Cuneiform hold-down mechanism for steel grating gang tool shearing machine

A technology of wedge-shaped pressing mechanism and combined tool, applied in shearing machine equipment, shearing devices, manufacturing tools, etc., can solve the problems of pull-off, warping deformation welding seam, flat steel deformation, etc., and achieve the effect of eliminating voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

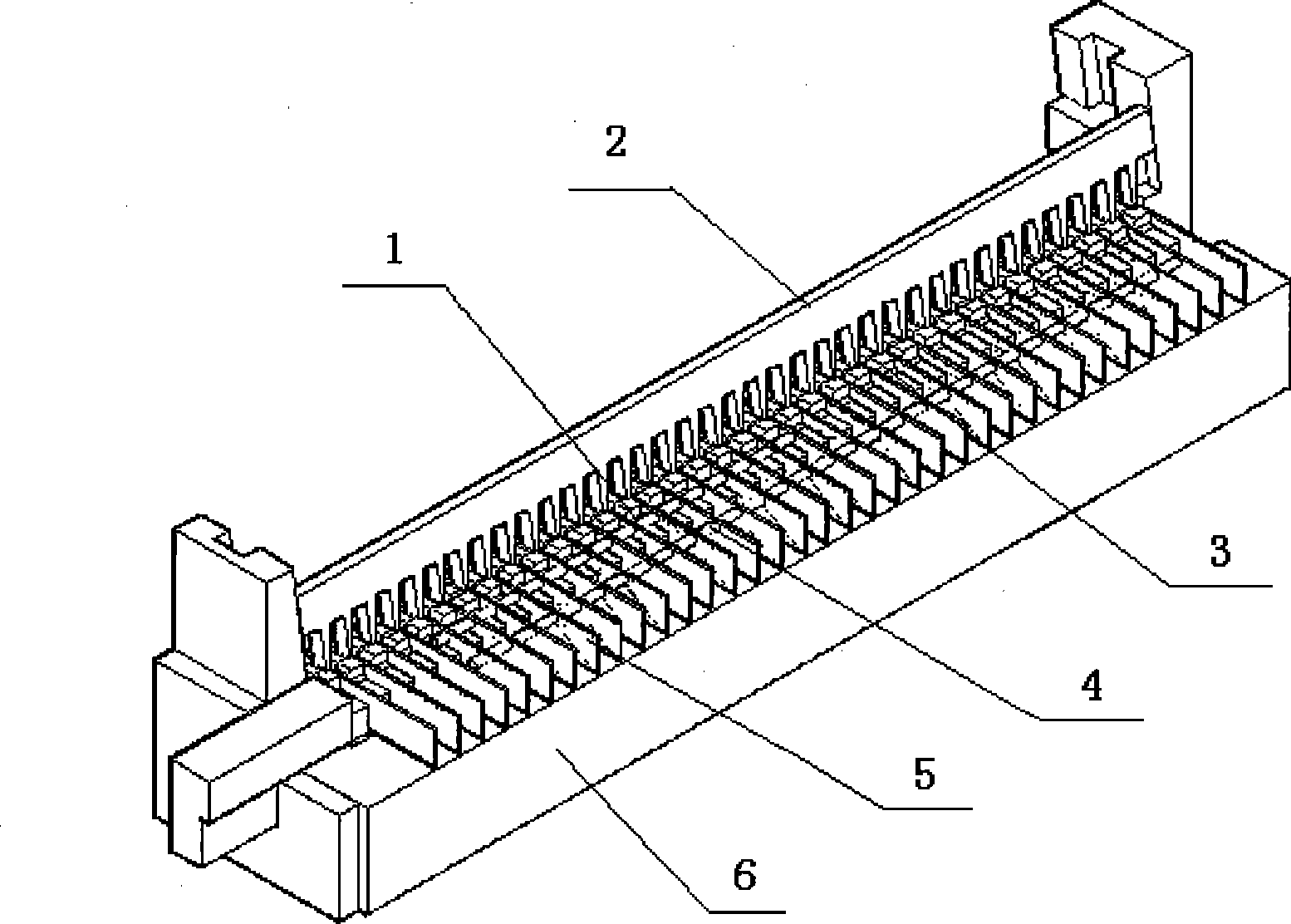

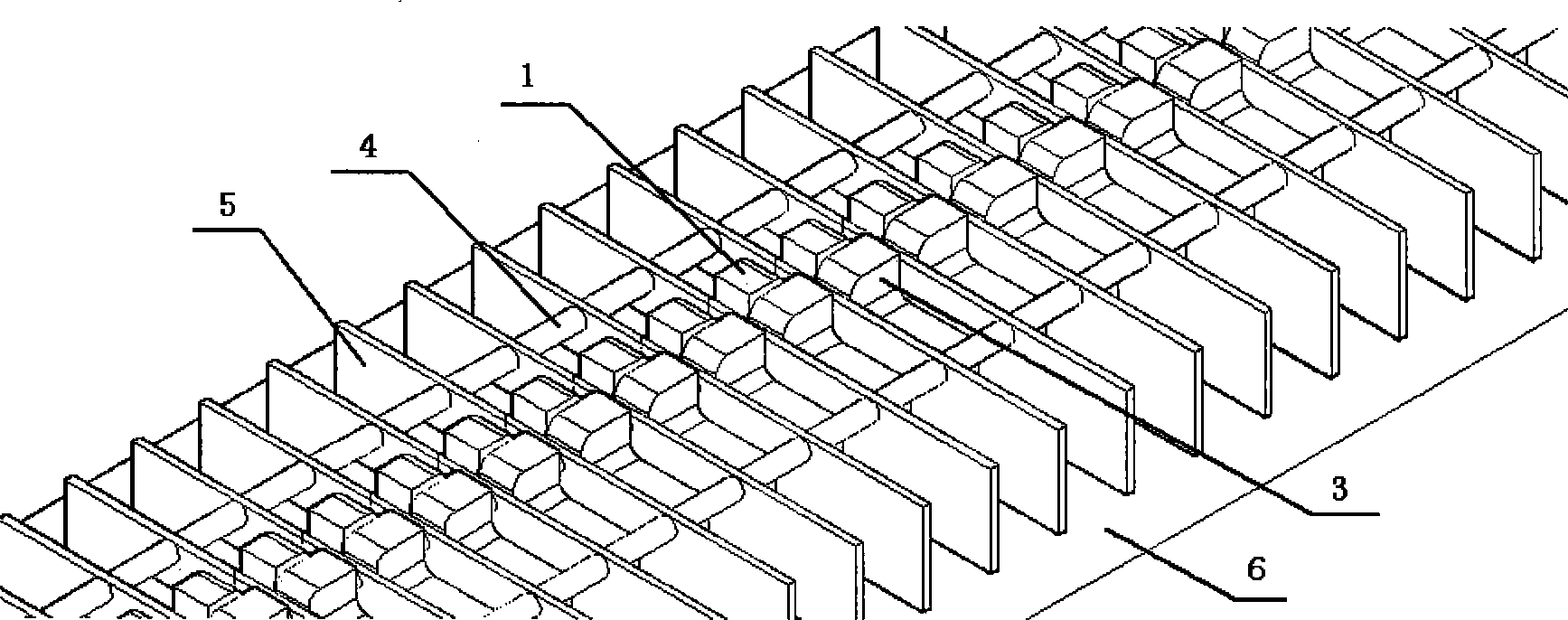

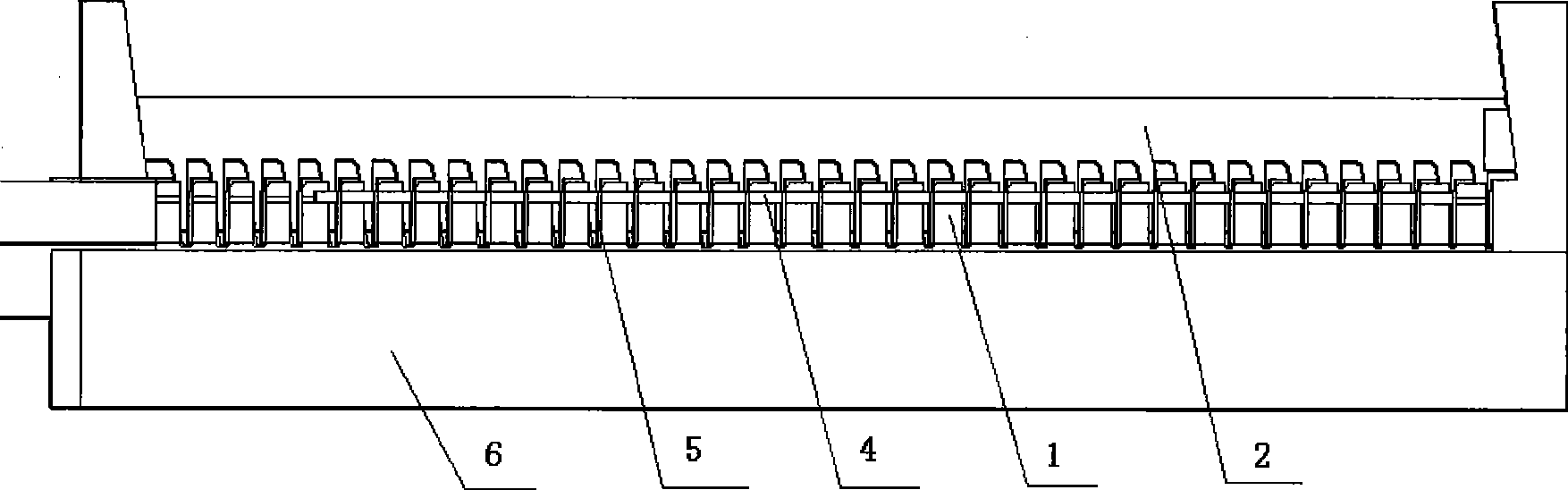

[0015] Such as Figure 1-5 As shown, the flat steel 5 of the steel grating is interspersed with the vertical bar 4 and arranged crosswise, and the fixed cutter 1 and the movable cutter 3 are composed of a combined cutter, and the combined cutter is installed on the cutter holder 6 . The flat steel 5 of the steel grating and the vertical cross bar 4 are passed through the gap between the fixed cutter 1 and the movable cutter 3 to form a knife groove. The back of cutter 1 blade is positioned at the rear portion of knife rest 6, and a plurality of upper wide and lower narrow chutes are set on the rear back of fixed cutter 1 blade, and the quantity of chute is identical with flat steel 5, and flat steel 5 just wears on in the chute. A wedge-shaped pressing piece 2 corresponding to the chute is set above the fixed tool 1. The number of wedges of the wedge-shaped pressing piece 2 is the same as that of the chute and the flat steel 5. The wedge-shaped pressing piece 2 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com