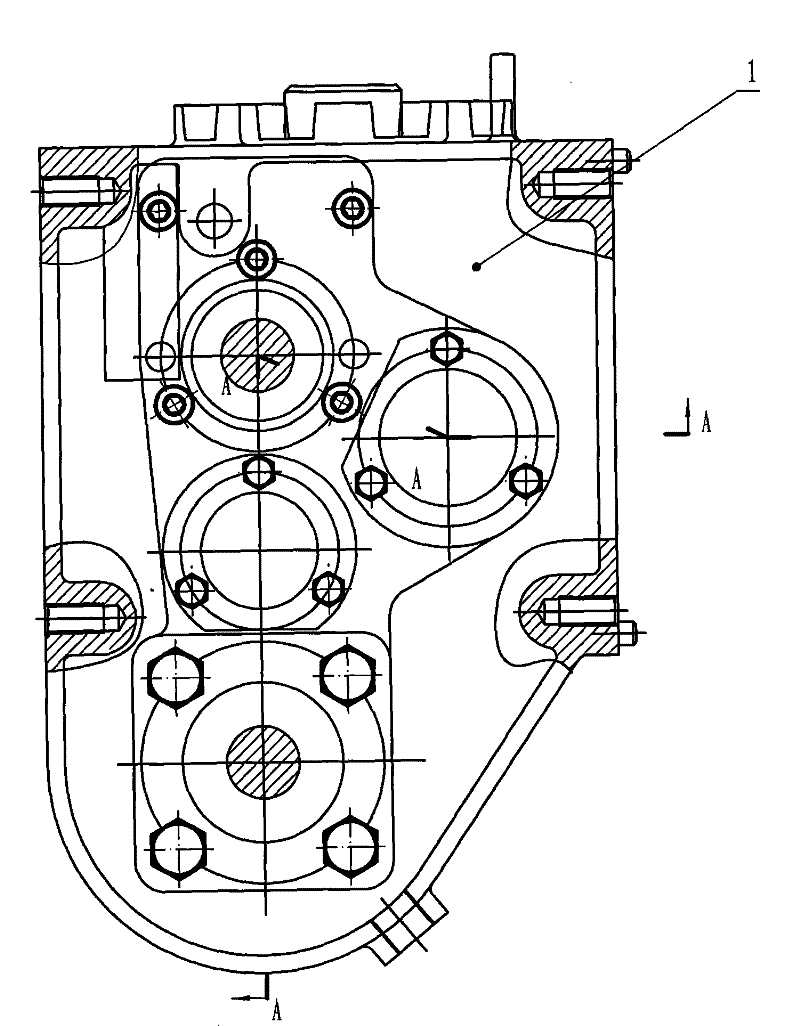

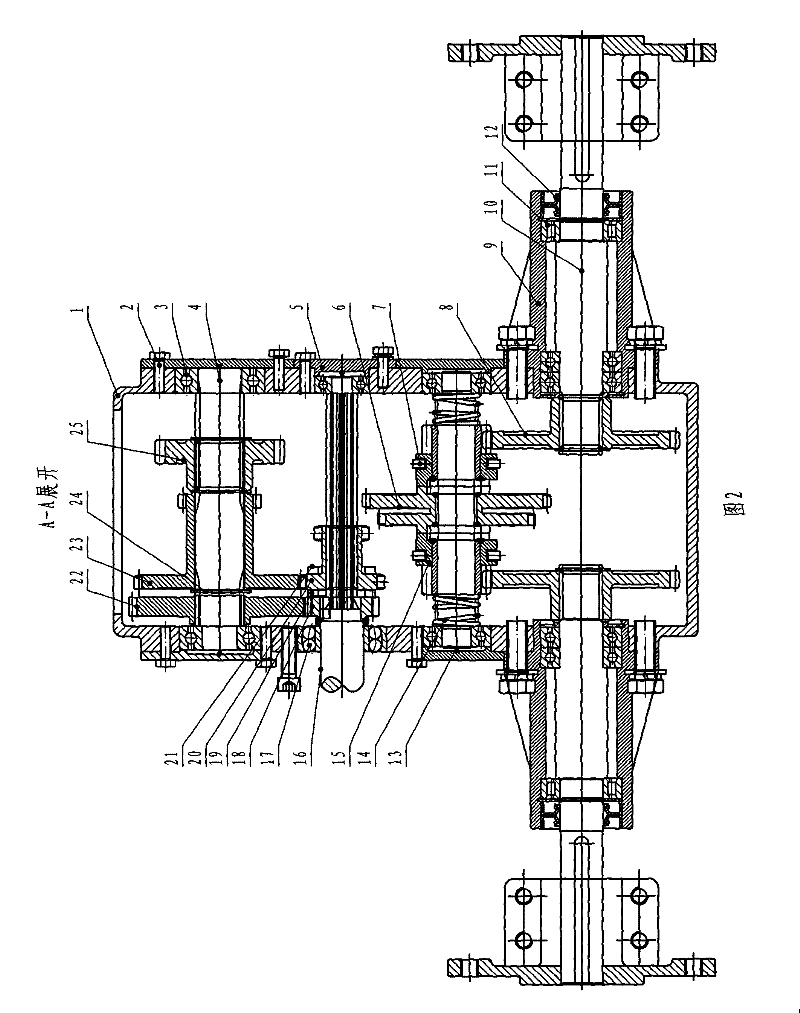

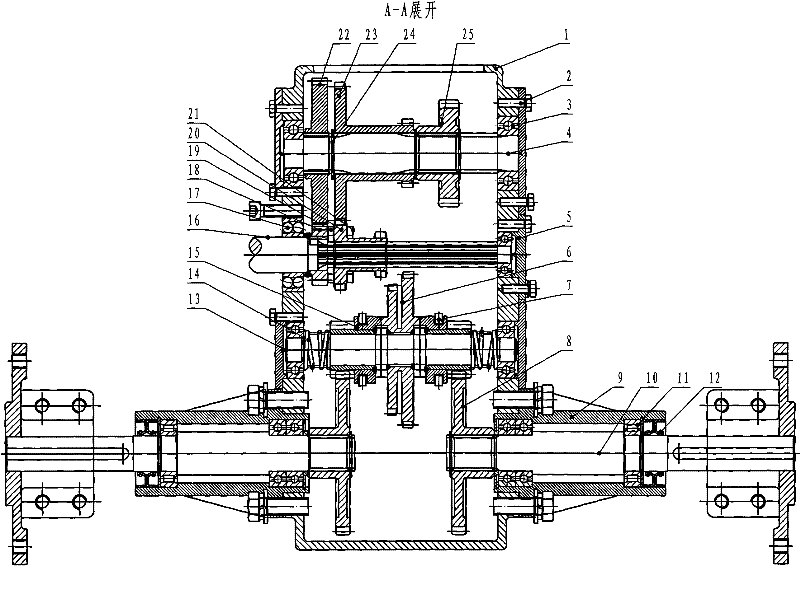

Minitype tiller gearbox

A technology for tillage machines and gear boxes, which is applied in the fields of tillage machines, agricultural machinery and tools, etc. It can solve the problems of long deceleration path, complex structure, and large power loss, etc., and achieve the reduction of the volume of the gear box, the simple structure of the speed change, and the Reasonable effect of variable speed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The input shaft 16 of the miniature cultivator gearbox is an integrally designed long shaft, a part of the long shaft is erected in the sprocket transmission box, and the other part is erected through the cylindrical hole self-aligning ball bearing 17 and the deep groove ball bearing 3 respectively. On the left and right side walls of the gearbox casing 1. The input shaft 16 protruding into the box body 1 is set on an involute spline, the main drive gear 18 is welded and fixed on the side of the input shaft 16 close to the chain transmission box, and the slip shifting dual gear 20 is set on the side with an involute On the input shaft part of the linear spline, an installation positioning spacer 19 is arranged between the main drive gear 18 and the sliding shifting double gear 20, and a shift fork 21 is arranged on the slip shifting double gear 20, and the shifting fork 21 toggles Sliding variable speed duplex gear 20 makes this gear box walking drive output be four gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com