Micro-electro-mechanical system intelligent security explosion initiation device and preparation method thereof

A safe detonation, micro-electromechanical technology, used in blasting cylinders, offensive equipment, weapon accessories, etc., can solve the problems of difficult processing, difficult assembly, bulky, inconvenient for large-scale production, etc., achieving good modularization and high process consistency. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

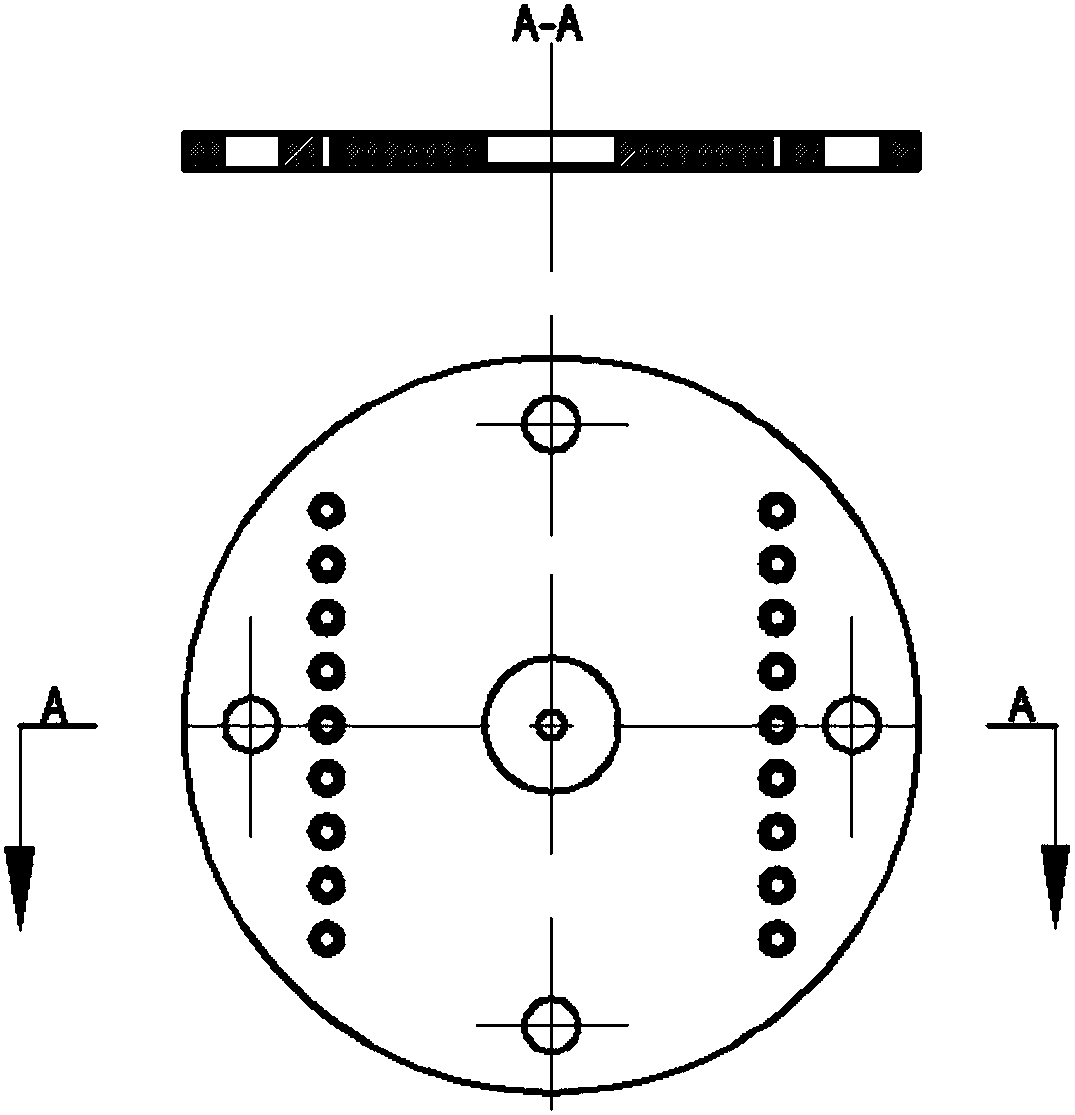

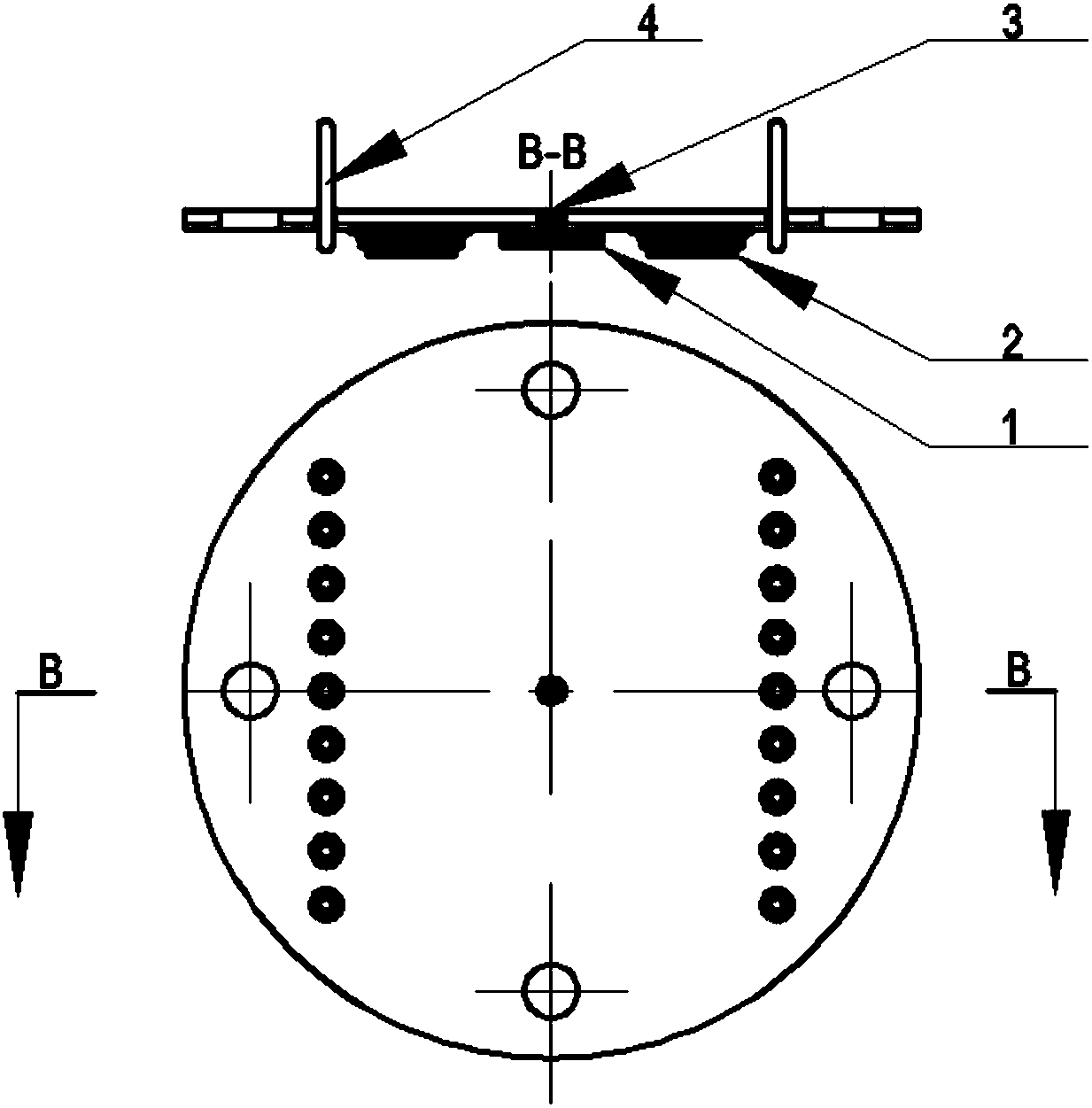

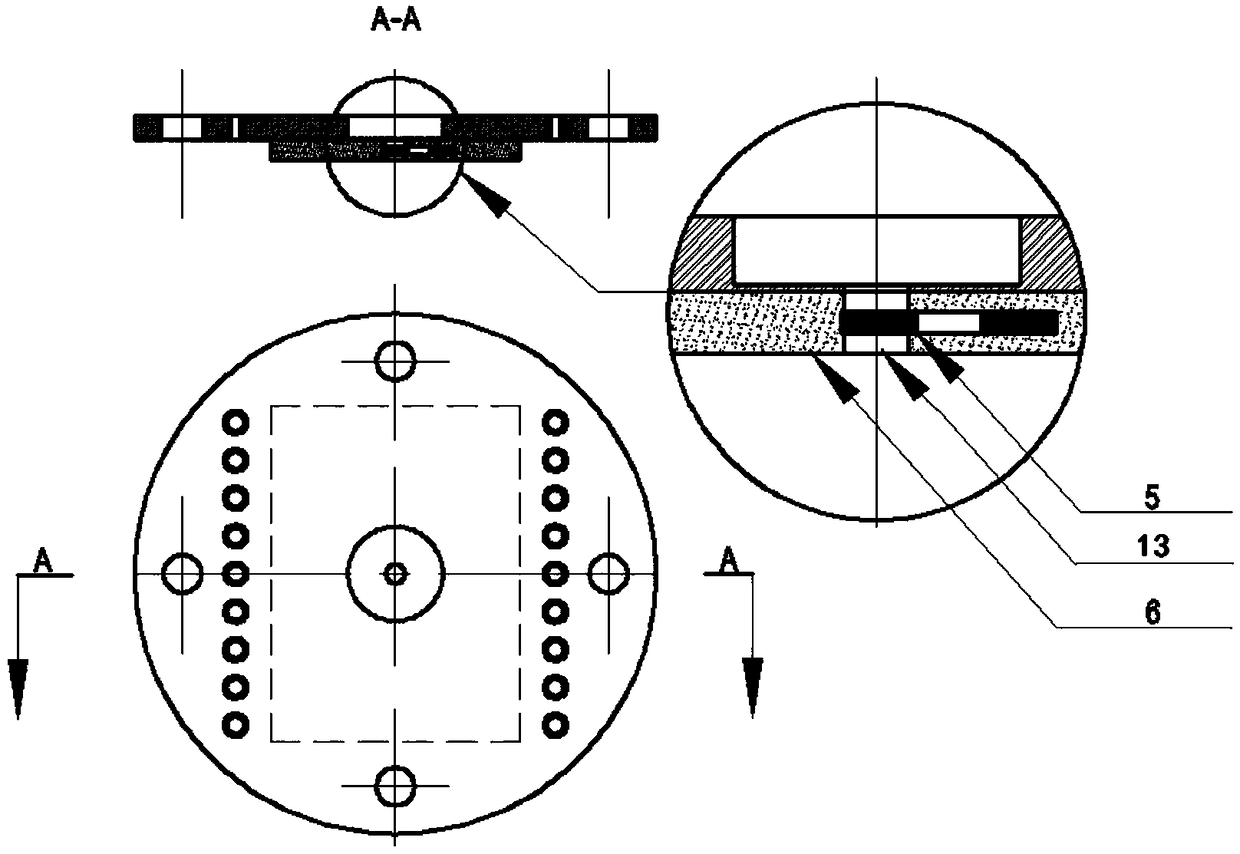

[0024] A specific embodiment of the present invention provides a micro-electromechanical intelligent safety detonation device, such as Figure 5 As shown, the device includes a detonation system and an encapsulation shell, and the encapsulation shell is wrapped on the outside of