Heatable housing, device for producing steam and cooking appliance

A heating device and casing technology, which is applied in the field of cooking appliances and steam generating devices, can solve problems such as damage, steam generator failure, and expensive maintenance work, and achieve the effect of increasing thermal power density and improving heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

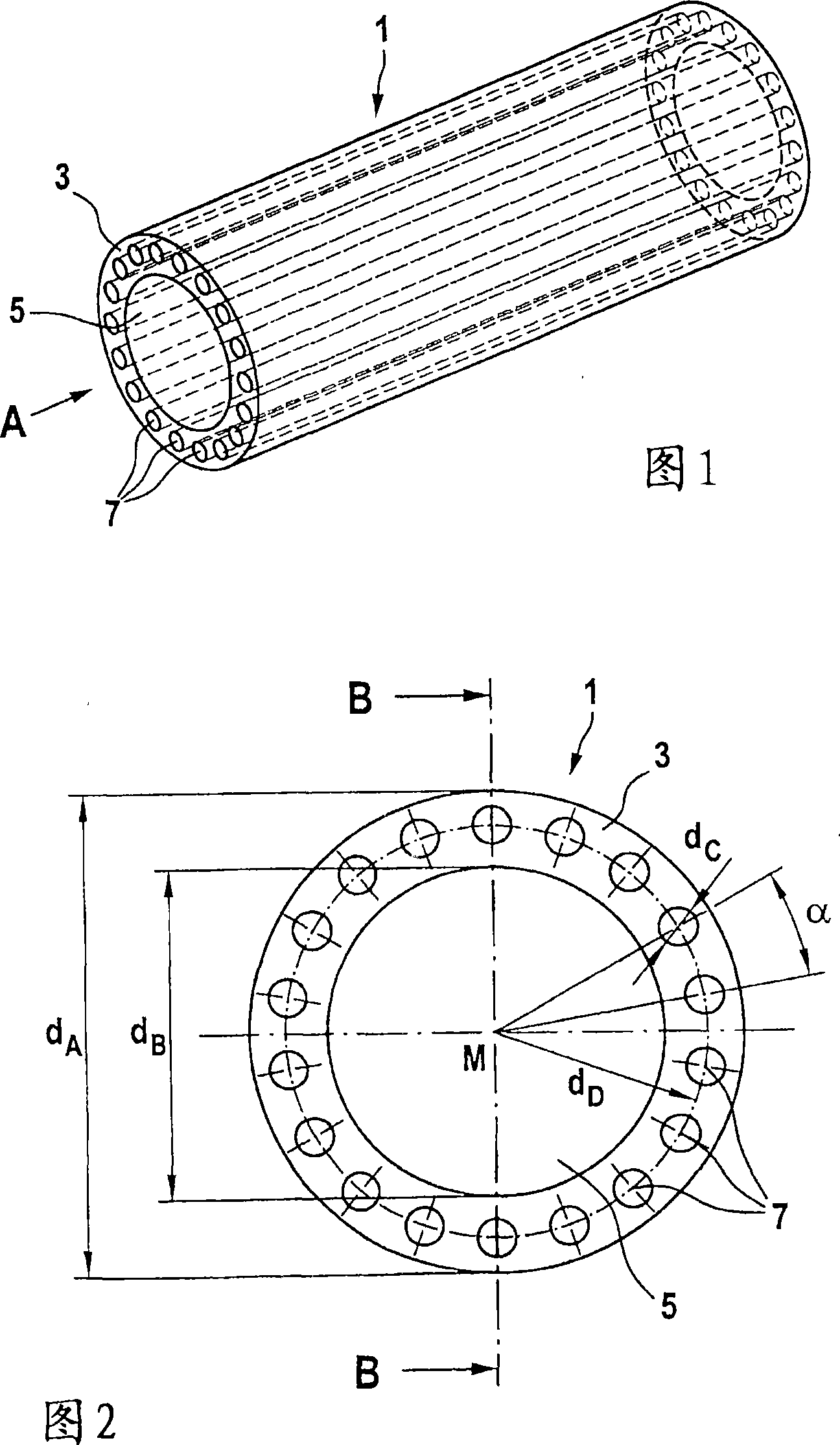

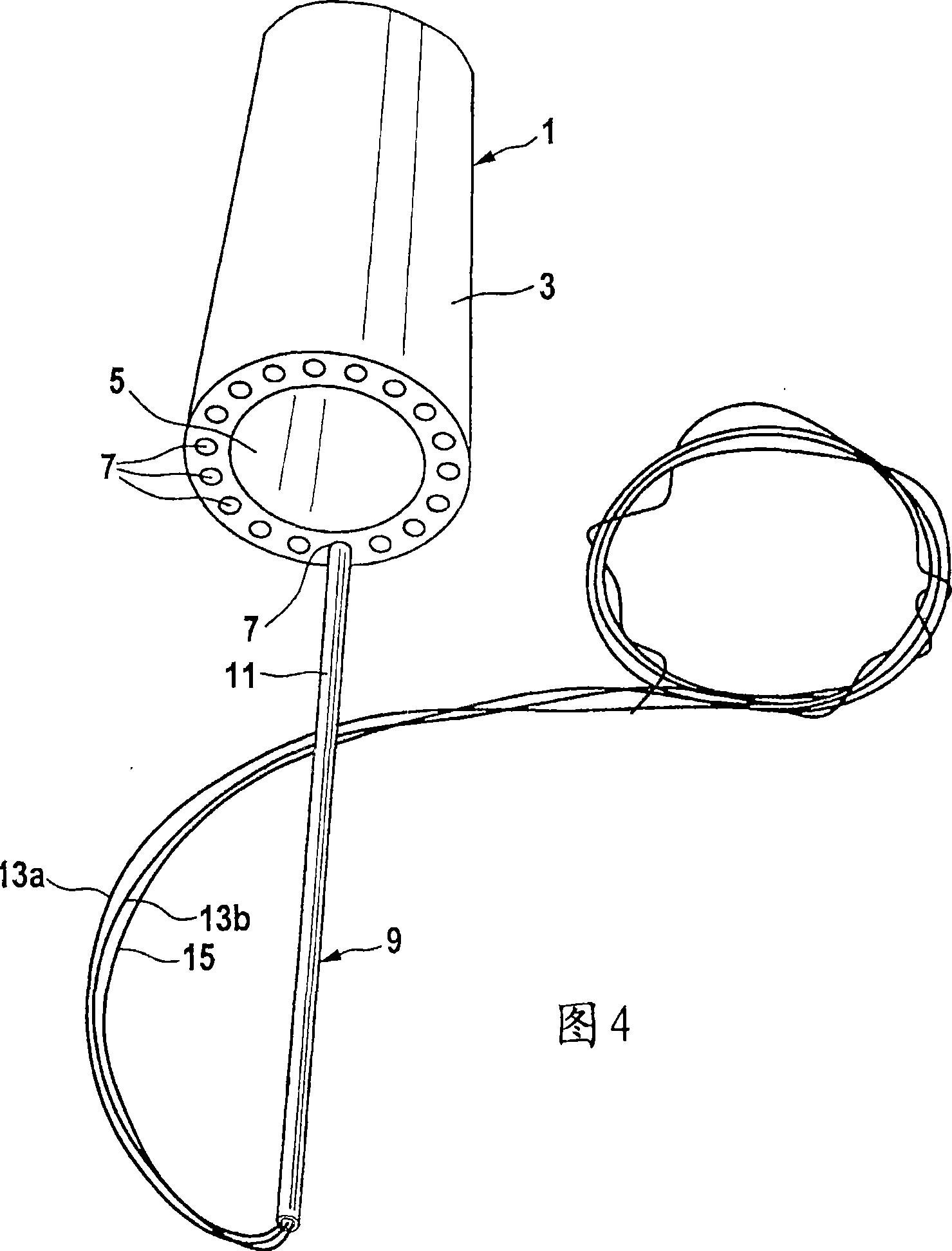

[0115] FIG. 1 shows a simplified diagram of a heatable housing 1 according to the invention. The housing 1 is substantially tubular and has a wall 3 . Wall 3 surrounds an interior 5 . A large number of recesses in the form of holes 7 are formed in the wall 3 . As can be seen in particular from FIG. 1 , the holes 7 pass completely through the wall 3 of the housing 1 along the entire longitudinal axis of the housing 1 . At the same time the holes 7 extend substantially parallel to the surface of the wall 3 facing the interior 5 .

