Biological degradable pearl powder, and preparation technique

A technology of biodegradation and production process, which is applied in the direction of powder transportation, medical raw materials derived from molluscs, medical preparations containing active ingredients, etc. Many problems, to achieve the effect of improving absorption rate, ensuring safety, scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

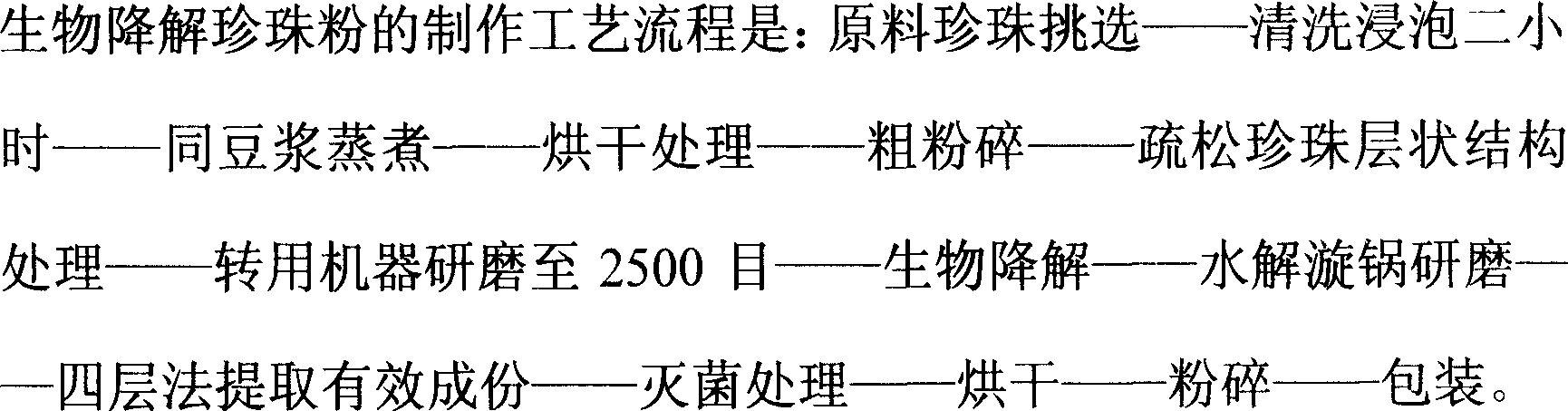

Method used

Image

Examples

Embodiment Construction

[0030] 1. Determination of the process conditions for steaming pearls with soybean milk:

[0031] Soybean milk is used as a medium to cook pearls at a certain temperature and time to loosen the internal structure of pearls to the greatest extent and lay a foundation for the next step of extracting amino acids and other components in pearls. This is the key to degrading pearls by biological methods. If the cooking temperature is too high and the cooking time is too long, the amino acid composition in the pearl will be destroyed; if the temperature is too low and the cooking time is too short, the internal structure of the pearl cannot be effectively loosened, which will directly affect the dissolution rate of the product and the extraction of amino acids. The temperature of the present invention is controlled between 90-98 degrees centigrade, and the cooking time is controlled at about 1 hour.

[0032] 2. Determination of process conditions for loose pearl layer structure:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com