Underground real-time control system for density of drilling fluid

A real-time control system and technology of drilling fluid density, applied in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve problems such as inability to convert bottom-hole pressure difference, reduce non-productive time, and reduce drilling costs , the effect of improving the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

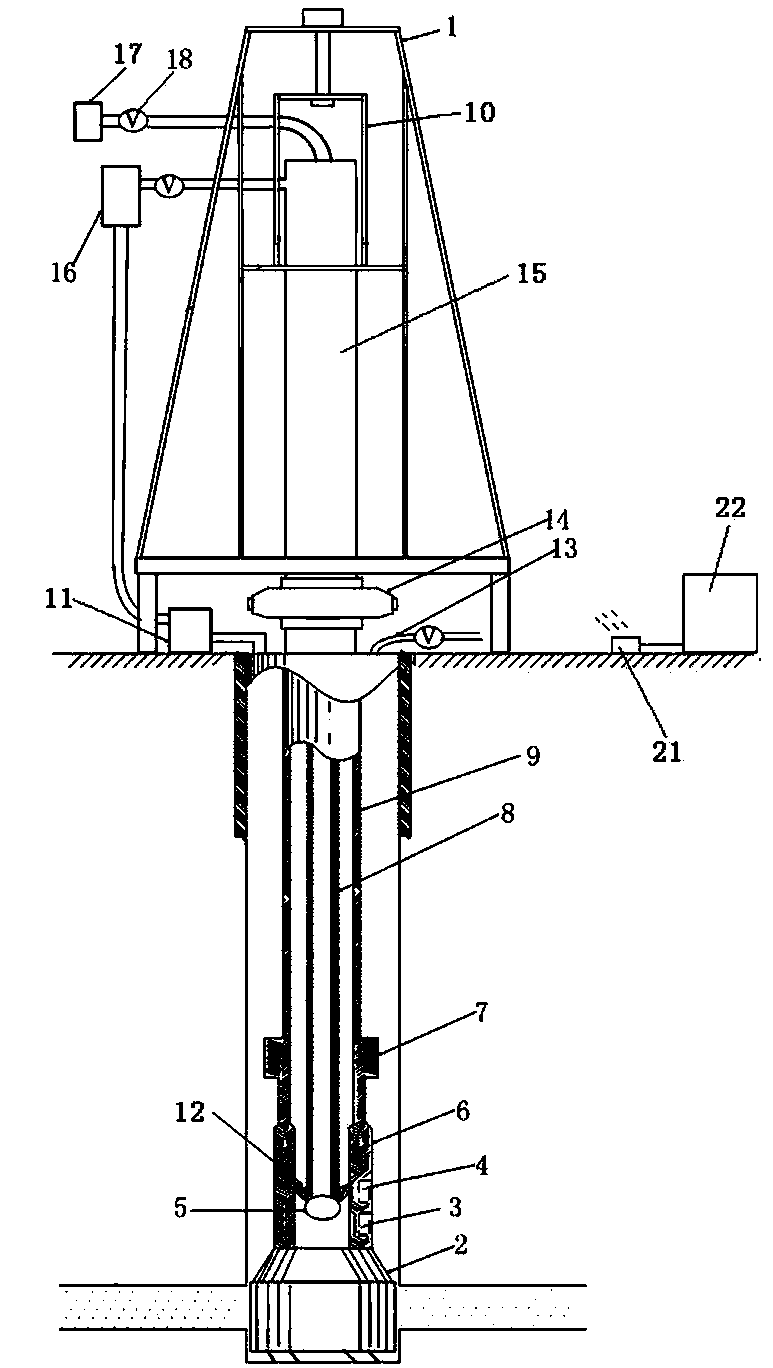

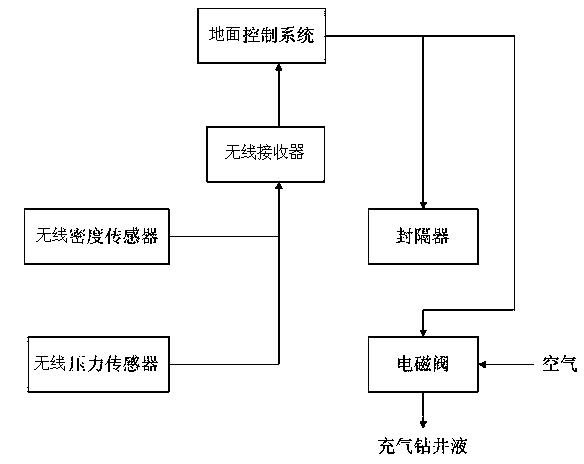

[0018] Such as figure 1 As shown, this downhole real-time control system for drilling fluid density includes a drilling rig 1, a blowout preventer 14, a double drill pipe drilling tool, an air compressor 17, a mud pump 16, an intermediate transmission device 15, a drill collar 6, a solenoid valve 5, a seal Spacer 7, wireless receiver 21, ground control system 22, the drilling rig 1 on the ground drives the drill pipe to rotate through the transmission system 10 to provide rock breaking energy for the drill bit 2, the blowout prevention device 14 is installed under the drilling rig 1, and the blowout prevention pipeline 13 runs from the wellhead protrude at the blowout prevention pipeline 13, a valve is set on the blowout prevention pipeline 13, the double drill rod drill has an inner drill rod 8 and an outer drill rod 9, the inner drill rod 8 and the outer drill rod 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com