Micro-explosion atomization oil gun

An oil gun and micro-explosion technology, applied in the field of oil gun and micro-explosive atomization oil gun, can solve the problems of affecting complete combustion, large atomization particle size, and increased pollution discharge, and achieve improved combustion efficiency and small atomization particle size. , the effect of reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

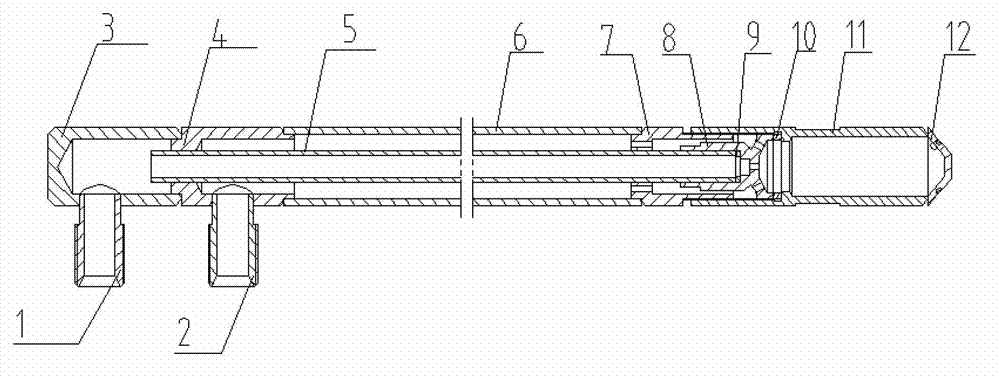

[0015] Such as figure 1 The present invention shown includes an oil interface 1, an air interface 2, an oil chamber 3, and an air chamber 4. The oil chamber 3 communicates with the oil interface 1, the air chamber 4 communicates with the air interface 2, and the oil chamber 3 communicates with the inner pipe 5 , the air chamber 4 communicates with the outer pipe 6, and the front ends of the inner pipe 5 and the outer pipe 6 are provided with a flow mixer 8, and the flow mixer 8 communicates with the front end of the inner pipe 5 through a small copper pad 9, and the flow mixer 8 communicates with the front end of the inner pipe 5 through an air pipe joint 7. The front end of the outer tube 6 communicates, the front end of the flow mixer 8 connects with the premixing chamber 11 through a large copper pad 10 , and the atomizing head 12 communicates with the front end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com