Fixed cutting device and paper tube smoothing mill comprising same

A technology of cutting device and precision cutting machine, applied in metal processing and other directions, can solve the problems of cumbersome operation, waste of resources, low production efficiency, etc., and achieve the effects of eliminating edge burrs, increasing cutting speed and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

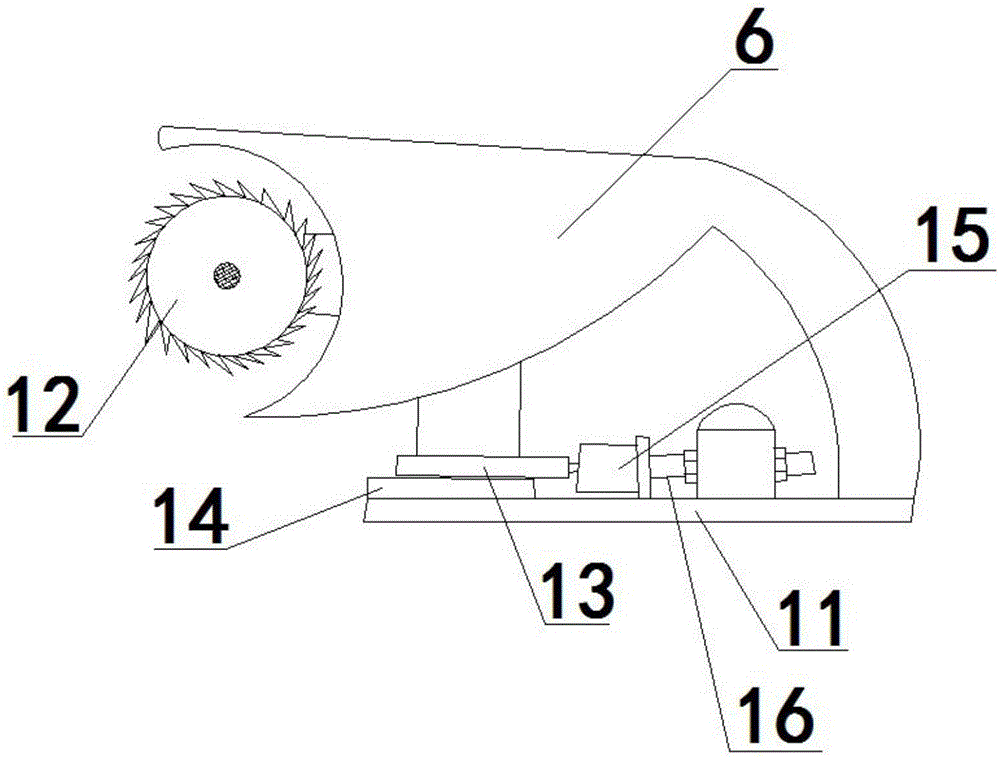

[0023] Such as figure 1 As shown, the present invention provides a kind of fixed cutting device 1 and comprises cutting saw 12, cutting frame 11 and draft device 6, and cutting saw 12 and draft device 6 are arranged on the cutting frame 11 respectively, can cut frame 11 according to the needs of work. Be fixed on the cutting equipment, also can install a convenient hand-held handle on the cutting frame 11, people can hold mobile operation. The air passage opening of the draft device 6 covers the working area of the cutting saw 12. When the cutting device 1 is used, the cut debris on the cutting piece can be sucked in through the air passage opening of the draft device 6, thereby preventing the debris from being in the working area. The ring will fly inside and pollute the working environment.

[0024] The cutting saw 12 is arranged on the cutting frame 11 by a sliding mechanism. The sliding mechanism includes an upper slider 13 and a lower slider. The cutting saw 12 is fixe...

no. 2 example

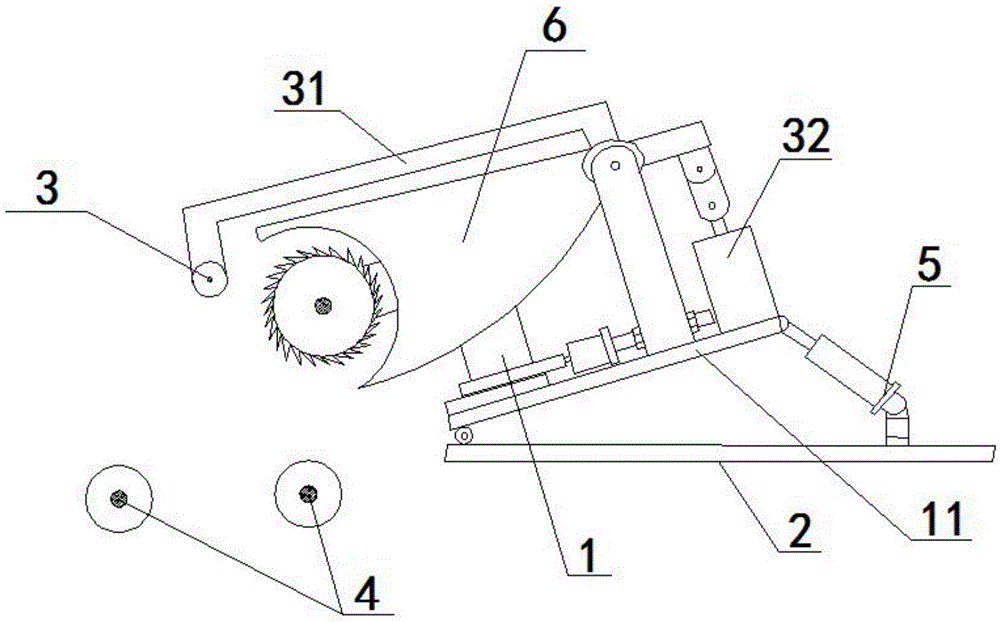

[0027] Such as figure 2 Shown is a paper tube fine cutting machine comprising the cutting device 1 in the first embodiment, the frame 2, the roller 4 carrying the paper tube, the cutting device 1 and the control unit, the cutting device 1 and the rollers are matched and arranged on the machine 2, and are respectively electrically connected to the control unit, through which the cooperative work between the various devices can be controlled, so as to achieve an intelligent cutting effect. The front end of cutting device 1 is hinged on frame 2, and its rear end is connected with frame 2 through cutting cylinder 5, and cutting cylinder 5 is in order to control cutting device 1 to carry out cutting work. By controlling the angle and position of the cutting device 1 hinged on the frame 2 when the cutting cylinder 5 works, it is possible to better cooperate with the roller 4 carrying the paper tube, and accurately carry out the paper tube fixed on the roller 4 carrying the paper tu...

no. 3 example

[0035] A cutting method for cutting a paper tube: a. Place the paper tube to be cut on a roller shaft that can rotate in both directions, push the cutting device so that the cutter cuts into the paper tube to be cut, and then start the rotation of the roll shaft to make the paper tube to be cut Rotate the cutter on the cutting device in the opposite direction, so that the outer edge of the cutter is located between the inner and outer sides of the paper tube to be cut and perform a circular cut to complete the first cut; b. Push the cutting device again to make the cutter Cut through the paper tube to be cut, and at the same time control the roller shaft so that the paper tube that has been cut for the first time in step a rotates in the same direction as the cutter on the cutting device. The paper tube is cut off, and the cutting is completed.

[0036] The concrete operation method of the paper tube fine cutting machine in conjunction with the second embodiment is: operation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com