Method and device for improving efficiency in engraving three-dimensional images in large-area flat glass

A technology of flat glass and three-dimensional images, which is applied in the field of optics, can solve problems affecting the efficiency of engraving processing, etc., and achieve the effect of improving engraving speed and efficiency, improving efficiency, and improving engraving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

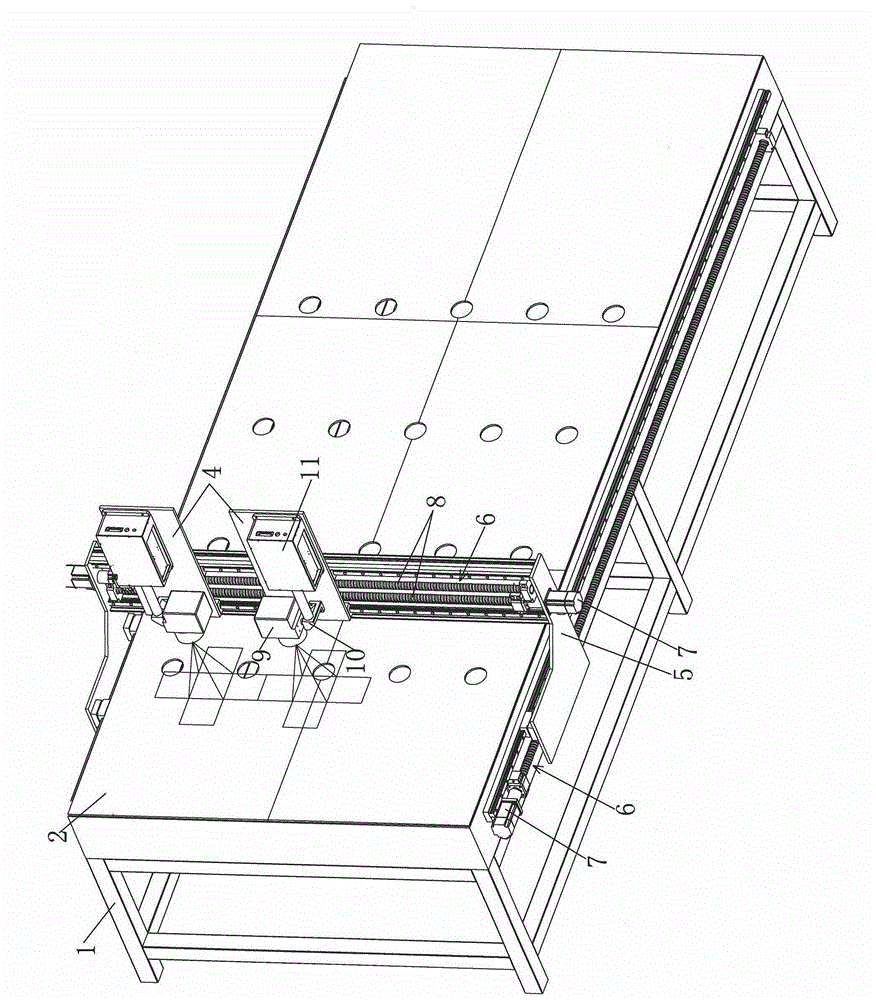

[0033] Embodiment: A method for improving the efficiency of engraving three-dimensional images in large-area flat glass, including a process of using laser focusing to form microburst points in the flat glass, and also including a process of moving the laser focus point in the flat glass, Wherein, before the laser forms the first microburst point in the flat glass, the image is first divided into at least two areas, preferably two areas, each area is correspondingly provided with a high-speed galvanometer, and then each area is respectively set Determine the displacement path range of the corresponding high-speed galvanometer; in the process of setting the displacement path range of the high-speed galvanometer, each area is divided into at least two parallel engraving partitions, and the high-speed galvanometer is between each other On the premise that there is no collision between them, the image carving of each area is completed separately.

[0034] Furthermore, the coordina...

