Lubricating oil composite dewatering technique

A lubricating oil and process technology, applied in the field of lubricating oil composite dehydration process, can solve problems such as the impact of lubricating oil quality, and achieve the effects of improving quality, avoiding oxidation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

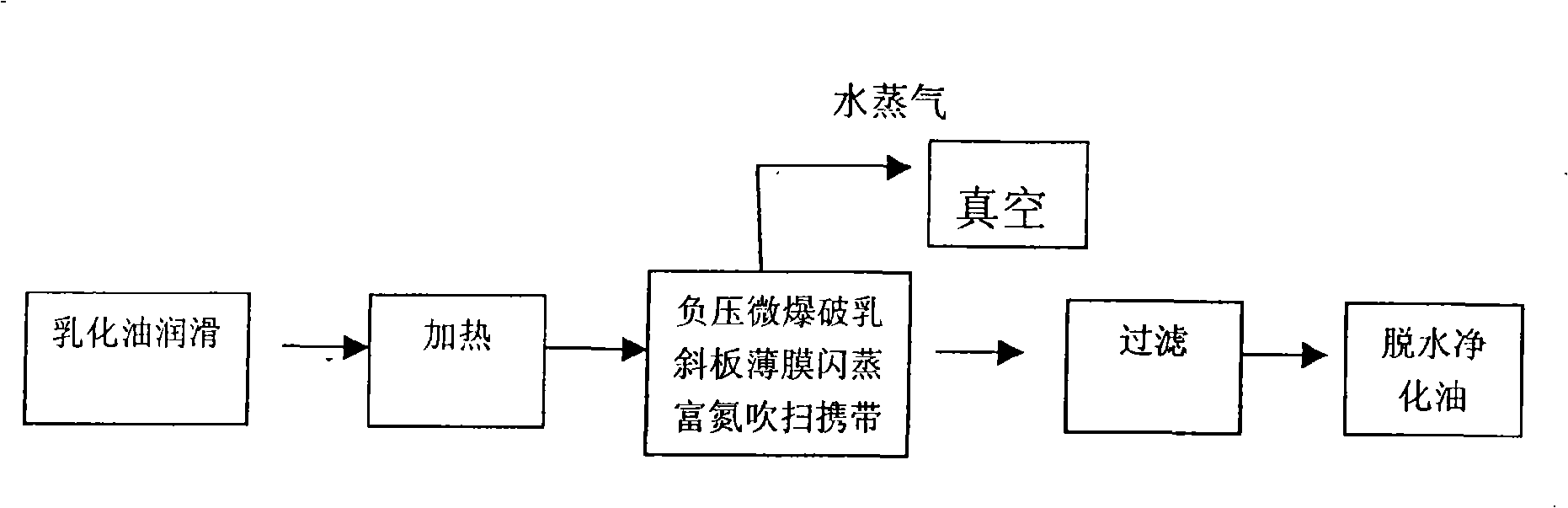

Method used

Image

Examples

Embodiment 1

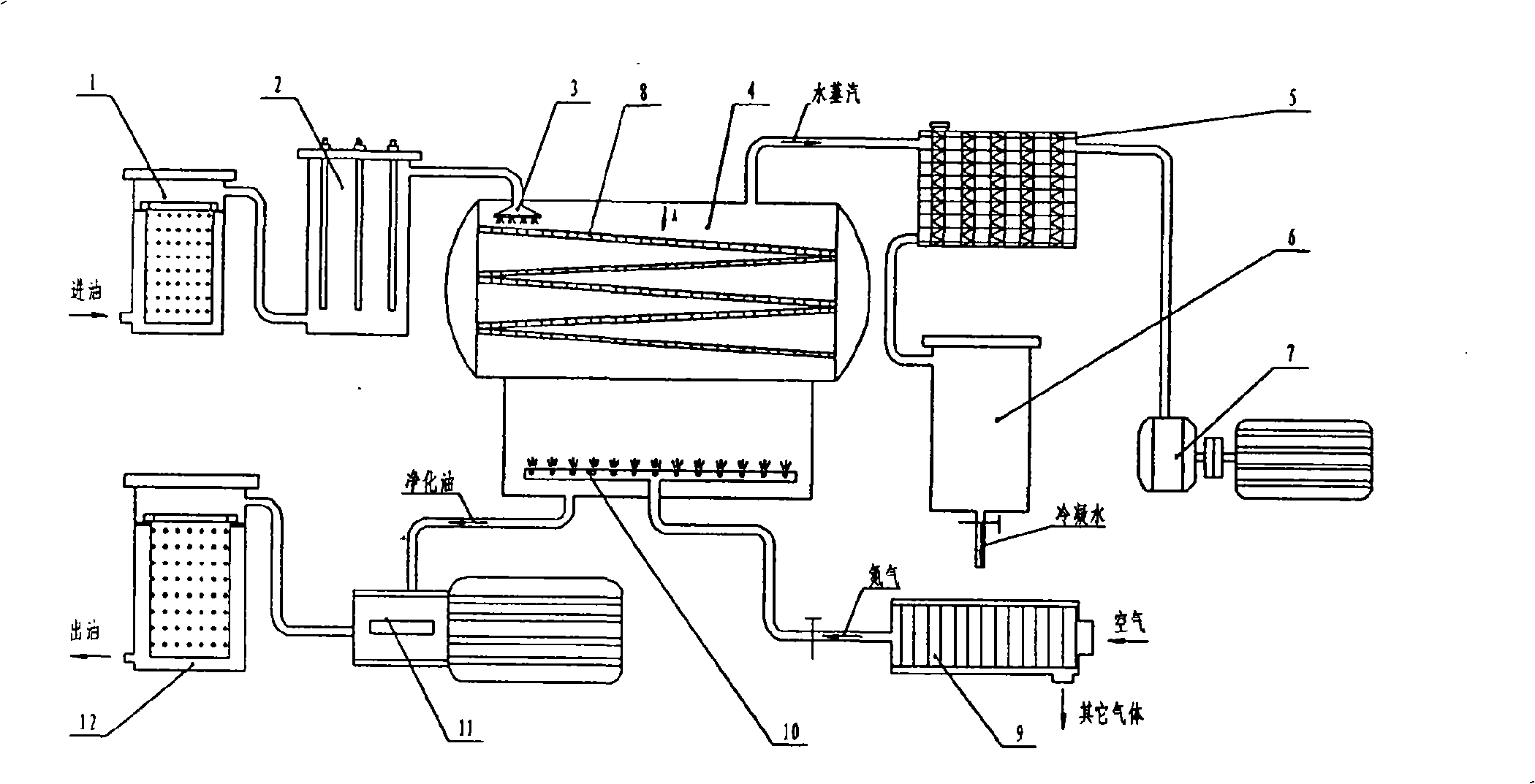

[0018] Embodiment one: the lubricating oil dehydration purification process of diesel engine, the steps are as follows:

[0019] The first step is to start the vacuum pump 7 to form a negative pressure in the composite dehydration device 4, so as to suck oil and nitrogen;

[0020] The second step is to filter the emulsified lubricating oil: the emulsified lubricating oil of the diesel engine enters the coarse filter 1 under the negative pressure formed by the composite dehydration device to remove solid particles in the oil;

[0021] The third step is to heat the emulsified lubricating oil: after removing the solid particles, the emulsified lubricating oil also enters the electric heater 2 for heating under the negative pressure formed by the composite dehydration device, and the temperature is controlled between 40-80°C; the temperature of the emulsified lubricating oil Elevation is conducive to the evaporation of water in it;

[0022] The fourth step, negative pressure micr...

