Vacuum wool brushing and dust sucking box

A technology of vacuum cleaner box and bristles, applied in the field of vacuum brush cleaner box, can solve the problems of inability to solve the weft structure, lack of centralized collection of fluff, and aliasing of fabric printing, and achieves stable operation, strong practicability and applicability, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

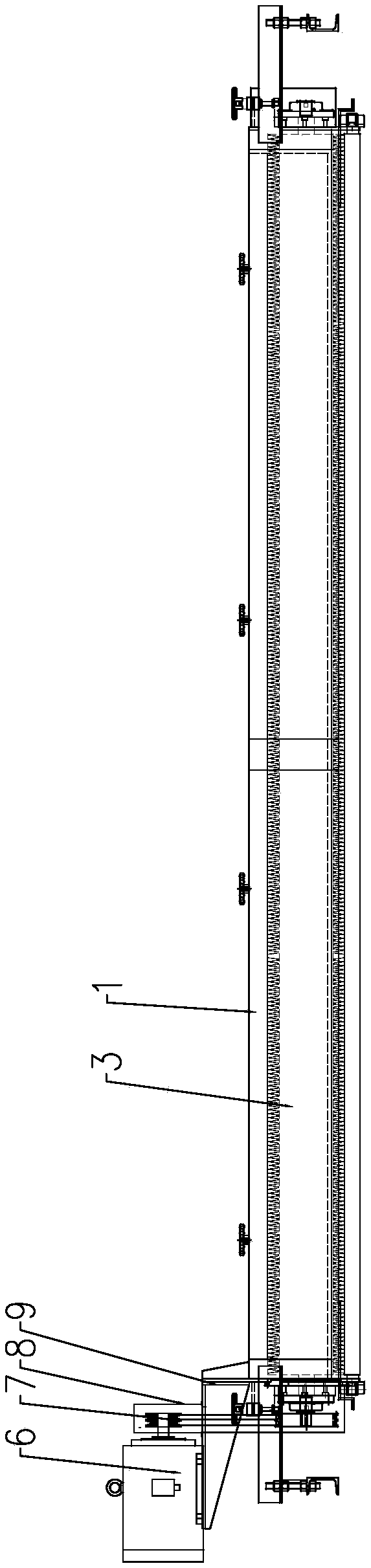

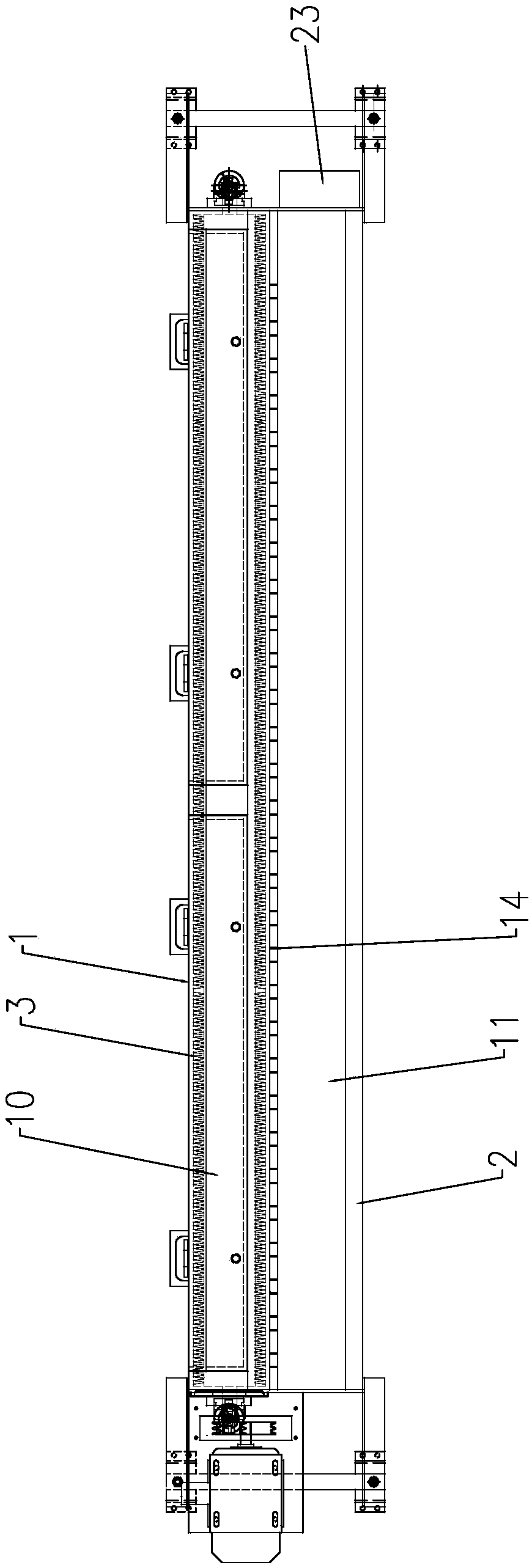

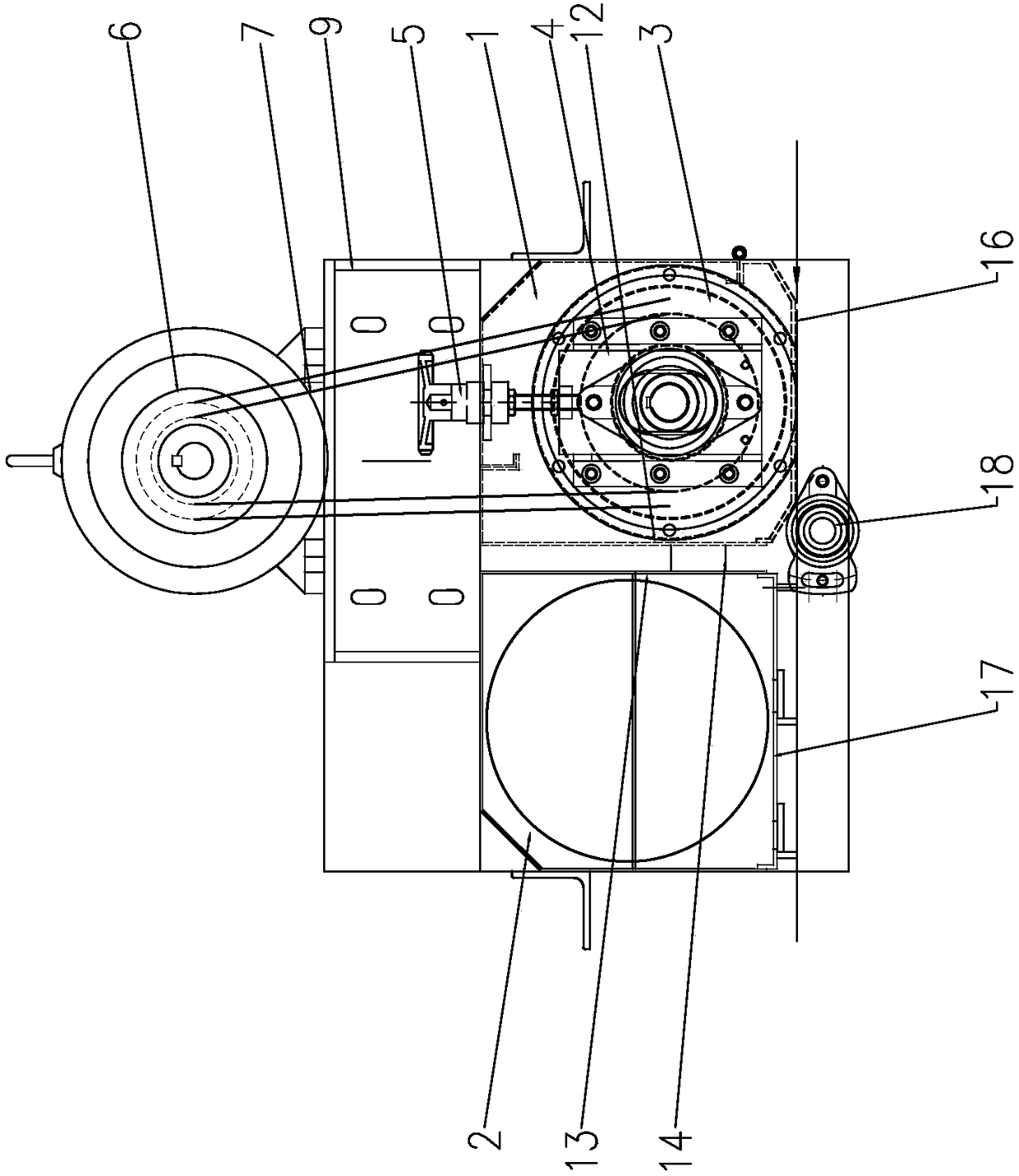

[0026] like Figure 1~6 As shown, the present invention mainly comprises the bristle box 1 and the dust collection box 2 that are arranged side by side, the bristle box 1 is provided with a bristle partition 12 facing the side of the dust collection box 2, and the dust collection box 2 is provided with a dust suction box 2 facing the bristle box 1 side. The partition 13, the bristle partition 12 and the dust suction partition 13 are communicated through the box connection air duct 14.

[0027] The bristle partition 12 and the dust collection partition 13 are provided with a plurality of ventilation holes 15 along the length direction, and the plurality of ventilation holes 15 on the bristle partition 12 and the dust collection partition 13 communicate with the box connecting air duct 14 .

[0028] The bristle box 1 is provided with a bristle roller 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com