Spherical projecting screen and manufacturing method

A manufacturing method and technology for projection screens, which are applied to projection devices, coatings, instruments, etc., can solve problems such as unfavorable promotion and use, affecting visual effects, and image quality interference, and achieve projection effects and projection quality. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

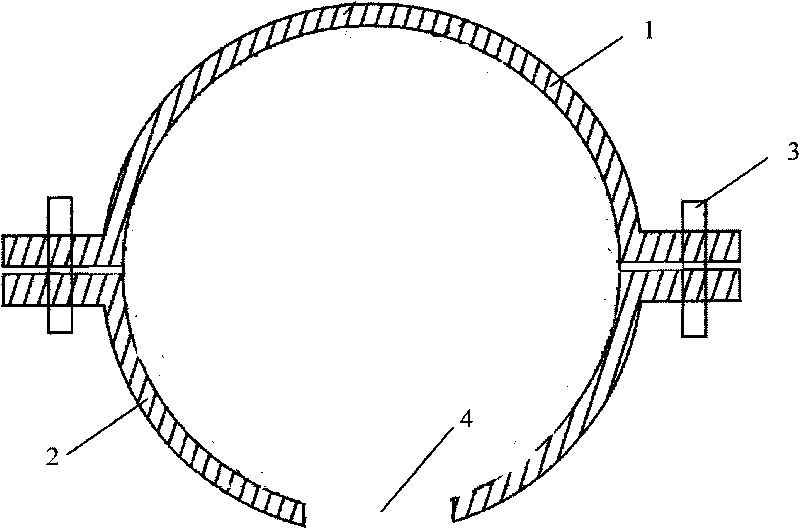

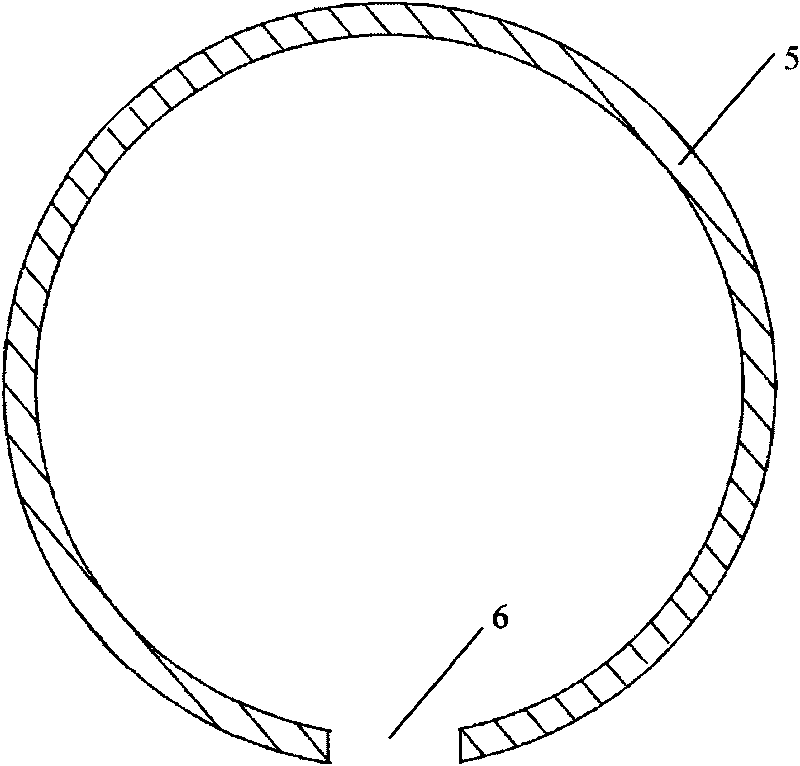

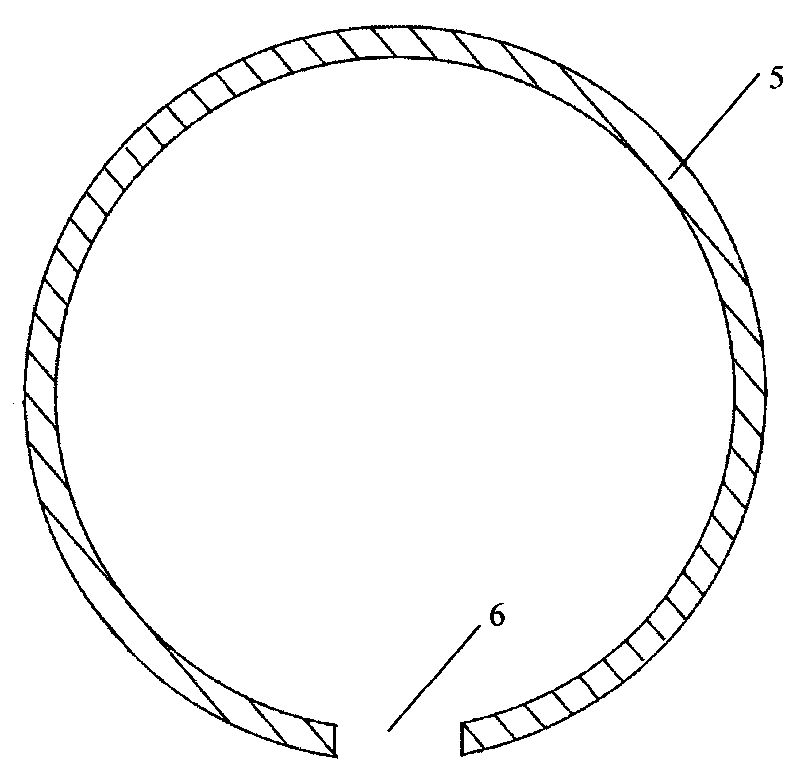

Image

Examples

Embodiment 1

[0056] The weight percentages of the rolling plastic components used are: 100 parts of resin, 1.5 parts of optical additive, 2 parts of accelerator, 0.8 part of defoamer, and 0.6 part of anti-yellowing agent.

Embodiment 2

[0058] The weight percent of the rolling plastic components used is: 100 parts of resin, 2.2 parts of optical additive, 3 parts of accelerator, 1.5 parts of defoamer, and 1 part of anti-yellowing agent.

Embodiment 3

[0060] The weight percent of the rolling plastic components used is: 100 parts of resin, 2.8 parts of optical additive, 4 parts of accelerator, 2.5 parts of defoamer, and 1.2 parts of anti-yellowing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com