Embodiment 2

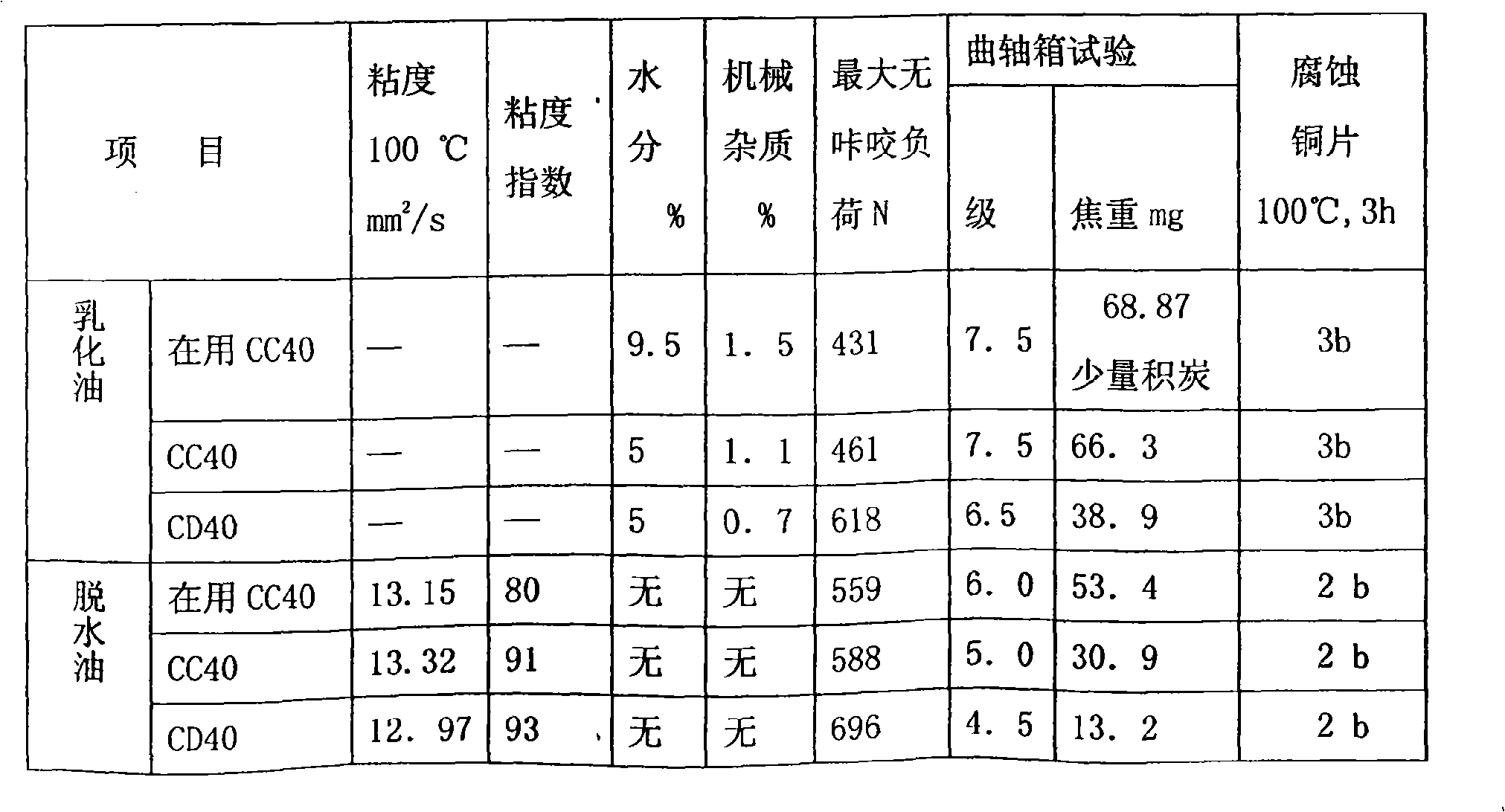

[0029] Embodiment 2: The dehydration and purification process of lubricating oil for gasoline engines, the steps and conditions are the same as those in Embodiment 1, and the results after dehydration and purification are shown in Table 2.

[0030] Table 2 Test results after dehydration and purification of lubricating oil for gasoline engines

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com