Medical two-component addition-type liquid silicone rubber and preparation method thereof

A liquid silicone rubber, two-component technology, applied in the field of silicone rubber, can solve problems such as poor physical properties and processing performance, and achieve the effect of satisfying processing performance and molding periodicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned high-transparency medical two-component addition type liquid silicone rubber comprises the following steps:

[0037] a. Preparation of component A

[0038] Firstly, add vinyl polysiloxane with formulation amount of 50-80%, silane coupling agent with formulation amount and fumed silica with formulation amount to the kneader, stir at room temperature for 1-6 hours; heat up to 120-180°C, Stir under vacuum conditions for 1-6 hours, then stop the vacuum, continue to add the remaining formula amount of vinyl polysiloxane for dilution, then add the formula amount of platinum catalyst, and stir evenly to obtain component A;

[0039] b. Preparation of component B

[0040] Firstly, add vinyl polysiloxane with formulation amount of 50-80%, silane coupling agent with formulation amount and fumed silica with formulation amount to the kneader, stir at room temperature for 1-6 hours; heat up to 120-180°C, Stir under vacuum conditions for...

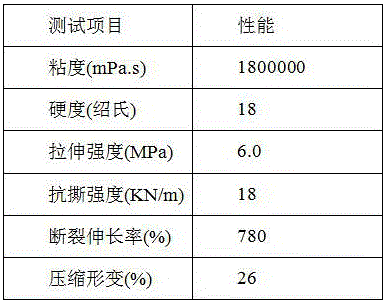

Embodiment 1

[0044] (1) Preparation of component A

[0045] ①Mix 100kg of octamethylcyclotetrasiloxane and 1.5kg of tetramethyldivinyldisiloxane, add 0.2kg of catalyst tetramethylammonium hydroxide under stirring, raise the temperature to 120°C for 4 hours, and then Raise the temperature to 200°C, delower the molecule for 6 hours under a vacuum of 0.08-0.09MPa, and obtain vinyl polysiloxane after cooling. The viscosity at 25°C is 11000mPa.s, and the mass percentage of vinyl is 0.42%.

[0046] ② Add 300kg of vinyl polysiloxane, 34kg of silane coupling agent (dimethyldiethoxysilane) and 240kg of fumed silica into a 1000L kneader, stir to form a group and continue to stir at room temperature for 2 hours; heat up to 140 ℃, stirred for 3 hours under the condition of vacuum 0.8MPa, then stopped the vacuum, added 100kg vinylpolysiloxane after cooling down; added 1.28kg tetramethyldivinyldisiloxane complex of chloroplatinic acid, stirred evenly, and obtained component A;

[0047] (2) Preparation...

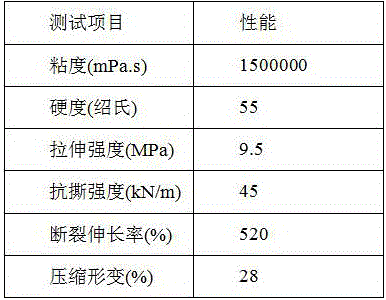

Embodiment 2

[0055] (1) Preparation of component A

[0056] ①Mix 100kg of octamethylcyclotetrasiloxane and 1.5kg of tetramethyldivinyldisiloxane, add 0.2kg of catalyst tetramethylammonium hydroxide under stirring, raise the temperature to 120°C for 4 hours, and then Raise the temperature to 200°C, delower the molecule for 6 hours under a vacuum of 0.08-0.09MPa, and obtain vinyl polysiloxane after cooling. The viscosity at 25°C is 11000mPa.s, and the mass percentage of vinyl is 0.42%.

[0057] ②Add 290kg of vinyl polysiloxane, 22kg of silane coupling agent (dimethylcyclosiloxane) and 203kg of fumed silica into a 1000L kneader, stir to form a group and continue to stir at room temperature for 2 hours; heat up to 170°C , stirred for 3 hours under the condition of vacuum 0.8MPa, then stopped the vacuum, added 180kg vinyl polysiloxane after cooling down; added 1.35kg chloroplatinic acid tetramethyldivinyldisiloxane complex, stirred evenly, and obtained the Part A;

[0058] (2) Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com