Application of ultrasonic and rotary electromagnetic field in aluminium melting refining

An electromagnetic field and ultrasonic technology, applied in the field of metal refining and purification in high-temperature metallurgical smelting, can solve the problems of low, unstable and uneconomical production of genuine products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

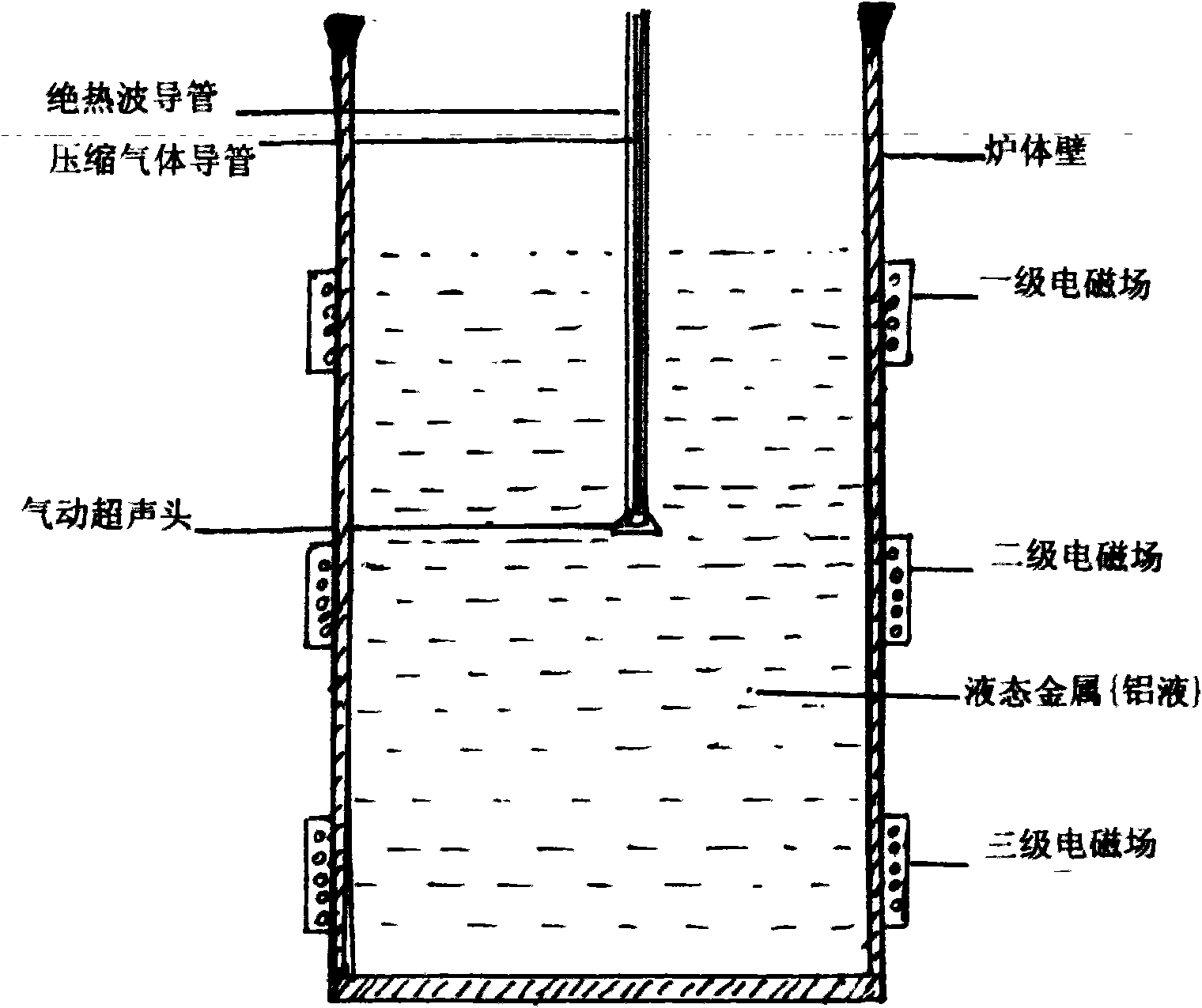

Image

Examples

Embodiment 1

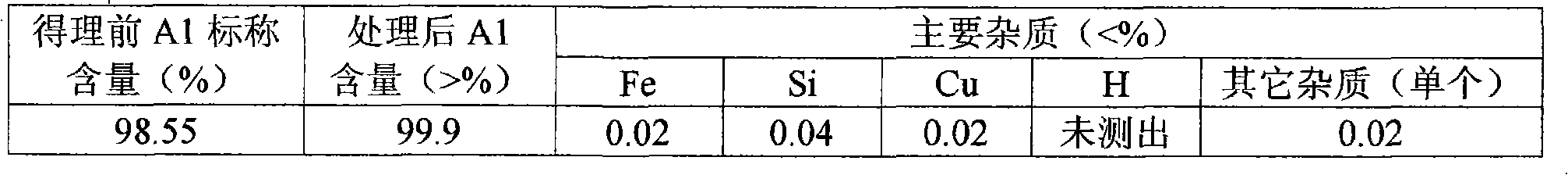

[0013] With 98.55% ordinary aluminum 5kg, put in the container, heat and melt with resistance furnace, argon protection, after processing 2min with the physical field technology of the present invention, sampling analysis, record following result:

[0014]

Embodiment 2

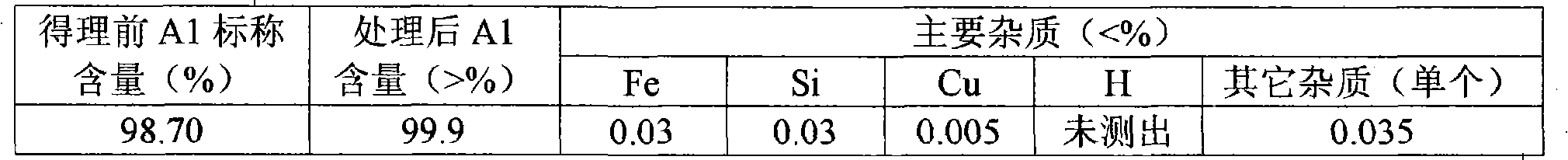

[0016] Use 5kg of industrial 997% pure aluminum, heat-melt it on a resistance furnace, protect it with argon gas, and treat it with this method for 1min, the results of sampling analysis are as follows:

[0017]

Embodiment 3

[0019] Use 5kg of 98.55% common aluminum, heat and melt it on a power frequency furnace, and protect it with argon gas. After using this method for 3 minutes, the measured results are as follows:

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com