Extracting method of duck chondroitin sulfate by compound enzymolysis

A technology of chondroitin sulfate and cartilage, which is applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of lack of systematic research on effective active substances and their functions of duck cartilage, and the technology of extracting chondroitin sulfate is blank, etc., to achieve shortening The effect of production cycle, reduction of production cost and increase of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention comprises the steps of:

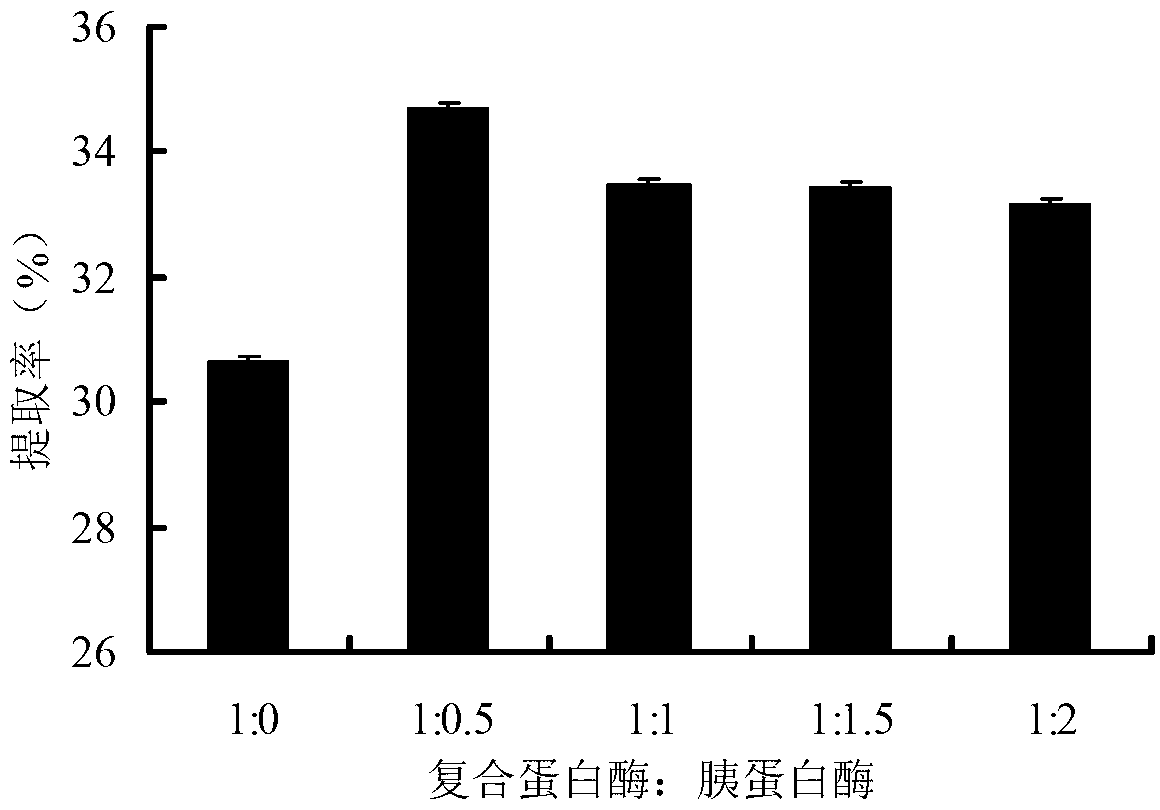

[0025] 1) Compound protease formula: collagenase, lipase, glycogenase, nuclease, according to the ratio of parts by weight: 1.5:1:0.5:0.5; and you can choose to add a certain amount of trypsin to increase the effect of enzymatic hydrolysis, add The amount is 50% of the total weight of collagenase, lipase, glycogenase and nuclease. During the enzymolysis process, the ratio of duck breast cartilage bone powder, novel composite protease and trypsin is 100:1:0.5 in parts by weight.

[0026] Since the main components of duck breast cartilage include chondroitin sulfate, type II collagen, fat and a small amount of nucleic acid substances; for this purpose, a new composite protease is designed, and its enzyme system mainly contains collagenase, lipase and glycogenase and nuclease, which can completely hydrolyze collagen, fat and nucleic acid substances in duck breast cartilage during the enzymatic extra...