the detonation system to encapsulate it; as Figure 4 As shown, the detonation system includes a micro-explosion chip assembly, a micro-security assembly, an initial charge and pins, and the micro-explosion chip assembly is connected to the micro-security assembly through pins 4 to form an electrical signal channel. The micro-detonation chip assembly is arranged below the micro-security assembly, and the back side of the micro-detonation chip assembly is installed with an initial charge 9 .

[0025] figure 2 It is a structural schematic diagram of a micro-initiating chip assembly, which includes an ignition circuit board 7, a micro-initiation chip 1 and an in-situ micro-charge 3, and a through hole i...

Embodiment 2

[0029]The present invention also provides a preparation method of a micro-electromechanical intelligent safety detonation device, which includes the following steps: using the ignition circuit board as the base, completing the assembly and welding of the detonation circuit element, the micro-detonation chip and the pin, forming a micro-detonation chip component, and The micro-initiating chip component is coated with a polymer protective film. After the polymer protective film is formed and stabilized, the in-situ micro-charge is filled into the charging hole of the ignition circuit board; the preparation of the micro-security chip is completed by MEMS technology, which can be decomposed Resettable, the micro-security chip and the micro-security chip base adapter board are packaged and integrated in the form of BGA, the micro-security chip can effectively drive the metal energy gate of the explosion channel with a thickness of not less than 200 microns, and the driving voltage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com