Combined machining device special for shifting fork

A combined processing and equipment technology, which is applied in the direction of mechanical equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of symmetry, parallelism, and positional tolerances that are difficult to guarantee, large cumulative positioning tolerances, and low production efficiency. , to achieve the effect of reducing tolerance accumulation, satisfying processing, and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further describe the present invention below in conjunction with accompanying drawing as follows.

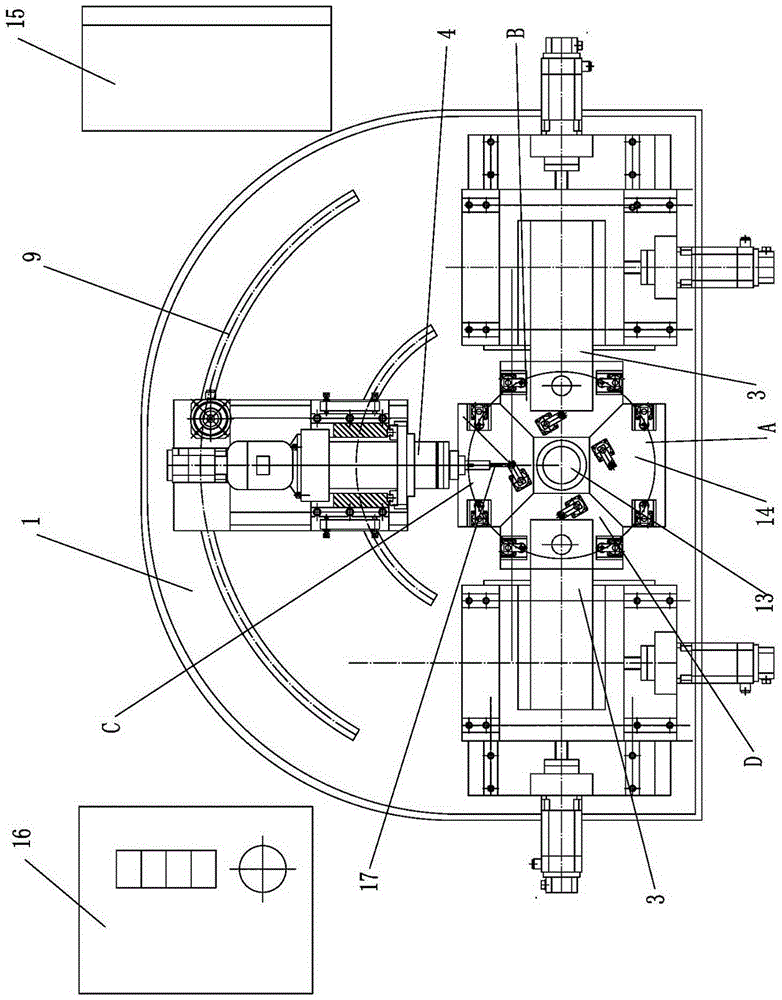

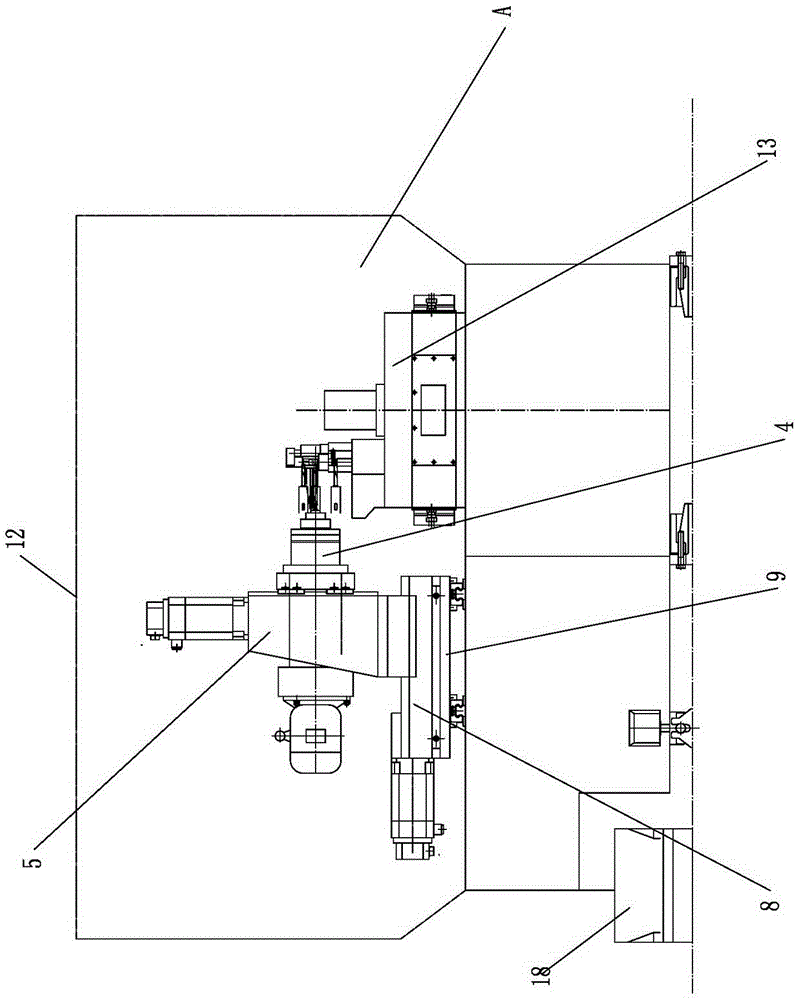

[0016] To make the figure clear, figure 1 The hydraulic rotary table and hydraulic fixture are omitted; image 3 The vertical milling power head