Full-automatic embossing machine

A printing machine, fully automatic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

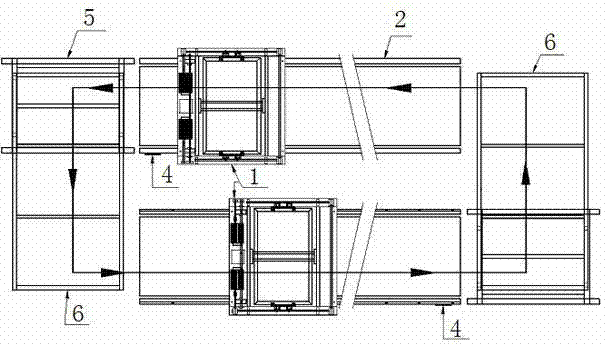

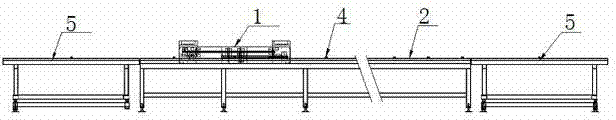

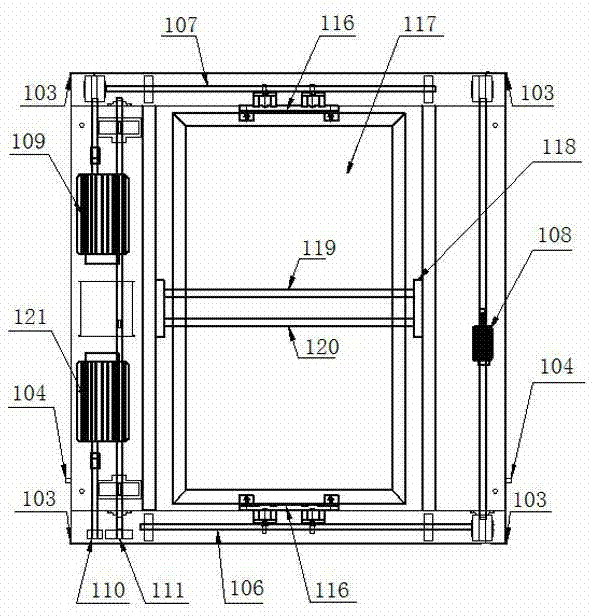

[0036] A fully automatic printing machine, comprising a printing machine body 1, the printing machine body 1 is arranged on a table case 2, the table table 2 is provided with a running track of the printing machine body, and a plurality of positions for positioning the printing machine body The yard 4 (orientation point) of the body, there are multiple tables 2 arranged side by side, and the multiple tables 2 are connected by a turning system 5 (connection vehicle), and the turning system 5 is provided with a The transfer car 7 transferred by the printing machine body, and the turning track 6 of the transfer car, the turning track 6 is a straight track, perpendicular to the plane of the table case 2, and forms an angle of 90° with the table case 2; System 5 is also provided with yardage 4 and signal transmitting device 122, and described signal transmitting device 122 is arranged on the transfer vehicle, and during the operation of the printing machine, the connecting vehicle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com