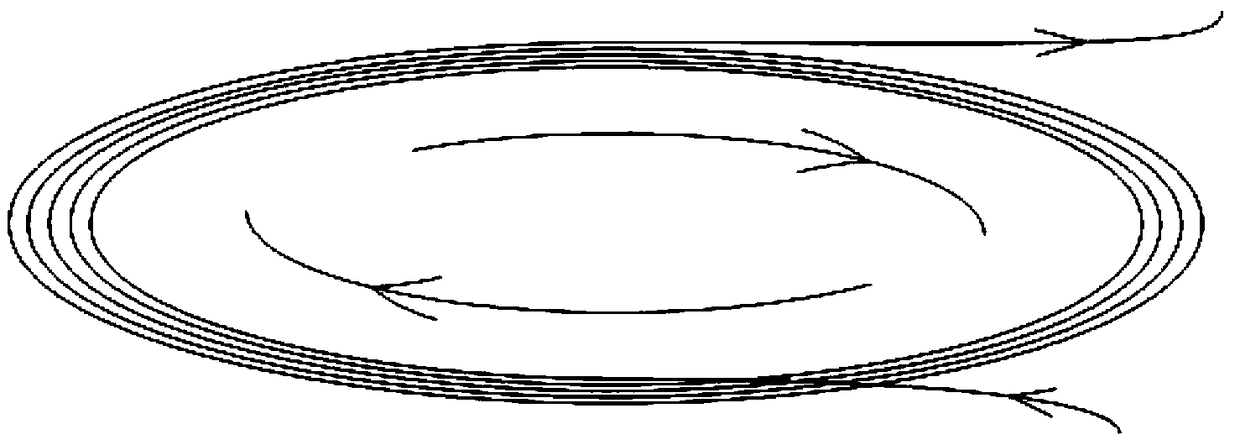

[0044] S1: Set the spiral line file: set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com