Embodiment 1

[0037] Embodiment 1: the screening test of protease

[0038] Raw material processing: Place the duck breast cartilage in a cooking pot with a constant temperature of 60°C to 80°C for 0.5h to 1h, remove the excess meat, fascia and grease on the cartilage, and rinse it with clean water. Then soak in methanol: chloroform (1-3:1) at low temperature for 7h-9h to remove fat, and rinse with clean water. Then soak the aggregate with 0.5mol / L~1.5mol / L NaCl solution, and slowly stir to remove most of the salt-soluble impurities, so that the duck cartilage is white. After drying and crushing at 60-80 mesh, store at -20°C for later use.

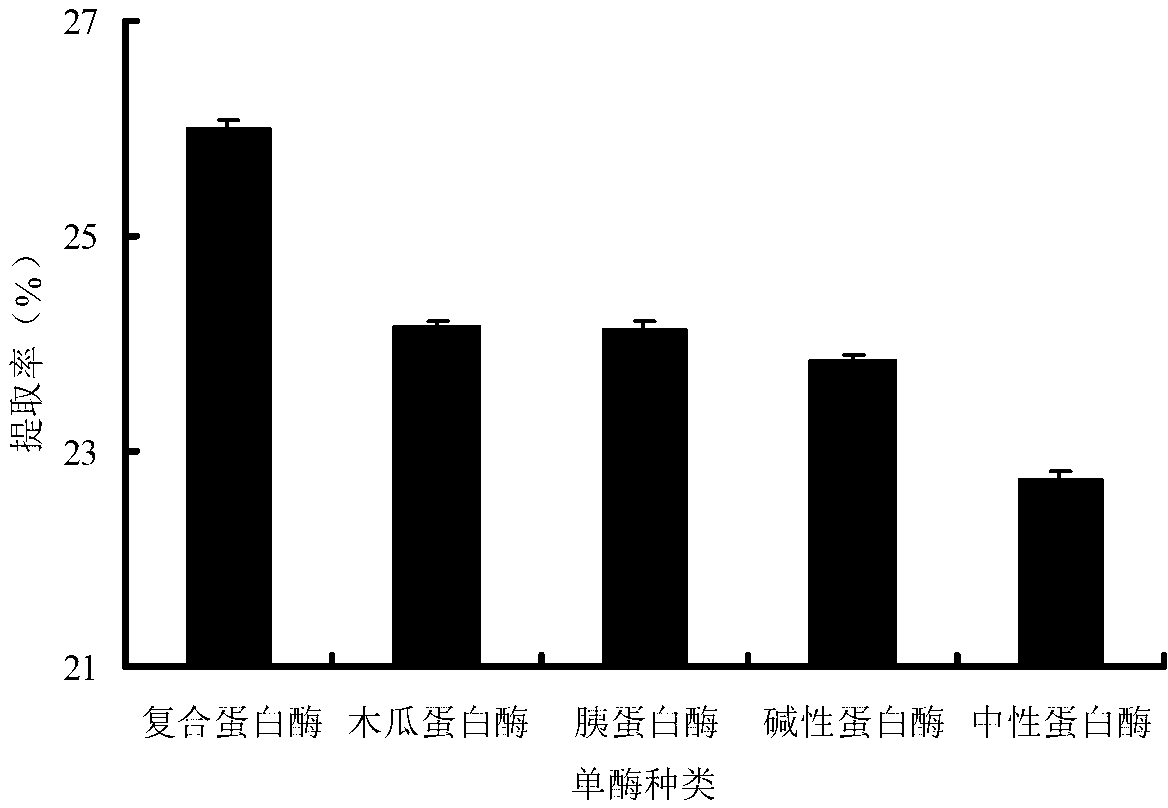

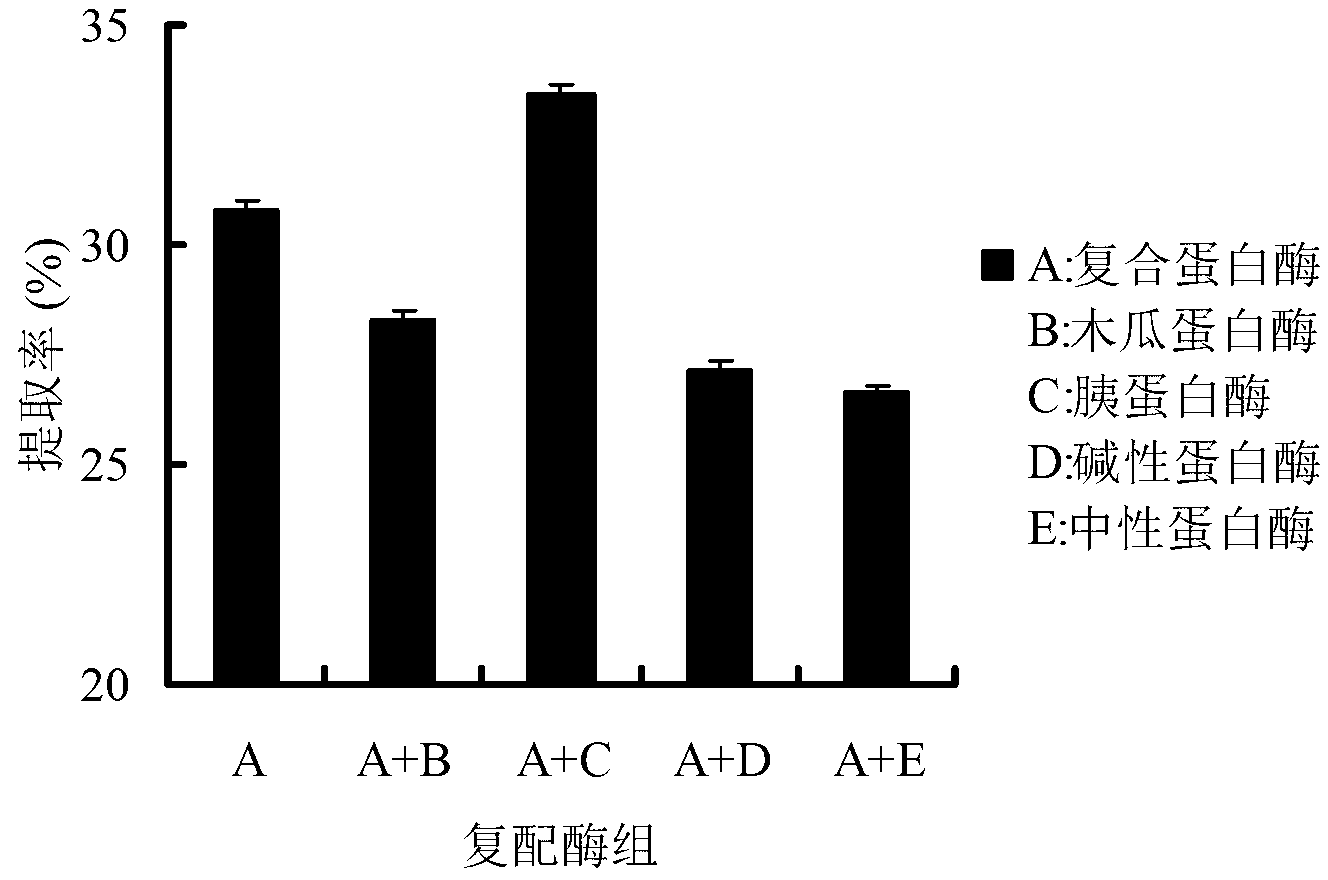

[0039] ① Compound protease and single enzyme enzymatic hydrolysis test

[0040] Take a certain amount of protease (new compound protease, papain, trypsin, alkaline protease, neutral protease), put it into a beaker, add a certain amount of distilled water and shake well, then add a certain amount of pre-treated duck breast cartilage powder, Enzymolyze ...

Embodiment 2

[0046] Example 2: Screening of the best process for compound protease and trypsin compound proteolysis

[0047] (1) Enzymatic hydrolysis single factor test

[0048] Enzymolysis treatment: Weigh 10g of pre-treated duck breast cartilage bone powder into a 250mL beaker, adjust the pH value of the solution, add a certain concentration of new compound protease and trypsin according to a certain ratio of solid to liquid, and extract a certain amount in a constant temperature water bath. time, inactivate the enzyme in a boiling water bath for 10 minutes, and then filter out the enzymolysis solution with four layers of filter cloth.

[0049] ①Effect of material-water ratio on extraction of duck chondroitin sulfate

[0050] The test results show that the extraction rate of duck chondroitin sulfate enzymatic hydrolysis first increases and then decreases with the increase of material-water ratio, and reaches the maximum value at 1:10, but no matter the extent of increase or decrease is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com