Method and system for treating chemical abraum salt containing organic matter through self-propagating pyrolysis method

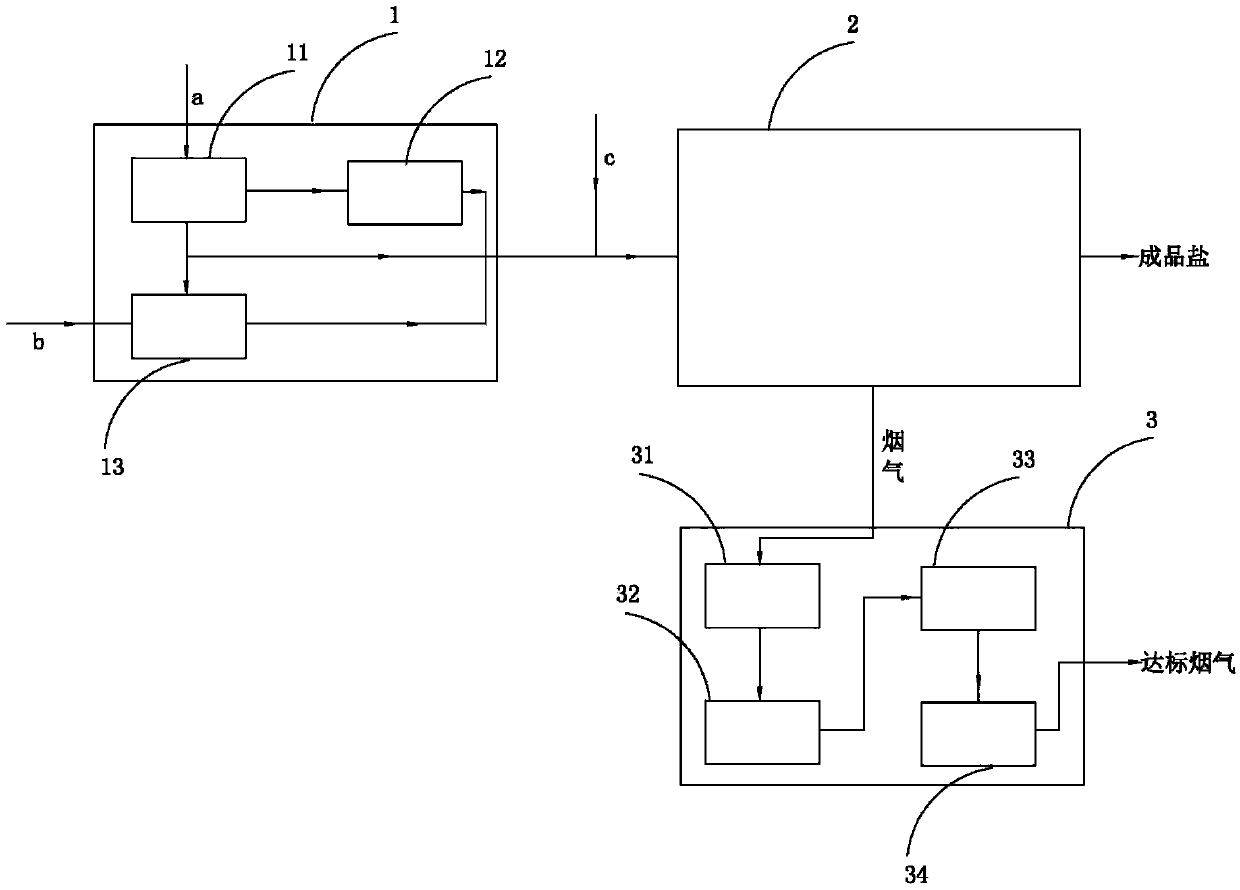

A self-propagating, organic technology, used in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of finished salt TOC can not meet the standard, difficult to expose, difficult to remove, etc., to achieve stable and controllable pyrolysis temperature, temperature distribution Uniform, load-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 processes chlor-alkali industry by-product dry salt

[0049] Before treatment, the particle size of more than 5% of the dry salt is greater than 30mm, and the TOC of the by-product dry salt in the chlor-alkali industry is 750ppm.

[0050] The method for treating waste chemical industry salt containing organic matter by self-propagating pyrolysis comprises the following steps:

[0051] (1) Pretreatment

[0052] The waste salt with a particle size greater than or equal to 30mm is broken into granular salt, and the waste salt with a particle size less than 30mm is directly distributed.

