Cellulose fibre, textile assistant for union biochemical pretreatment, perparing method and use

A technology of cellulose fibers and blended fabrics, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of industrial application and retention, etc., achieve good impurity removal effect, improve quality, and good whiteness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

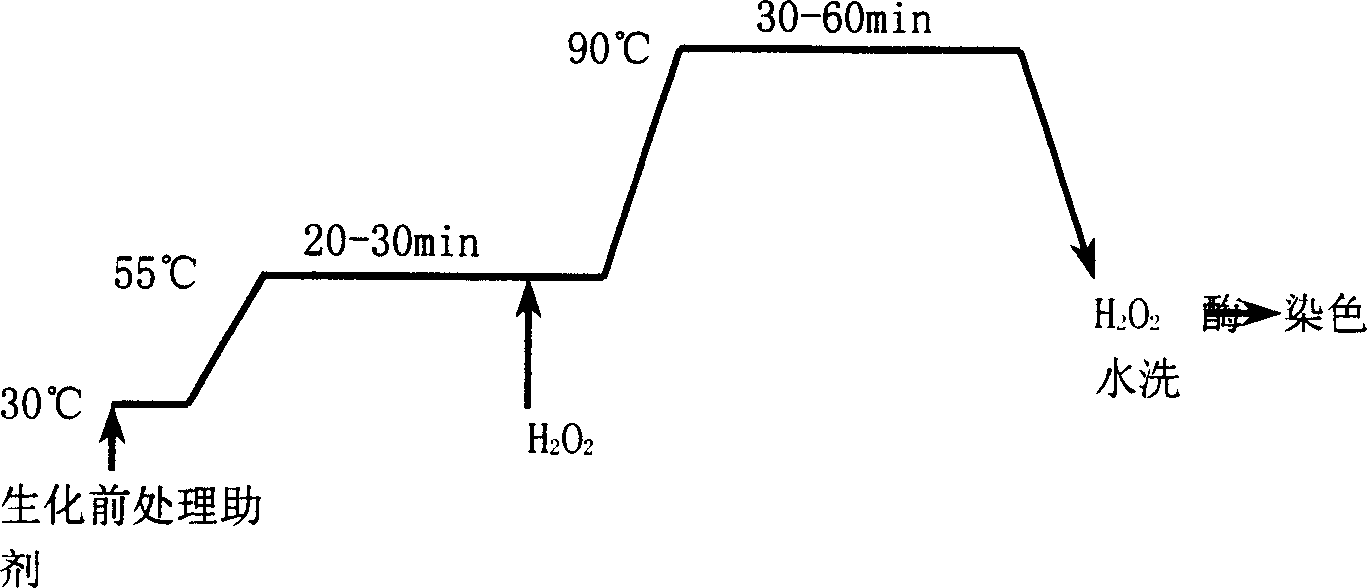

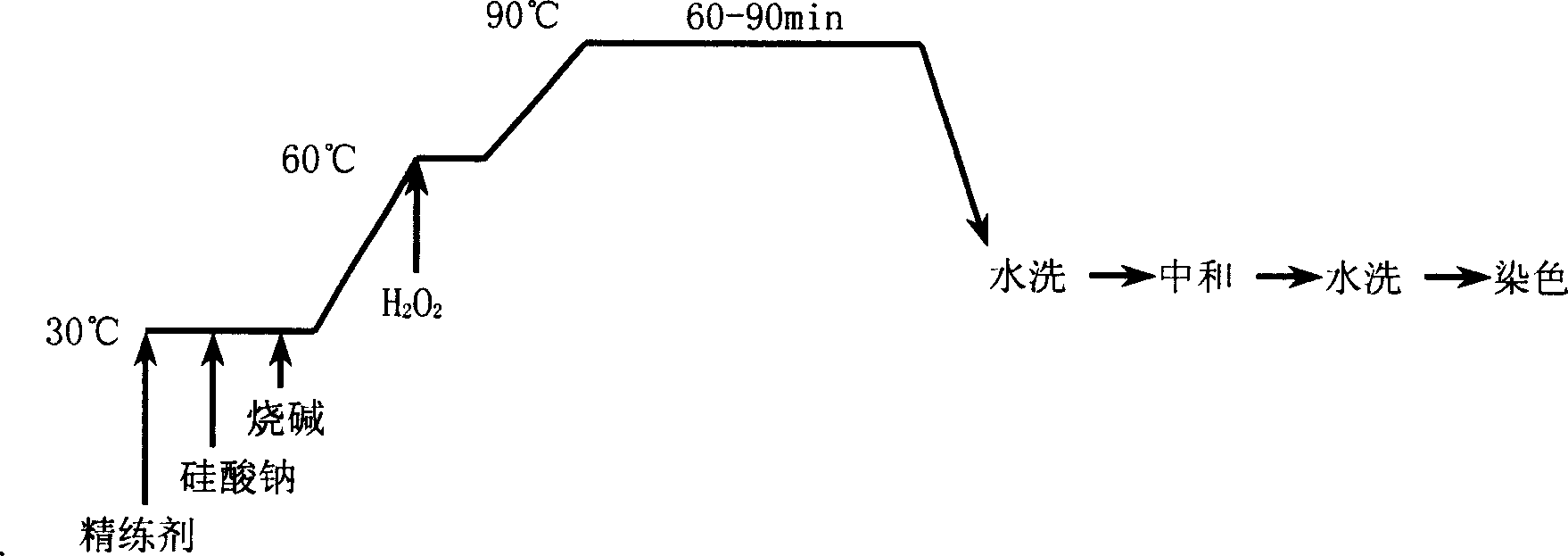

Method used

Image

Examples

Embodiment 1

[0040] Pure cotton knitted fabrics (40 × 40, 130 × 76) are respectively adopted the ecological short-process pretreatment of the present invention and the conventional pretreatment, and the performance indexes of the processed products are compared respectively as shown in Table 1:

[0041]

Performance

Impurity rate (%)

Gross effect

(cm / 30min)

BaiDu

(N)

slow play

waxy

cottonseed hulls

gray cloth

0.60

0.91

+++++

0

38.7

276

196

common law

0.10

0.15

+

9.5

80.6

247

173

Ecological Short Process Method*

0.12

0.16

+

11.8

84.7

253

182

[0042] * Ecological short flow process; the weight ratio of various substances of the biochemical enzyme preparation of the present in...

Embodiment 2

[0046] Cotton-nylon woven fabrics (60 / 40) were treated with ecological short-process pretreatment and conventional pretreatment, and the performance indexes of the treated products were compared. The results are shown in Table 3.

