Strontium-running fold strontium pliers and processing method

A processing method and technology of strontium pliers, which are applied in strontium-through strontium-stacked pliers and processing fields, can solve problems such as difficult processing, unsightly pliers, and unsatisfactory, and achieve the effects of not easily deformed, compact and beautiful, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

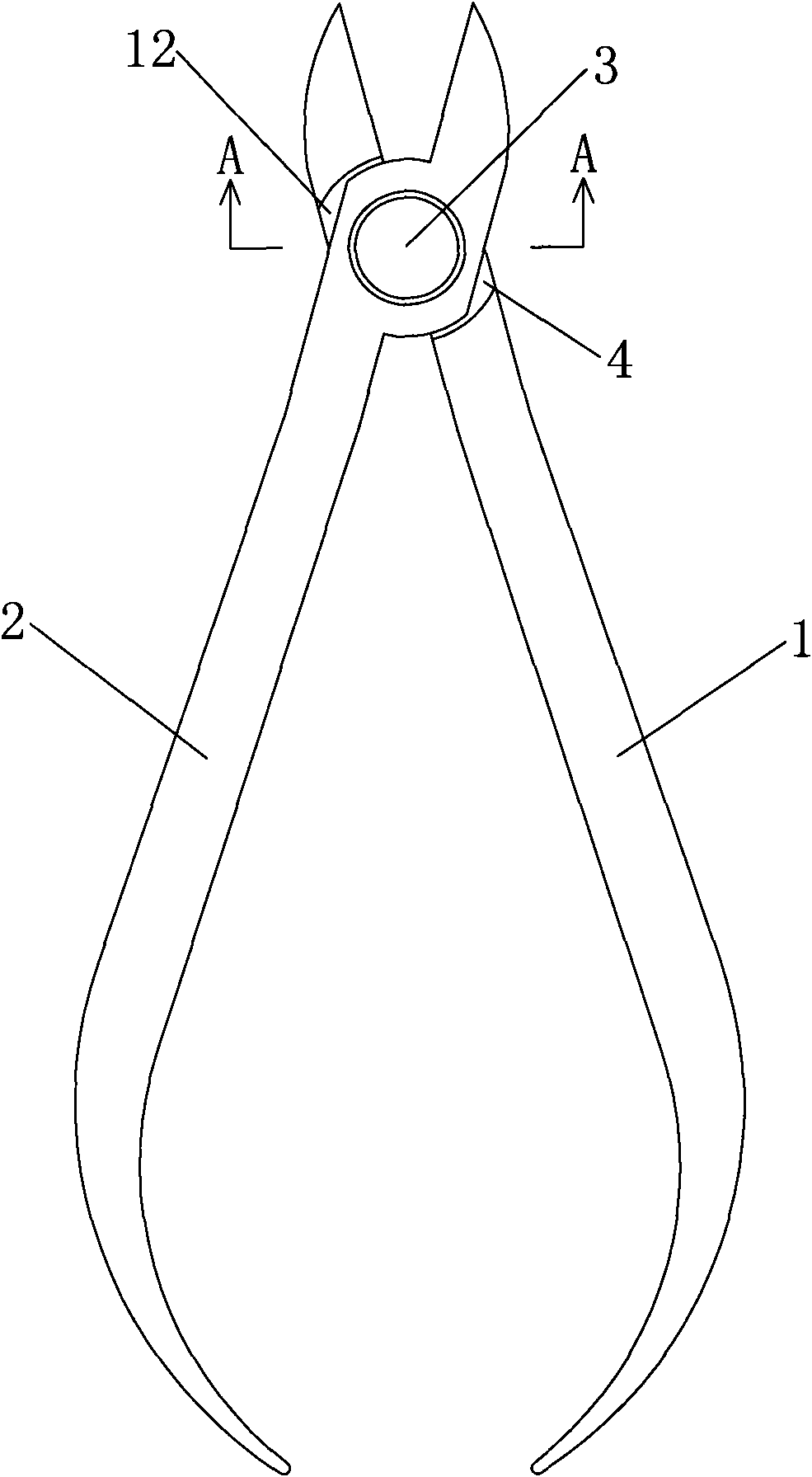

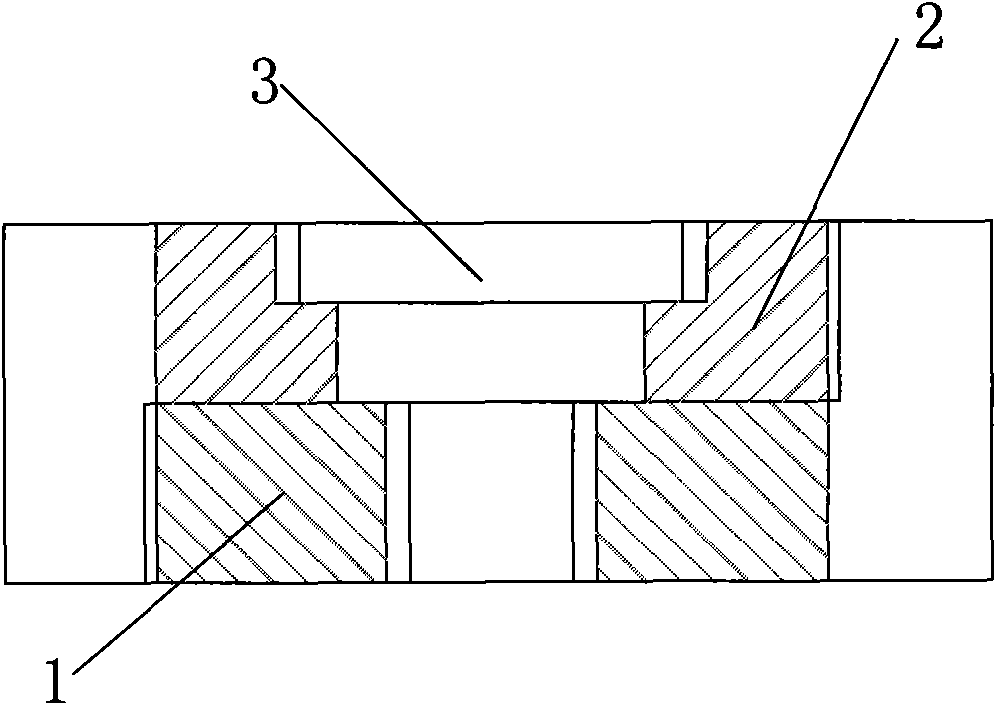

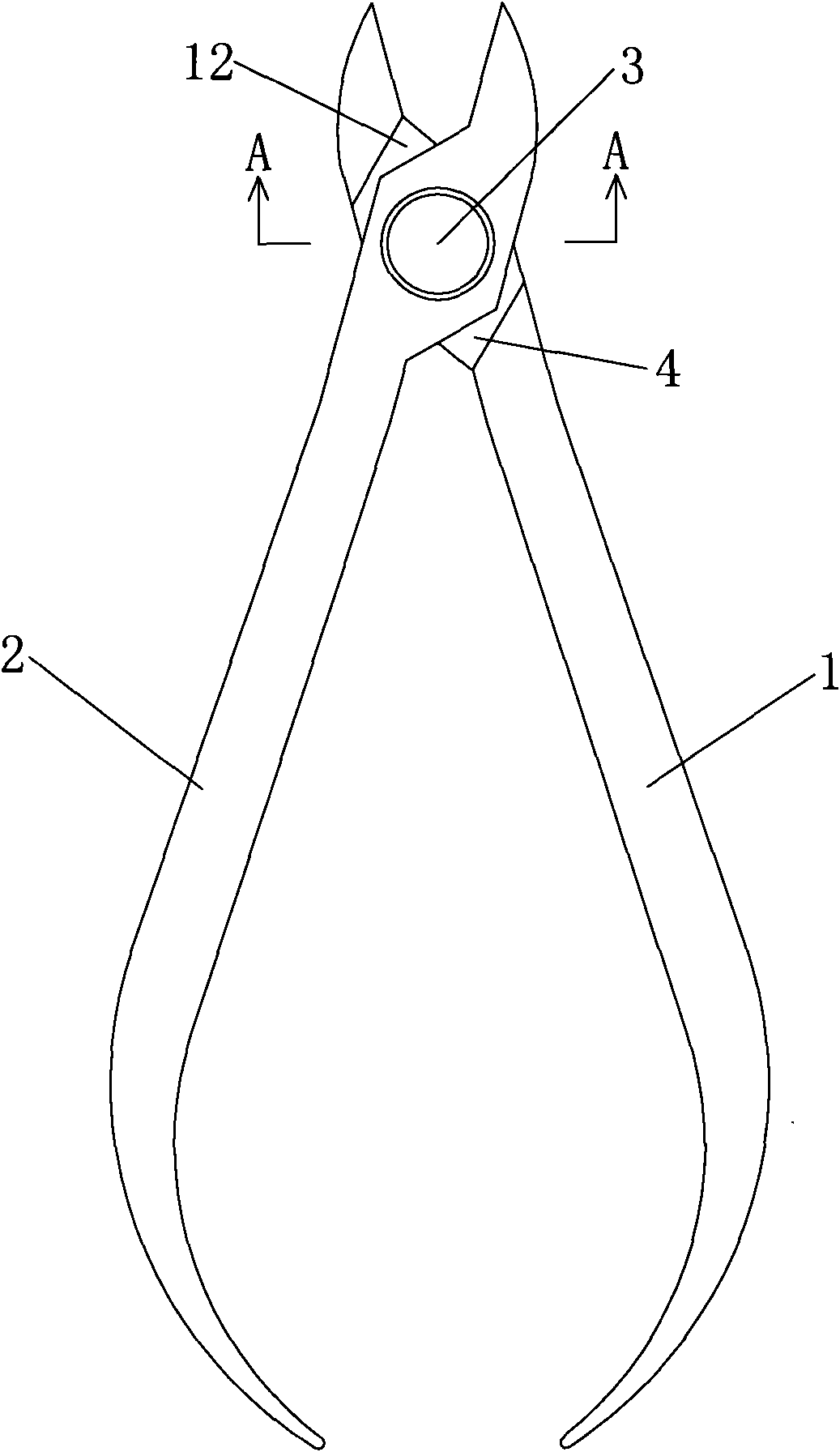

[0031] Embodiment: This embodiment particularly relates to a kind of strontium-piercing type round stacked strontium type pliers and processing method, such as Figure 7 , Figure 8 As shown, it includes a left pliers body 1 and a right pliers body 2, and a pivot joint groove 3, 4 is respectively provided on the opposite inner surfaces of the right pliers body 2 and the left pliers body 1, and the right pliers body 2 and the left pliers body 1 are hinged. The connecting grooves 3 and 4 are fitted together, and the outer surface of the left pliers body 1 is provided with a second pivotal groove 5 corresponding to the position of the inner surface pivotal groove 4, and the second pivotal groove 5 is provided with a Cover plate 7, cover plate 7 closes the second pivot groove 5, and the upper and lower ends of the cover plate 7 along the length direction of the clamp body are welded and fixed with the joint surface 21 of the right clamp body 2; The body 1 and the right pliers bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com