High-strength three-layer co-extrusion lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery, three-layer co-extrusion technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., to achieve the effect of enhancing puncture strength, optimizing porosity and pore size distribution, and avoiding delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

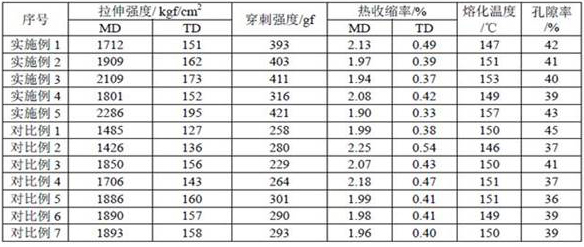

Examples

preparation example Construction

[0033] In parts by weight, the components of the B layer include 90-99 parts of homopolypropylene and 1-10 parts of lubricating nucleating particles, and the melt index of the homopolypropylene at 230°C is 1-5g / 10min , the isotacticity is not less than 98%; the preparation method of the lubricated nucleating particles comprises the following steps: A) mixing polytetrafluoroethylene micropowder and pimelic acid for ball milling; the ball milling medium is ethanol, and the ball milling time is 1~3h ; B) adding calcium stearate, and continuing ball milling for 0.5~1h; after ball milling, the obtained product was washed and dried to obtain the lubricated nucleation particles; wherein, the added polytetrafluoroethylene micropowder, pimelic acid and stearic acid The mass ratio of calcium is 5~10:1:1~2; the ball milling temperature in steps A) and B) is -20~-10°C, the mass ratio of the balls added during ball milling is 1:10~30, poly The mass volume ratio of fluoroethylene micropowder ...

Embodiment 1

[0043] A high-strength three-layer co-extruded lithium-ion battery separator, including a B layer and an A layer arranged on both sides of the B layer; the total thickness of the separator is 16 μm, wherein the thickness of the B layer is 14 μm, and the thickness of the A layer is 1 μm;

[0044] The component of layer A is copolymerized polypropylene (Korea Petrochemical CB5230, its melt index at 230°C is 30 g / 10min, and its rigid modulus is 18000 kgf / cm 2 , heat distortion temperature is 135 ℃); in parts by weight, the components of layer B include 90 parts of homopolypropylene (Korea Petrochemical S801, whose melt index at 230 ℃ is 3.0 g / 10min, isotactic degree of 98%) and 5 parts of lubricating nucleating particles;

[0045] Among them, the preparation method of lubricating nucleating particles includes the following steps: A) mixing polytetrafluoroethylene micropowder (DuPont MP1300 in the United States) and pimelic acid in a high-energy ball mill for ball milling; the bal...

Embodiment 2

[0055] The difference between Example 2 and Example 1 is: in parts by weight, the components of layer A include 99 parts of copolymerized polypropylene (Korean Petrochemical CB5230) and 1 part of calcium sulfate whisker (Video Bio), and the rest are Same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com