[0047]

Performance

Gross effect

(cm / 30min)

Self-degree

Breaking Strong Retention

(%)

slow spring retention

(%)

common law

9.6

81.6

84.3

88.0

Ecological Short Process Method*

12.9

83.9

92.5

93.7

[0048]Ecological short flow process; the weight ratio of various substances of the biochemical enzyme preparation of the present invention: 5 pectinase, 3 cellulase, 0.6 lipase, 0.3 protease, 1 laccase, 4 xylanase, 3 glucanase , 20 fatty alcohol (C 12-14 ) Polyoxyethylene ether (EO7-9), sodium 16-secondary alkylbenzene sulfonate.

[0049] ●Biochemical aids: the above-mentioned biochemical enz...

Embodiment 3

[0051] The cotton and wool knitted fabrics (50 / 50) were treated with ecological short-process pretreatment and conventional pretreatment respectively, and the performance indexes of the treated products were compared. The results are shown in Table 4.

[0052]

[0053] *The weight ratio of various substances of the biochemical enzyme preparation of the present invention: 12 pectinase, 4 cellulase, 1 lipase, 0.5 protease, 4 laccase, 2 xylanase, 5 glucanase, 18 fatty alcohol ( C 12-14 ) polyoxyethylene ether (EO7), sodium secondary alkylbenzene sulfonate (10%); biochemical additives: the above-mentioned biochemical enzyme preparation 2g / L; hydrogen peroxide (30%) 12g / L, catalase 0.15g / L, the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com