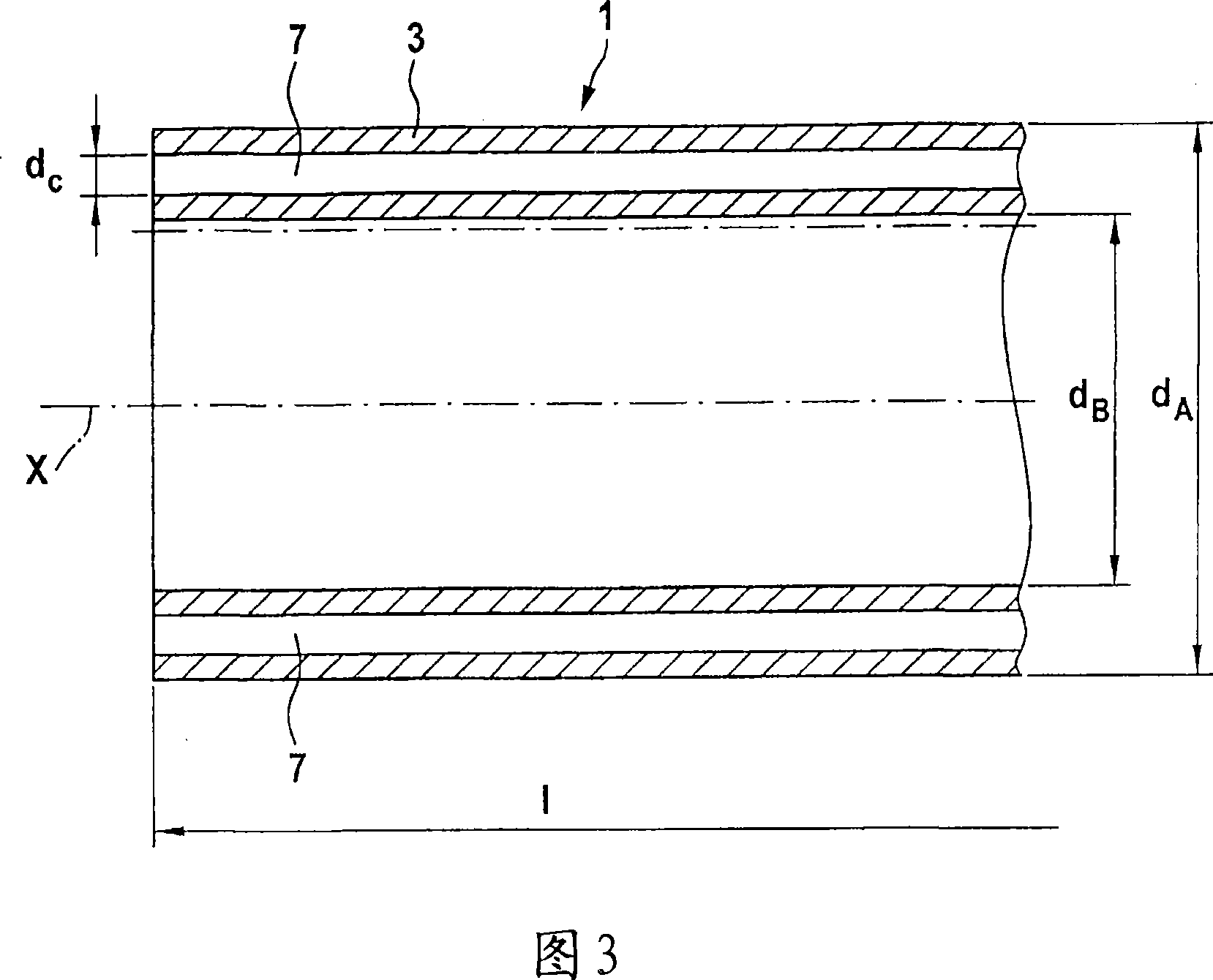

[0116] As can be seen in particular from FIG. 2 , which shows a side view of the housing 1 in direction A in FIG. 1 , the holes 7 are regularly distributed along the circumference of the wall 3 . In particular, the housing 1 has 18 holes 7 , ie the angular spacing α between the individual holes 7 is approximately 20°. When the housing 1 is inserted as a kettle into a steam generator, the housing 1 can, for example, have the following dimensions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com