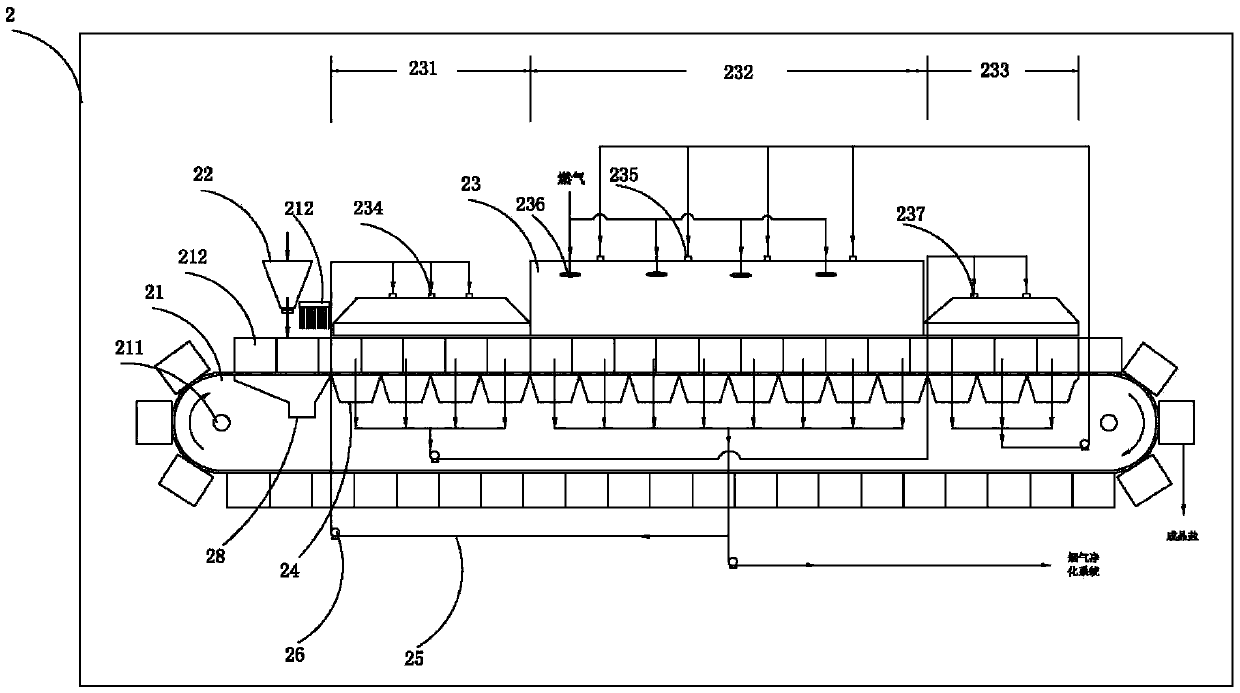

[0053] (2) Pyrolysis treatment:

[0054] Granular salt is used as the base material, and the powdered salt is arranged on the pyrolysis device. The thickness of the base material is 2 mm, and the thickness of the material layer is 350 mm;

[0055] After the fabric is ignited and burned, the burning flame does not directly contact the material. The negative pressure ventilat...

Embodiment 2

[0059] Embodiment 2 processes chlor-alkali industry by-product dry salt

[0060] Before treatment, the particle size of more than 95% of the dry salt is less than 2mm, and the TOC of the by-product dry salt in the chlor-alkali industry is 1200ppm.

[0061] The method for treating waste chemical industry salt containing organic matter by self-propagating pyrolysis comprises the following steps:

[0062] (1) pretreatment,

[0063] The by-product dry salt is formed into balls with a particle size of 6-10 mm.

[0064] (2) Pyrolysis treatment:

[0065] Lay the pellets directly on the pyrolysis device, the thickness of the material layer is 500mm;

[0066] After the fabric is ignited and burned, the burning flame does not directly contact the material. The negative pressure ventilation method is adopted, and the negative pressure is 450-2500Pa. The high-temperature smoke generated by the continuous combustion of the fuel is transmitted from the surface of the material layer to th...

Embodiment 3

[0070] Embodiment 3 processes chlor-alkali industry by-product dry salt

[0071] Before treatment, the particle size of 95% of the dry salt is between 2 and 30mm, and the TOC of the by-product dry salt in the chlor-alkali industry is 2561ppm.

[0072] The method for treating waste chemical industry salt containing organic matter by self-propagating pyrolysis comprises the following steps:

[0073] (1) Pyrolysis treatment:

[0074] Lay the by-product dry salt directly on the pyrolysis device, with a material layer thickness of 400mm;

[0075] After the fabric is ignited and burned, the burning flame does not directly contact the material. It adopts the negative pressure ventilation method, and the negative pressure is 300-2000Pa. The high-temperature smoke generated by the continuous combustion of the fuel is transmitted from the surface of the material layer to the entire material layer by self-propagation, and the control The temperature of the high-temperature flue gas is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com