and CNC cross slide table on both sides are omitted; figure 2 The hydraulic system and electrical control system in the figure 1 and figure 2 is omitted.

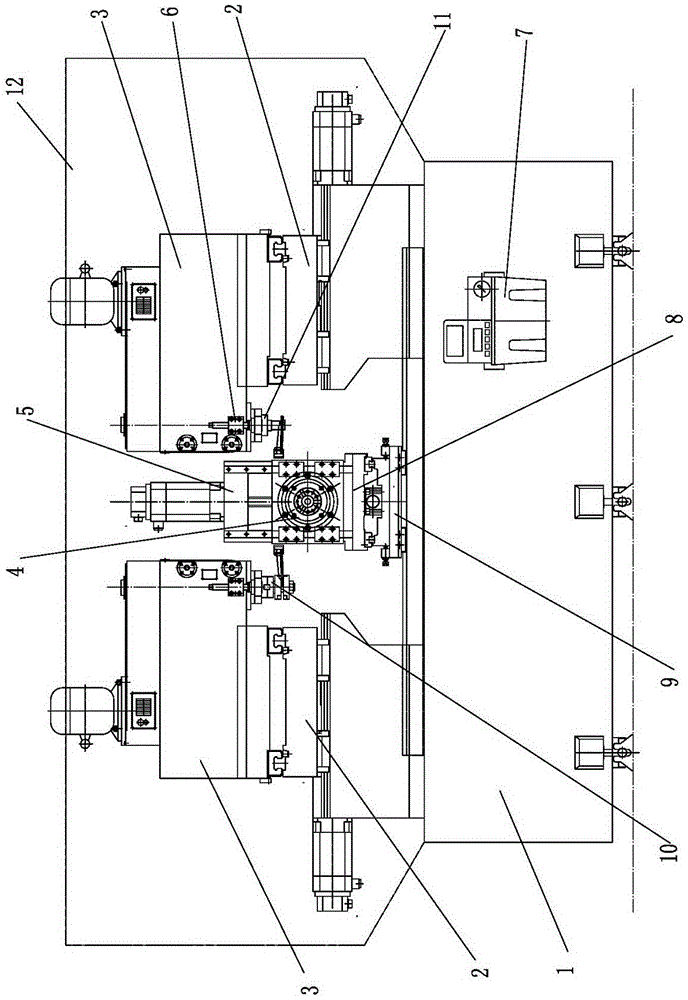

[0017] like figure 1 , figure 2 and image 3 As shown, the special combined processing equipment for shift fork includes integral bed 1, a set of hydraulic rotary table 13, two sets of CNC cross slides 2, two sets of vertical milling power heads 3, a set of boring power heads 4, four Set of hydraulic clamps 14, electrical control system 15, hydraulic system 16, centralized lubrication device 7, cooling chip removal device 18, hydraulic rotary table 13 is fixed in the middle of the overall bed 1, and two sets of CNC cross slides 2 are respectively installed on the On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com