High-viscosity nylon 6 and preparation method thereof

A nylon, high-viscosity technology, applied in the field of polymer synthesis, can solve the problems of difficulty in stirring and by-product diffusion, and achieve the effect of obvious improvement effect, reasonable ingredients and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 A kind of preparation method of high viscosity nylon 6

[0050] This embodiment is carried out according to the following steps:

[0051] (11) mixed

[0052] 80kg of nylon 6 with a relative viscosity of 2.8Pa·S, 15kg of low-temperature toughening agent (a mixture of 3.75kg of binary ethylene-propylene rubber and 11.25kg of grafted EPDM rubber), 2.7kg of wear-resistant agent (of 1.4 kg polytetrafluoroethylene and 1.3kg molybdenum disulfide mixture), 0.3kg antioxidant {is 0.075kg tris(2.4-di-tert-butylphenyl) phosphite, 0.075kg tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol, and 0.15kg N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexanedi Amine mixture}, 1kg of black masterbatch, and 1kg of reactive masterbatch with nylon 6 as the carrier, produced by Brüggemann Chemical Company in Germany, the model is M-1251, placed in a mixer with a speed of 200rpm, and mixed evenly get A1;

[0053] (12) Mixing

[0054] Add A1 i...

Embodiment 2~6

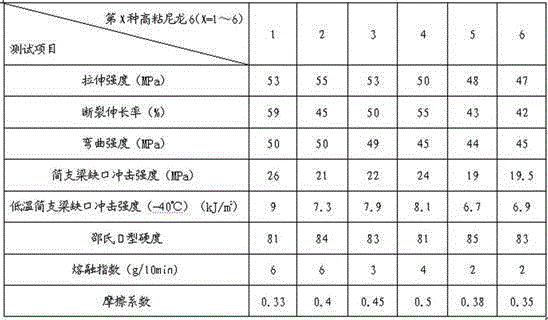

[0057] Embodiment 2~6 high-viscosity nylon 6 and preparation method thereof

[0058] Example 2 ~ 6 are a kind of high-viscosity nylon 6 (referred to as the second to sixth high-viscosity nylon 6 in turn) and its preparation method, which are similar to Example 1, the only difference is the ratio of raw materials and the preparation process The technical parameters are different, see the table below for details.

[0059] Table 1 Technical parameter list

[0060]

Embodiment 7

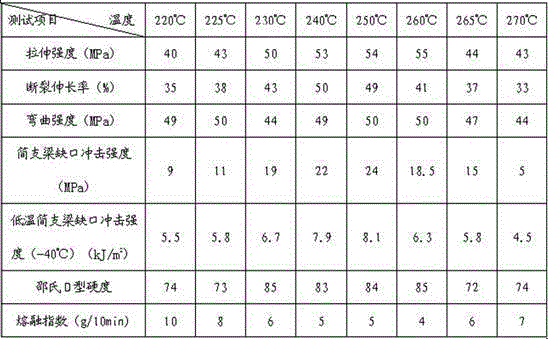

[0061] Embodiment 7 Performance test of the first to sixth high-viscosity nylon 6

[0062] This embodiment is to embodiment 1 ~ The first to sixth high-viscosity nylon 6 prepared in 6 were tested for their mechanical properties, and the testing methods were all the testing methods in the prior art, specifically:

[0063] 1) Tensile strength

[0064] Test according to GB / T1040, test speed: 50mm / min;

[0065] 2) Elongation at break

[0066] Test according to GB / T1040, test speed: 50mm / min;

[0067] 3) Bending strength

[0068] Test according to GB / T9341, test speed: 2mm / min;

[0069] 4) Charpy notched impact strength

[0070] Test according to GB / T1043;

[0071] 5) Low temperature Charpy notched impact strength (-40°C)

[0072] Test according to GB / T1043;

[0074] Test according to GB / T2411;

[0075] 7) Melt index MFR

[0076] Test according to GB / T3682.

[0077] The test results of the mechanical properties of No. 1 to No. 6 high-visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com