Activated carbon preparation method of sludge type argillaceous biomass

A technology of biomass and activated carbon, applied in pyrolysis treatment of sludge, chemical instruments and methods, dehydration/drying/thickened sludge treatment, etc., can solve the problems of low quality of activated carbon, reduced volume, and inability to meet resource utilization, etc. Achieve the effects of increasing specific surface area, improving drying rate and good physical space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

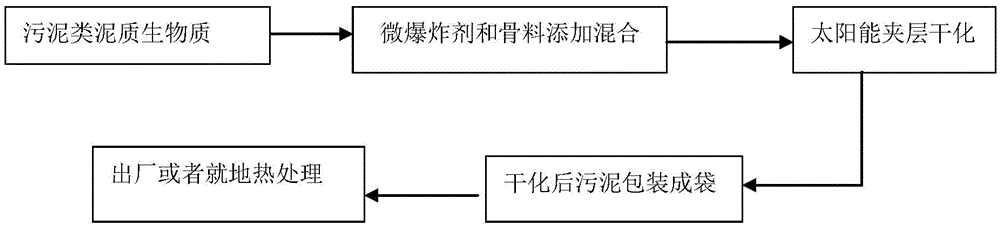

Method used

Image

Examples

Embodiment 1

[0047] After dehydration, the moisture content of the sludge is 95%. After dehydration, the sludge: micro-explosive agent: aggregate is 6:2:2 (dry basis), and the thickness of the solar interlayer drying system is 1cm, and it is dried for 4 days. After reaching 5%, the temperature was raised at a rate of 20°C / min. In the initial carbonization stage, control the temperature at 230°C and stay for 20 minutes, then raise the temperature to 400°C at a rate of 20°C / min and stay for 30 minutes; The temperature is 600°C, the residence time is 20min, and the BET of the prepared sludge-based activated carbon reaches 500m 2 / g.

Embodiment 2

[0049] After dehydration, the moisture content of the sludge is 80%. After dehydration, the sludge: micro-explosive agent: aggregate is 7:1:2 (dry basis), and the thickness of the solar interlayer drying system is 10cm. After drying for 3 days, the moisture content up to 25%. In the initial carbonization stage, control the temperature at 230°C, stay for 20 minutes, then raise the temperature to 400°C at a rate of 30°C / min, and stay for 60 minutes; at 550°C, stay for 0.5h, and the BET of the prepared sludge-based activated carbon reaches 200m 2 / g.

Embodiment 3

[0051] The moisture content of the sludge after dehydration is 85%. After dehydration, the sludge: micro-explosive agent: aggregate is 8.5:0.5:1 (dry basis), and the thickness of the solar interlayer drying system is 5cm, and the moisture content is 4 days. up to 20%. In the initial carbonization stage, control the temperature at 230°C and stay for 20 minutes, then raise the temperature to 400°C at a rate of 20°C / min and stay for 40 minutes; The temperature is 650°C, the residence time is 60min, and the BET of the sludge-based activated carbon can reach 350m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com