Three-waveband laser double-focusing-head laser processing system and method

A laser processing, three-band technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced beam quality, reduced light intensity, complex optical switch structure, etc., to achieve clear imaging and observation, reduce the direction Adjustment requirements, ease of fine adjustment and effect of imaging control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

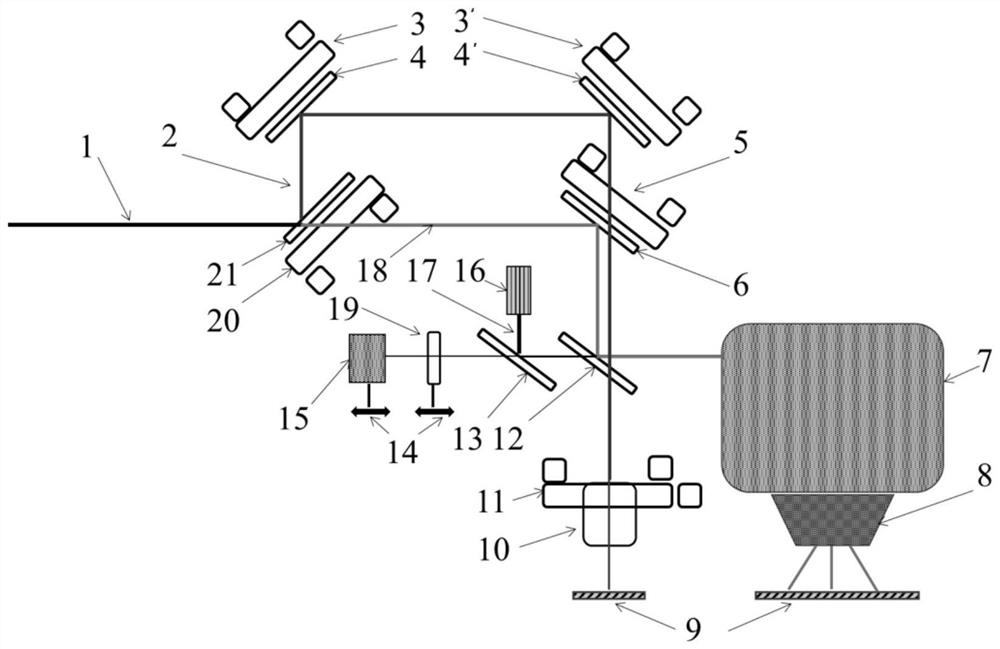

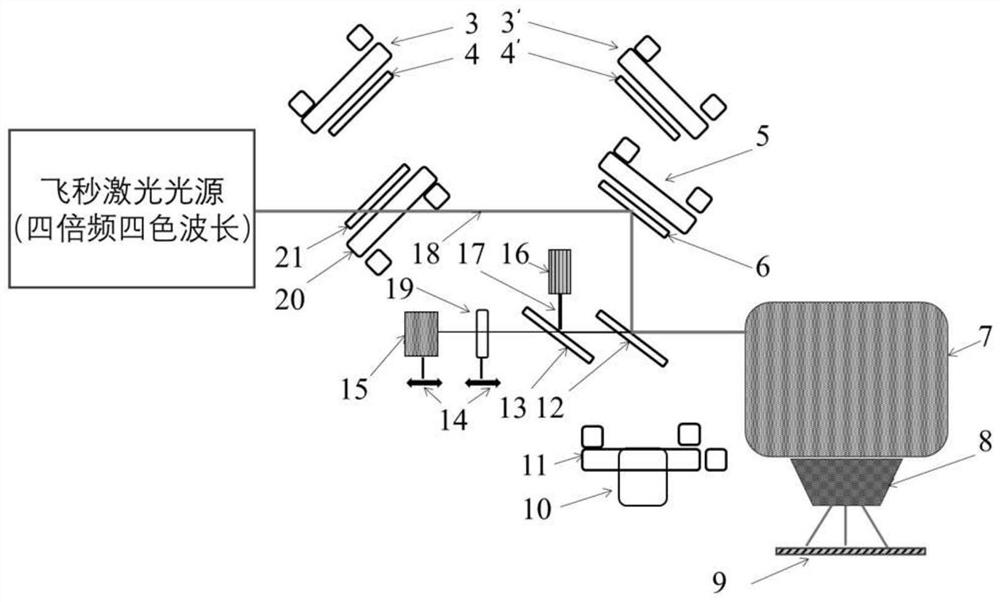

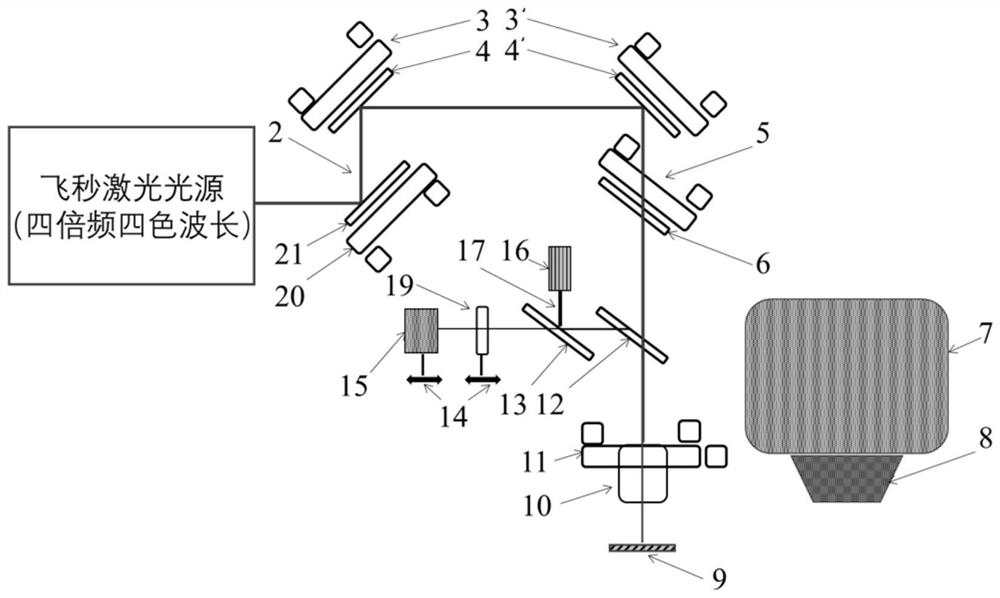

[0036] Such as figure 1 As shown, a three-band laser double-focus head laser processing system includes a femtosecond laser light source, a first reflector 21, a second reflector 4, a third reflector 4', a fourth reflector 6, and a fifth reflector 12. The first processing department, the second processing department and the lighting and imaging department;

[0037] The femtosecond laser light source is a femtosecond laser that can emit ultraviolet band laser, visible light band laser and infrared band laser;

[0038] The first reflecting mirror 21 transmits light in the visible and infrared bands and totally reflects the light in the ultraviolet band; the second reflecting mirror 4 and the third reflecting mirror 4' fully reflect the light in the ultraviolet band; the fourth reflecting mirror 6, the fifth Reflector 12 transmits light in the ultraviolet band and reflects light in the visible and infrared bands;

[0039]The femtosecond laser light source emits light in the ult...

Embodiment 2

[0066] This embodiment specifically introduces the laser processing method using the device, which uses the device of the present invention to perform laser processing on composite materials.

[0067] The composite material to be processed is a multi-layer material, and the light absorption capabilities of each layer for different wavelengths are different; for example, a composite material with three layers, the composite material includes the first layer, the second layer and the third layer ; The first layer has a high absorption rate of ultraviolet light, which is greater than 50%, but a high reflection rate of infrared light, greater than 70%, and the second layer has a high absorption rate of 50% for visible light, but the absorption rate of infrared light , less than 30%, the third layer has a high absorption rate for infrared light, greater than 60%, but a high reflectance rate for ultraviolet light, which is 75%; using traditional single-wavelength laser processing met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com