Embodiment 2

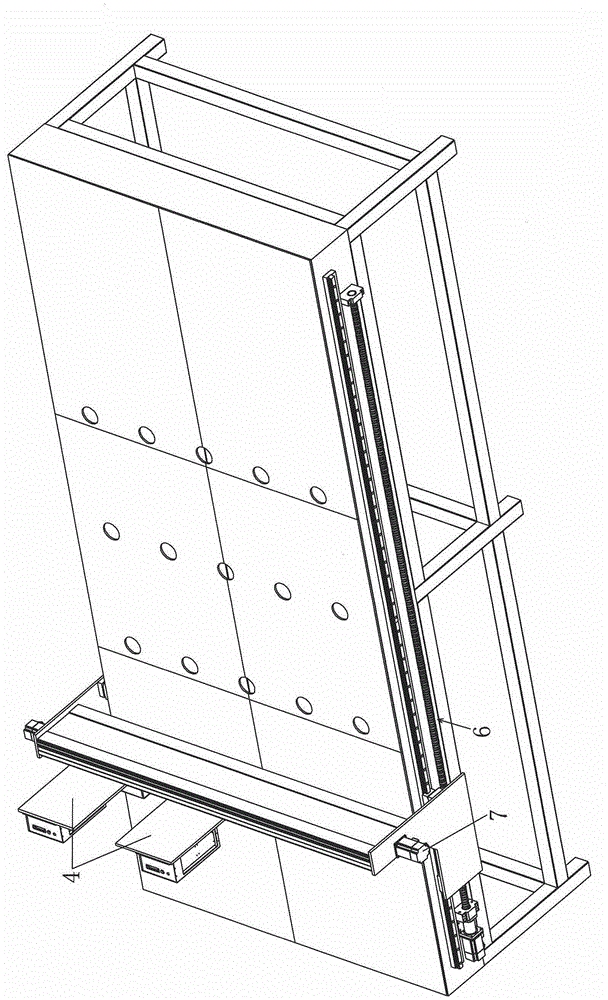

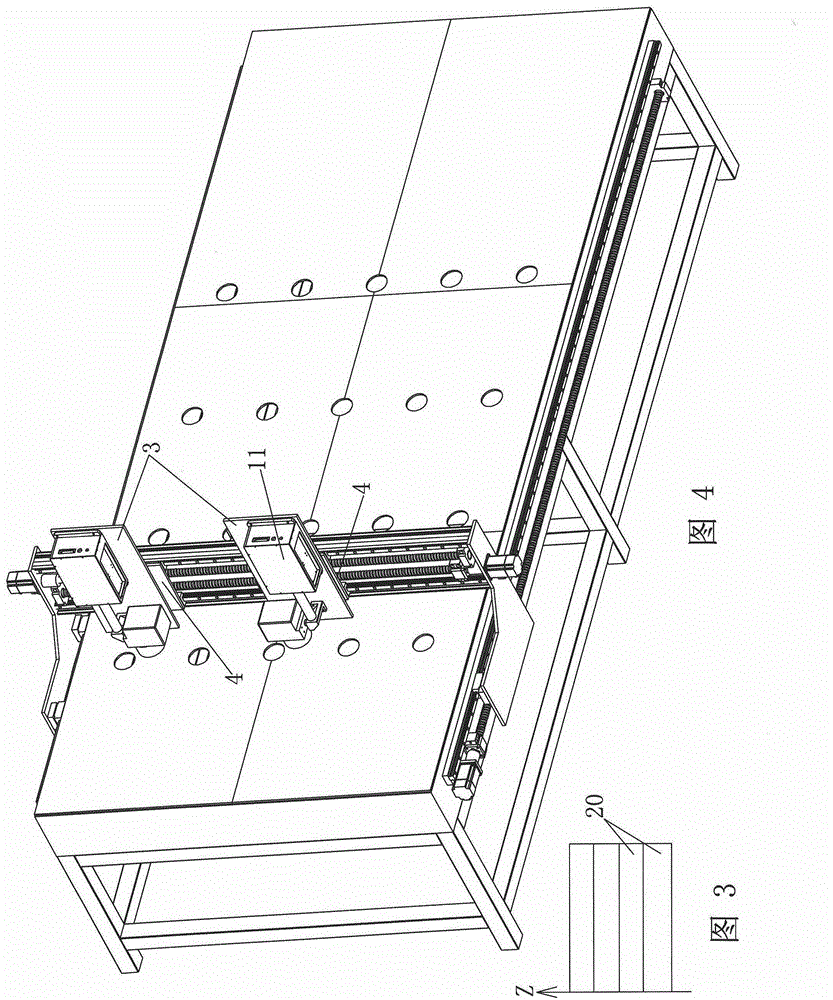

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that, as Figure 4 As shown, it also includes two Z-direction mobile stations 3, each Z-direction mobile station 3 is correspondingly connected to an X-direction mobile station 4, and the high-speed vibrating mirror system is arranged on the Z-direction mobile station 3; The screw nut pairs and servo motors (not shown) connected to the platform 3 are all arranged on the X-direction mobile platform 4. In the high-speed galvanometer system, the emission direction of the laser source 11 is parallel to the motion track of the Z-direction mobile platform 3 .

[0046] When the three-dimensional pattern is too thick, such as image 3 As shown, the area to be engraved is divided into at least two layers of parallel engraving blocks 20 in the direction of the Z axis. One layer engraves the engraving partitions in the X-Y axis direction of this layer until the engraving of each layered block in the Z-axis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com